Computer-Controlled Machining

Assignment

Make (design+mill+assemble) something big

From fusion360 - to Vcarve - to the CNC

For this week's individual assignment we had to make something big usig the CNC machine. The goal was to design, mill and then assemble the pieces.

CNC Machine

CNC (Computer Numerical Control) machining is a subtractive manufacturing technology. Objects are created by removing material from a solid block using a variety of cutting tools. Almost every material can be CNC machined such as metals, plastics, foam, and wood. The basic CNC process can be broken down into 3 steps. The engineer first designs the CAD model of the part. The machinist then turns the CAD file into a CNC program (G-code) and sets up the machine. Finally, the CNC system executes all machining operations with little supervision, removing material and creating the objects. You can have a 3 axis or a 5 axis CNC machine.

First attempt

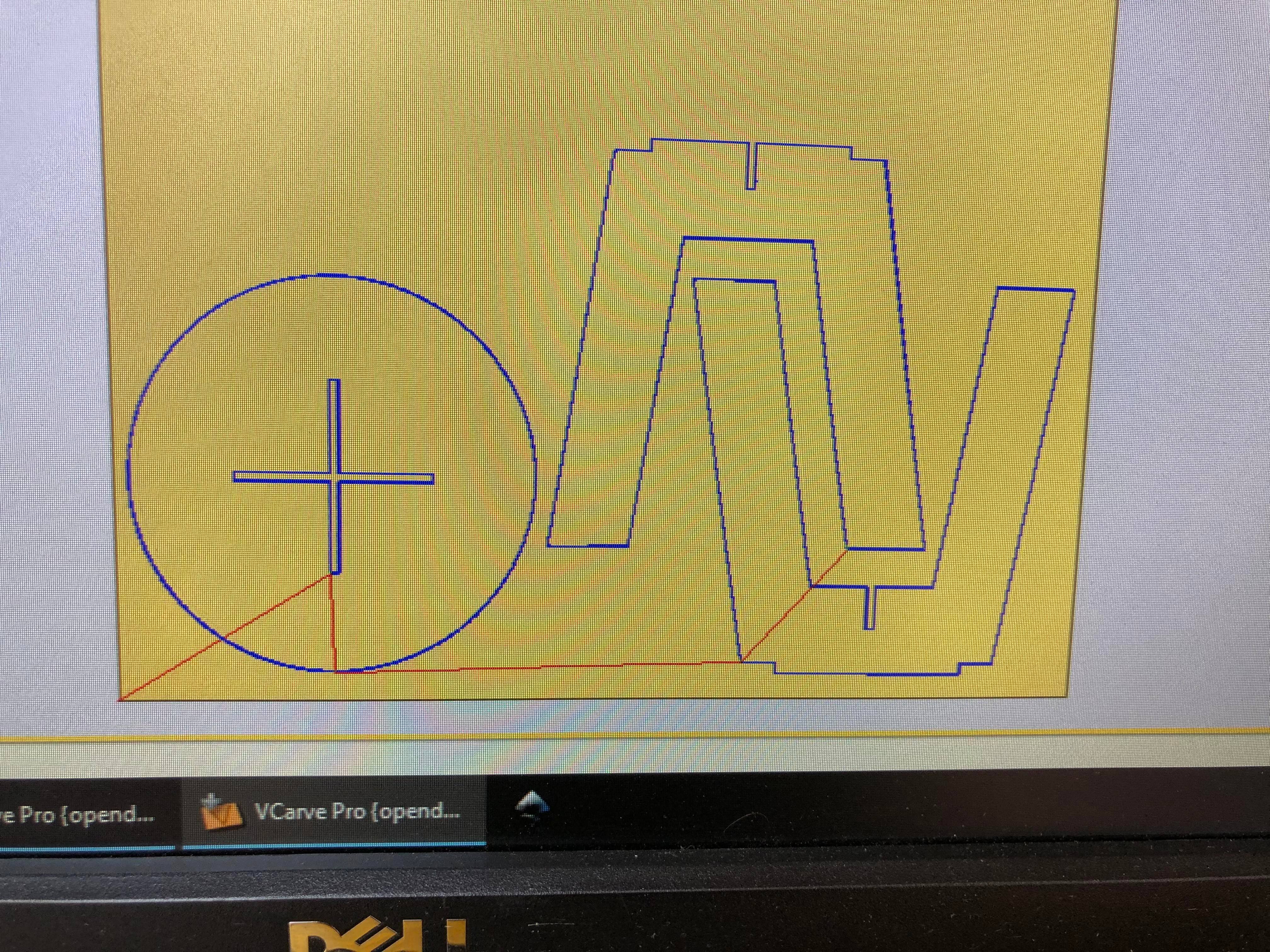

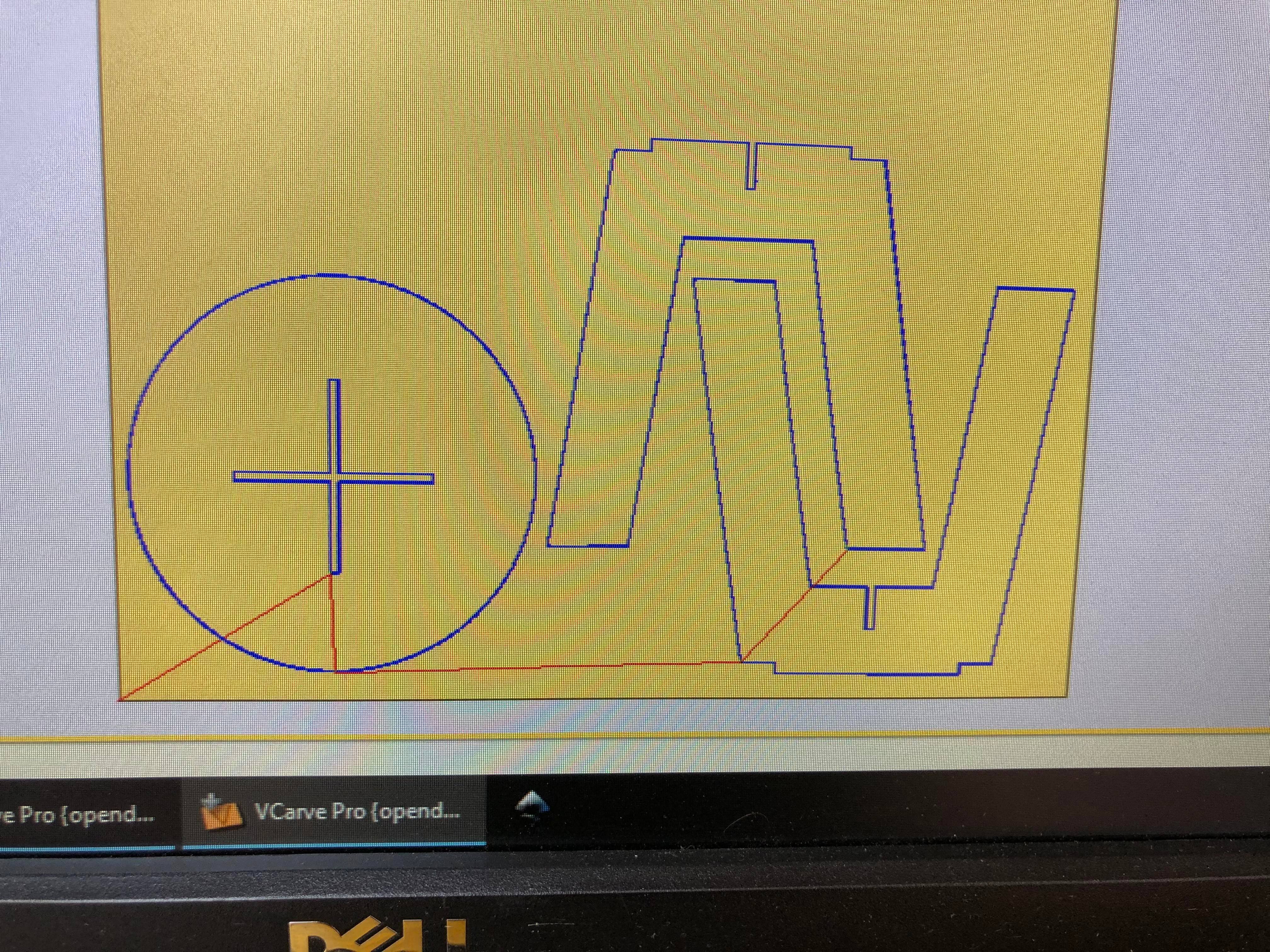

First step: familirizing with Vcarve.

I made a very simple draw made by 3 words with Illustrator and imported it into Vcarve.

The goal was to try different depths for each word. I tried with 4 mm for "dream", 8 mm for "explore" and 12 mm for "discover". The piece of wood I choose was 15 mm.

I exported the file, set the piece of wood on the cnc and pressed play.

Unfortunatelly it did not work proprially because it was to deep so I stop the file before the end. Here the first fail ;)

So I tried again. I turned the piece of wood and set it again on the CNC. This time I set the deepths at 2 mm for "dream", 4 mm for "explore" and 6 mm for "discover".

I exported the file again and set the new try.

The result:

Second attempt: THE table

To create my design I used Autodesk Fusion 360. I decided to do a simple flat pack design table.

