Jose Alegria - Fab Academy

Computer

Controlled Cutting

ASsignment

wHAT iS THE ASSIGNMENT ABOUT?

The goal for

this assignment is to develop a way to parametrically design a project to cut

it with the laser-cutter, and finally to report the learning process.

Group

Assignment:

Characterize

your lasercutter’s focus, power, speed, rate, kerf,

and joint clearance.

While

doing the group assignment I learned:

·

The machines have different functions

we will not be using during our fabacademy projects, nevertheless

we should at least know what they do and where we can find the information in

the case we need to learn more about them later. For

example, the engraving features of our laser cutter.

·

The same will happen with some of the

parameters that the machines allow us to change, even if we don’t inquire about

them for now.

·

While making the cardboard

parameters, I found that different materials need to be treated differently

because of special conditions, for example: if I tried to engrave over the

cardboard a different letter font, what I would get was a few holes over the

first layer of the cardboard.

1st Step. Vinyl

Cutting

For this week's

assignment’s first part, I have decided to use the vinyl cutting machine.

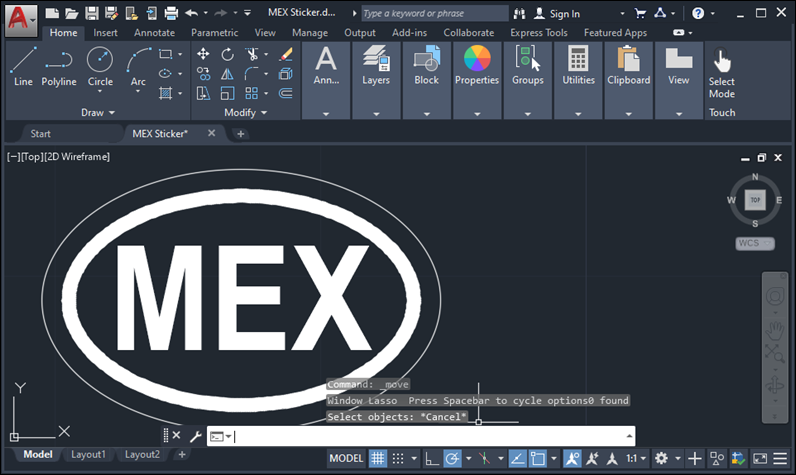

I made a very

simple drawing in Autocad, an international oval ID

sign displaying MEX to make a sticker, I saved the drawing as a DXF file in

order to be able to export it, and use it in the machine, as I was suggested,

prior to get into the machine's software, I made a copy of my drawing in a

different file format, so I've got a .eps file, as well as a .plt one using Corel to make this changes.

