Part I: Final project description

When I decided to tell my boss about my plans to finish up the FabAcademy, I told her because there was a plan. Back when I was intern at the company, we already had the problem that will be described down below. I also wanted to work on it, and even started a prototype but there were more pressing matters that had to be done for my thesis. Therefore, this problem never got the attention that it needed.

The problem

During the past months I had the honour to observe several workshops about micro-controllers given by Ingegno. And there were a few things that caught my attention

First of all: out of children (and adults that are new to this) might be overwhelmed the moment they see a breadboard or microcontroller in front of them. Especially if they never

came into contact with a micro-controller before.

Second: a breadboard has a lot of small holes where you pin the jumperwires in. Even though the teacher in question was using pictures that were being enlagerd due to a projector,

some children still found it difficult to follow where the jumper wire needed to be added.

The Ingegno Makerspace feels that teaching microcomputers to children and adults can be quite demanding due to the small insert holes of the breadboards. To make this more easy and understandable they have asked to develop a giant breadboard with working components to explain the basis of physical computing to children and adults.

Next to that, Ingegno also uses their self developed LED up Kidz. As this is still one of the first versions, it is time to make the design a bit updated and review the project. In the end we’d like to combine the giant breadboard with the LED up Kidz.

What

A giant breadboard, including components that can be used to teach children about micro-controllers. The teacher gets a giant breadboard that can be used as a board, but also the children get a bigger than usual breadboard.

The second part of the assignment is to make giant components, that work. For now we keep it down to 3 components: a LED, resistor and push button.

The last part of the assignment is to adapt the LED up Kidz to the breadboard - or the other way around. The LED up Kidz is a workshop that we give to children aged 8 tot 14 to learn about SMD soldering, electronics production and programming.

Where

Most of the prototyping will take place in the FabLab in Drongen. During the FabAcademy, Amy is connected to the ULB FabLab in Brussels, but as this ain’t close to her, she will make the final project in her own FabLab where she works. The latter will also provide most of the materials that she needs for the development of the final project. The FabLab in Brussels will stand in for extra guidance, grading and feedback on the project.

How

During the development of the project, we’ll use several known prototyping techniques like 3D printing and laser cutting. But we’d also like to use some time to test out new things. For example textile and electronics, or DIY projects combined with high tech. For example. A lot of sites and companies are swearing with conductive ink or paint. But or, it arrives and doesn't work, or it dries out to fast. What if we combine making our own ink with hightech electronics like a breadboard made with it. Or combine our conductive paint with textiles.

Planning

The assignment will be prototyped during the FabAcademy 2019. This course runs from the middle of january until the end of june.

- 16th of january 2019: Start Academy

- 13 february: electronics production: Hello World

- 27 february: electronics design: LED up KidZ

- 13 march: embedded programming

- 3 april: input devices: LED up Kidz

- 10 aprl: output devices: LED up KidZ

- 17 april: interface and app programmming

- 24 april: networking and communications

- 1 may: mechanical design: Chocolate 3D printer

- 8 may: machine design: Chocolate 3D printer

- 22 may: application and implication

- deadline prototype: 12th of june 2019

- deadline: 19th of june 2019. Includes everything

Whishes and demands

Demands

- A Giant breadboard, size circa A0 format () x1

- Small, kids breadboards, size circa A4 format () x12

- Components that fit the boards, including: LED, resistor and possibly a pushbutton.

- Connections that fit the boards and are conductive

- Transportable

- Easy in setup as time before workshops is limited

- See through, so that the children can see how the connections run

- Connections to the LED up KidZ.

Whishes

- Fitting within really useful boxes/li>

- Previous tests showed us that 3D printed connections are not ideal for the connections between jumper wires and breadboard.

Deliverables

- A working prototype/product

- A slide (1920x1080px) with name, project name, fablab name, photo/render/sketch of project, brief discription, function = money shot

- A project page on the website of FabAcademy student. With info on project

- Made a BOM of the project

- Link all the pages that have to do with the final project to the main final project page

- Link presentation.png and presentation.mp4 to final project page

- Add all of the original designfiles in the archive.

- Add a licence (standard one for Ingegno)

- Acknowledged work done by others.

- Full documentation of the project including instructables if needed.

