A12

Molding and Casting

Following some weeks towards electronic production and programming, we got back to design oriented hands-on activities. Taking off where "make something big" stood still, we are summarizing the machine oriented assignments.

AutoCad and Autodesk software

System requirements for AutoCAD 2018

Operating System

Microsoft® Windows® 7 SP1 (32-bit & 64-bit)

Microsoft Windows 8.1 with Update KB2919355 (32-bit & 64-bit)

Microsoft Windows 10 (64-bit only) (version 1607 and up recommended)

CPU Type 32-bit: 1 gigahertz (GHz) or faster 32-bit (x86) processor

64-bit: 1 gigahertz (GHz) or faster 64-bit (x64) processor

Memory 32-bit: 2 GB (4 GB recommended)

64-bit: 4 GB (8 GB recommended)

Display Resolution Conventional Displays:

1360 x 768 (1920 x 1080 recommended) with True Color

High Resolution & 4K Displays:

Resolutions up to 3840 x 2160 supported on Windows 10, 64 bit systems (with capable display card)

Display Card Windows display adapter capable of 1360 x 768 with True Color capabilities and DirectX® 9 ¹. DirectX 11 compliant card recommended.

The license server and all workstations that will run applications dependent on network licensing must run TCP/IP protocol.

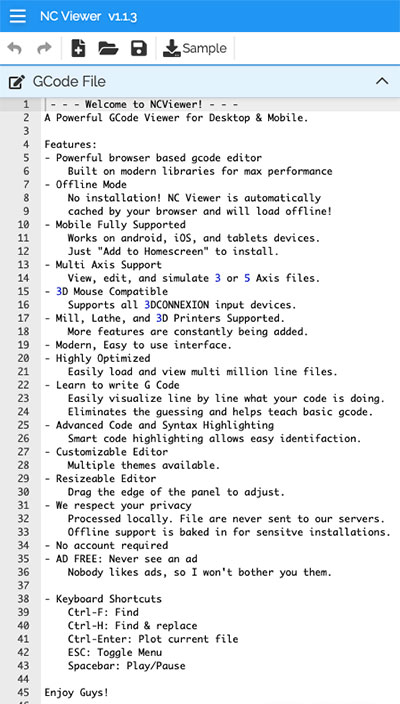

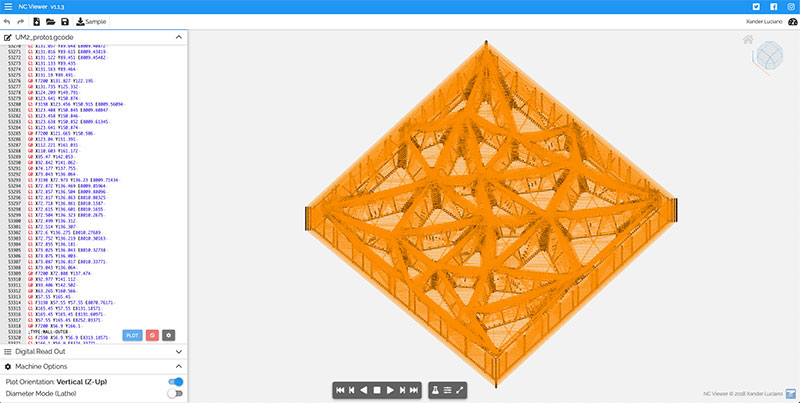

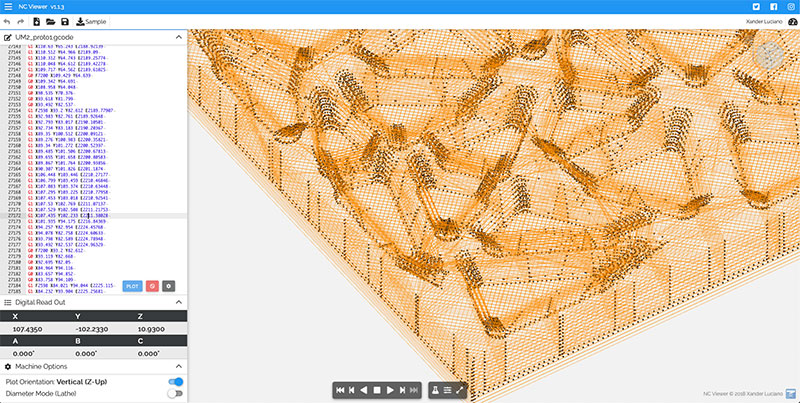

NC viewer

Opensource

Web-based G-code and nc viewer

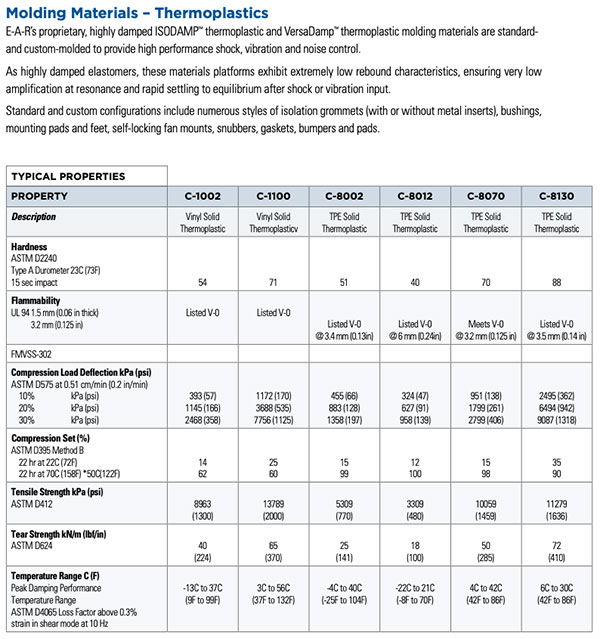

Materials.

A list of plastic materials, with molding capabilities, as well as development phases. Each one serves as a catalyst for creation, from soft to foamy.

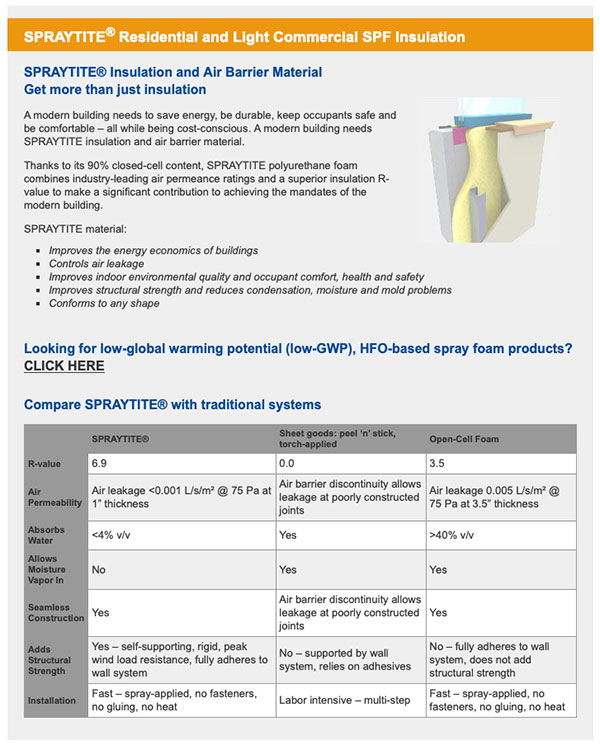

Polyurethane foam... filling spaces, ultra light, and isulation.

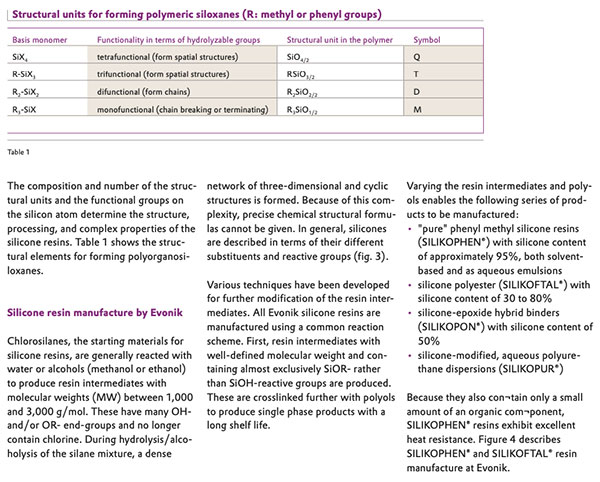

Polymeric sylicone, moldable, sealable, anti-corrosive, ultra durable, industrial grade in every drop.