** GRAZIE Albi **

Then I imported it into Vcarve

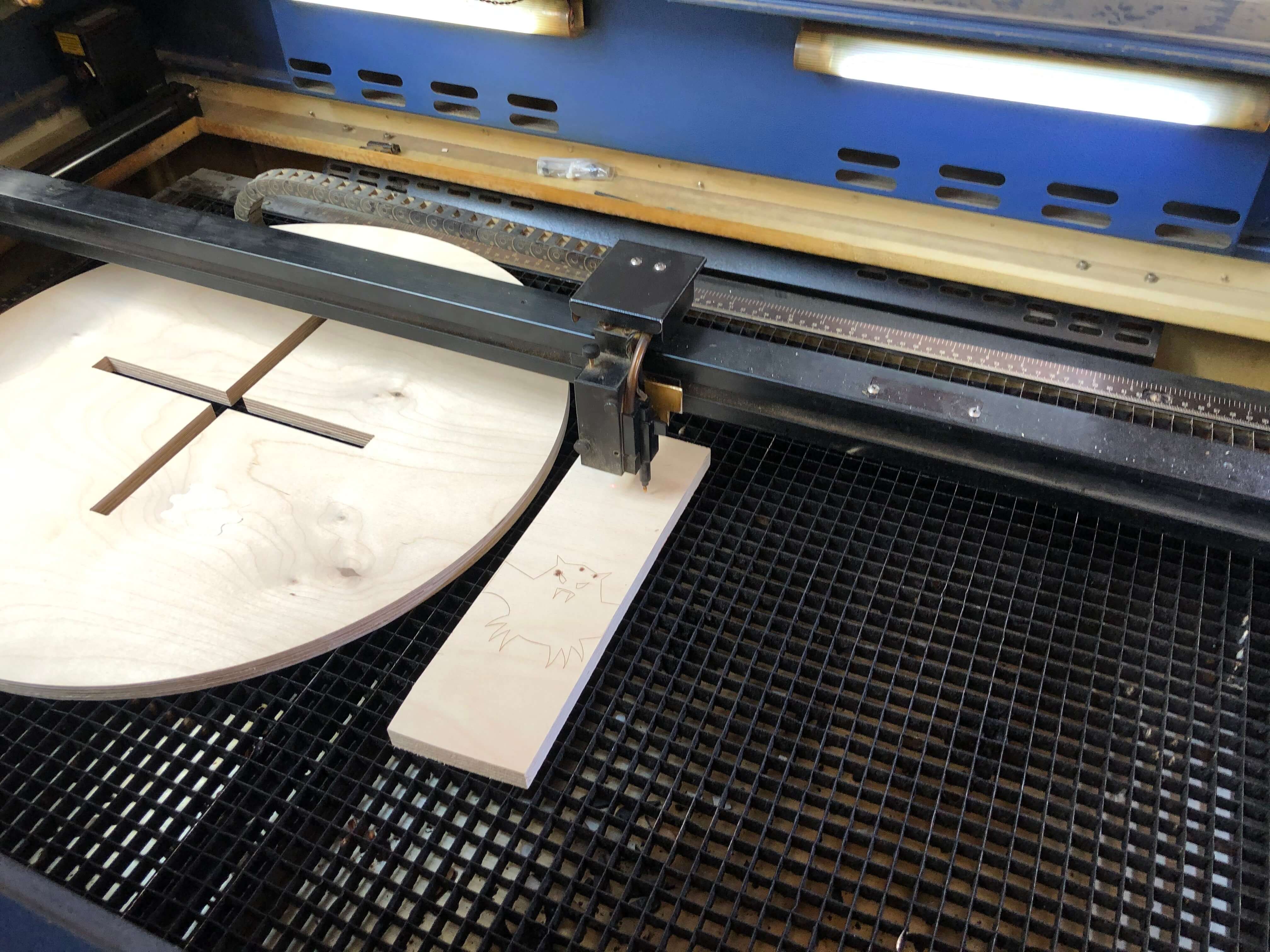

and the into the CNC

some sanding

