A16

Wildcard Week

This week is more a statement on recycling than a digital fabrication as is...

Since the Covid-19 outbreak, i have been involved in how to help local doctors and institutions with less known products that could be 3d-printed and be easily to share.

Using an Ultimaker 2+ and a davinci 1.0 printers we have been able to produce over 200 pieces in a 2 month period, however, thera hasn`t been as easy as it might look...

Bad warming, cloging, bad adhesion, low-quality filament, energy cut-off failures, etc. led to a waste that couldn't fit to send a finished product for hospitals.

So, i tried something different, WHY NOT, using it to create an architectural model, and a set of "growing steps" to show everyone how the pieces, in the end, are build.

This is a creative week, maybe, not as technical as it should be, but a rewarding one, beacuse i had the chance to use this leftovers, while i keep printing other models.

Research:

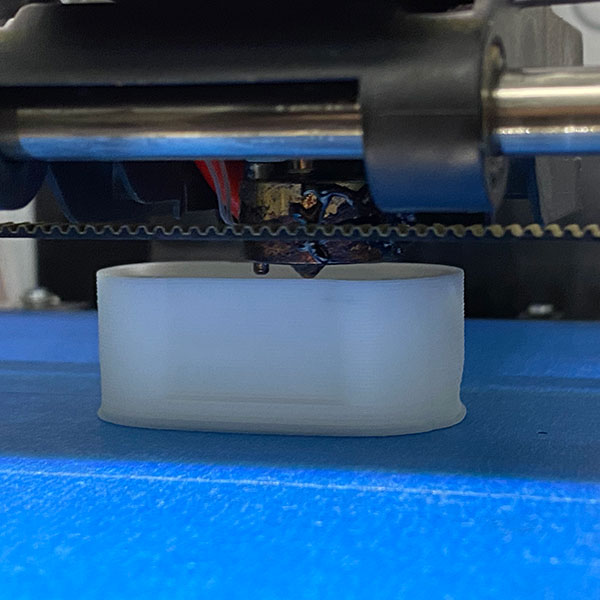

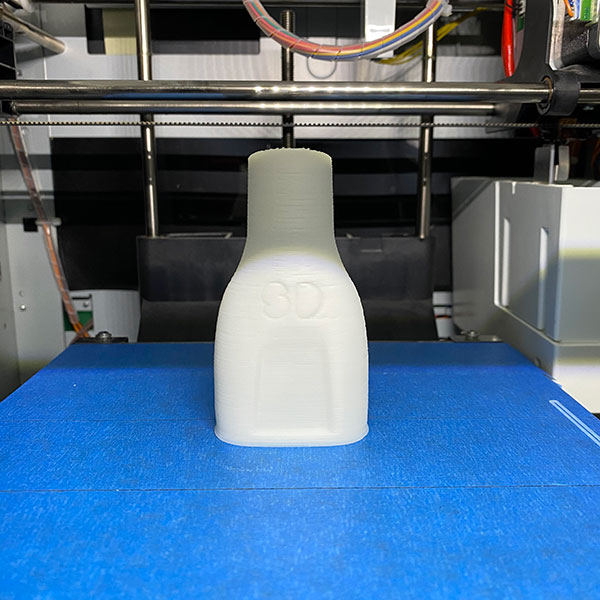

The original piece, a Coupler for a snorkeling VOIT mask that was donated to a Hospital in CDMX.

Measure 5cm long, by 2.4 cm wide by 7cms high, is quite an easy to print piece, it has been over 100 delivered... now, the leftovers were accumulating and wanted to do something insted of disposing them, that's when the idea came of a side architectural project would fit in a very different way.

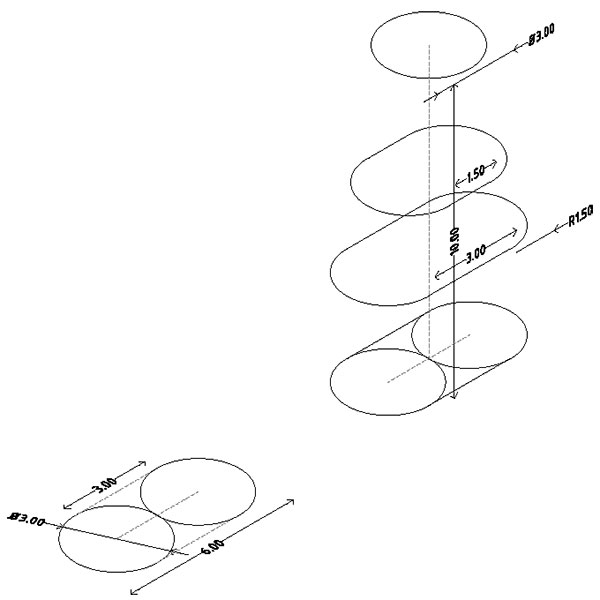

So, this are images from the original model, the process and the finished product.

