Jose Alegria - Fab Academy

Computer

Controlled Machining

ASsignment

wHAT iS THE ASSIGNMENT ABOUT?

Make (design+mill+assemble) something big.

Group Assignment:

Complete

your labs safety training

Test

runout, alignment, speeds, feeds, and toolpaths for your machine

Document

your work to the group work page and reflect on your individual page what you

learned

1st Step. Finding

an opportunity/necessity

The first

step is to find something big to build. The importance of the size in this

assignment is to make something that cannot be done with the laser cutter. So,

I was in the search for something that was big enough to be done with the CNC

and that could be assembled without any external help (i.e., without nails or

glue).

In

our Fablab, we needed something to keep the students

blueprints safe while rolled up, so I decided to make a container (600 mm x 600

mm) with space for papers and the rolled blueprints.

2nd Step –

Designing parametrically

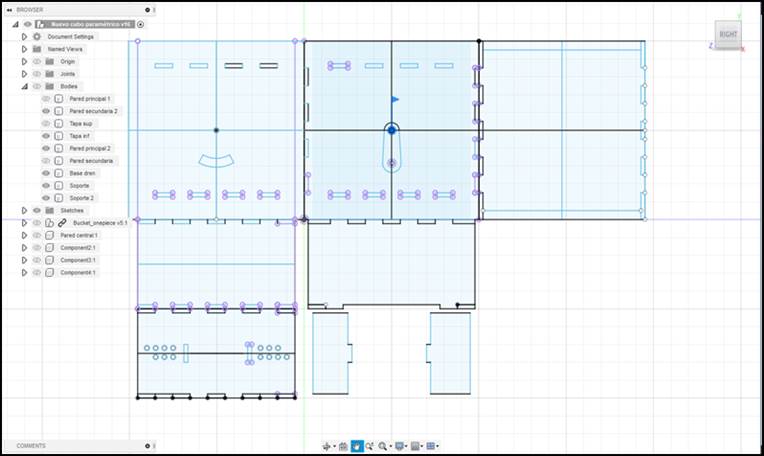

As I was going to design a container,

my needs were similar to the ones I had while designing a container for my

Final Project. While that was a case with special needs such as having dry

areas for the PCBs and wet areas designed to allow water through it, the

container I need for this assignment is a lot simpler. I decided to use my

original design as an origin for the new design, using the parametric settings

made in Fusion 360, I had to change the size of the panels from 100 mm to 600

mm and the size of the joints according to the material thickness, for I was

using a 3 mm acrylic for the final project case, and now I am using a 17 mm

pine wood sheet for my assignment.

After that, I had to consider the

differences in the cutting characteristics, for example, in the laser cutter I

had to be aware of the kerf changing the width of the joints, thus rendering my

press fit design harder to achieve. Here, in this assignment, the kerf could be

taken of the equation by designing in such way that the CNC cuts the wood

through the outside of the area to be used.

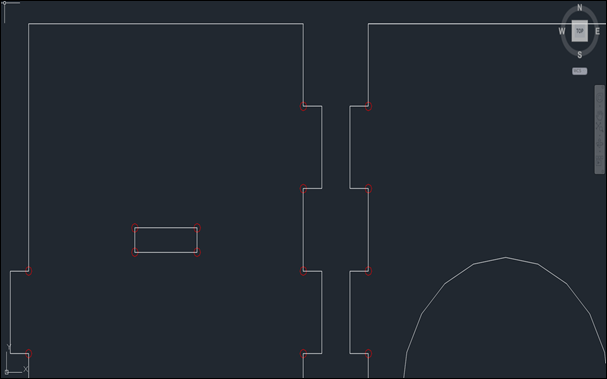

After changing the parameters

according to the new needs, I exported the design to Autocad

and made the final changes. For instance, getting all the pieces to fit in a

1.22 by 2.44 m wood panel.

3rd Step –

adjusting the design for the cnc cutting software.

After changing the parameters

according to the new needs, I exported the design to Autocad

and made the final changes. For instance, getting all the pieces to fit in a

1.22 by 2.44 m wood panel.