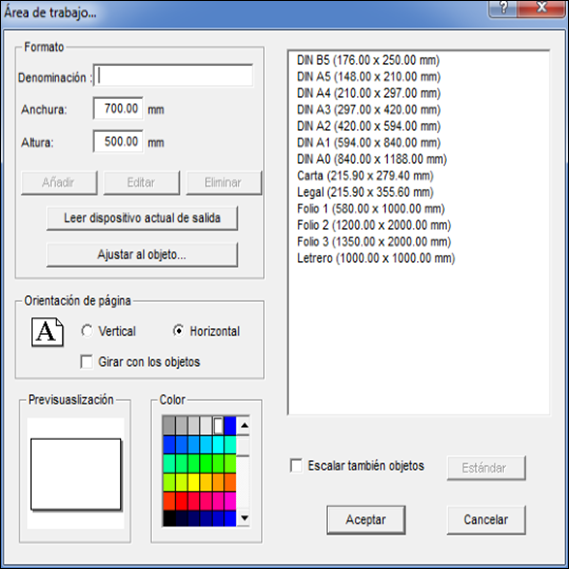

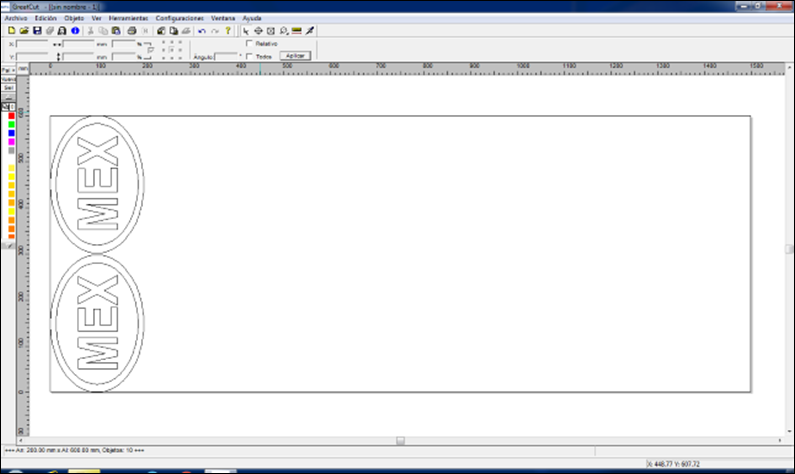

Then

I have got into the vinyl cutting machine software. It's called GreatCut, and it's essentially a blank canvas where you can

import the different files.

At

first, I tried with the DXF file, but it was rather not compatible as it showed

a distorted image of what I have

drawn,

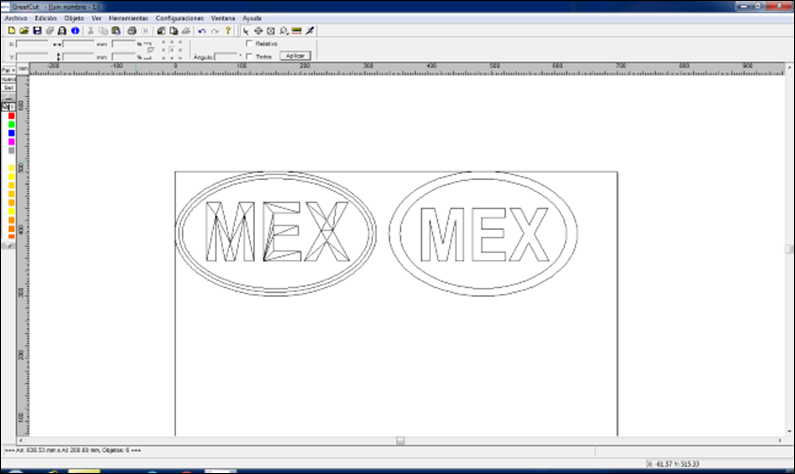

then I used the eps which changed the drawing by splitting the vectors into

triangles, so at last I used the plt file which

displayed the image as it was intended to be.

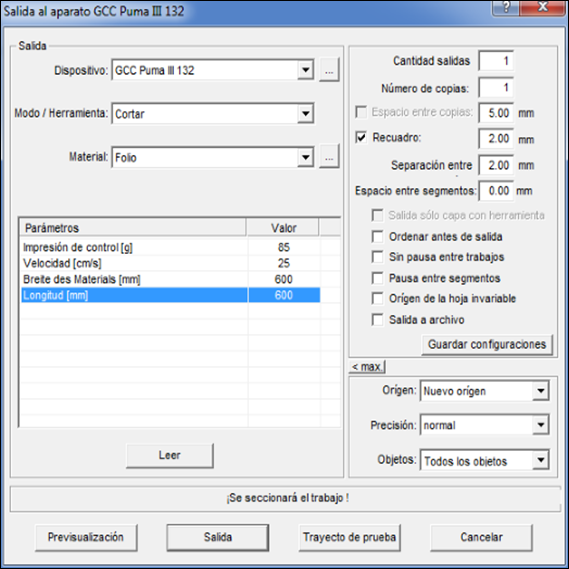

Then,

you must set up the machine with the vinyl or the material you're going to use,

setting the sheet dimensions, and finally you get to the tool's menu where you

should specify the parameters you need the machine to use, as the speed and

force, and for some reason, you must set again the material dimensions.

Once

you're over that, you must get the material into the machine and click OK.

