This page presents the assignments for week 6 of Fab Academy 2020: “Electronics Design”.

To do list:

Group

- use the test equipment in your lab to observe the operation of a microcontroller circuit board

- redraw an echo hello-world board,

- add (at least) a button and LED (with current-limiting resistor),

- check the design rules, make it, and test it,

- extra credit: simulate its operation

Week 6 files:

RedrawHelloBoard.kicad_pcb (own work)

RedrawHelloBoard.pro (own work)

RedrawHelloBoard.sch (own work)

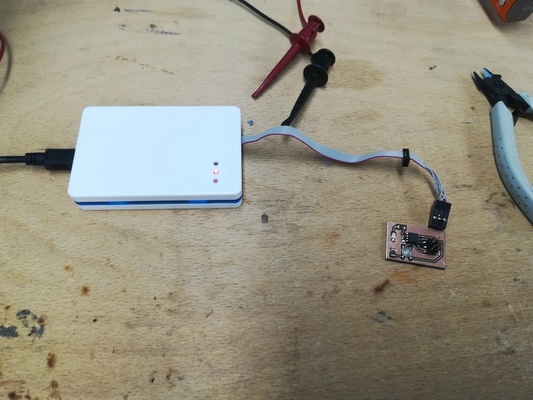

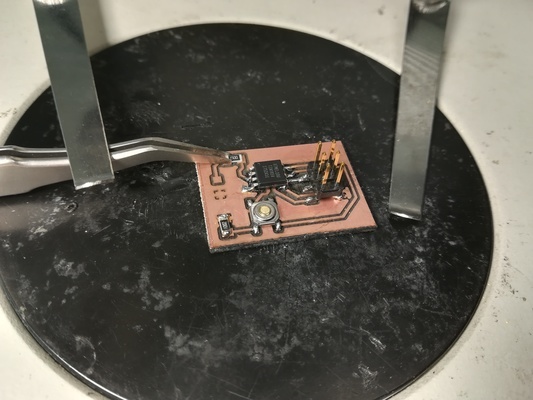

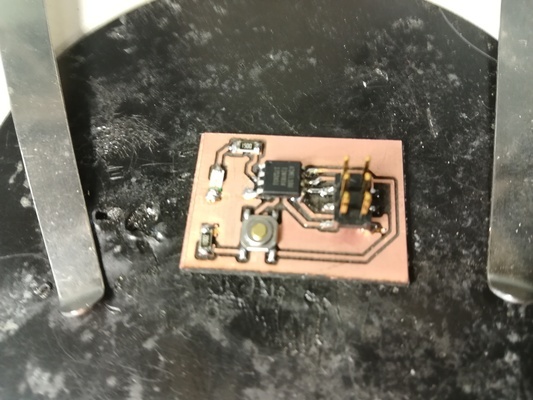

Week 6 "hero shot":

