Week 18 - Invention, Intellectual Property, and Income.

Posted on June, 10 2019

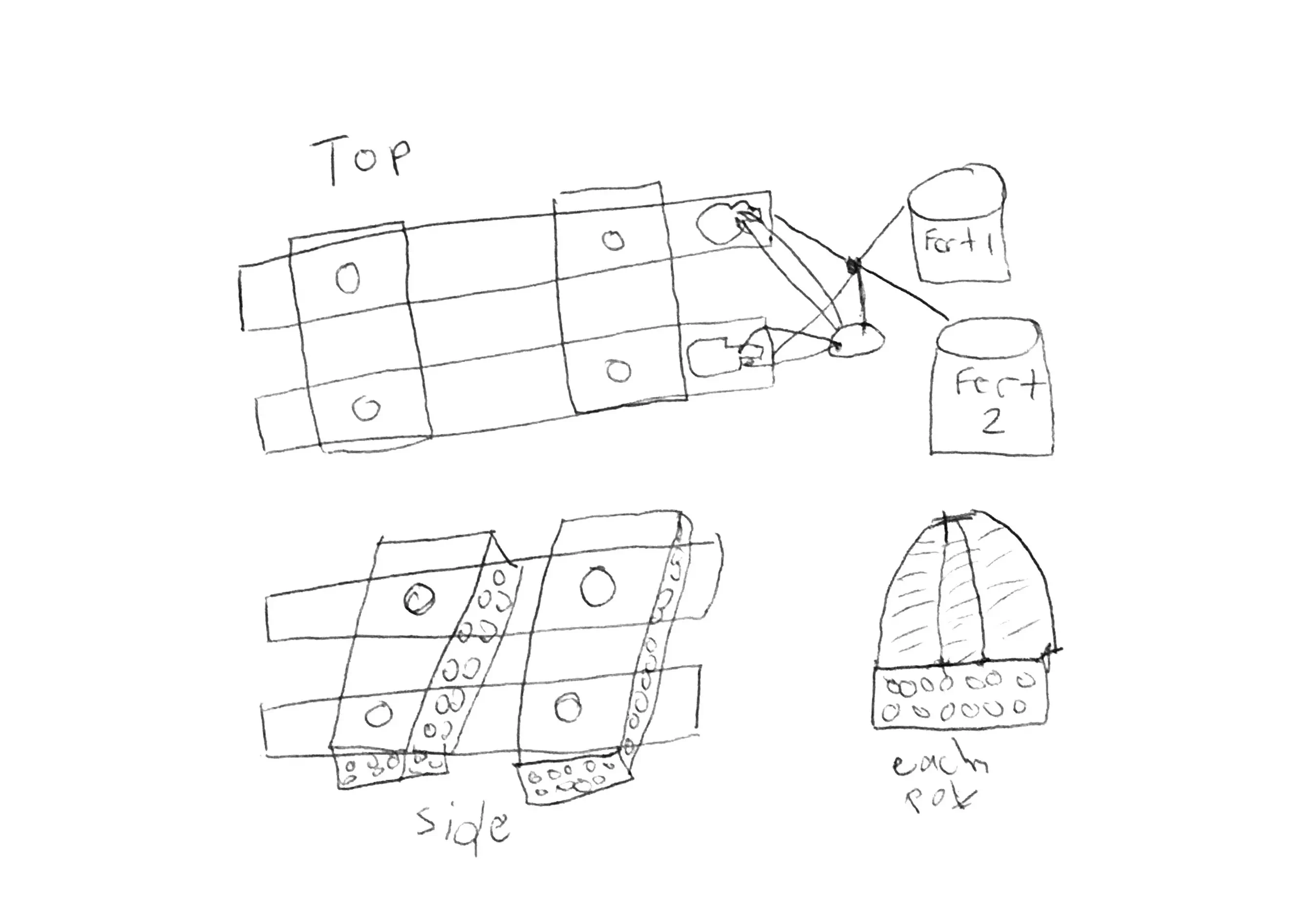

For this week's assignment I planned my final project FlatPack Farm: Cultivation for both Urban and Rural Areas. The FlatPack Farm is meant to be a shippable farm to be able to reach rural communities in times of need, but also can be used at homes around the world. The farming system I had developed is a hybrid farming system where I had taken the principles of commercial farming systems found in large greenhouses and scaled it down to be simple, modular, and in flatpack form. The FlatPack farm can be used for for both soil or hydroponic farming.

FlatPack Farm Features:

Self Watering Pots: Each bottom hole of the pots are connected to the reservoir pipe via a net cup, which I had based on a self watering wicking system where the plant takes as much water as it needs, when it needs it without over/under watering.

Fertilizer Dosing: Growing crops requires constant care in terms of using fertilizer it can be complicated to get the right ratios between the fertlizers and my AgriBoard PCB allows the user to fertilize thier crops in an automated way. Commercial growers often use expensive dosing pumps and I had recreated a dosing pump in a very cost effective way using pumps and the Agri-Board to give farmers a cheap alternative.

Shade Net/Poly Net Caging:This is meant to protect the crops from thier environment (extreme heat and cold) or pests. Since its summer we will be using a shade net, but farmers in cooler countries can use polyfilm to keep the heat in for the crops. Here in the Middle East farmers often suffer from locusts so having a insect net is very important to protect their crops outdoors.

Air Pruning Pots: This a special pots which help the roots of each crop to enhance the root zone by pruning the roots so that the plants do not get root bound and take up less nutrients and water. The Air Pruning Pot I made is modular so that you can adjust the size of each pot, also my pot is flatpack.

PH Sensor: This attached to my AgriBoard to allow farmers to moniter the PH of thier water. This helps in dosing the fertilizer.

Flat Pack Food Safe Reservoir: The main base is actually where the pots are sitting on is also a reservoir where the water cannot be evaporated as the plants receive water directly to their roots. The reservoir is made of foodsafe plastic (HDPE), so that chemicals do not leech into the water.

This is my sketch of my project.

This project can be broken down into five parts:

Food safe reservoir/base: CNC HDPE

Base Maintenance Lid: Lasercut Acrylic

Air pruning pots: CNC HDPE OR Lasercut Acrylic

Net Cage Connectors: 3D Printed

AGRIBOARD PCB: Milling/Soldering/Programming with Pumps and Sensors.

Final Assembly: putting all the parts together and potting up the crops (Okra and Zucchini).

This is how my final project looks like.

This is the parts list.

This is the project final video.