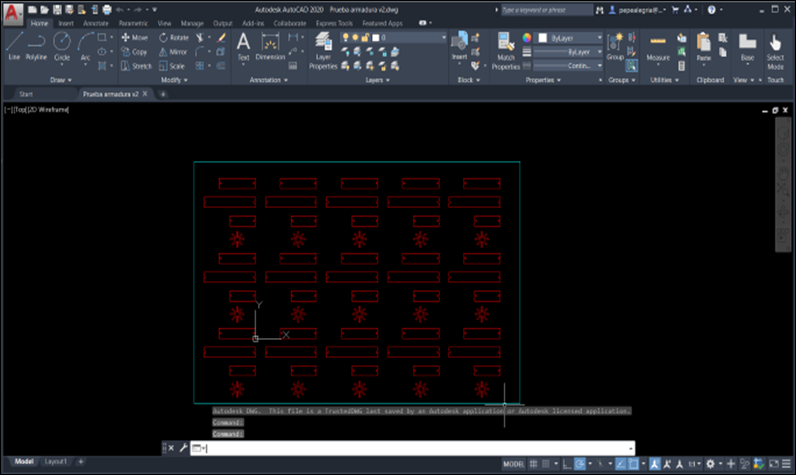

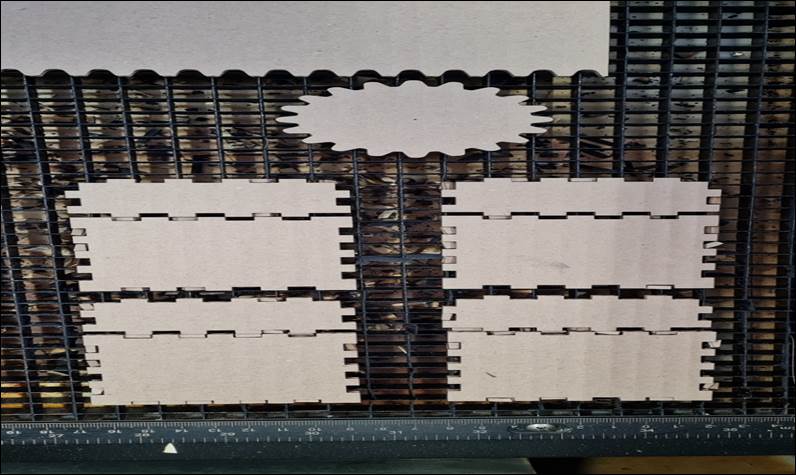

2nd Step –

Designing For Laser cutter

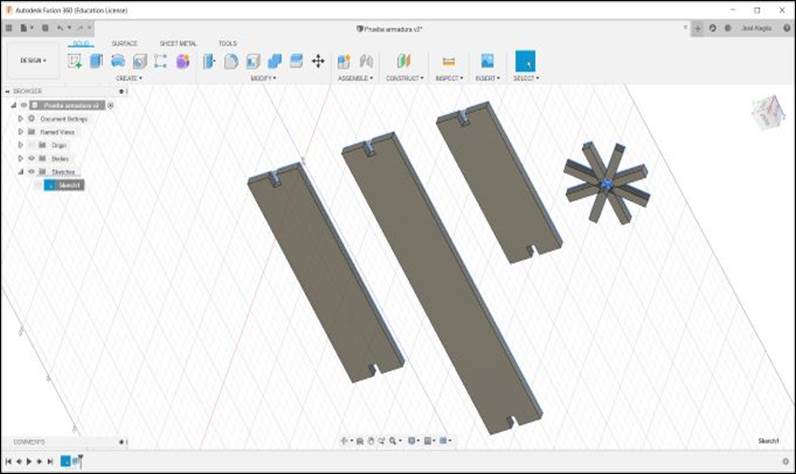

The assignment was to make our own

construction kit with the laser cutter.

I designed a truss bridge that could

be made as long or tall as wished. The first part was to design the pieces, so

I used Fusion 360 to make a parametric design in which I could change the

dimensions of the bridge pieces as I wanted and they

should stay aligned in a way that made the construction possible.

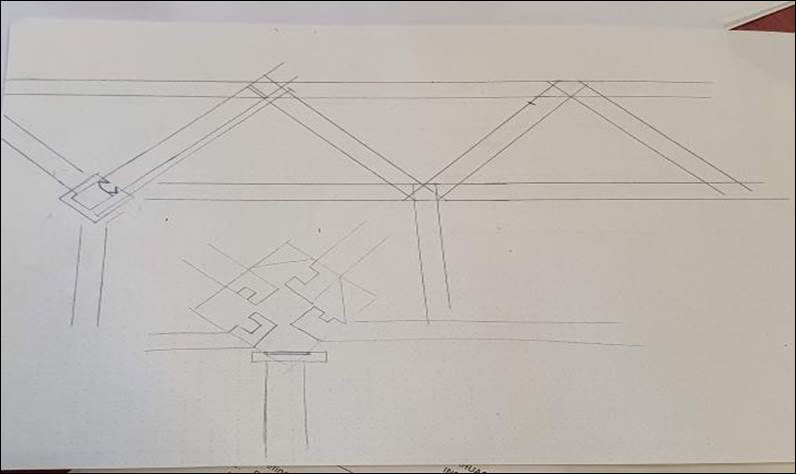

I made a draft to try to design the

main components of the bridge, the most difficult part was to design a joint

that would keep the different components in their place.