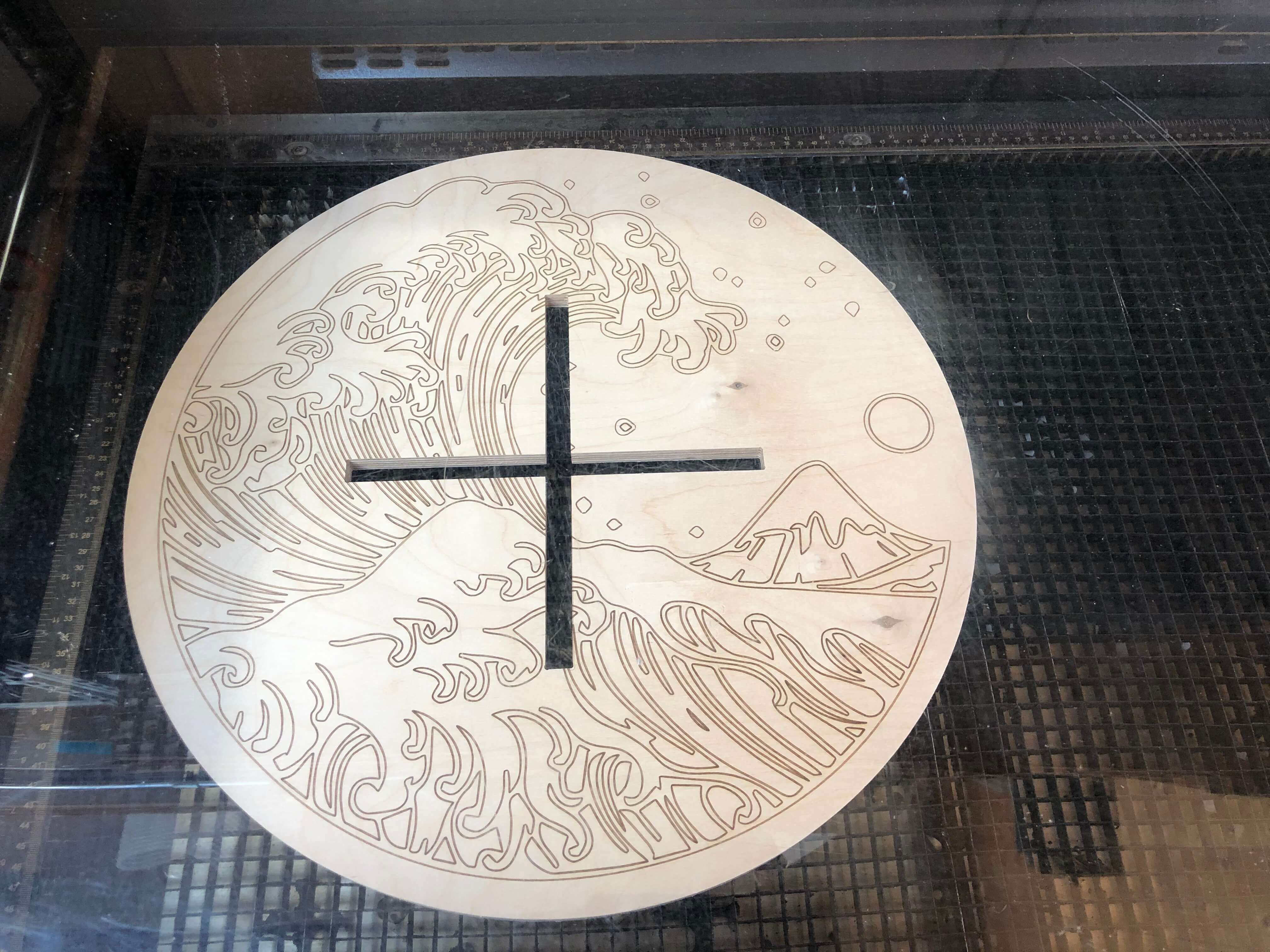

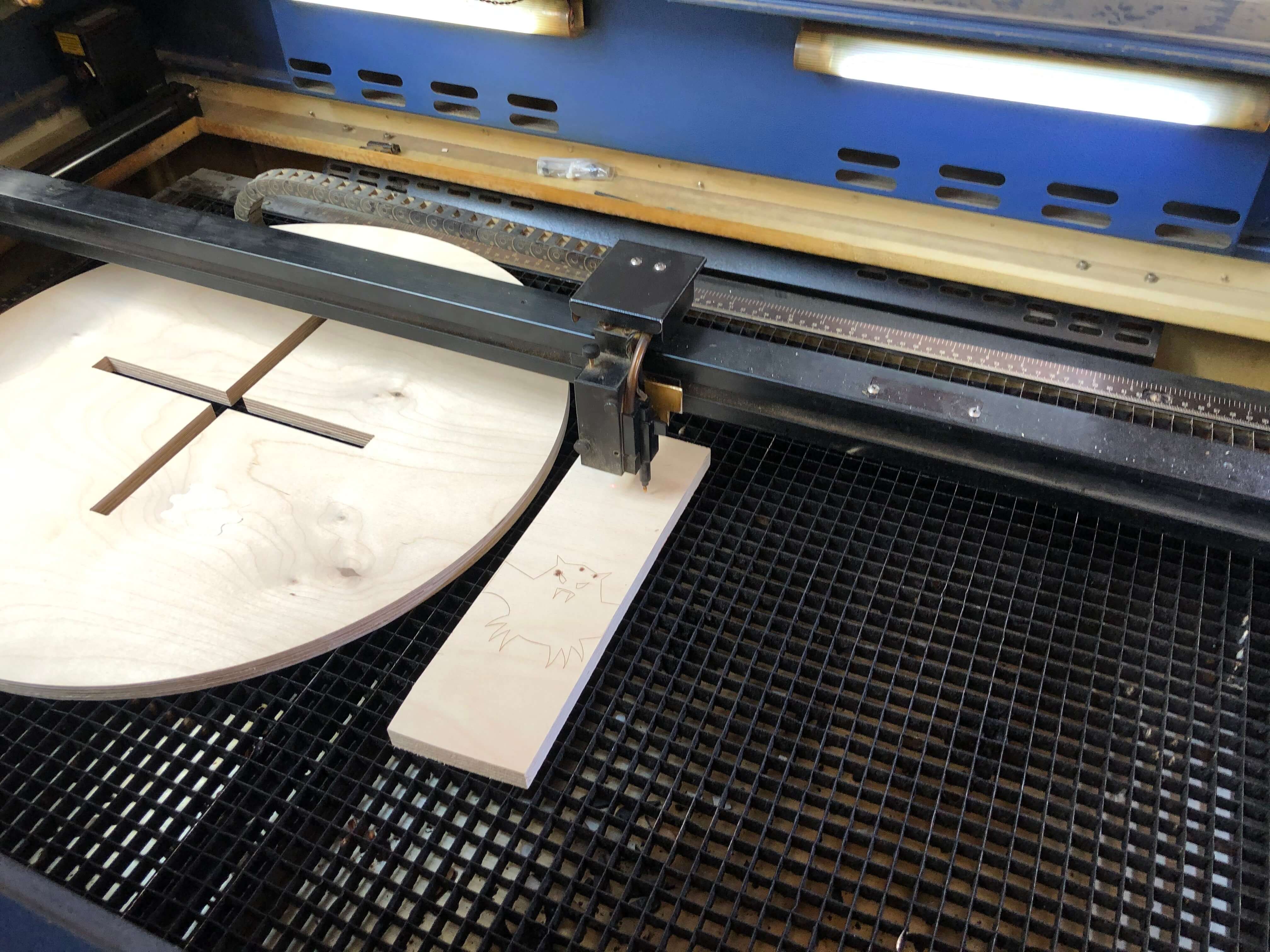

Then I decided to laser cut my wave design on the table top. With Antonio and Tiziano I made some tests in order to try the power of the cut. Tiziano showed me how move the Z axe in order to have a wider line.

