-

Fab Academy 2020

-

Design. Make. create.

-

Shape the Future

Our group work assignment is to characterize the lasercutter, making test part(s) that vary cutting settings and dimensions

For this week group assignment, we had to test our laser cutter performance, by measuring the kerf value for different materials.

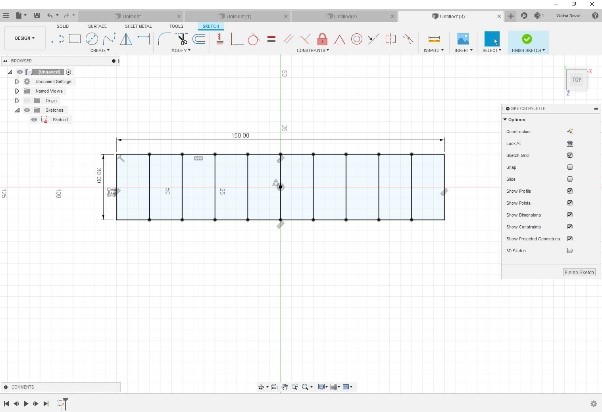

We drew a rectangle and divided it into 10 segments. The width of each segment was 15mm, and cut it using the laser cutter, you can find the setting used for each material in the table below. After cutting it we measured the true value of the width of the segment and the width of the whole rectangle using the caliper, see images below.

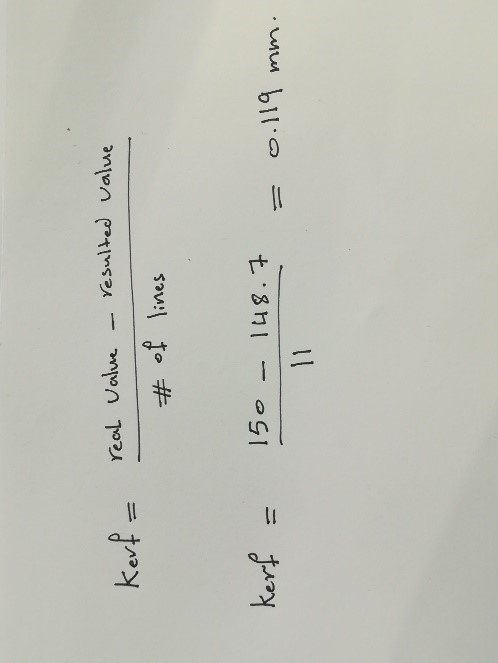

As you can see, the total width was 148.7mm. from this value, we calculated the kerf using the below equation.

| Material | Speed | Power | Frecuency | Kerf Value |

|---|---|---|---|---|

| Acrylic 2 mm | 0.6 | 89 | 1000 | 0.16 |

| Acrylic 3 mm | 0.5 | 89 | 1000 | 0.197 |

| Acrylic 6 mm | .15 | 89 | 1000 | 0.228 |

| MDF wood 2.5 mm | 0.8 | 89 | 1000 | 0.0563 |

| MDF wood 5 mm | 0.35 | 89 | 1000 | 0.142 |