Table of Contents

Individual assignments

Redraw an hello-world board

Using Eagle software

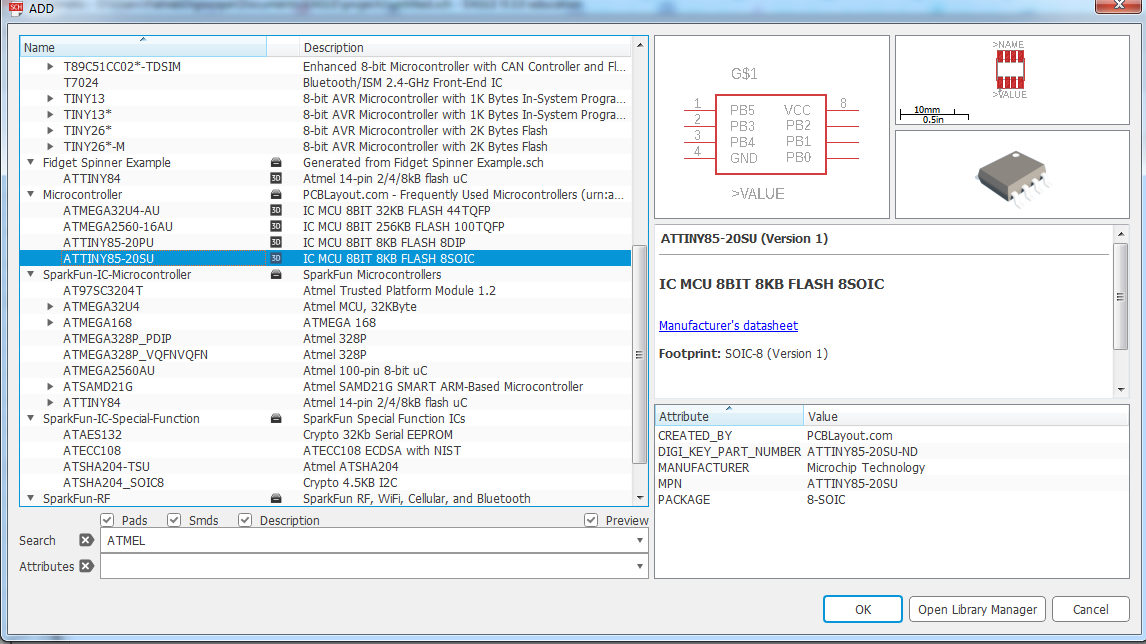

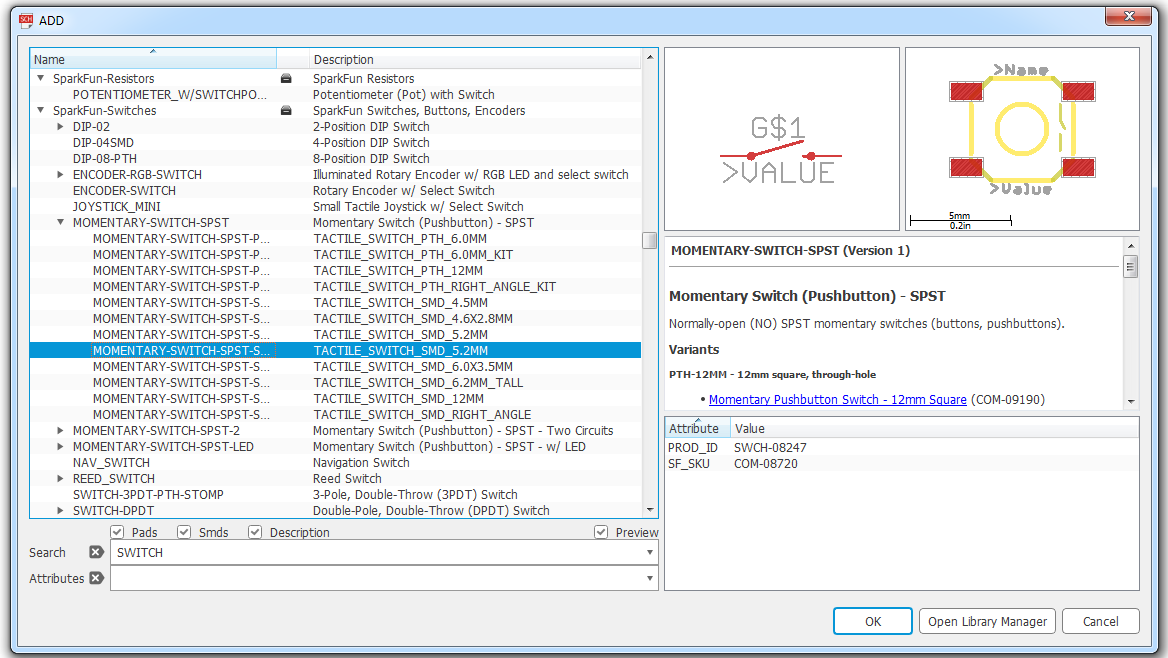

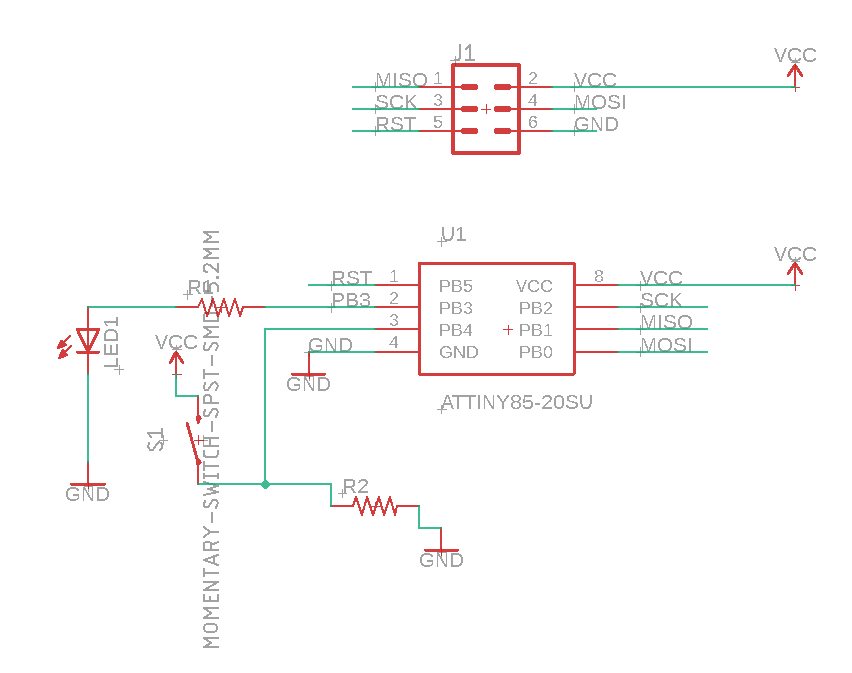

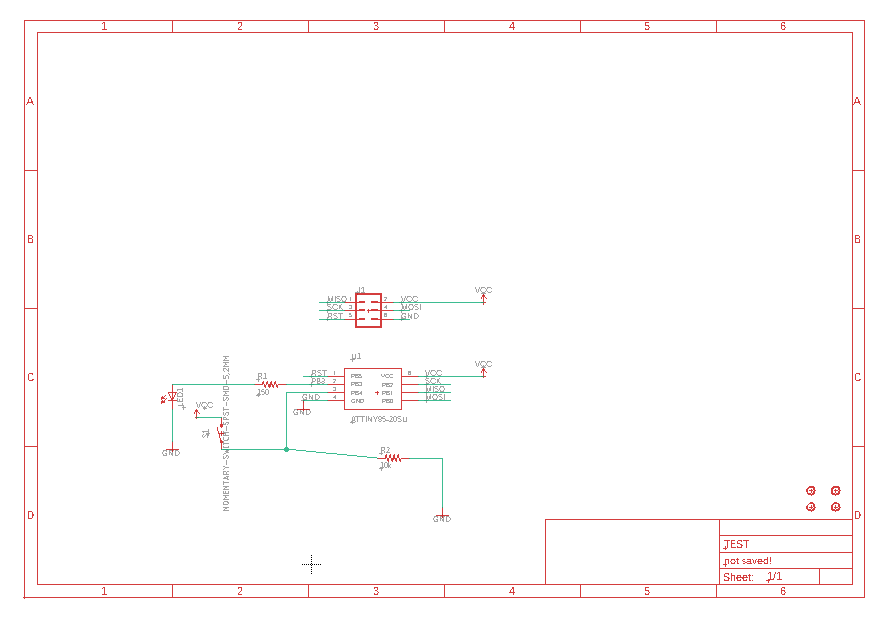