Water-based Rubber for easy molding and soft surfaces

Sylicone and resin for easy molding and casting

Thermoplastics, to fit any form, and embrace every material.

Research:

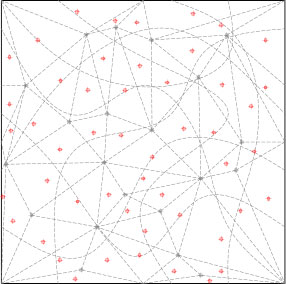

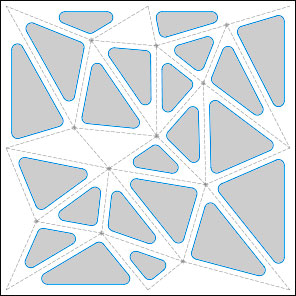

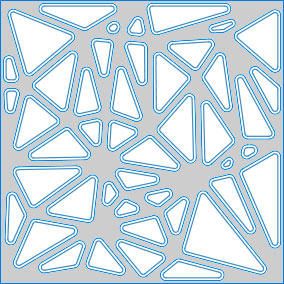

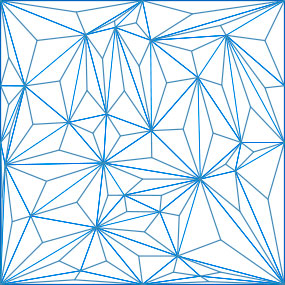

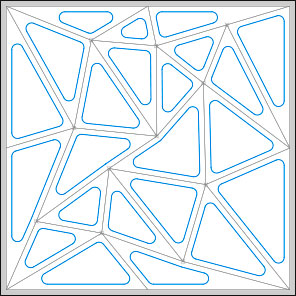

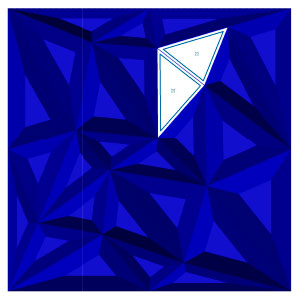

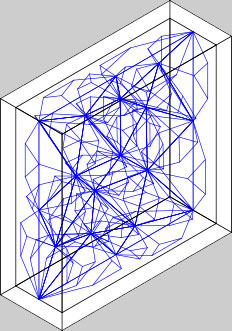

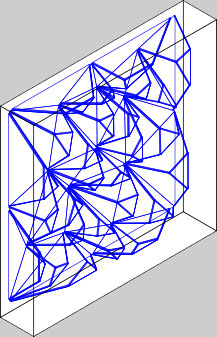

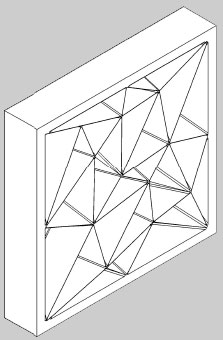

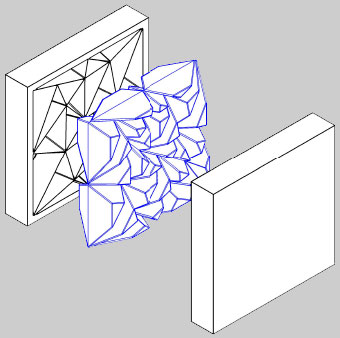

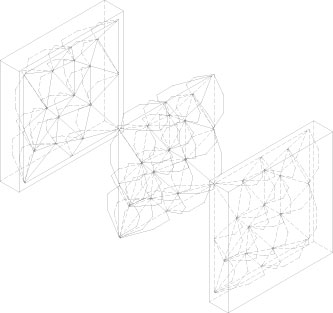

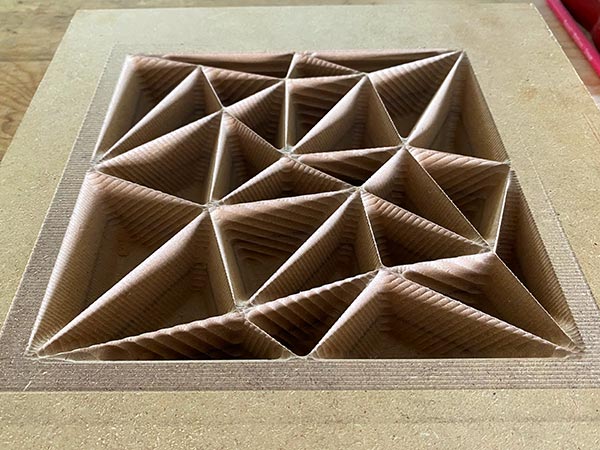

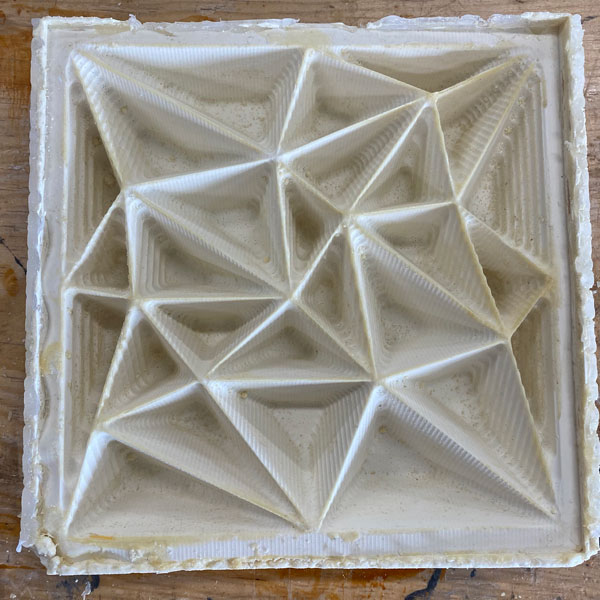

Getting to develop an old Voronoi based form, with DELAUNAY patterns, i dig deeper into lines and form, to have a very "pointy lattice" to create a negaive-positive sensation towards certain hexagonal form and be a companion as a sofa or as a partition, even a lamp.