I came up with an idea in which all

elements should be compatible with the joint. Once I had the design made, I

made a DWG file with the pieces I was going to cut.

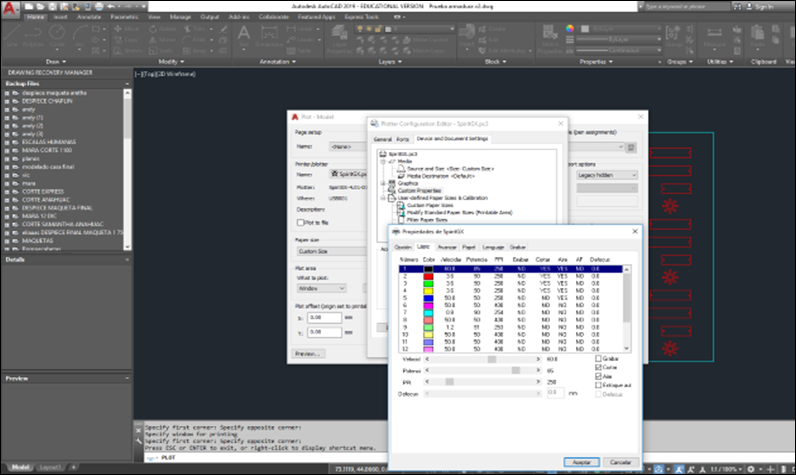

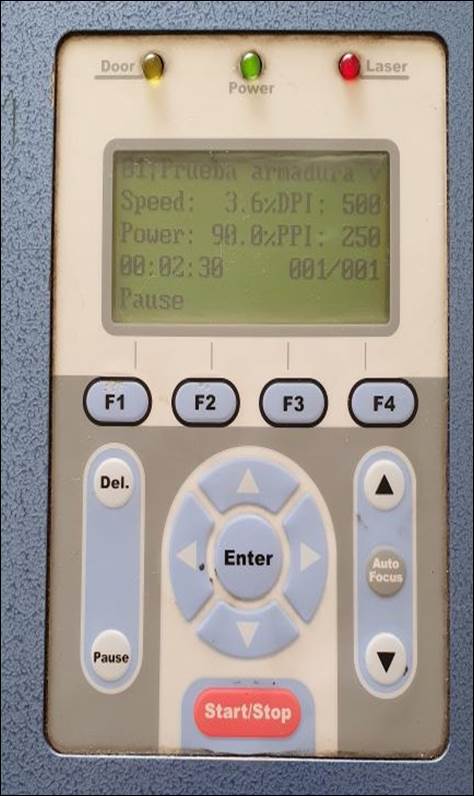

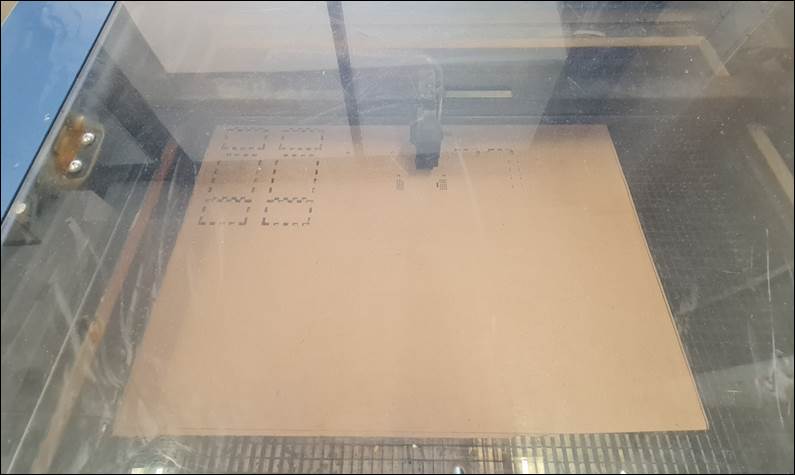

3rd Step – cutting

with the laser-cutter

As we did the

group assignment before the individual assignments, I already had the

laser-cutting parameters needed to cut all the pieces I needed.