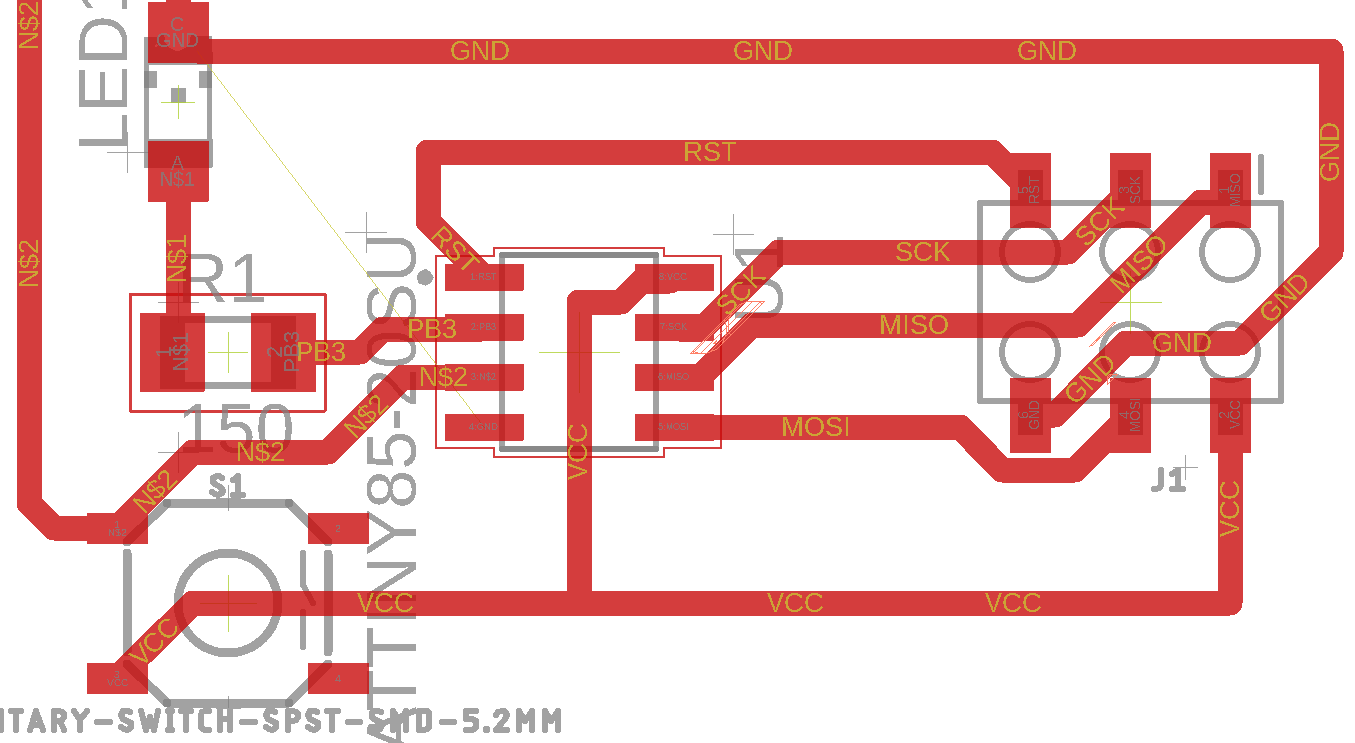

I create a new project in Eagle.In the schematic file I used the "place symbol" tool add the components needed to the drawing board.

After adding all components, I used the "wire tool" to connect component.