The main pattern is followed by a set of pints in the void, following a random path.

The opposites attract and the fill became the void, to find a some sort of triangular faces filling the blanks.

Now, the lines became the surface to be extruded and get a piece of a mountain with a high slope.

Finding:

After mixing those forms, i created a positive - negative additive form. Then i turned into a g-code printing pattern to se how with a milling system i would be able to fit that piece in the AXYZ router.

Partial conclusion:

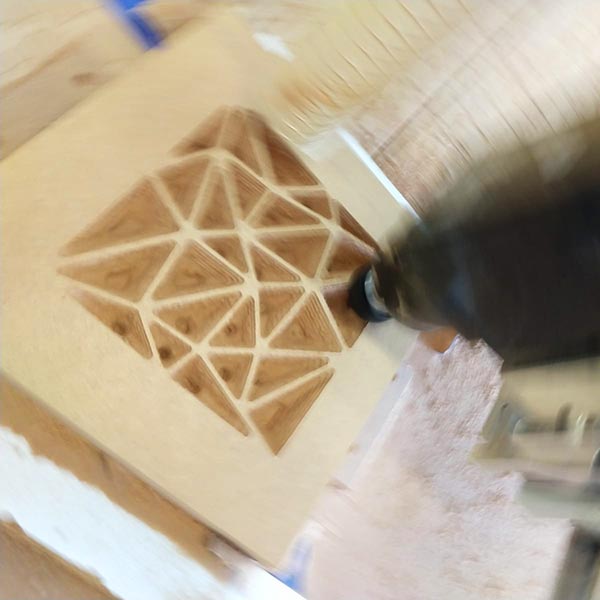

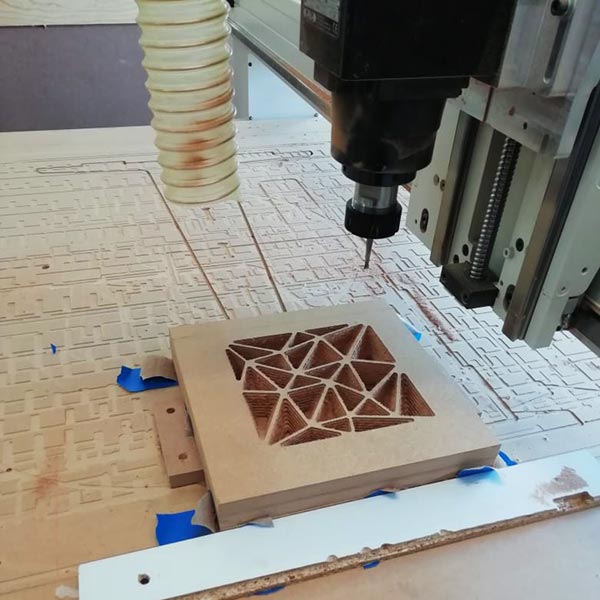

Becuase of the pandemic we were left out from workshops... trying to find a way to mill the mold. Thankfully, in April 2021 i had the chance to create the piece and make it happen.

