Mechanical Design

The machine task was an interesting opportunity to explpore the fields of gearing and interface to something animated.

The reaseaches I took where done especially from historical pieces taken from an old hobbistic book and encicolpedic images, to start having a general understanding of what a mechanism is.

WILLIE'S FIREGUN

In the old animations, the machine was in entertainmant crazy visual tool for humoristic scenes.

Starting from the old-style looney tunes cartoons, as a concept I noticed that Wile E. Coyote is basically the best maker of animated cartoons.

This chatacter invented so many machines trying to caputure Beep-Beep, so the goal to achive in the project is to recreate in the real world one of these fantastic inventions.

Firegun

We choose to create a firegun as machine.

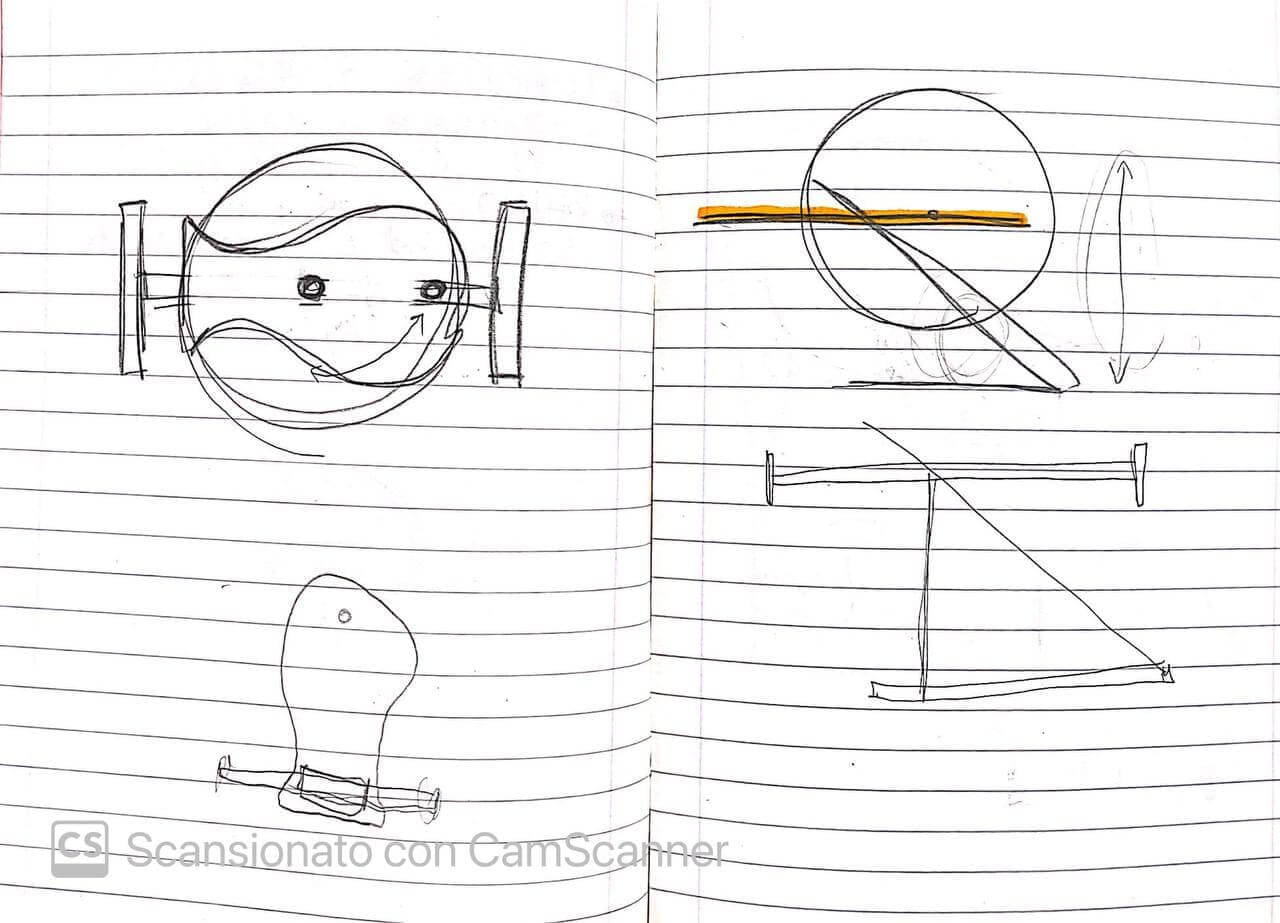

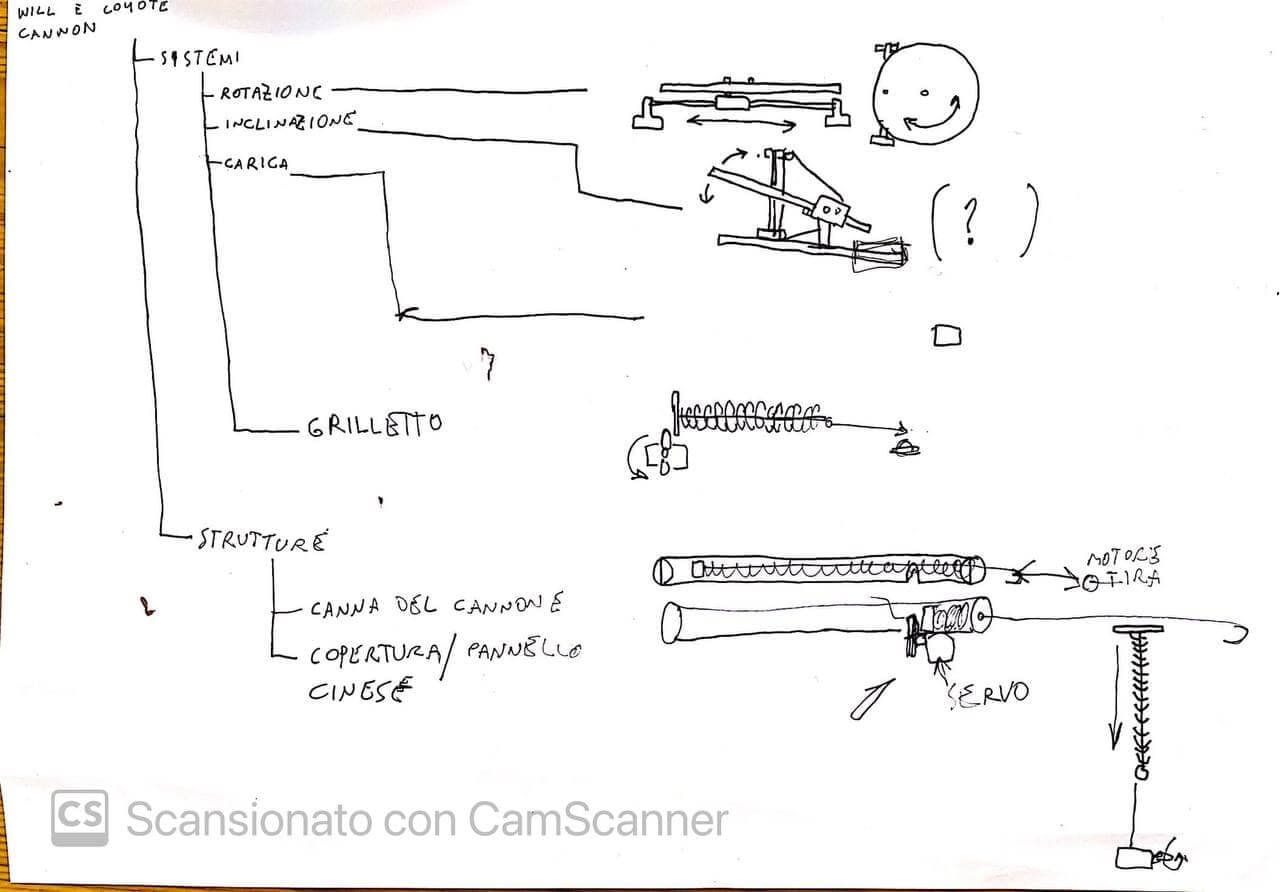

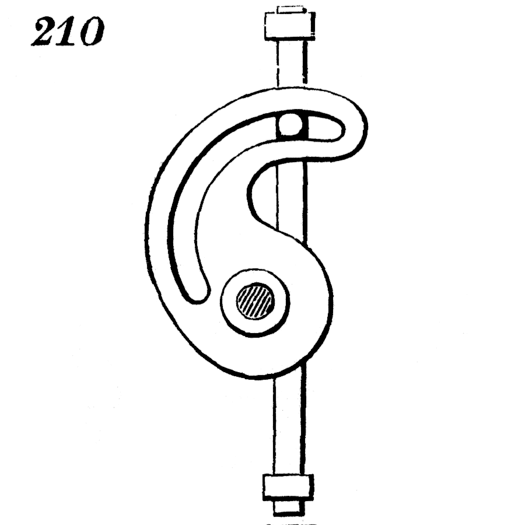

Sketch

And starting making sketches and building a gearing sistem starting from an axis and a stepper-motor.