And this are some of the leftovers...

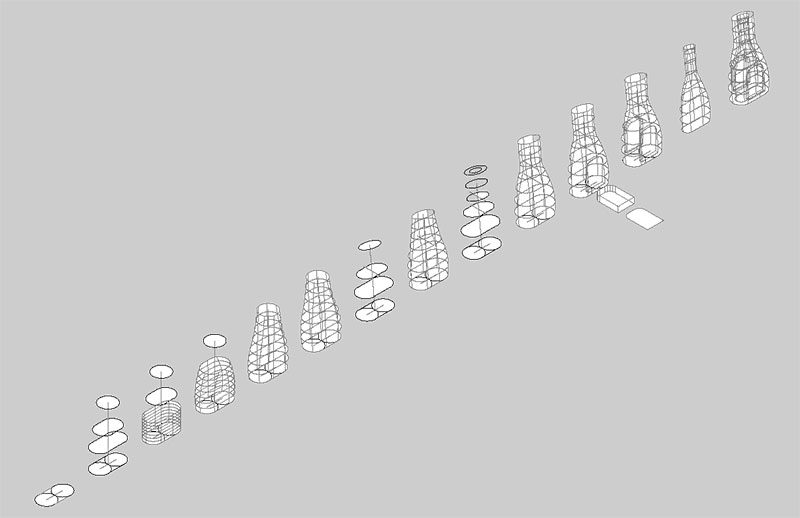

So, this is a quick study of how this piece came altogether.

