assignment characterize your lasercutter's focus, power, speed, rate, kerf, and joint clearance

cut something on the vinylcutter design, lasercut, and document a parametric construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways, and for extra credit include elements that aren't flat

The Roland CAMM-1 SERVO GX-24is the ultimate companion for print and-cut jobs with its built-in optical registration system that accurately aligns pre-printed material for contour cutting. The GX-24 comes fully loaded with everything you need to create professional-grade graphics and signs right on your desktop. Under the hood, the digital servomotor drives the cutter with maximum accuracy on anything from reflective vinyl and paint mask, to twill, heat transfer and sandblast material. A built-in curve smoothing function ensures precision cutting even at top speeds of up to 20 inches per second — 25 percent faster than its predecessor. And when it comes to ease-of-operation, the CAMM-1 SERVO GX-24 wins over even vinyl cutting rookies in seconds. Simply connect the USB interface to your computer, pan through features and functions on the easy-to-read LCD screen, and use the included CutStudio TM drawing software to create incredible graphics for banners, vehicles, store displays, point-of purchase materials, informational signs, backlit displays and more.

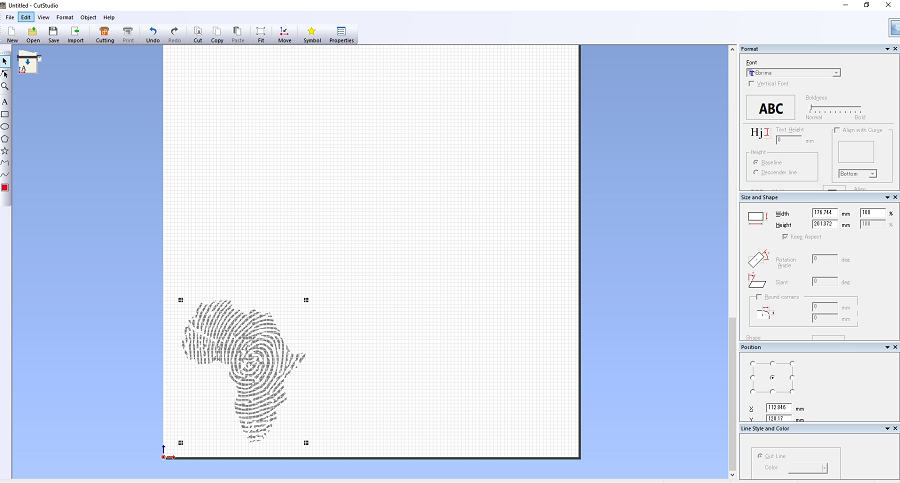

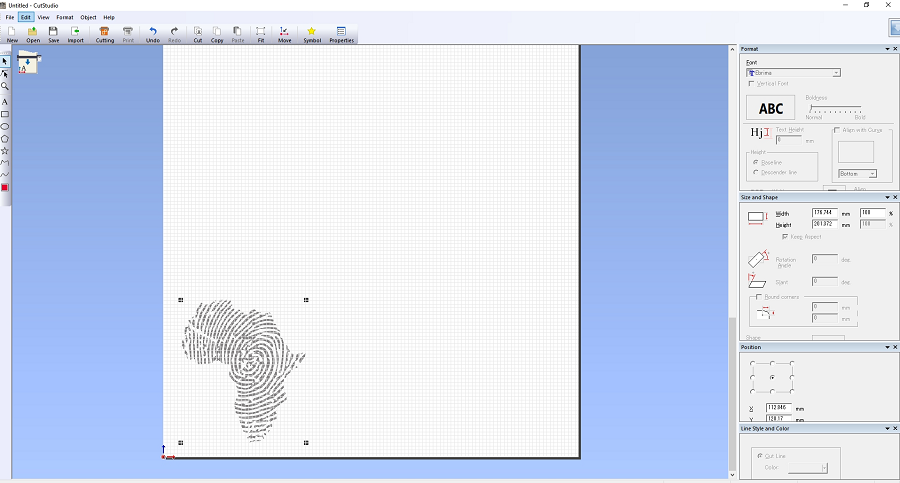

RolandIn our Lab, we use the Roland GX-24 for cutting the sheet. in designing the shape or the Font we use the CutStudio software. In first time, I learnt to draw with CutStudio