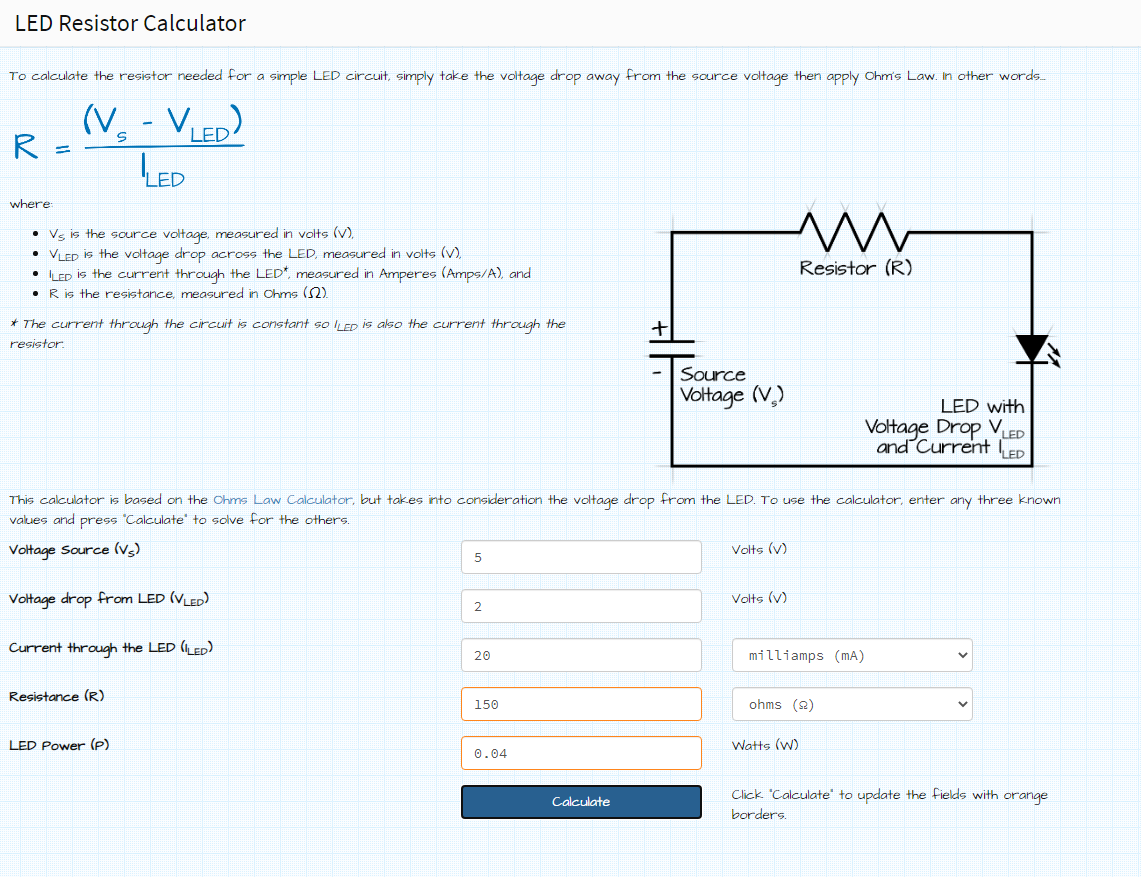

I checked the LED datasheat and use a website to calculate the appropriate value to use for its resistor.

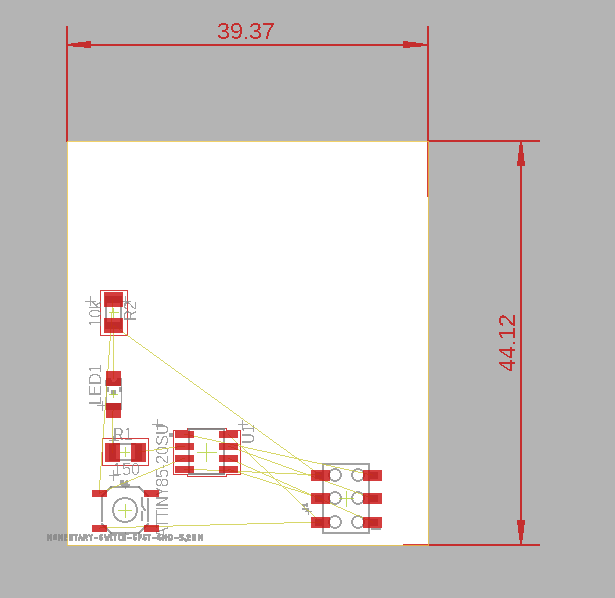

I tryed several combination for components wiring and positioning.

