Computer Aided Machining

Lab's safety training

Runout test, alignment, speeds, feeds, materials, and toolpaths for your machine

Task

Select one material, size and thickness

make a characterization table for diferente cutters

Task development

for this assignment we had to choose a material to cut (we chose 15 mm MDF) and our cutters diameter and flute type

this are the ones we used.

From top to bottom and left to right

1/4" ER-32 Nozzle

3/8” ER-32 Nozzle

1/2" ER-32 Nozzle

60° V Bit

1/8” upcut 2flute Endmill

1/4" Upcut 2flute endmill

3/8” compresión 2 flute endmill

1/2" upcut 2 flute endmill

From top to bottom and left to right

1/4" ER-32 Nozzle

3/8” ER-32 Nozzle

1/2" ER-32 Nozzle

60° V Bit

1/8” upcut 2flute endmill

1/4" upcut 2flute endmill

3/8” compresión 2 flute endmill

1/2" upcut 2 flute endmill

We have a A2MC AXYZ CNC router and a licence for Vectric’s Vcarve pro that was our software of choice.

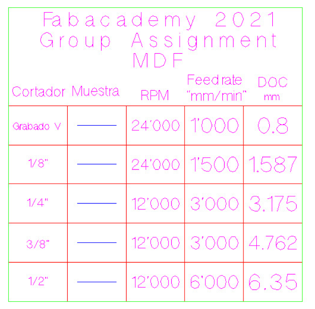

Picture of the design:

We create a settings by colors, to indicate different operations in the software.

This are the parameters we used for the different flutes.

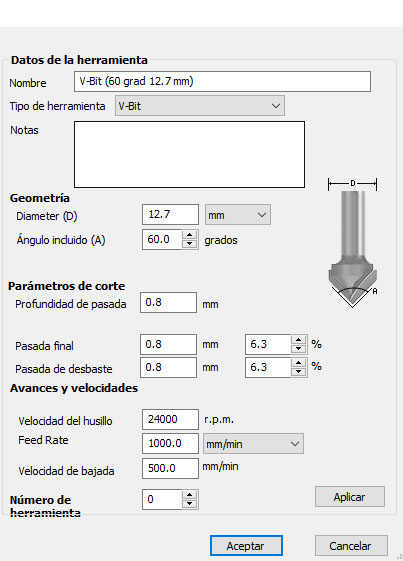

60 degrees "V" bit

1/8" endmill

1/4" endmill

3/8" endmill

1/2" endmill

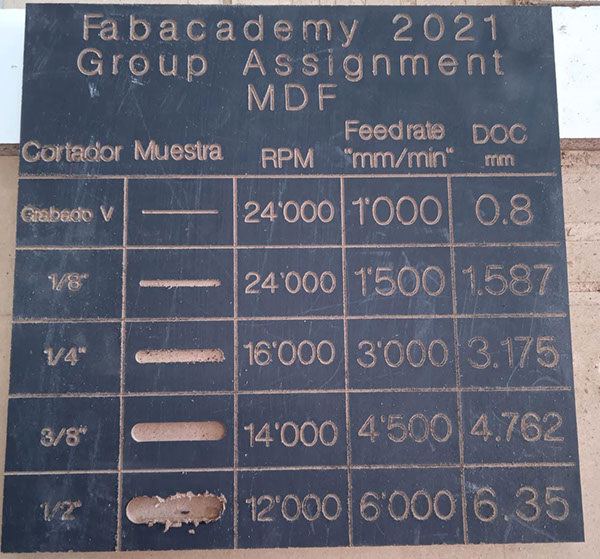

This is the final engraving board, using the 5 flutes, measuring how it works in a regular environment.

And this is the video of the whole process.