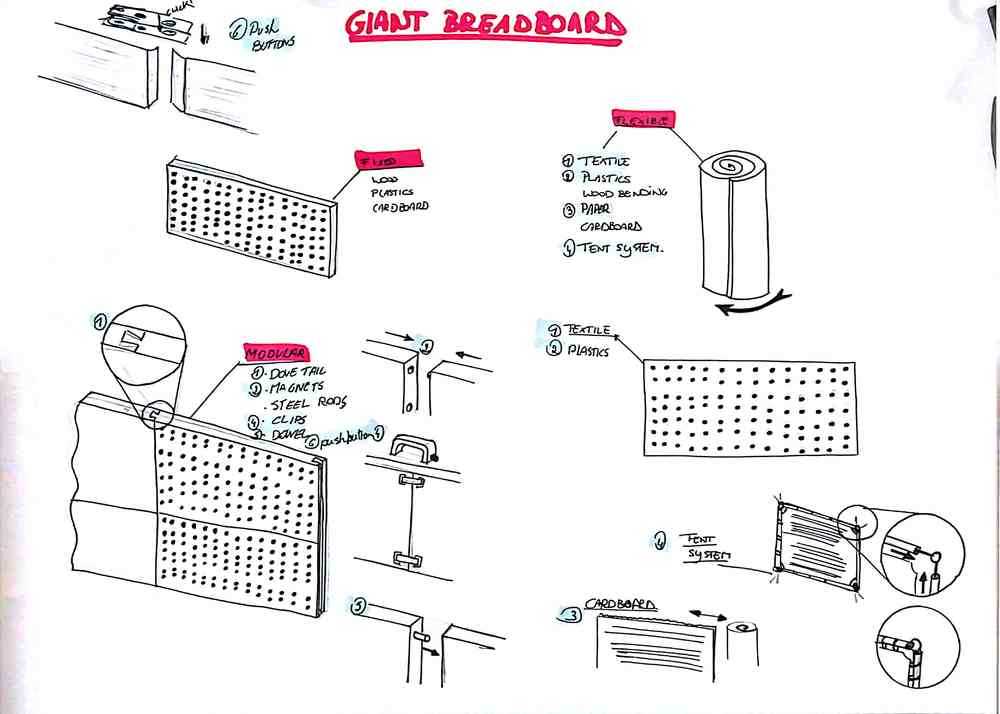

Sketches

First sketch: possible ways for making the giant breadboard

First sketch: possible ways for making the giant breadboard

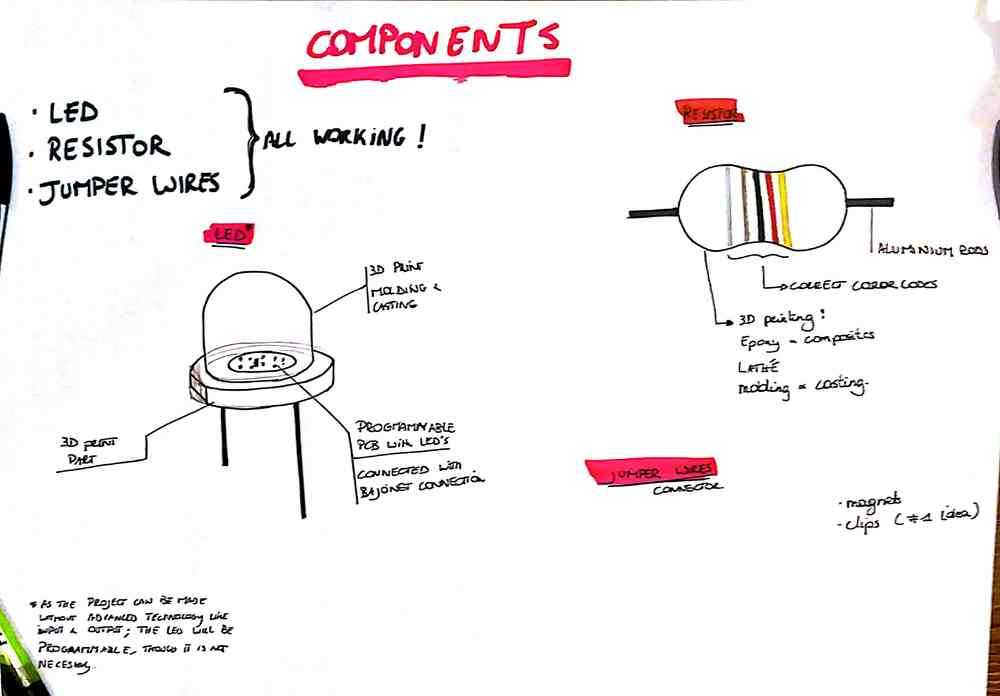

Second sketch: what components will I include?

Second sketch: what components will I include?

Full documentation

Full final project descriptionTo top

Part II: What has been done before?

And what can we learn from it?

When I got the question to make a giant breadboard, my instinct was to open a search engine and look up what already exists. There were 2 big players online: Sparkfun, OSH Park and Hackaday

Sparkfun

The SparkFun video was not only fun to watch, but also interesting. As they are making a time lapse, you can clearly see all the materials that they used.

Pro

- Basic materials (isomo, metal plates, wires...)