So,

the task was half done, I only had to set the parameters and then I was able to

cut.

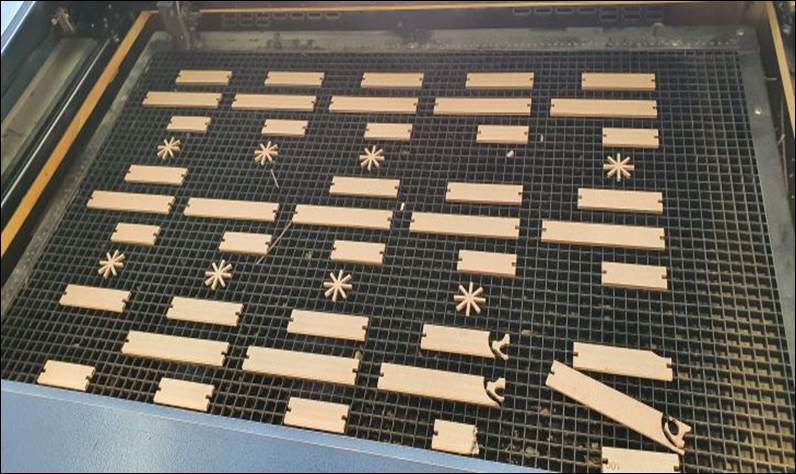

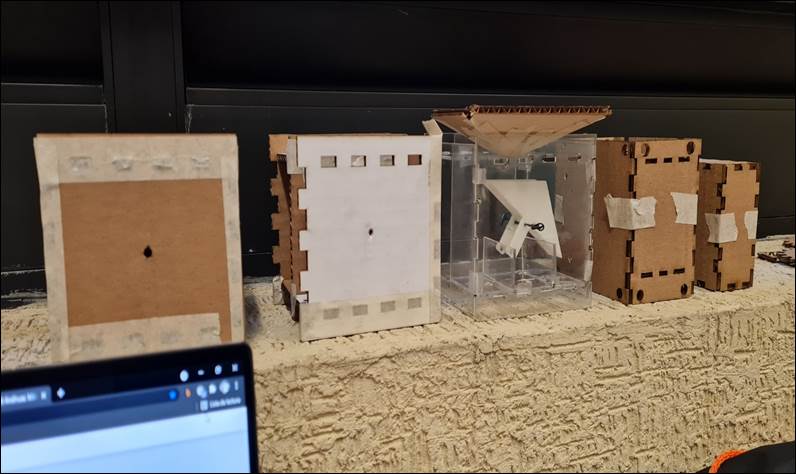

4th Step –

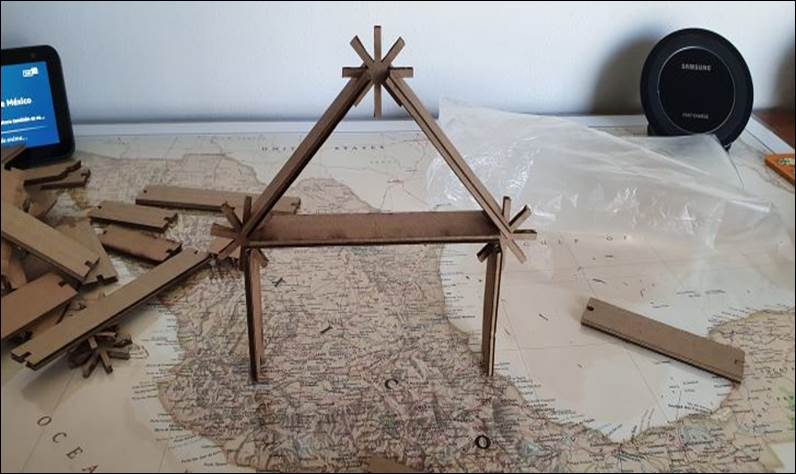

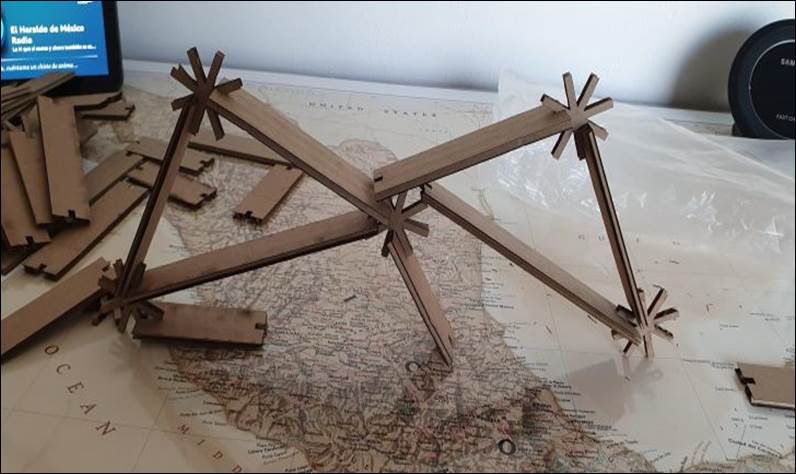

Assembly

Having

cut my construction kit, I started building the truss bridge. The cardboard

wasn't as rigid as I thought so the small joints I cut

weren't able to keep the structure up, I think the design could work if I

repeat the assignment with a stiffer material, maybe I could use MDF for the

next attempt. I'm posting here the structure as I was able to assemble it.

5th Step – New