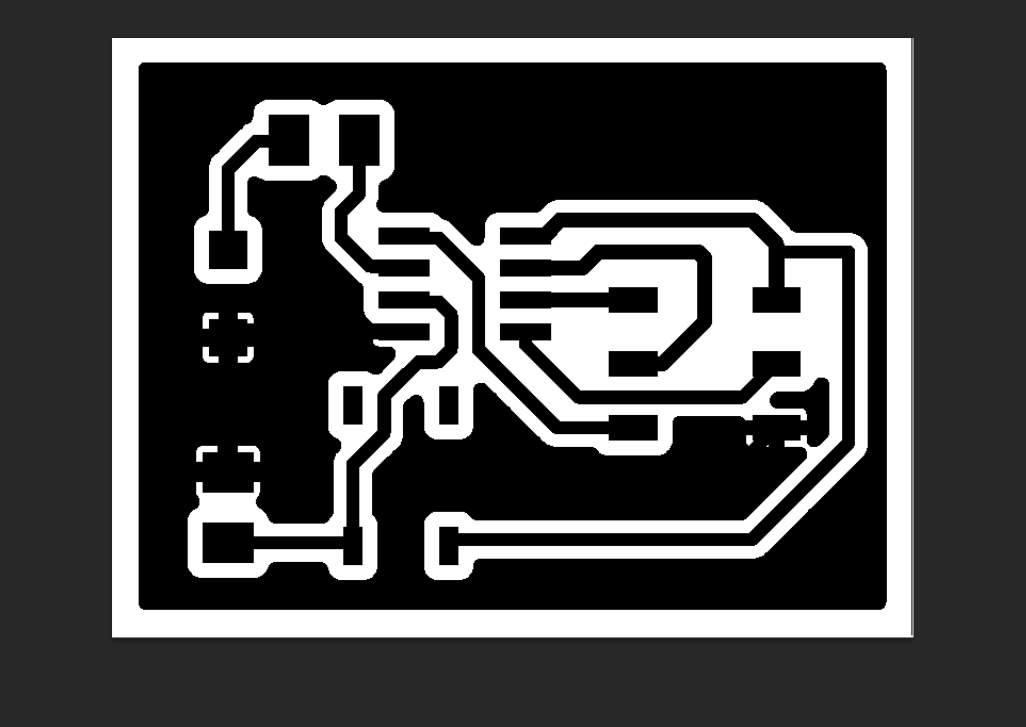

Then I generated a black and white picture.

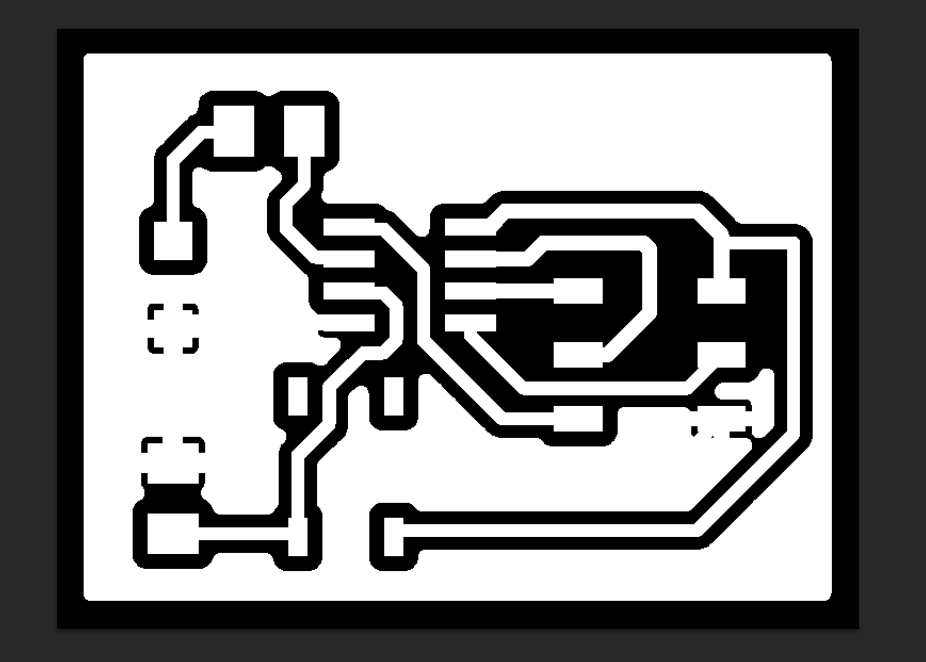

Finaly I inverted the black and white to get a picture ready for engraving on the laser cutter.

Make it

Laser cutter

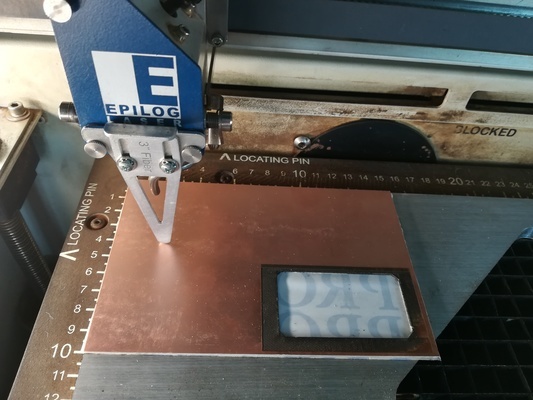

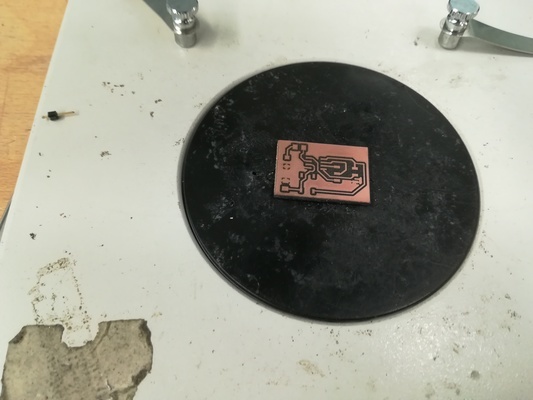

I used one job on the laser cutter to engrave the copper with the layout produced in Eagle.I used a beeping oscilloscope to check that the trace have been correctly made before cutting the fiberglass.

I then used 20 simple jobs to cut trough the fiberglass of the board.