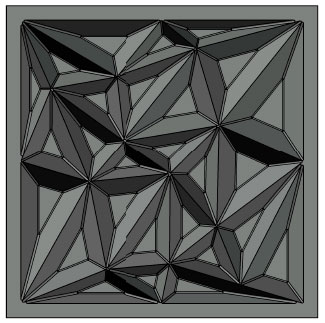

i sent the piece with my gcode yo a AXIS machine, with a 1/16" tungsten milling pipe to a 4800 rpbm

The 1ft by 1 ft (30.5cms x 30.5cms) board

Three layers deep to have a 57cms thick piece.

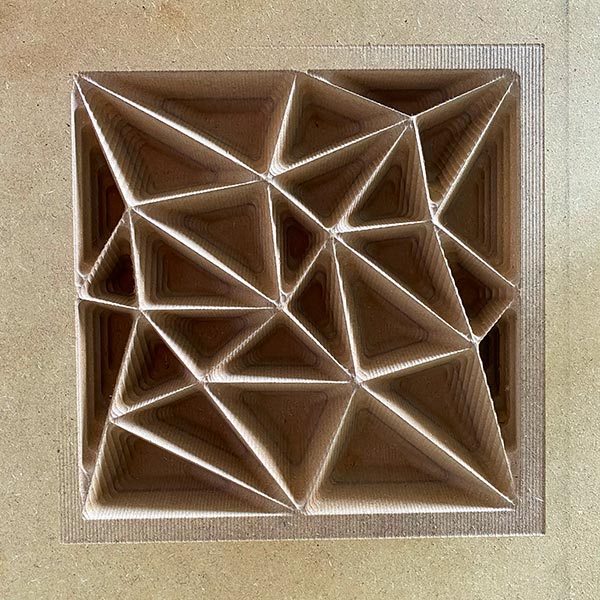

I wanted to preserve the grooves that made the triangular forms more natural and quite rough.

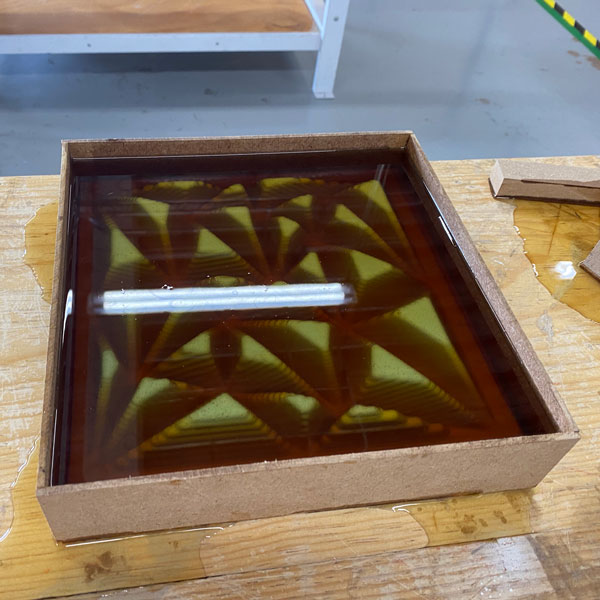

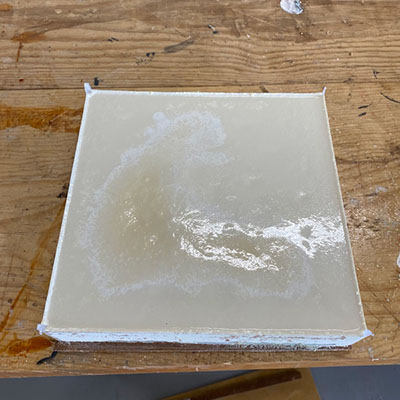

Then, i applied a sealant to the whole surface, in order to let it dry and have a consitent layer to avoid unpleasent effects.