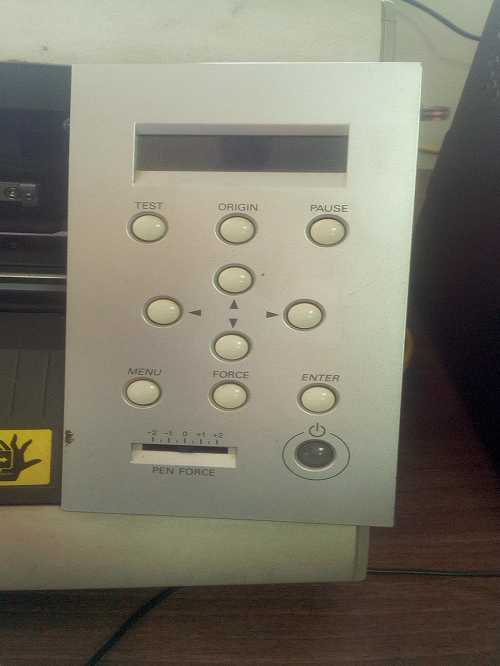

Roland machine

Button Roland control

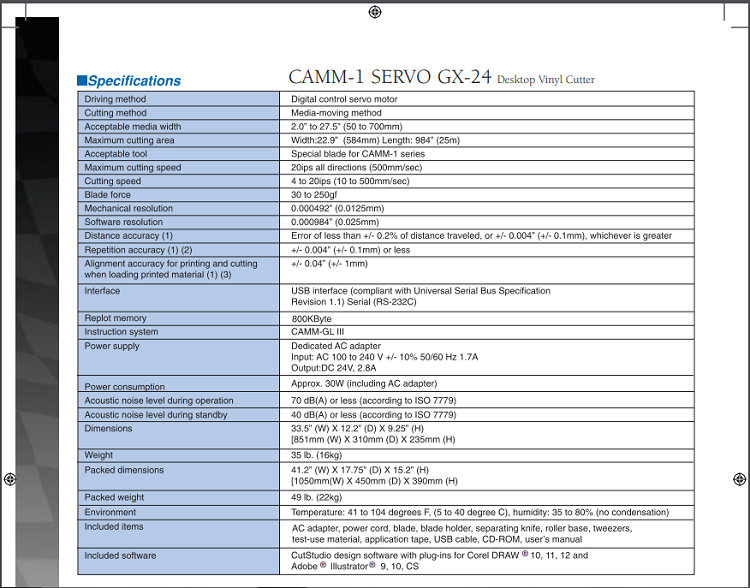

There is specification of Roland Machine

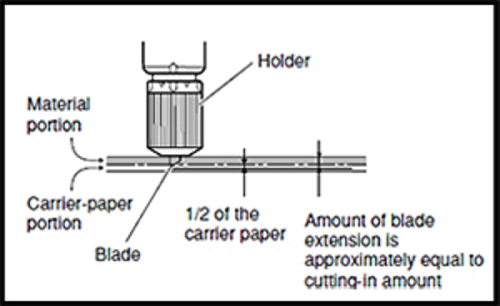

Plotter Blades extention

Roland machine

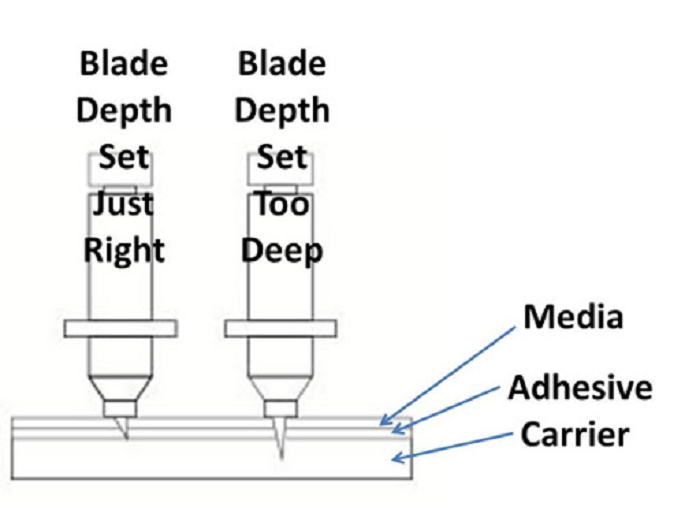

Depth Set

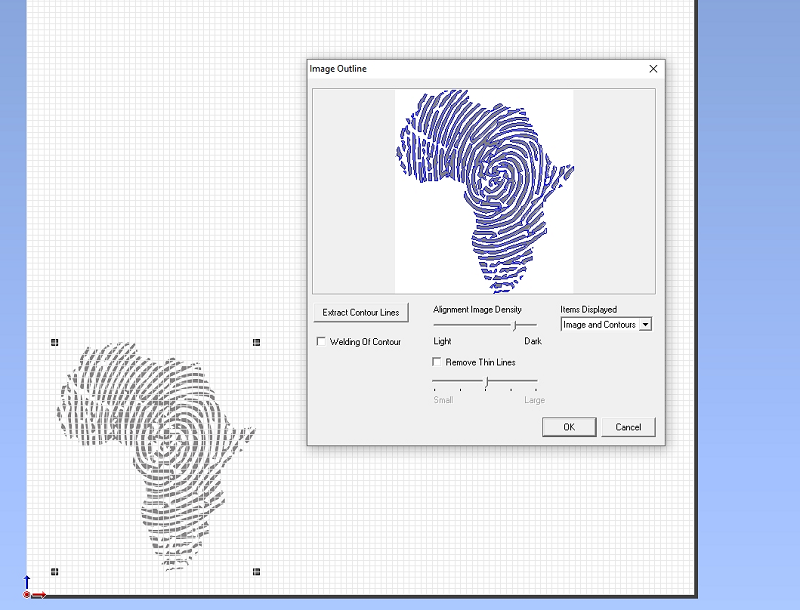

I imported the the africa image for making the Ectract contour lines

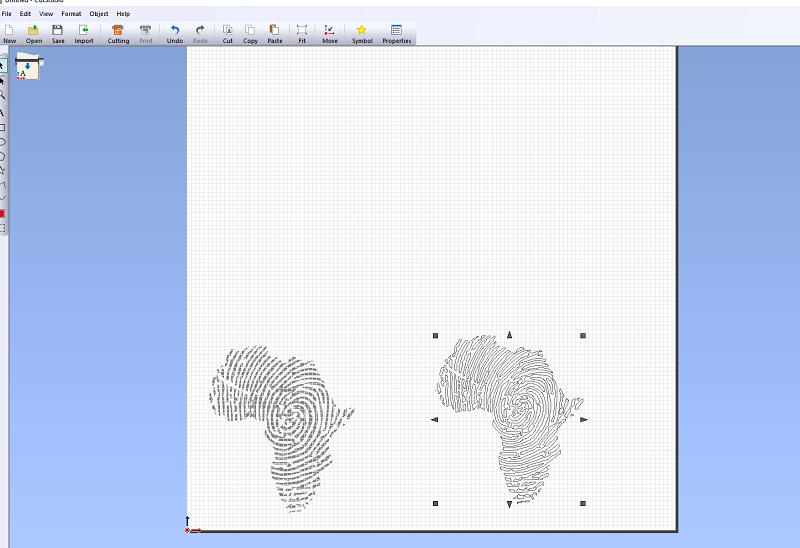

