|

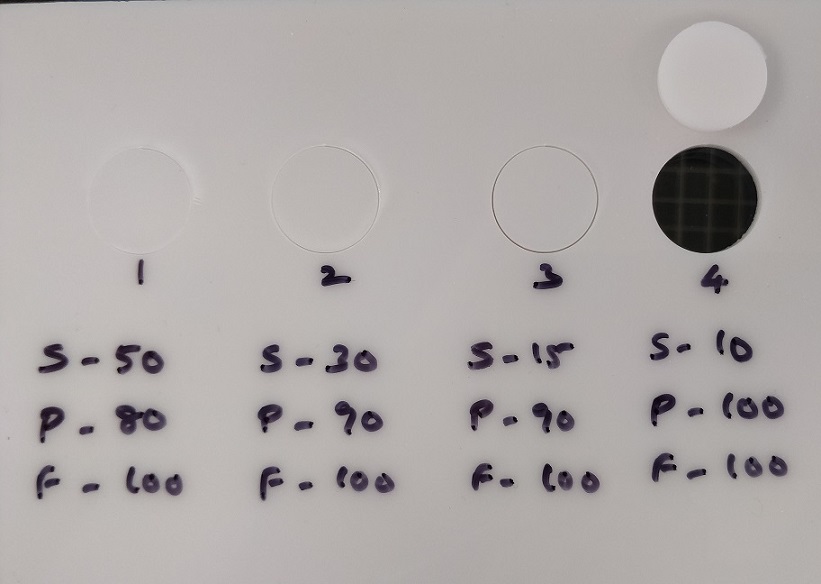

1

|

Speed (in %) |

50

|

30

|

15

|

10

|

|

2

|

Power(in %) |

80

|

90

|

90

|

100

|

|

3

|

Frequency(in %) |

100

|

100

|

100

|

100

|

|

Results

|

A simple cut was observed but the design was intact in the Acrylic.

|

Cut was a little bit deeper but the design did not extract from the wooden ply. Some dark spots were visible on the Acrylic

|

The cut was extracted from the Acrylic with ease

|

Through this dimension also the cut was easily removed from the Acrylic

|

|

The design of our circle was with a diameter of 1.9 cm but the material removed from the 3mm Acrylic Sheet was of 1.8 cm. Hence the kerf in this case is 0.1 cm.

The images of the characterization for cut are shown below:

|

Description

|

Speed(%)

|

Power(%)

|

Frequency(%)

|

Results

|

|

|

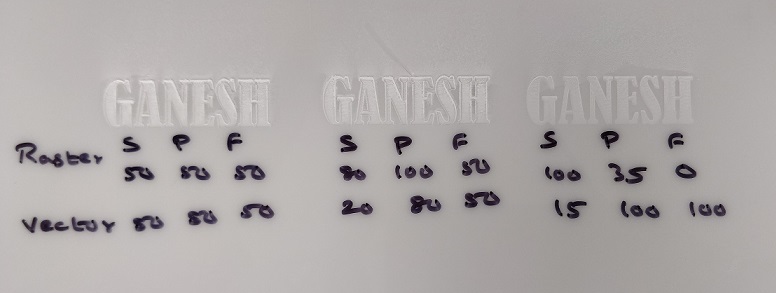

Engrave-1

|

Raster

|

50

|

50

|

50

|

The letters engraved but with dark around the design

|

|

Vector

|

50

|

50

|

50

|

||

|

Engrave-2

|

Raster

|

80

|

100

|

50

|

Engraved but the depth of the design less as compared to the 1st case

|

|

Vector

|

20

|

80

|

50

|

||

|

Engrave-3

|

Raster

|

100

|

35

|

0

|

Clear engraving was done with clear alphabets and proper depth of the engrave.

|

|

Vector

|

15

|

100

|

100

|

||