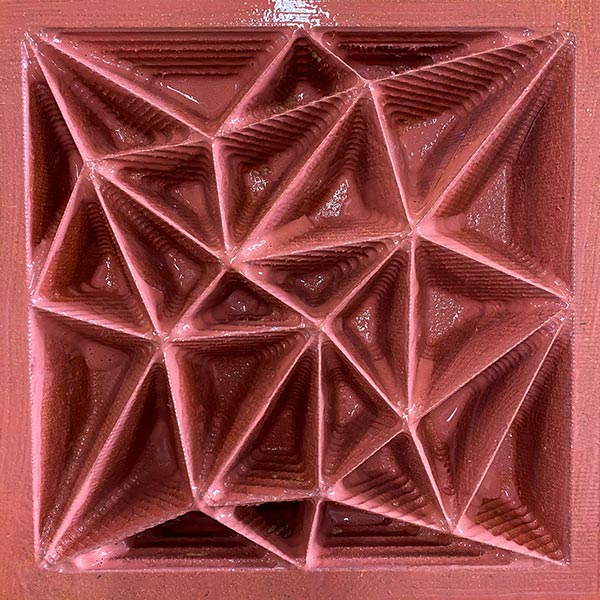

The finished sealed surface with its redish colour.

After let it dry for over 24 hours, the unstained layer became a little bit more brownish, and ready to have an product...

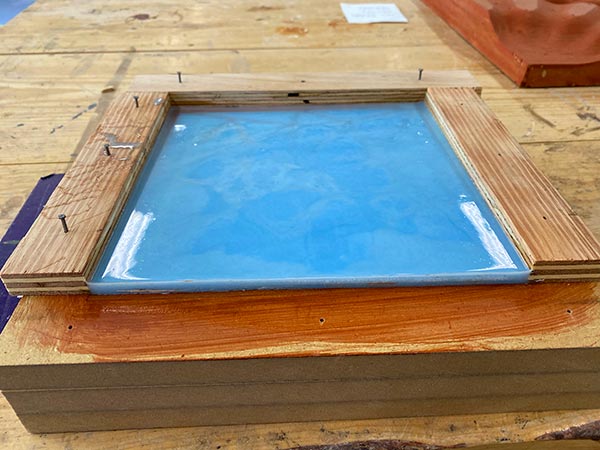

I used a spray release agent to set a new layer right before pouring the silicone based mixture.

Then, after mixing and stirring for over 3 minutes, i porued the finished "blueish" silicone mix into the mold.

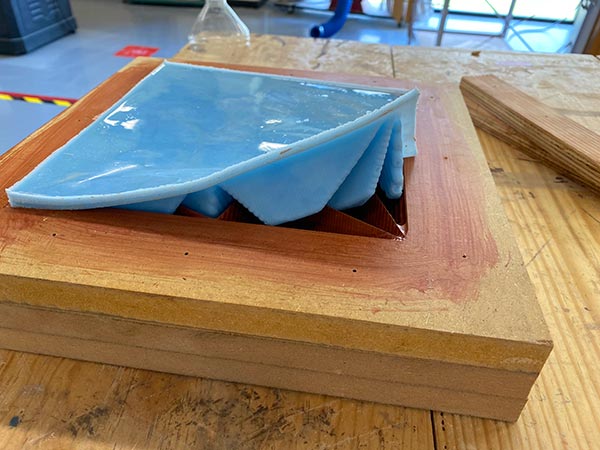

After 24 hours, the silicone based material is ready to be demoulded.

Thanks to the already applied products, the process is quite easy

Pulling gently out of the mold, and little by little releasing all of the corners first.

In here, the top view! a set of crests and valleys.