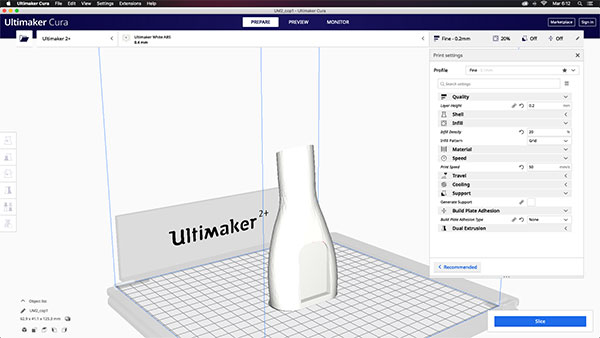

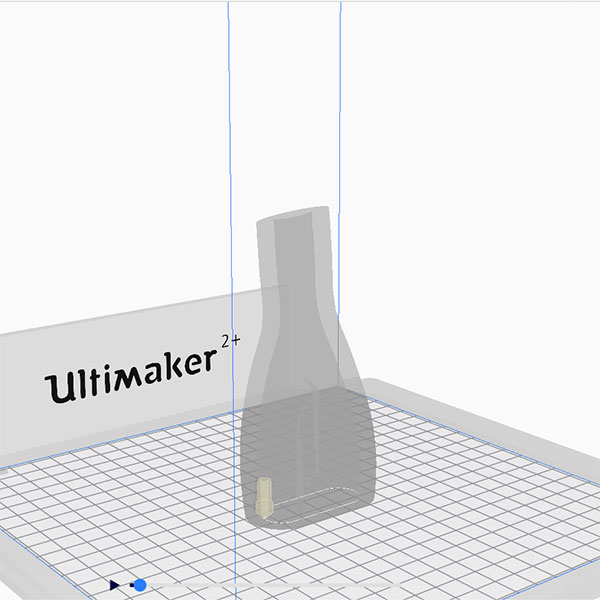

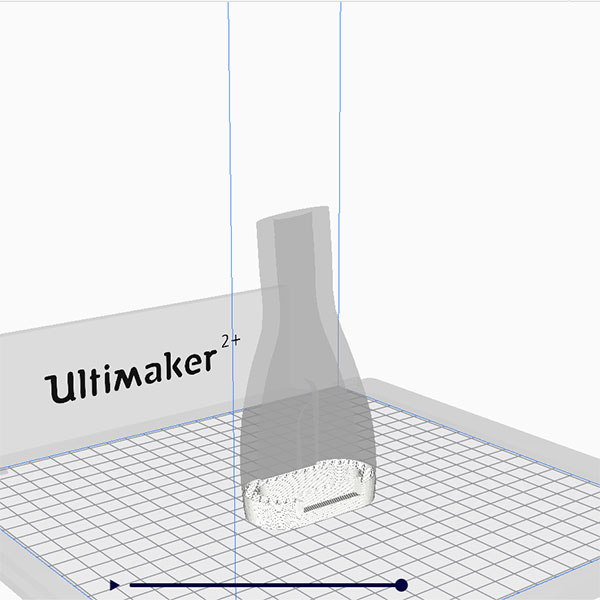

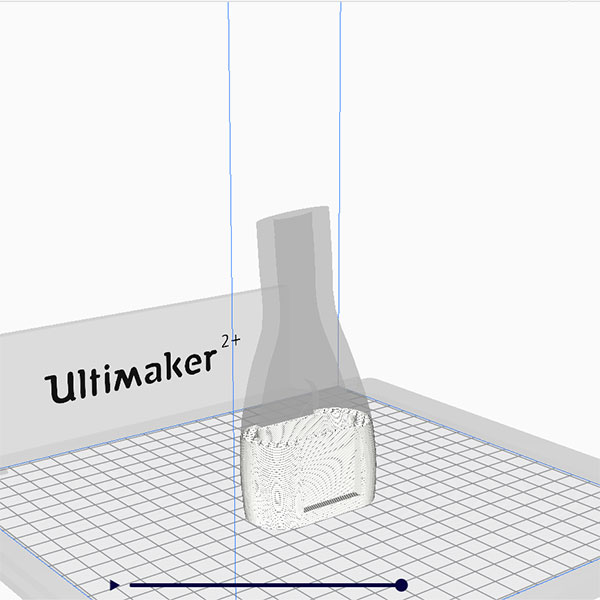

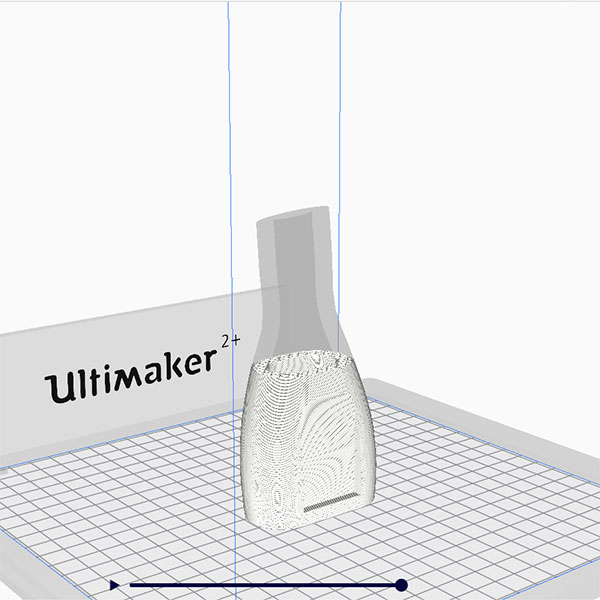

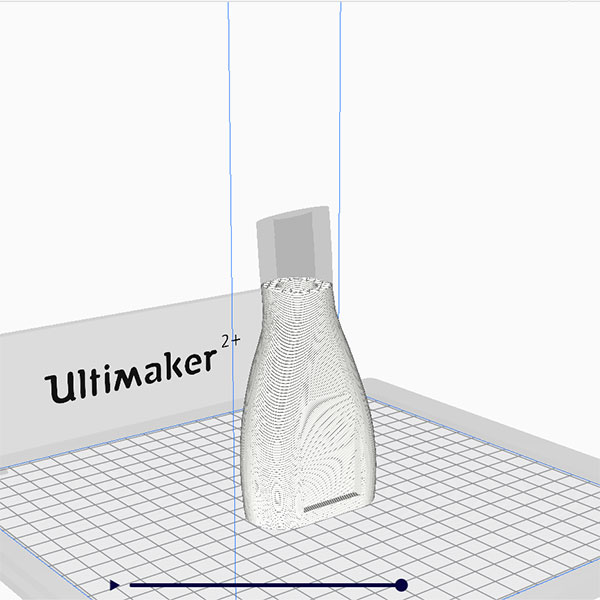

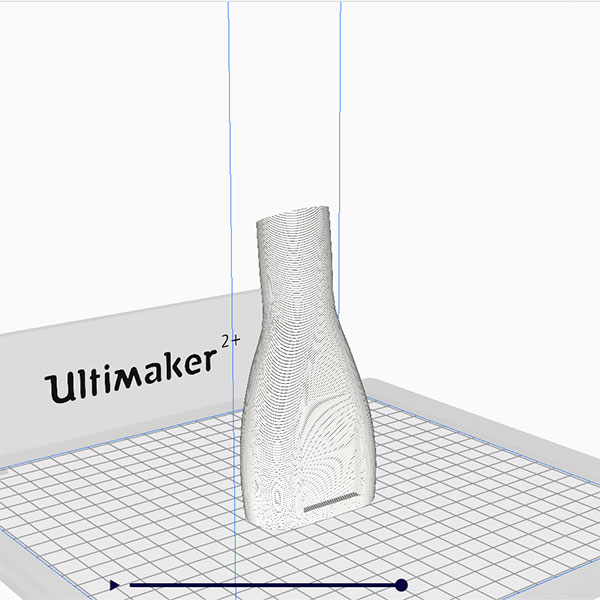

And the STL file that i used for a sample in CURA software, to see the process.

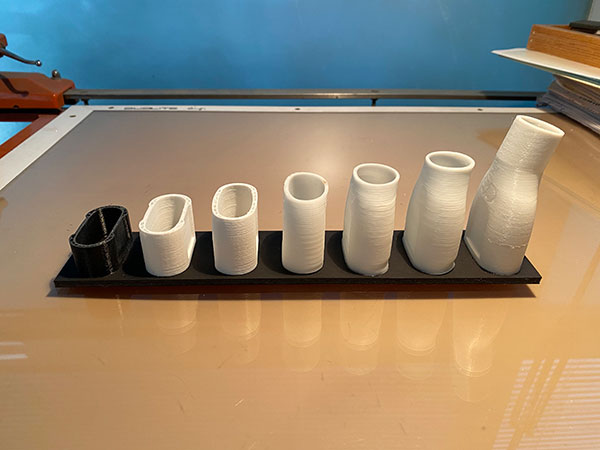

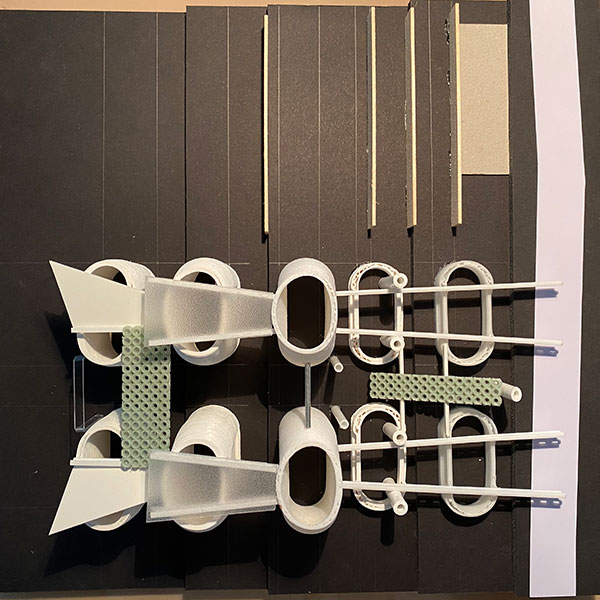

Firts recycled example, arrange 7 pieces to see how it grows, in here i used 4 different PLA and ABS filaments.

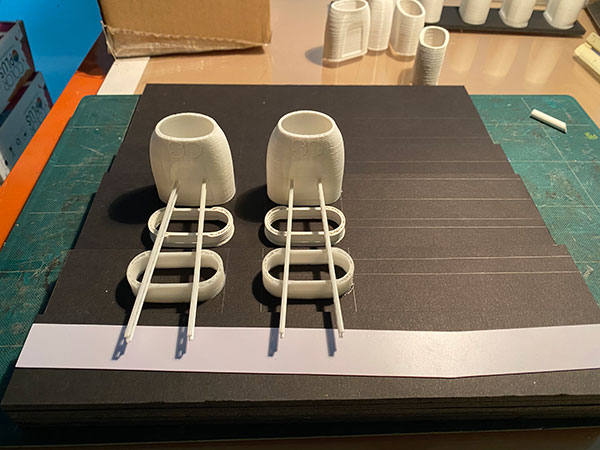

Second recycled option: architectural model.

A cultural center reusing an existing structure in a slope, using the leftovers to emulate the silos.

Trying to improve all angles in a lab, and to do something out of waste, i want to follow that circular economy and create awareness for eveyone around.