Design for the final project

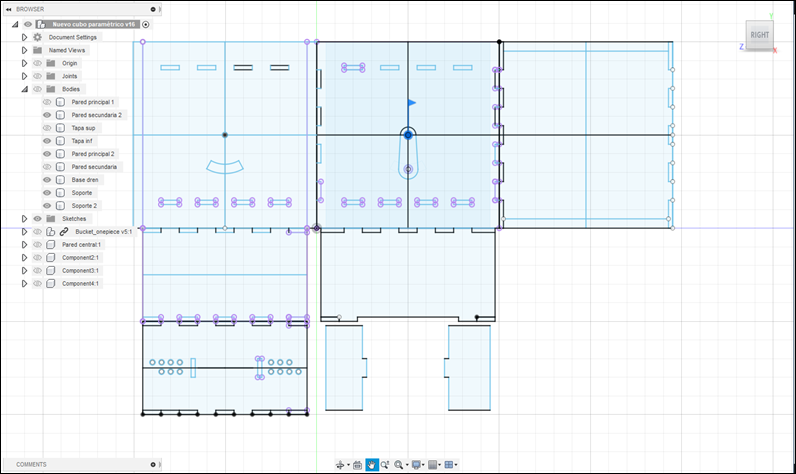

For

the final project I tried a new approach to the parametric design. Using Autocad for parametric design proved difficult and slow,

due to the constraints needed to be used, so I tried to design with Fusion 360.

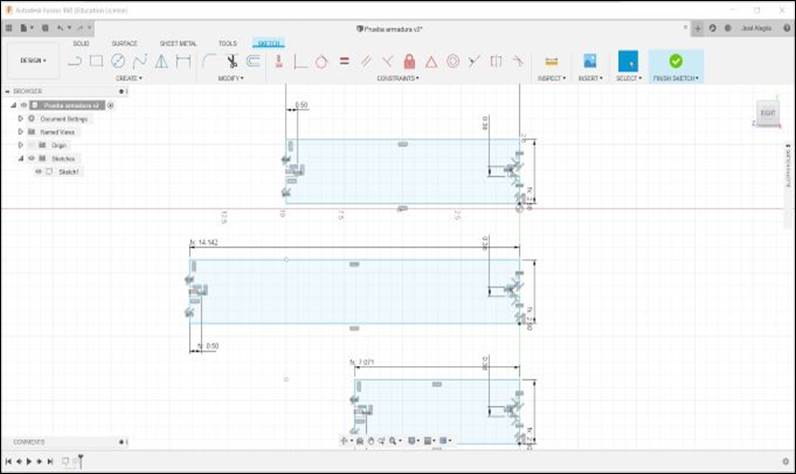

First,

as I explained in the last assignment, if designing in Fusion you should start

by making 2D sketches of the bodies that you will be using. This

sketches should be thought to be converted into bodies by extrusion, so

when you cut certain material in the laser-cutter it will become the parts you

want to assemble.