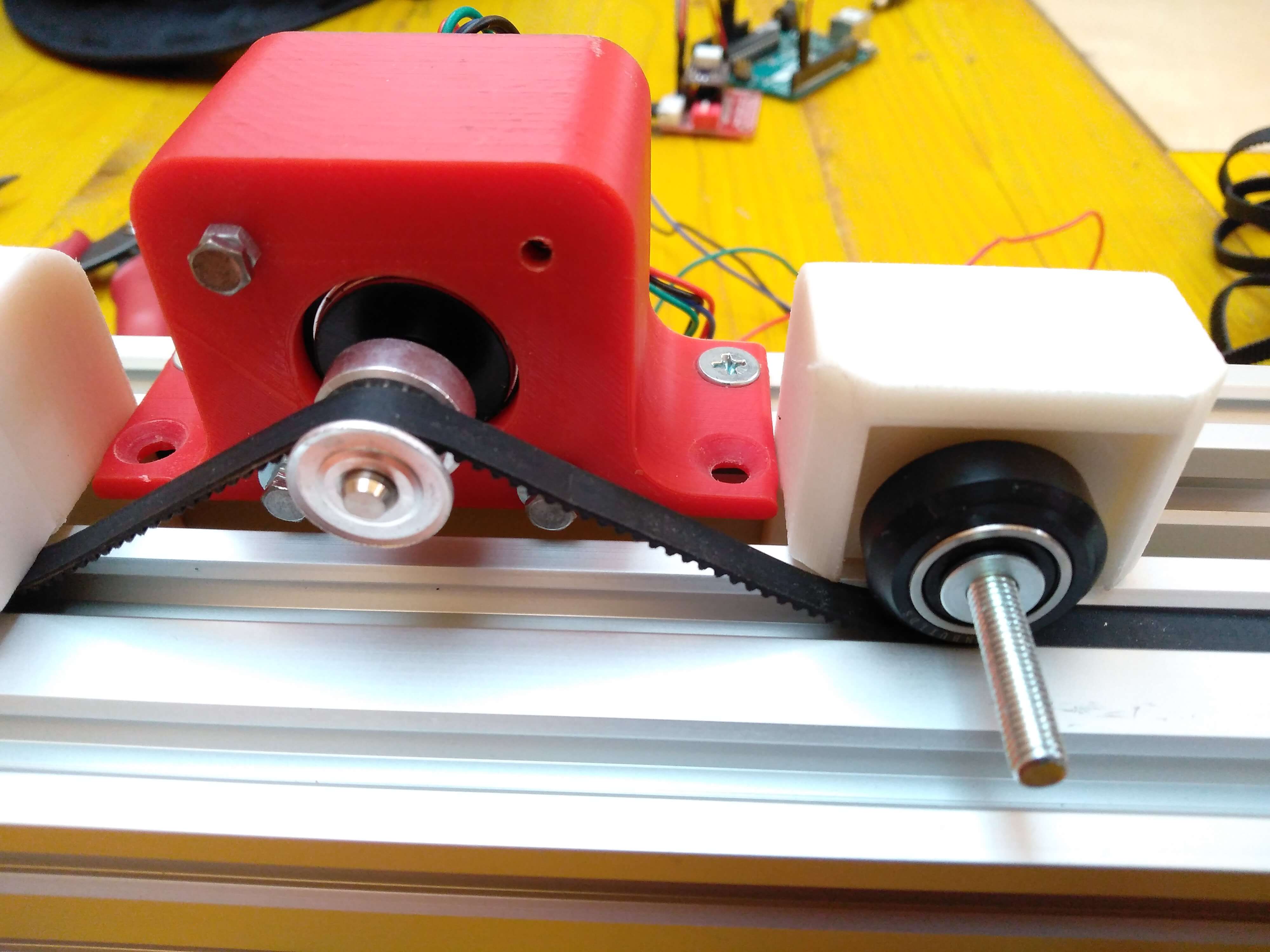

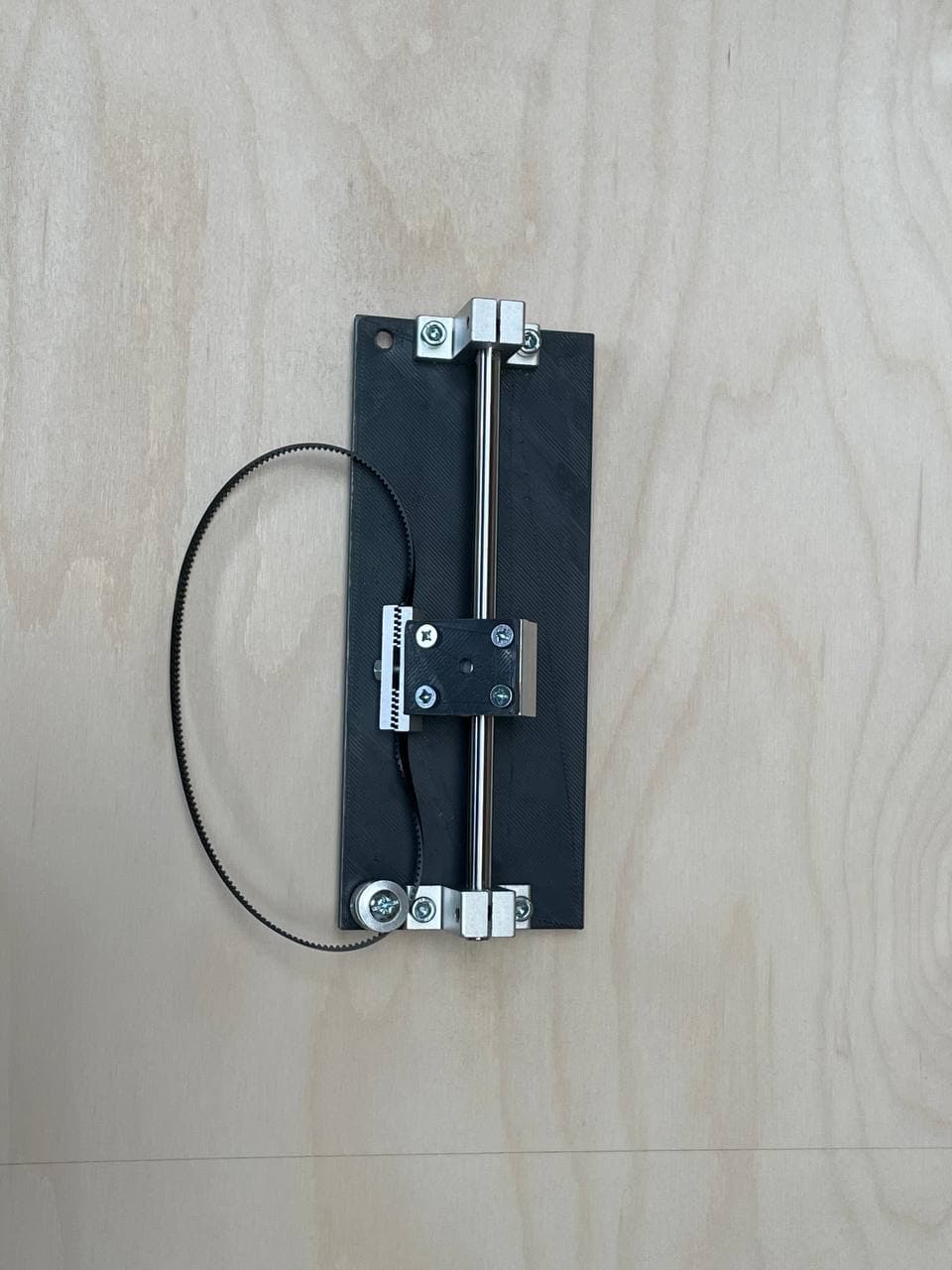

Axis railing mechanism

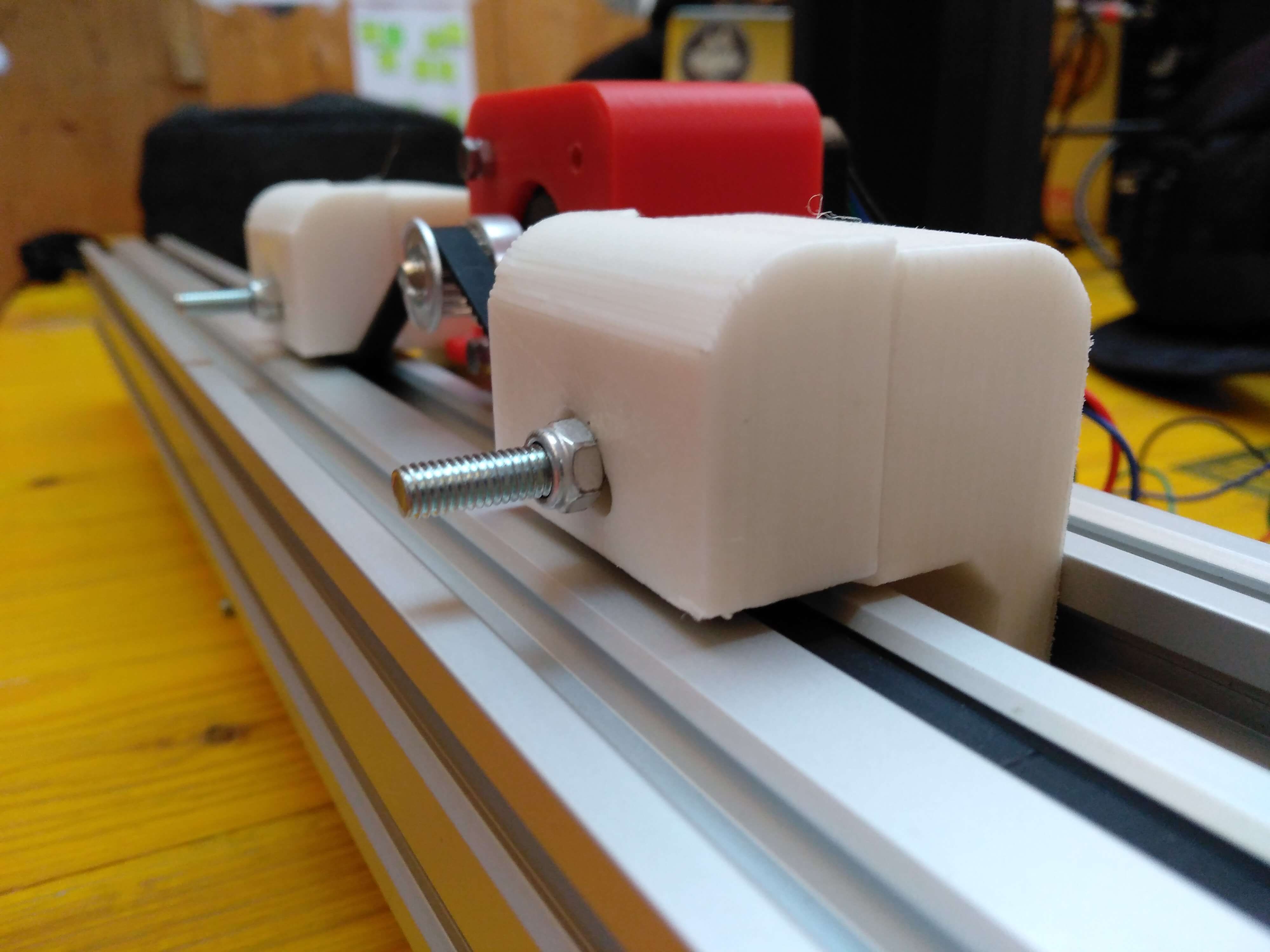