Copper engraving

Fiberglass cutting

Soldering

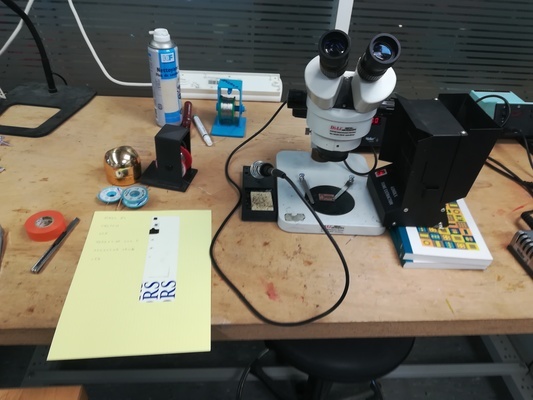

I used the microscope to search for copper hairs.I used beeping oscilloscope for more testing of the traces.

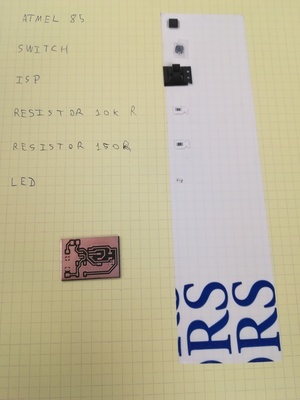

I then glued all needed components on a "to solder list" paper.

I soldered each component and then make beeping oscilloscope test.

