|

|---|

:: COMPUTER CONTROLLED CUTTING::

:: LASER CUTTING ::

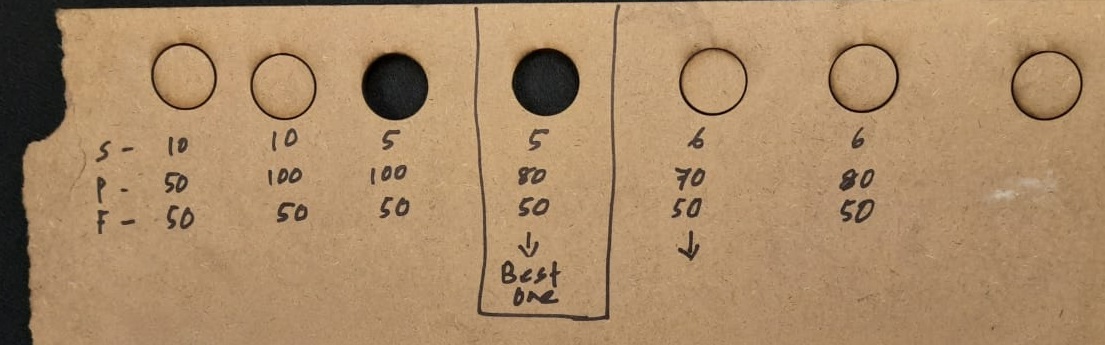

Laser Cutting is a non-contact process which utilizes a laser to cut materials, resulting in high quality, dimensionally accurate cuts. The objective is to learn how to operate the machine and how to transform a 2D model into a real design. During this week Computer Controlled Cutting was the topic. We had a task to understand about the cutting machines installed in our FAB LAB, STPI-Bhubaneswar. As a part of our Group Assignment, we were required to characterize our Laser Cutter for Engraving and Cutting Process. I had selected 3 mm thick piece of wood and started with the engraving process first. As a group we tested the effect of different parameters on various materials, acrylic sheet and cardboard.