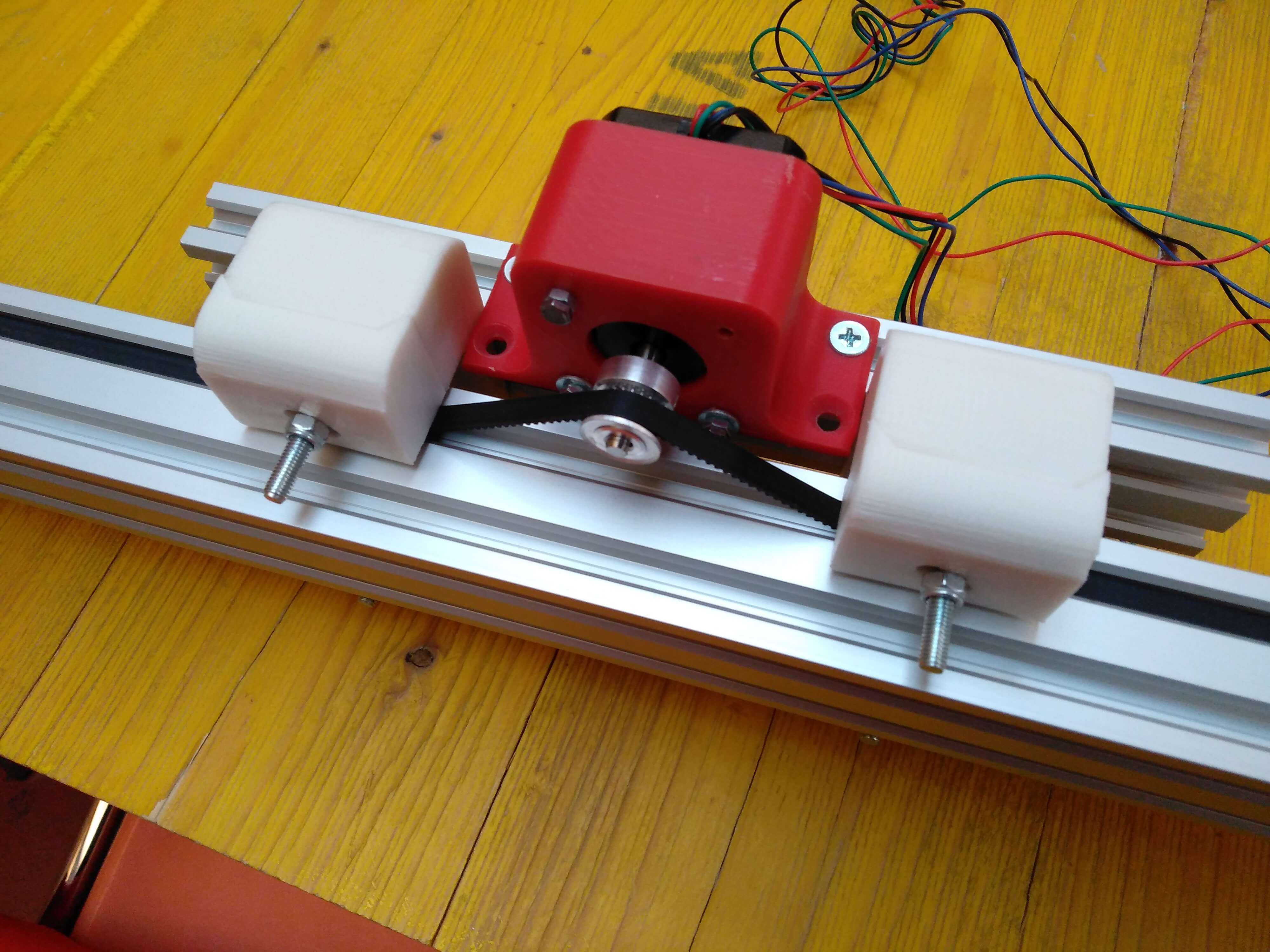

We started from a mechanism based on an axis with a movable slot connected to a belt.

With this solution we would achive a linear movement on the axis.

By turning the shaft carrying the curved slotted arm, a rectilinear motion of variable velocity is given to the vertical bar.

Spring system

The cannonballs will be thrown with a spiring system controlled from the motors.