Search for copper hairs

Test it

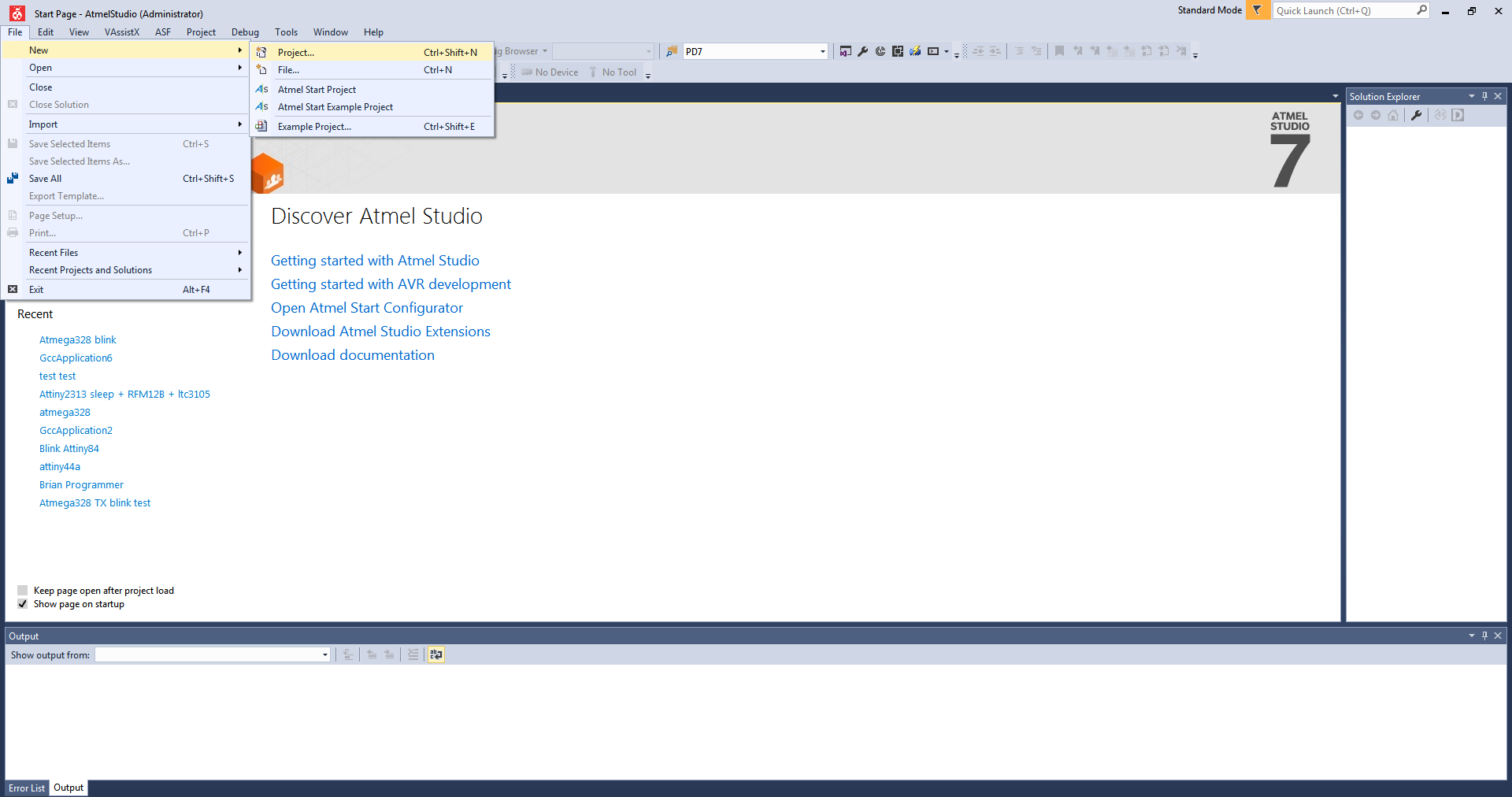

Programming the board

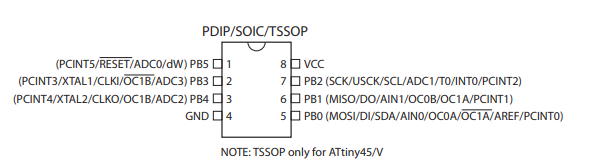

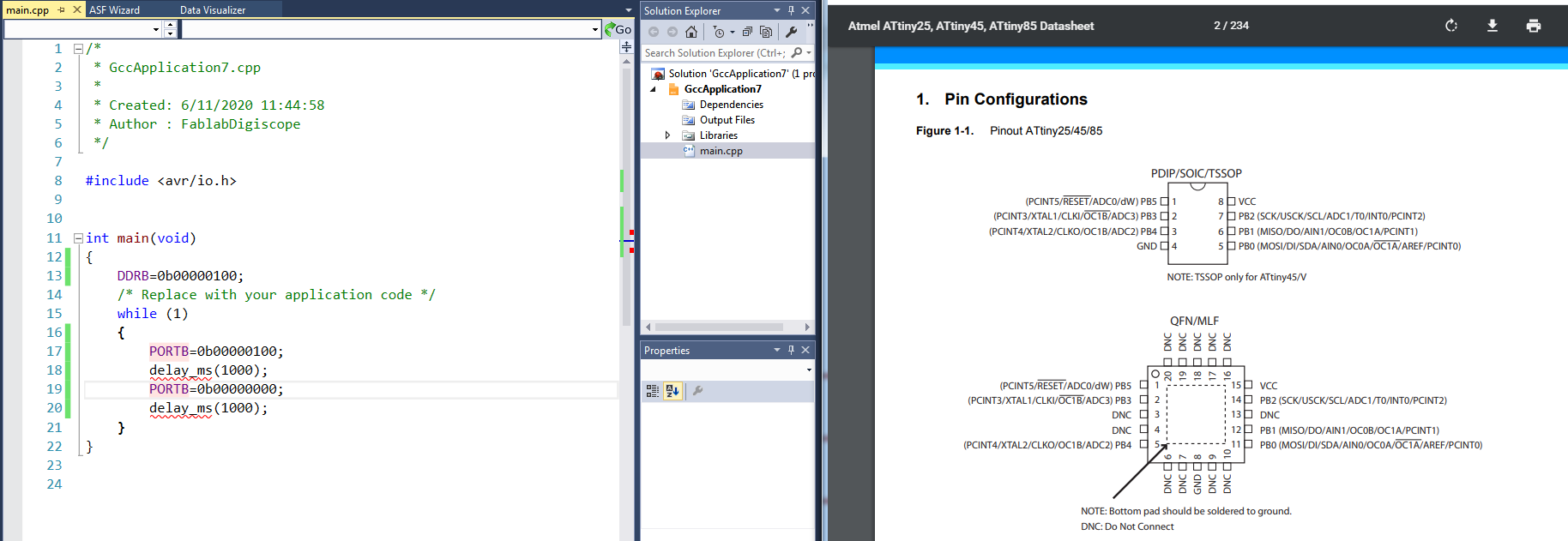

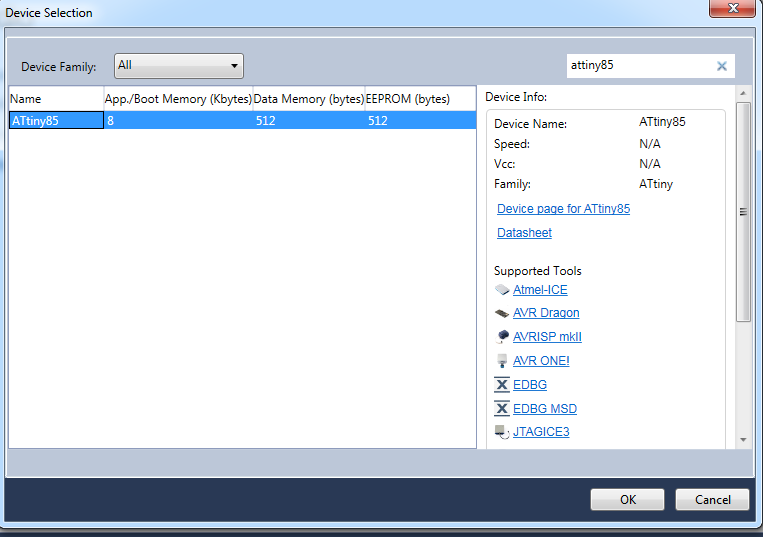

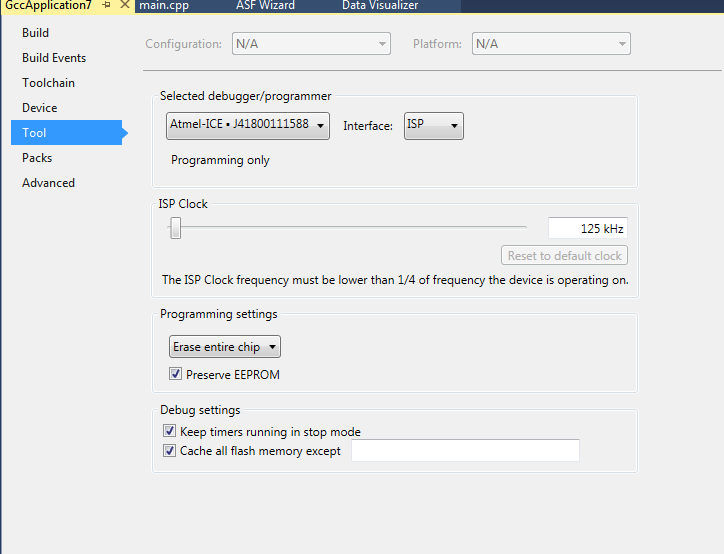

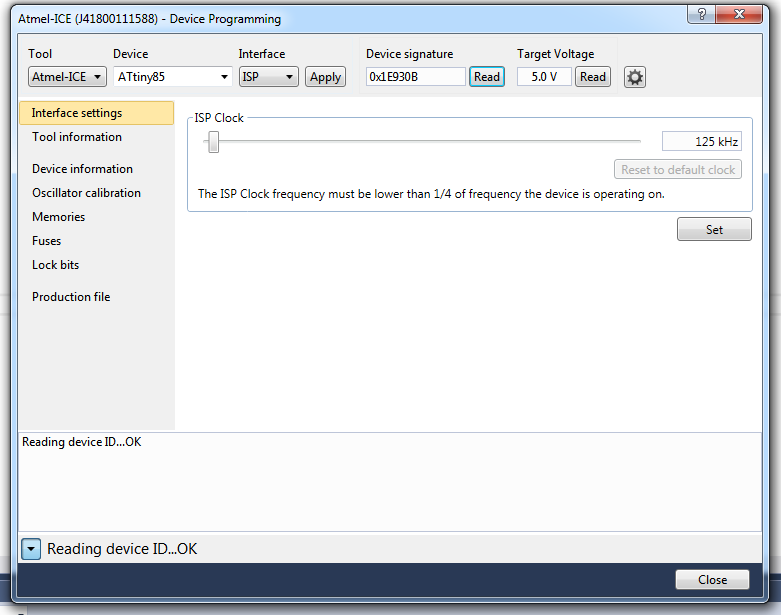

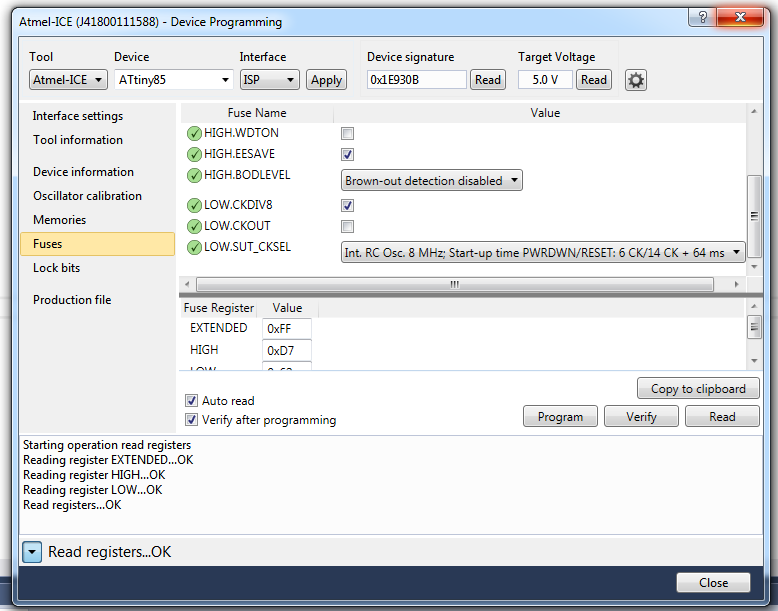