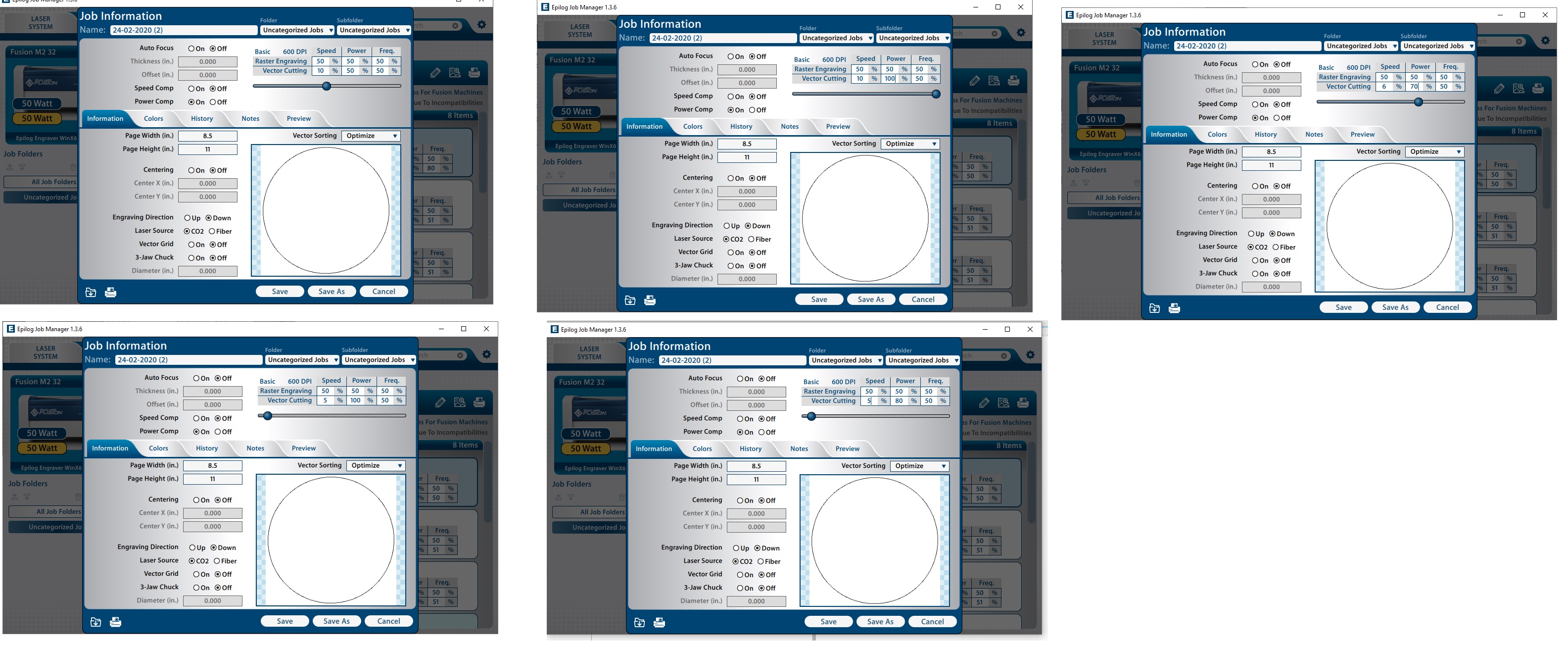

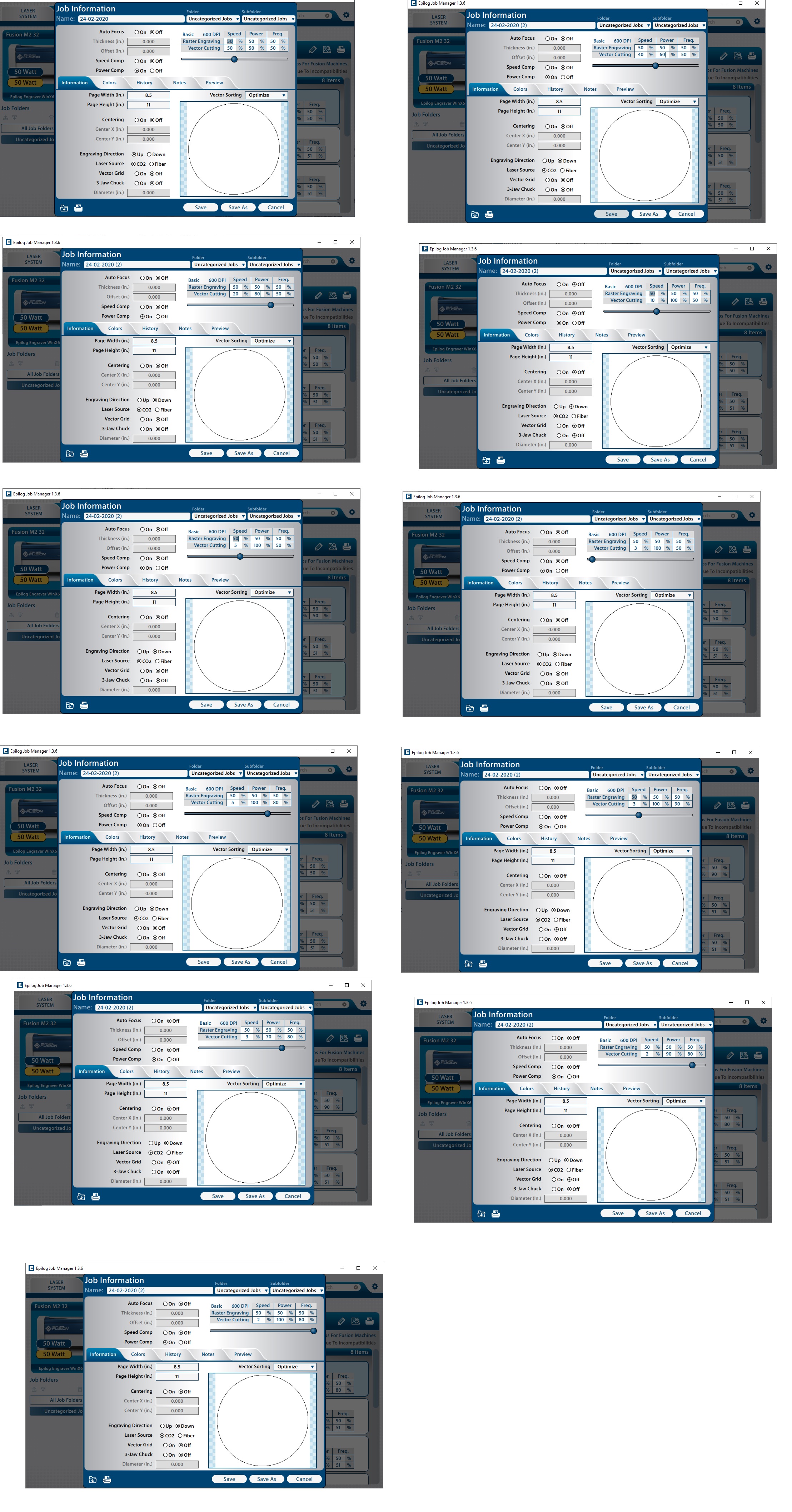

Setup and Test Make test part(s) that vray cutting and dimensions, to characterize our laser cutter. Hardware Set-up

|

|---|

Here are few cutting iamges with different parameters and their output |

||

|---|---|---|

|

||

|

||

|

||

|

||