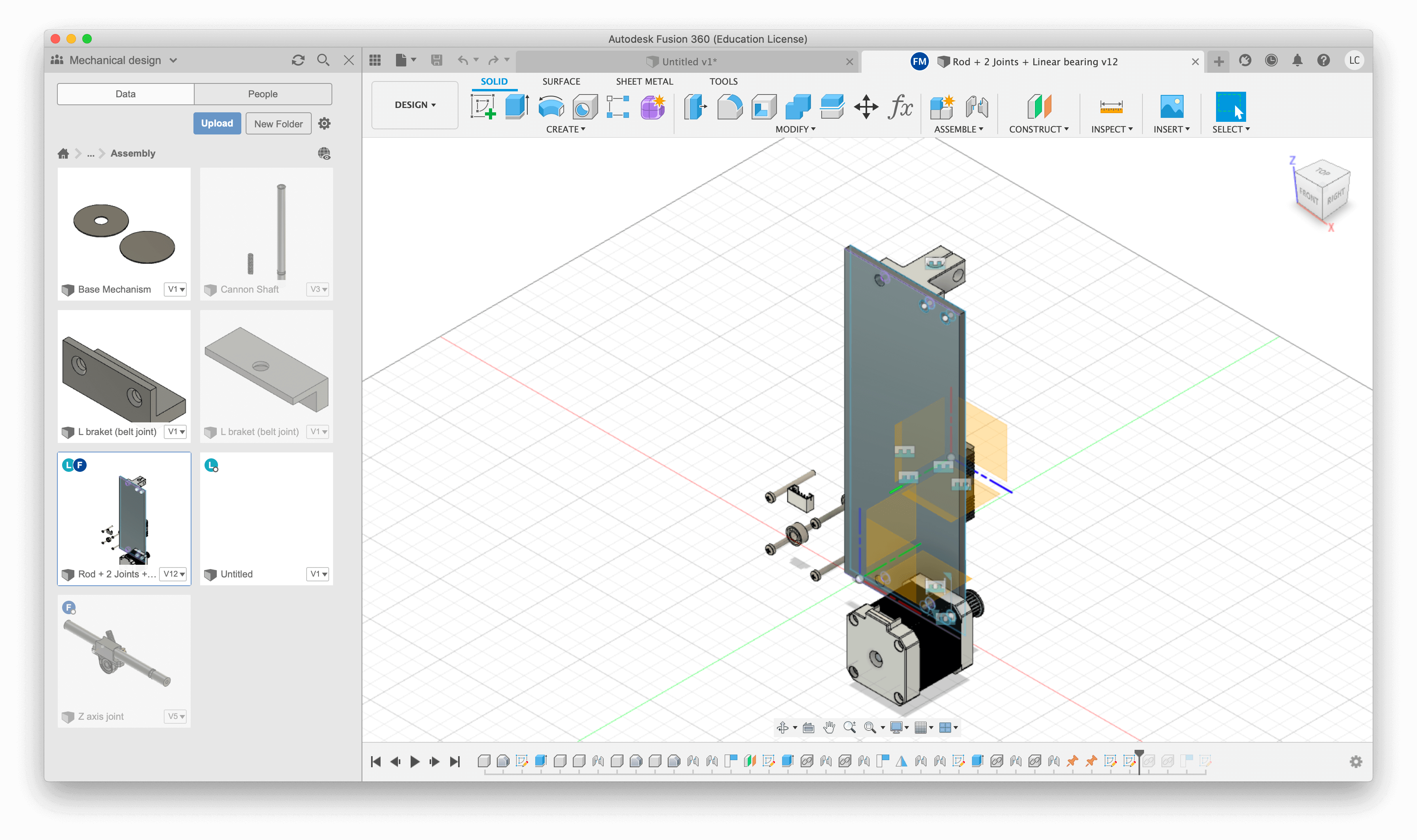

Fusion 360 assembly

The workflow went on with Fusion 360, we created part by part the 3D printed components.

FOAM CUTTER

For this task for Fab Academy 2020 we started building an automated Foam-cutting machine.

Unfortunately this group project has been delayed due to the ongoing health crisis. The following is an overview over our design (goals), as well as my personal contributions.