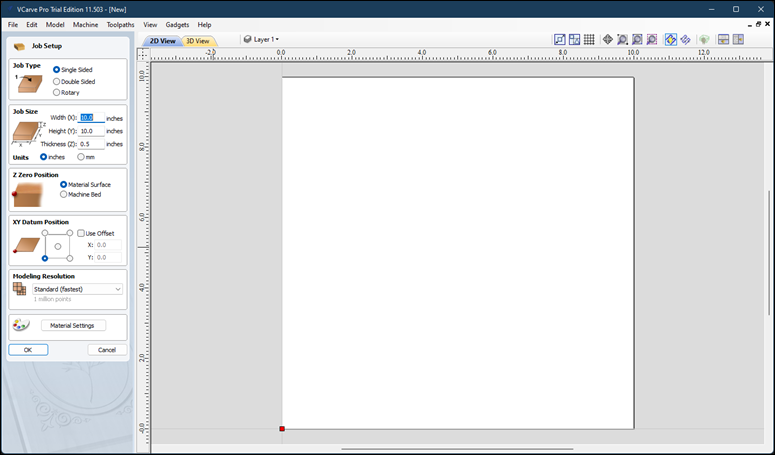

After that, I had to adjust the

parameters in the CNC Controller Software. I was using VCarve

to create a file that the machine could read. The first thing is to import our

DWG file to the Software.

There were three different jobs that

I had to create to cut the container: The first one was a set of borings made

to create a dogbone effect and allow the parts to fit

properly. I designed them to be just a hole with a diameter set by the tool I

was going to use (0.25 in).

The second and third jobs were the

main cutting procedure and was divided into two parts: the first passes and the

final cutting to split the parts from the main board. These are explained

ahead.

Inside the software I had to set the

parameters which were:

Job type

-

Single Sided

-

Job Size: 1220 x 2440 x 18.5 (mm)

-

Z Zero Position: Over the material

surface

-

XY Datum Position: 0, 0.

The

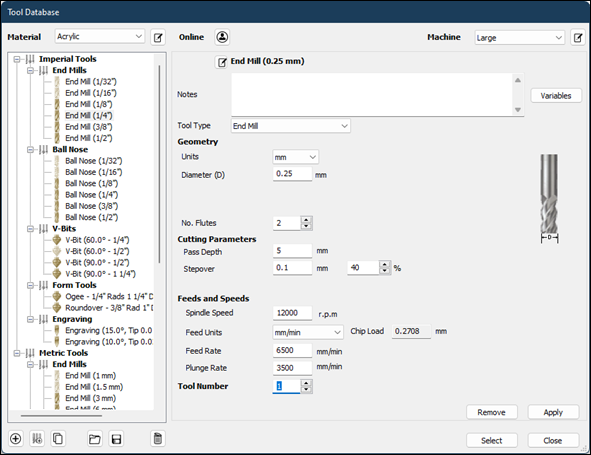

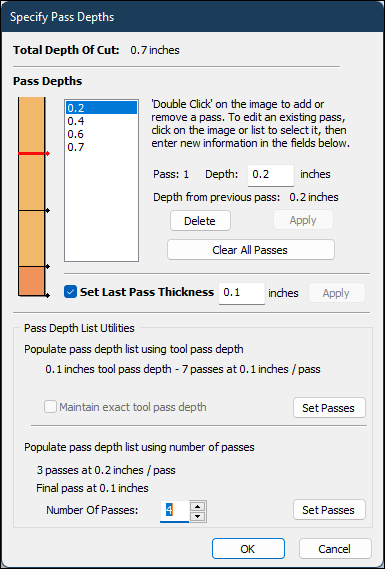

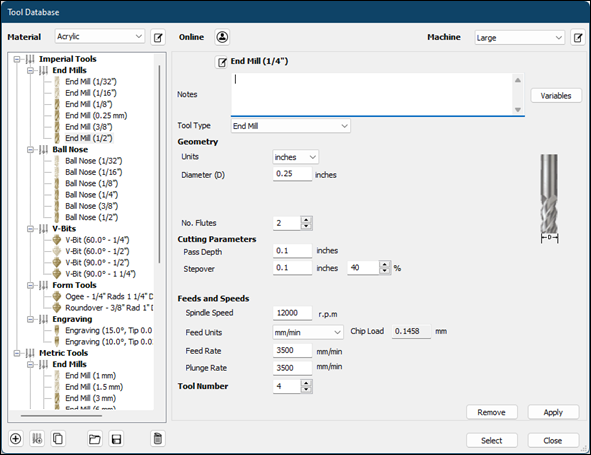

next step is to set up the cutting tool I was going to be using:

Tool

name: End Mill

Size:

0.25 in. or 6.35 mm

Spindle

Speed: 12 000 RPM

Feed

Rate: 6 500 mm/min

Plunge

Rate: 3 500 mm/min

Cutting

parameters: our cutting will be done with a step depth of 5 mm (It was

programmed for three main passes with a depth of 5 mm, and a final pass of 3.5

mm).