There are two images, then I have chosen Extract contour line

This is the image I cutted on the vinylcutter

this is the image i wanted

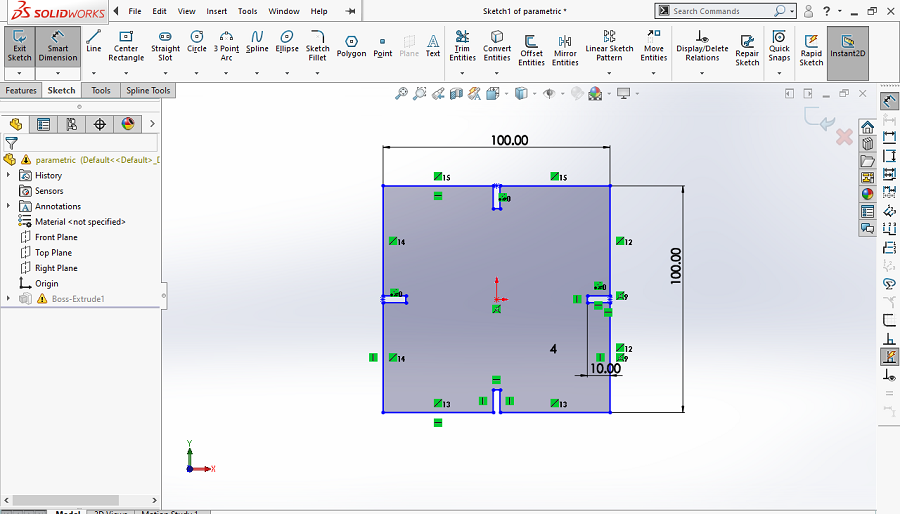

To the Laser cutter, we have Epilog laser mini 24x12. The first started to draw with SolidWorks! In parametric construction kit, i have shown the measurement of my drawing, in solidworks. After, I saved my drawing in DXF because I would like that i found the way to print my puzzle with CorelDRAW software.

