The scope of the group assignment was to characterize and formation of design rules for 3D printers. The 3D printer available at our FAB Lab is Sindoh- 3DWOX. Each member of the group has played their part during the group assignment process

Different 3D printing processes have different capabilities and different design restrictions. In this article we will talk about key design considerations that apply to all 3D printing processes.

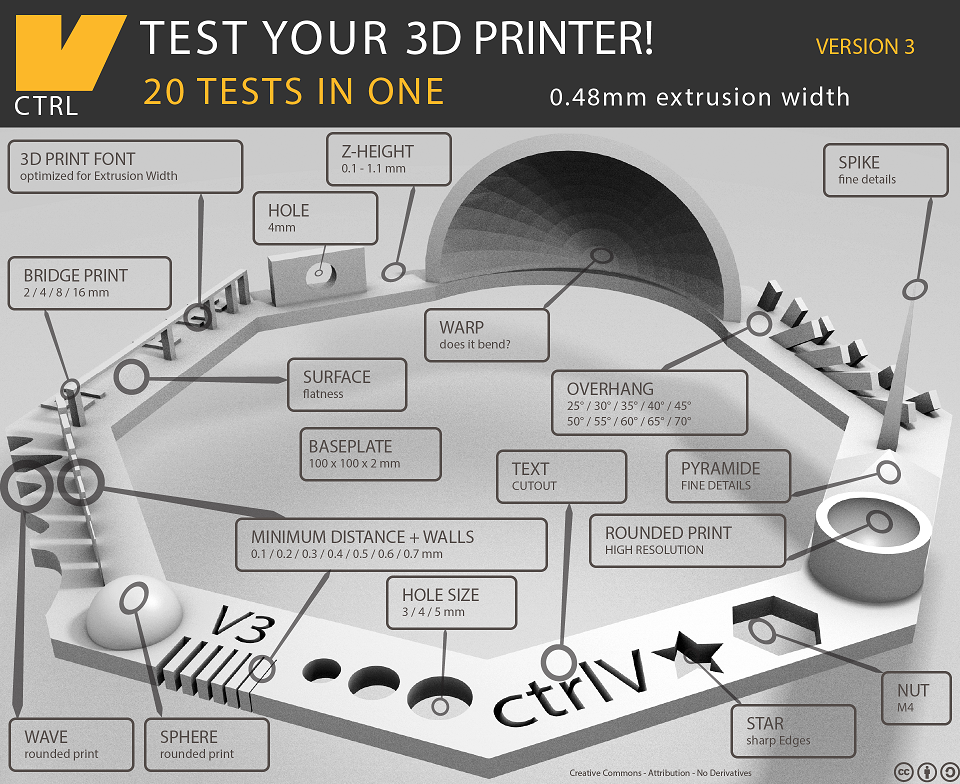

I got a set of tests for checking the design rules. Luckly I found a full set of test from Thingverse

We followed the instructions and put it to print. The step by step outcome of unsuccessful 3 D printing is briefed below:-

The parameters for providing support in the Bridge print was at distance of 2 mm, 4mm, 8mm and 16mm. The printer printed well for 2, 4 and 6 mm but the print was not clear at a distance of 16 mm without providing support in between.

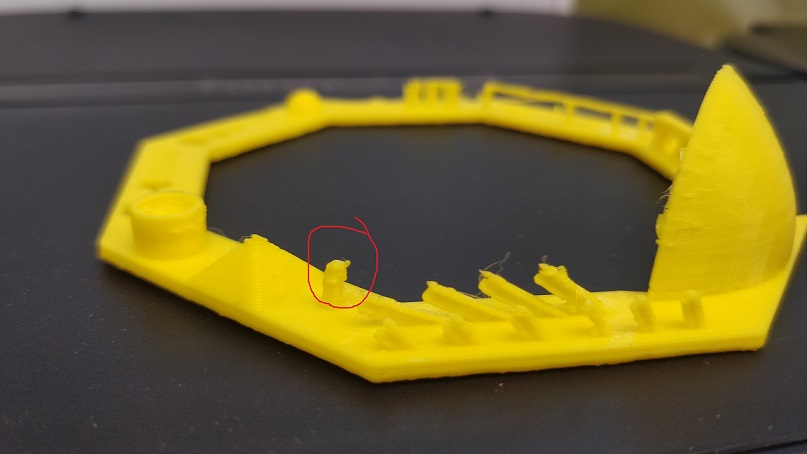

The criteria for spike was minimum Layer Time, 21 mm height from Bottom (include Baseplate). The result we got in our 3D print was not good. The spike was having a height of only 6 mm. The rest of the part was printed by the printer but was very weak and broken during the print was removed from the bed of the printer.

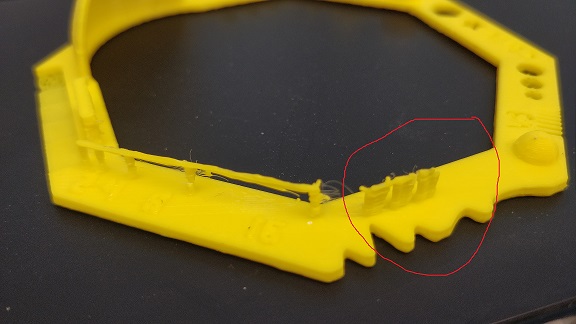

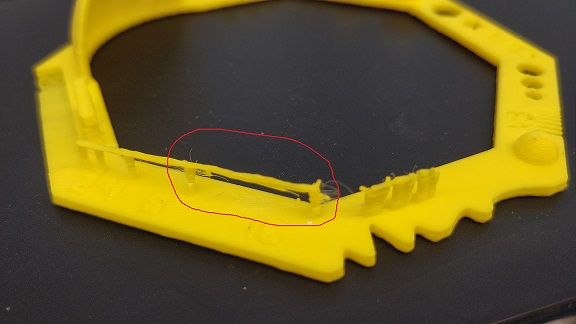

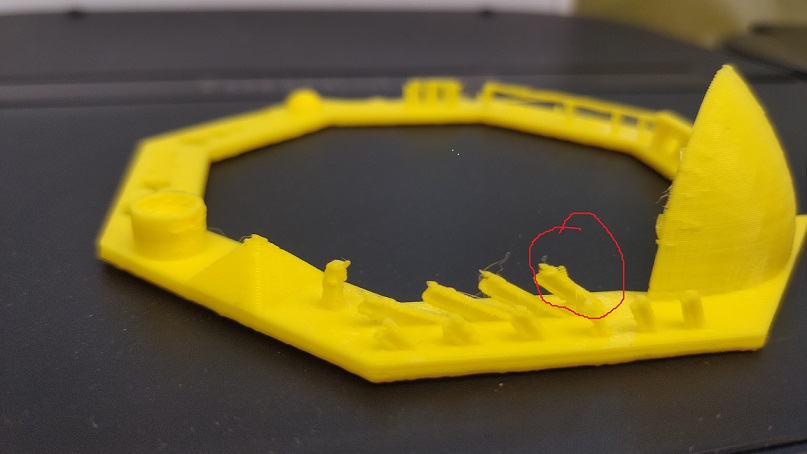

This parameter was tested for various angles i.e. 25, 30, 35, 40, 45, 50, 55, 60, 65, 70°. The result for 45 degree was not satisfactory as the deposition of PLA was not done properly in the section as shown in the image below-

The thickness of the wall was measured for 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 mm. The result of printing was not up to the mark. The 3D print was done only for 3 walls and for rest of the walls, the 3 D printer did not print anything.