This

setting allowed me to set a faster Spindle Speed (6 500 mm/min) for the first

passes, the last pass of 3.5 mm had to be programmed for a slower Spindle Speed

of 3 500 mm/min to avoid the material to be moved once it gets separated from

the main board.

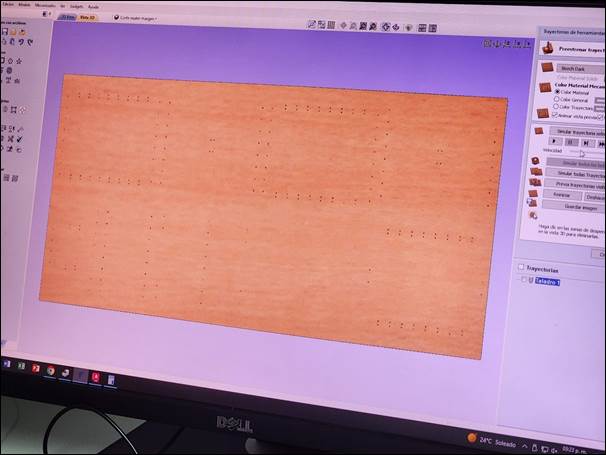

Once

the parameters are set, I let the software to provide the optimum cutting path

and it shows it with a diagram

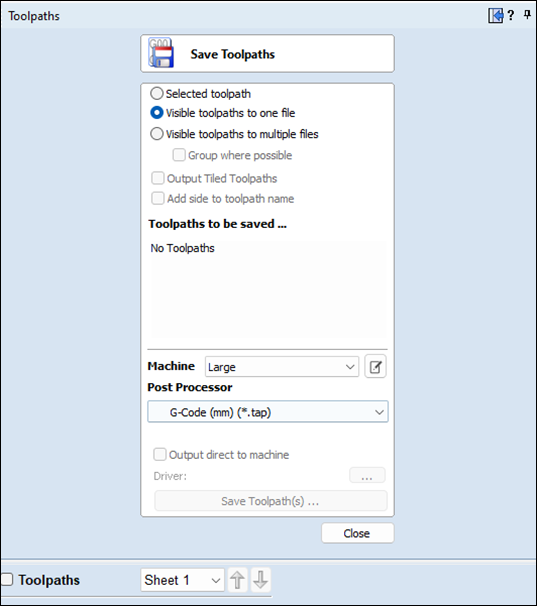

Now, we only need to export the

settings as a gcode file that can be send directly to the CNC.

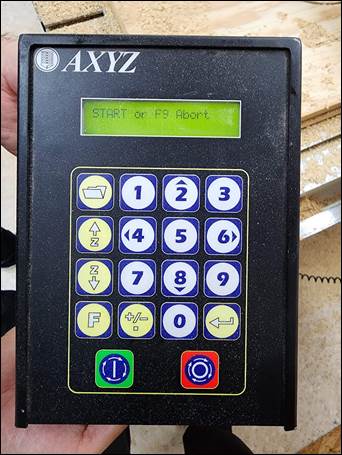

5th Step – Setting

up the Machine

To

set up the CNC I needed to insert the cutting tool (0.25 inch cutter) and set a

few parameters before starting the process:

-

Set the lowest point to cut into

(Function 24).

-

Set the material thickness (Function

20).

-

Set the origin coordinates (Function

10).

These

parameters are set through the CNC Remote Control:

6th Step – Cutting

The next step

is to start cutting, I sent the instruction to allow the machine to drill all

the dogbones before cutting, this was working fine

until there was a problem with the cutter and it was broken during the process.

I changed the instructions to cut first and then drill, this allowed me to get

to know a different function: the machine can restart the job wherever you tell

it to. The machine displays where it is currently working when you pause the

job.

After that

incident, the process went straight forward:

7th Step –

Assembly

In order to

assemble the container, I took off the parts that had been cut and started

cleaning them from burr by using a file, just to leave the assembly joints

clean enough to be assembled. Then, I assembled it using a mallet and nothing

else.

1

Conclussions

This was the last assignment I

completed. It was difficult to start the design but once I got the idea of what

to do I was able to solve the main problems that happened without suffering as

much as I predicted.

Original

Files

If you wish

to see or download the original files, click on the following links:

Nueval

Checklist

ü

Linked to the group assignment page

ü

Documented how you designed your

object (something big)

ü

Documented how you made your

CAM-toolpath

ü

Documented how you made something BIG

ü

Described problems and how you fixed

them

ü

Included your design files and hero

shot photos of your final object.

2022