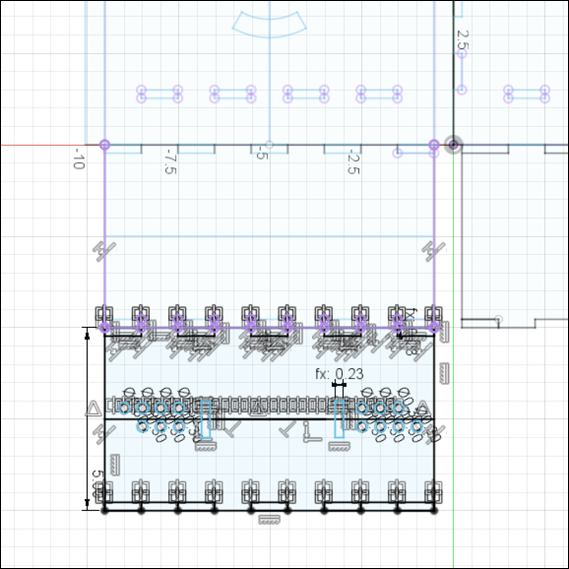

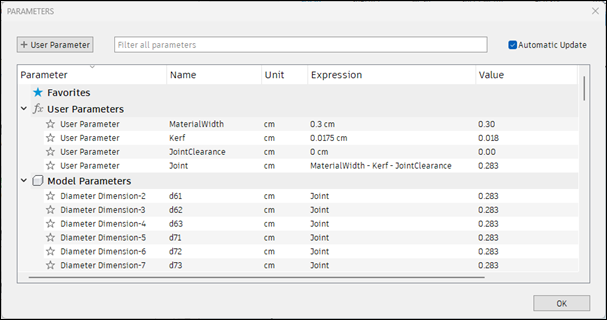

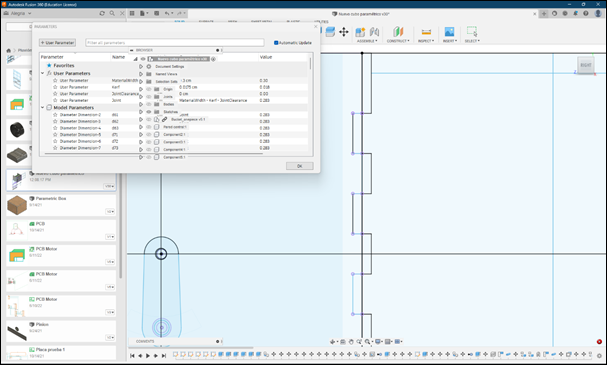

These

are the parametric sketches I made in Fusion 360, they have parametric measures

that helped me to cut in different materials, mostly changing the size of the

tabs accordingly with the material thickness, also to change the size of the

container to make different tests and redesign the container as I discovered

new needs to be considered.

To

accomplish this you should take kerf into account. The

Kerf value is the width added to the cut by the laser during the cutting

process. This value is characteristic of the material being used and the method

of cutting.

To

take that value into account you should add it to the parameters you are

designing with. For example: in this case I parametrized the size of the

notches in my container to be the result of the material width minus the kerf.

If the adjustment is not tight enough you can add another adjustment setting.

This

will help for easier parameters change if you should modify your project.