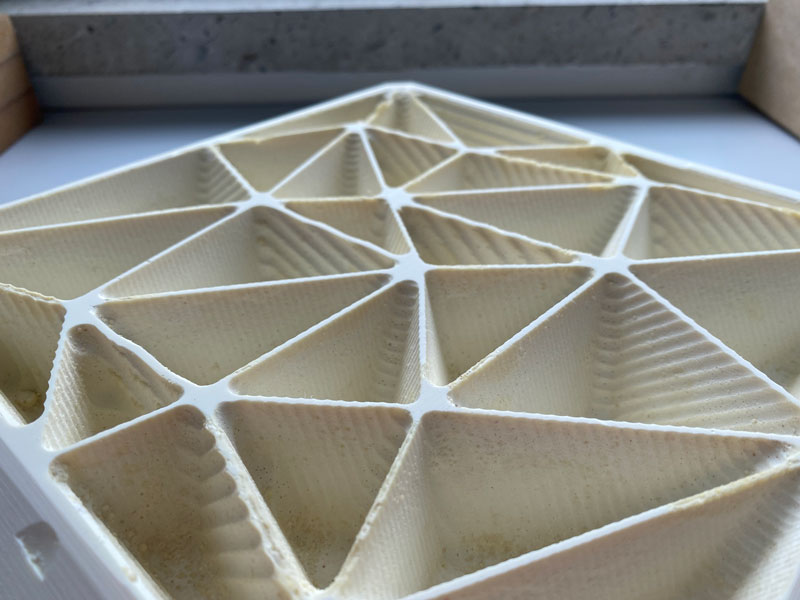

And the hero shot focusing on the grooves and textures of the "mountain range"

Finally after so much delay and speculation, i had the chance to create this molded topography based on a DELAUNAY pattern and dig deeper into what i consider is very important to research in a scale model, territories and terrains of the impossible.

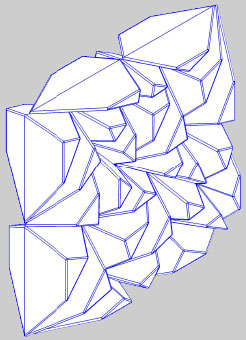

After that, i used this mountains as a positive to create a negative version of a lattice

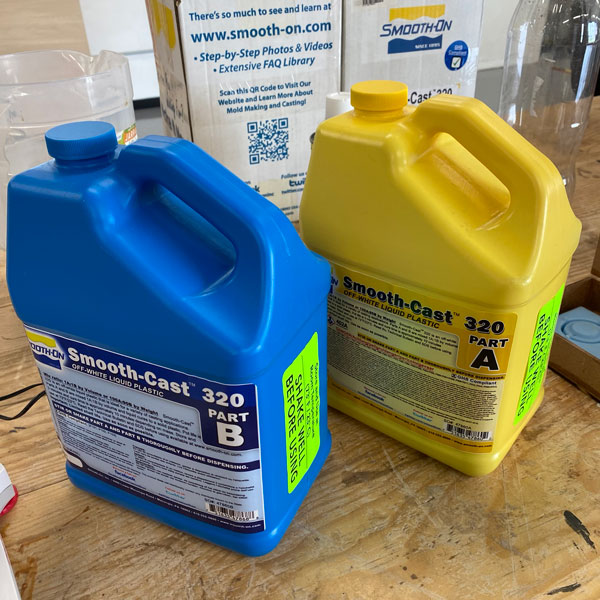

I used the 320 smooth-cast epoxic resin, veru smelly and sticky product, but i wanted a solid not so heavy material.

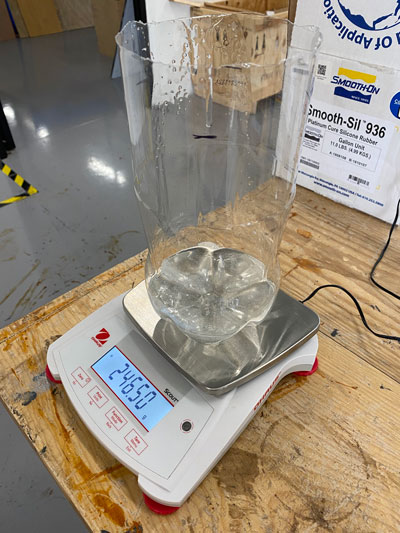

In order to be effective, we mixed a double batch for a possible misteke or use it for another project from my classmates.

We used a 85%-15% measure to get the desired resistance

So, i poured the liquid into the box up to 5 to 7 mm thickness on the base of the pattern... and waited 3-4 hours to get dry and solid

The mix got a creamy-milky color, but very soft and shiny... something that in the end was not useful, beacuse i neede to sand it to get rid of the coarse edges.

This is the final piece without any final preparations.

And after sanding and removing the extra edges, i had a very smooth surface preserving the original rugged internal edges.

Conclusion...

Finally after this new material and experimentation, i created a lattice that could easly be turned into a partition wall or a background lamp.