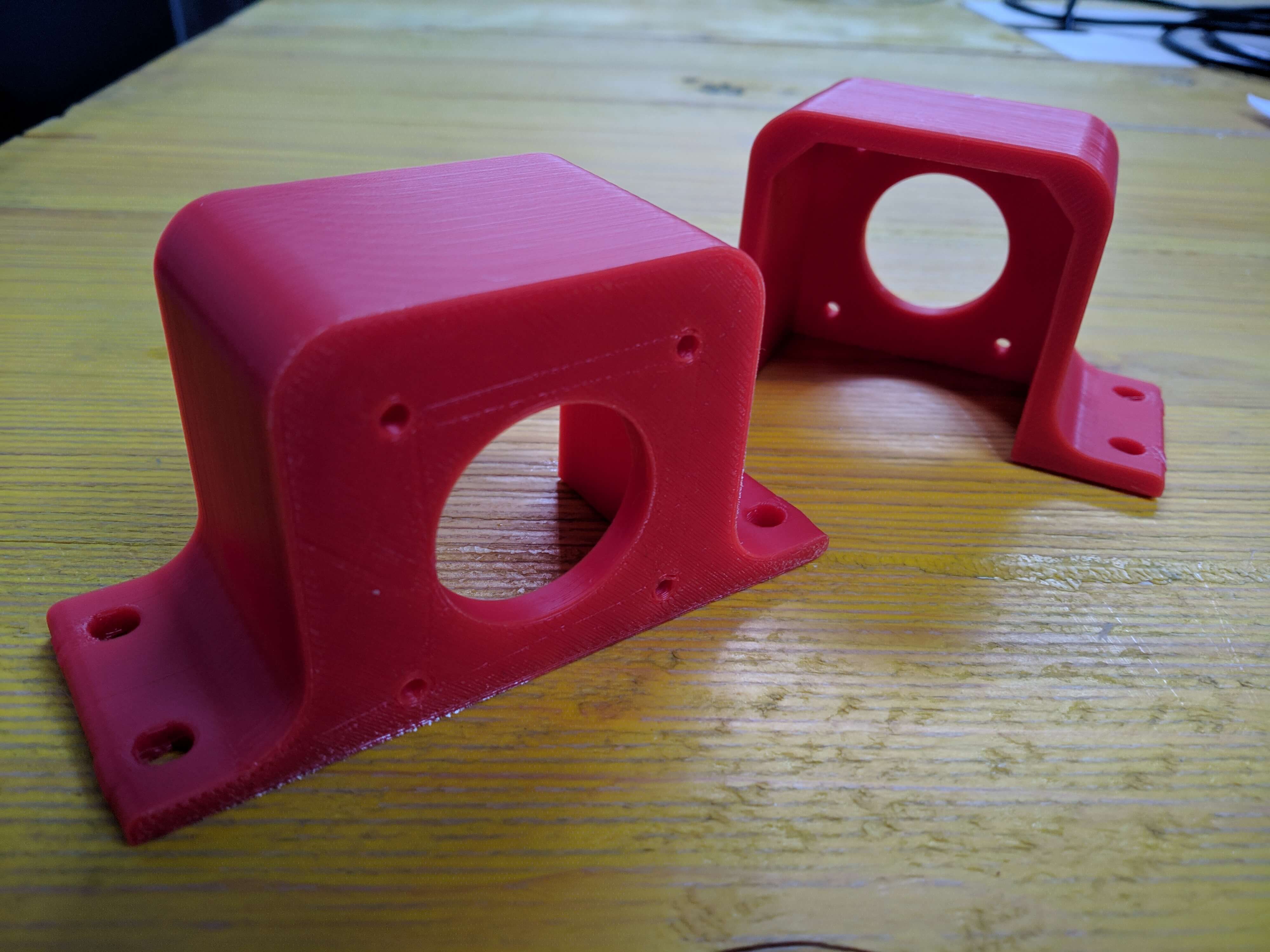

I collaborated to the group workflow activities and was responible of the design of the 3D printed parts.

For the machine design assignment, we decided in our group tp build a hot-wire foam cutter. We wanted to design it in such a way that the machine could be partially disassembled easily for transportation for a theoretically infinite working volume.

I took inspiration from the fillet design of the Valentine Typing machine of Olivetti by Ettore Sottsass, that in the 60s has been iconic for his portability and smooth suface.

The filletted designs allows to 3D print the components easily and to avoid the user to get hurt during the use.

Two wheel mounts were made to allow the sled to ride on the extrusion.