- Clear building instructions

Con

- Where are the giant components? Note: we found them much much later

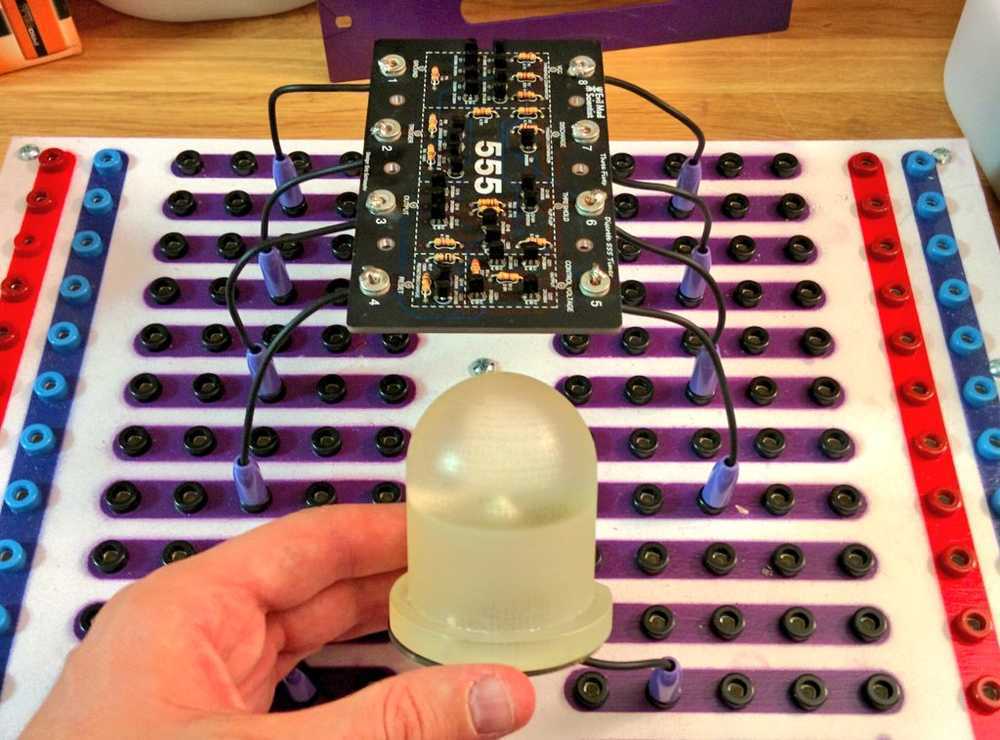

OSH Park

During my search I found a tweet form OSH park and the fact that they made a giant breadboard that looked quite resistant to children. We looked further into it but we didn't find more

info on it. We reached out on twitter, but only got info about the 555 kit and nothing about the board.

Turns out this will be look and learn documentation.

Pro

- Clear and understandable

- Good connections to the breadboard

Con

- Only documentation is the twitter-tweet

Hackaday

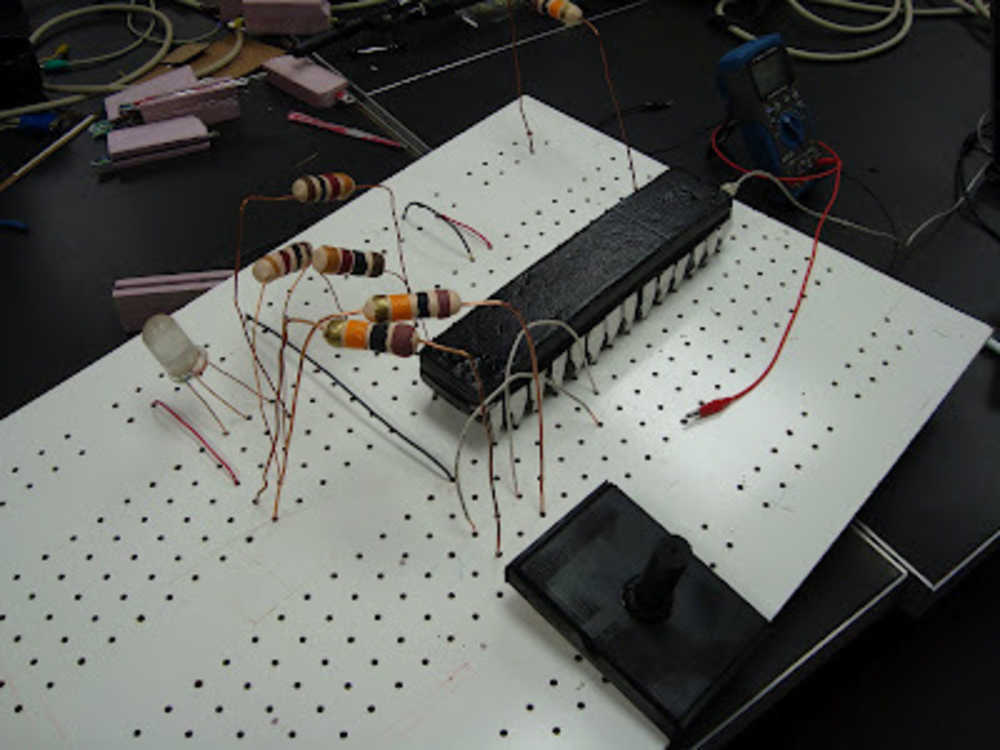

The search also led us to the hackaday website. They have an article about a Minneapolis/St Paul based hackspace that made a giant breadboard. Sadly it only stayed at one article and some 404 links.

Pro

- A useful picture.

Con

- No extra information