I used ATMEL Studio and ATMEL ICE programmer to program the board.I checked for online documentation of ATtiny45.

I first programmed the board to wait 1 second before turning on or off the LED.

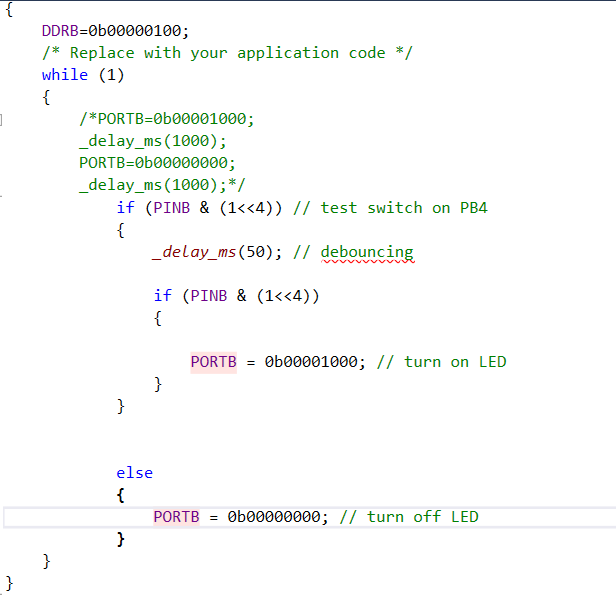

Then I programmed it to turn on the LED

Results

Turn on and off the LED every second

Turn on the LED when the button is pressed