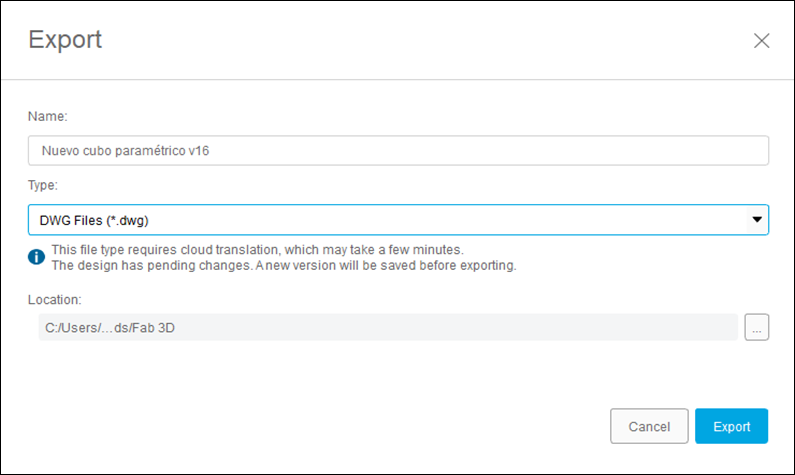

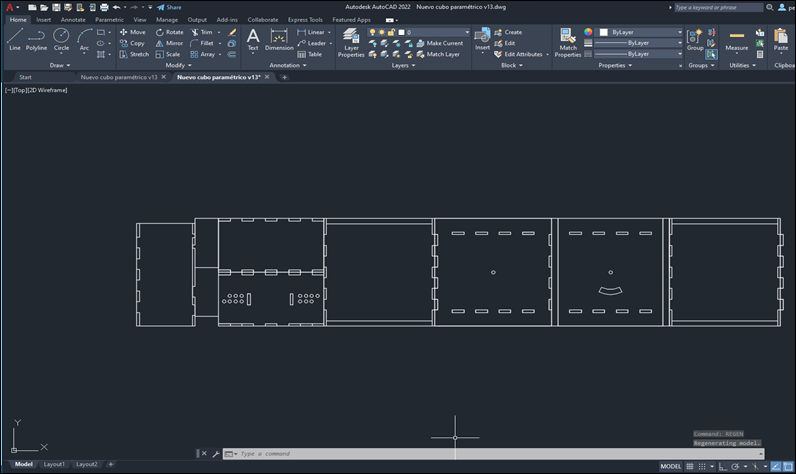

After

designing in Fusion, I exported the drawing to a dwg file to be used with the

laser-cutter machine. It is not as straightforward as I thought it would be,

but it is not as difficult to use as it was to design directly in Autocad.

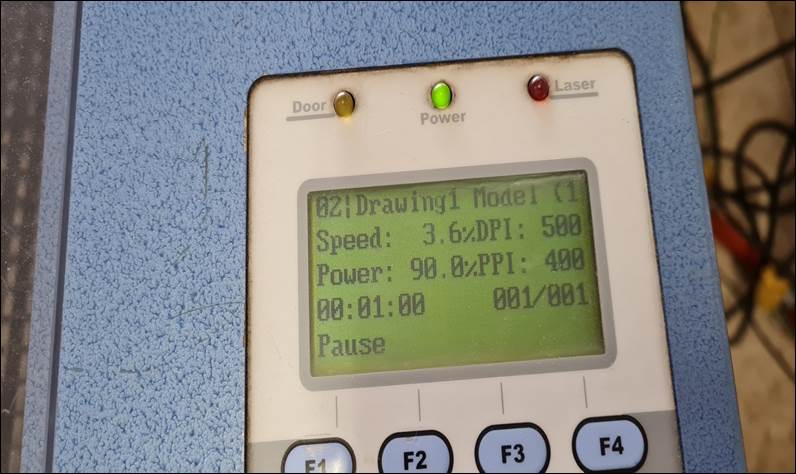

The cutting parameters for the first material

where as I stated them in the first part of the assignment, I cut the design in

cardboard to test it and find any detail that could be missing from my original

design. After a few revisions and a few new versions (exactly: 14) I finally

got to my final design and cut it in acrylic (instead of cutting at a 3.6 in/sec

90% power setting, I used a 0.7 in/sec 70% power setting).

|

Material |

Speed |

Power |

|

3mm cardboard |

3.6 |

90% |

|

3 mm acrylic |

0.7 |

70% |

Here

is a photograph of the different versions cut and assembled.

After

so many versions, I made extensive use of the timeline feature within Fusion

360. This feature helps to know when you started changing a certain part of

your project and what were you doing with it.

Conclussions

This assignment importance was to design

a webpage to keep track of our work, and to be able to demonstrate the steps we

would have to follow to replicate each assignment.

Original

Files

If you wish

to see or download the original files, click on the following links:

4.

Fusion

360. Cubo parametrico

Nueval

Checklist

ü

Linked to the group assignment page

ü

Explained how you parametrically

designed your files.

ü

Documented how you made your

press-fit kit.

ü

Documented how you made your vinyl

cutting.

ü

Included your original design files.

ü

Included your hero shots.

2022