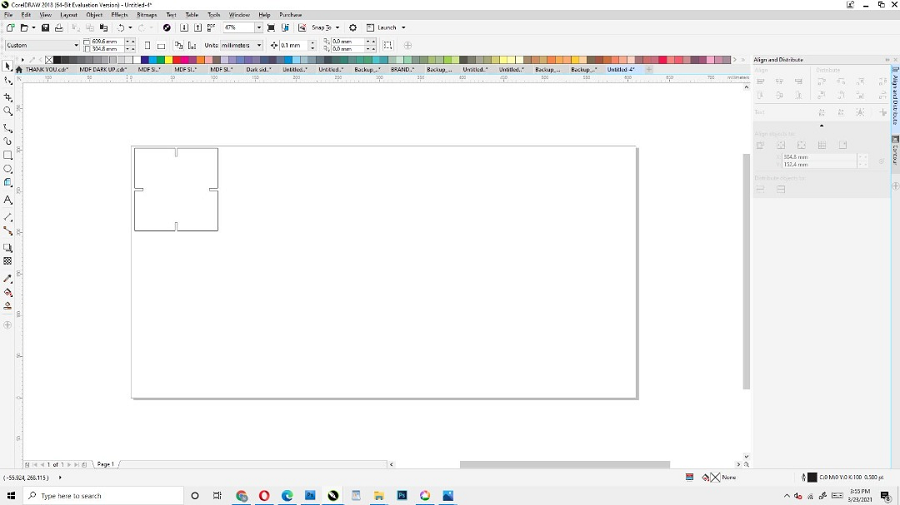

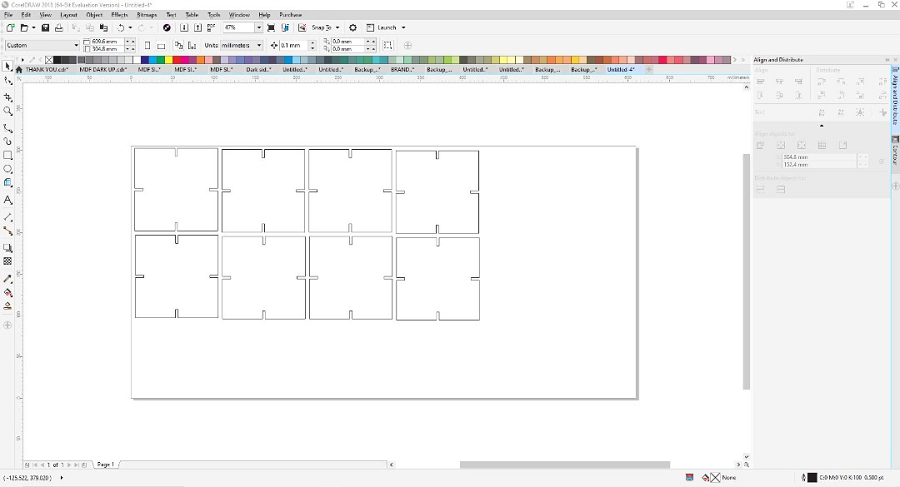

Here, I saved the drawing in DXF file, and I import in CorelDRAW

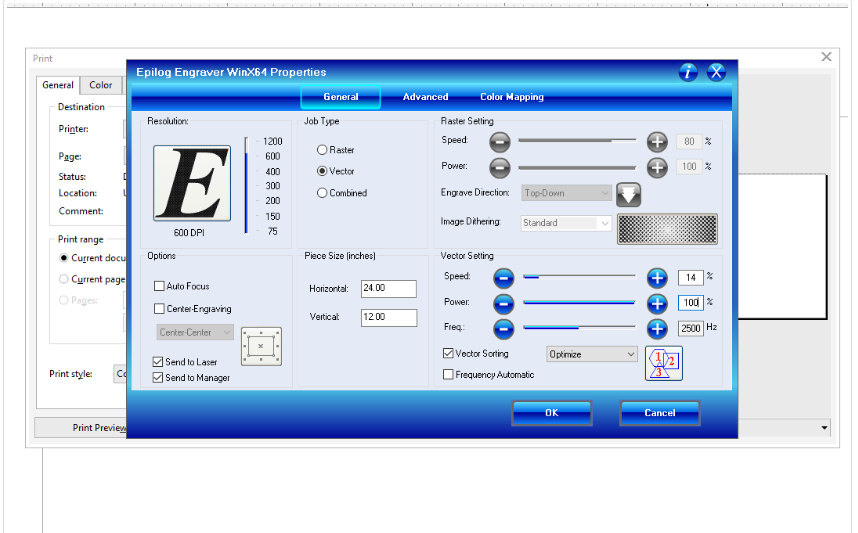

Before starting to print, they are table I set, the power, the speed, frequence and i have shosen the vector

Cutting Process

After cutting with laser cutter

Cutting Process

After cutting with laser cutter

I assembled my parts and I found my product

I assembled my parts and I found my product

This is the final look of the shape.

It is defined as the width of material that is removed by a cutting process. ... When talking about CNC shape cutting with typical cutting processes, kerf is the width of material that the process removes as it cuts through the plate.

What does kerf mean?

The laser burns away a portion of material when it cuts through. This is known as the laser kerf and ranges from 0.08mm – 1mm depending on the material type and other conditional factors.

The original files used for this assignment can be downloaded here.