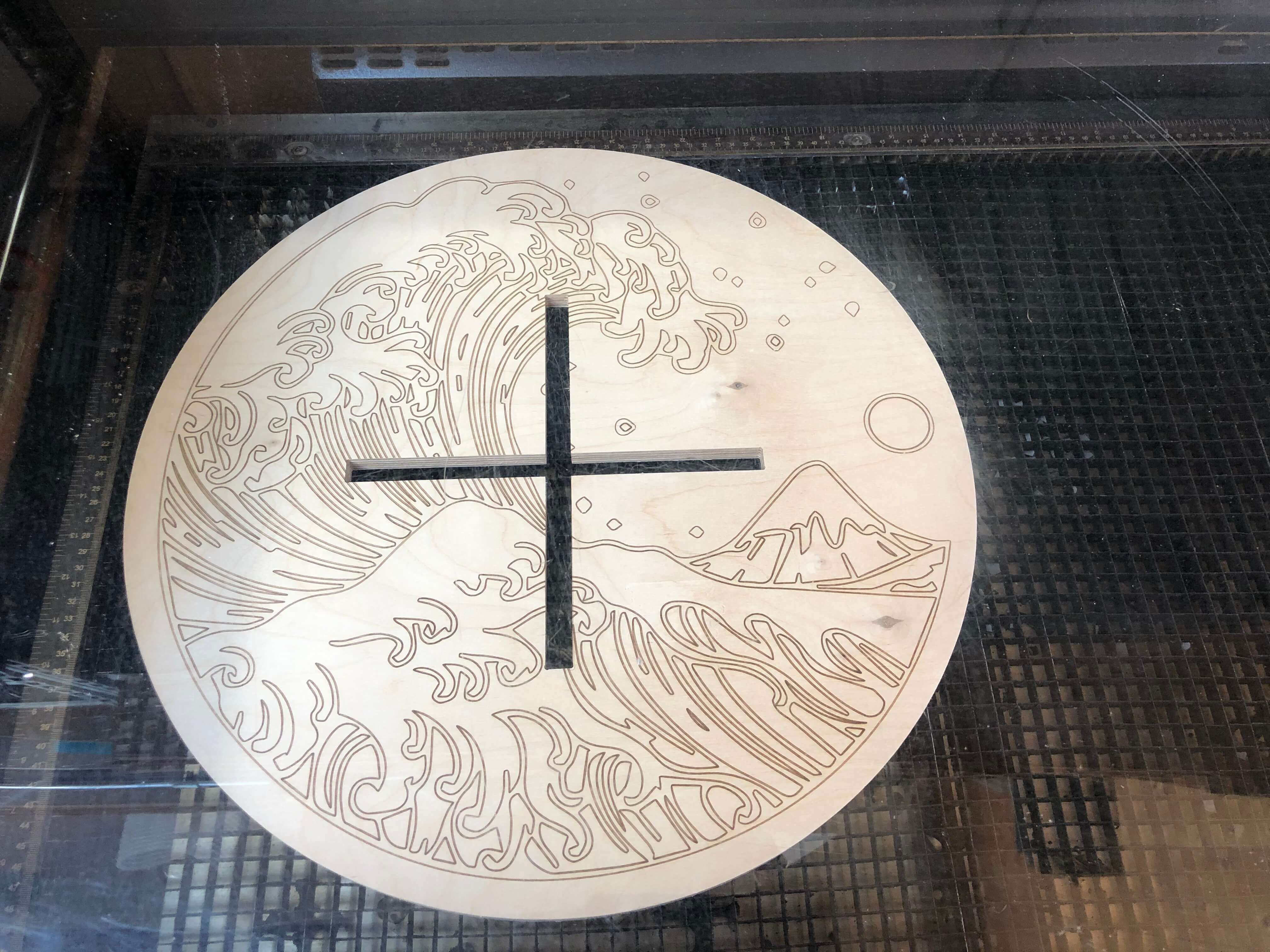

and then the "real" cutting

In conlusion, some wood treatment

And here the finished tableeeeee

CNC Machine

CNC (Computer Numerical Control) machining is a subtractive manufacturing technology. Objects are created by removing material from a solid block using a variety of cutting tools. Almost every material can be CNC machined such as metals, plastics, foam, and wood. The basic CNC process can be broken down into 3 steps. The engineer first designs the CAD model of the part. The machinist then turns the CAD file into a CNC program (G-code) and sets up the machine. Finally, the CNC system executes all machining operations with little supervision, removing material and creating the objects. You can have a 3 axis or a 5 axis CNC machine.

First attempt

First step: familirizing with Vcarve.I made a very simple draw made by 3 words with Illustrator and imported it into Vcarve.

The goal was to try different depths for each word. I tried with 4 mm for "dream", 8 mm for "explore" and 12 mm for "discover". The piece of wood I choose was 15 mm. I exported the file, set the piece of wood on the cnc and pressed play. Unfortunatelly it did not work proprially because it was to deep so I stop the file before the end. Here the first fail ;)

So I tried again. I turned the piece of wood and set it again on the CNC. This time I set the deepths at 2 mm for "dream", 4 mm for "explore" and 6 mm for "discover". I exported the file again and set the new try.

The result:

Second attempt: THE table

To create my design I used Autodesk Fusion 360. I decided to do a simple flat pack design table.** GRAZIE Albi **

Then I imported it into Vcarve

and the into the CNC

some sanding

Then I decided to laser cut my wave design on the table top. With Antonio and Tiziano I made some tests in order to try the power of the cut. Tiziano showed me how move the Z axe in order to have a wider line.

and then the "real" cutting

In conlusion, some wood treatment

And here the finished tableeeeee