Assignment 1 : Principle & Practices

Week 1

Hi everyone, My first day class started on jan 16 and I was little bit scared because it was my first class online face to face mode . intallity I had problem how to attended class remotely then all the issues resolved by Instrutor . During the class I learn History of Digital world and how world shift to analog to Digital electronic . during the lecture Prof Neil also dicussed about how to Mange 6 months Course,Assigment and Final project . Most Impartant was to how to choose Idea of Final project and source of the Idea /Inspriation need to citation .

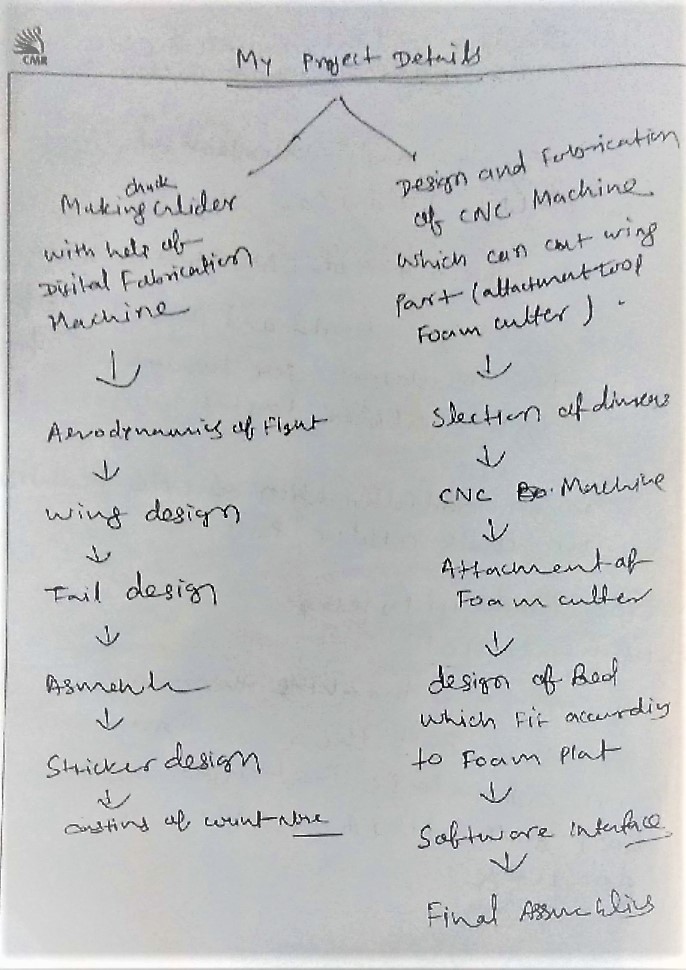

This week assignment was to outline of Final project Idea; included rough sketch of the idea of final project and details of project

Project Title :

Design and Fabrication of Chuck Glider Cutting Zig/Machine

Introduction :

To understand what makes a glider fly, first have an understanding of aircraft aerodynamics and how flight is possible. An understanding of aerodynamics and how it affects takeoffs, flight maneuvers, and landings allows pilots to be more skillful and aware of the capabilities of the glider.

Inspriation/Problem observe :

My Fab academy project Idea coming from my hand's on experience from Make and Fly Chuck Glider Program , As Maker ever time we having stiuation ,what to teach student within 45 minutes and I found Make and Fly Program. In this program within time Frame student has to assemble the Glider kit or they can Make own kit ,In this process many step involve i.e Drawing,Cutting,sanding,Assembling then flying ,During this program I was diccusing about design and Fabrication challenge to fabricate a idea after student leaning basic physics of prcatical application .I like to solve and Make on STEM kit and Machine which can solve this problem

Solution:

currently in Market Chuck Glider is avialable price between 200 rupess- 400 rupess Apart from this there is another method to make Glider From Balsa wood but not cheaper or not easyly avialble ;Most important part not everyone can make glider within 45 minute with these kit . Last 4-5 years I am working on serval Design to reduce cost and Finally I found Foam Plate Glider is very good Material to replace balsa wood Glider ,Each Glider Material cost 20 rupees but Making one kit require 45 minitues . The main objective of taking this project to reduce time involement of Design and Fabrication Zig/machine which can replace human inovemnt of Making this Glider part .

Feasibility of Project scope:

Making Glider Parts Currently sevral Method is avilable i.e CNC Router ,Hand Foam Cutter which also can reduce the time of Making but steup time in CNC router is More and Foam cutter is not a precision cutting solution . A zig of fixed geometry of Glider part and attched cutting Tool can help me to cut precisely . Proposed soloution of cutting glider parts zig cost come arround 1000 rupess and 30 minute it will Make 30 glider parts . Small Glider Zig /machine reduce the cost of Glider approx 10 rupess .Major challenges :

1. Power supply

2. Protable Glider Making Machine