Back to Mónica Pedro ←main page ←Final Project

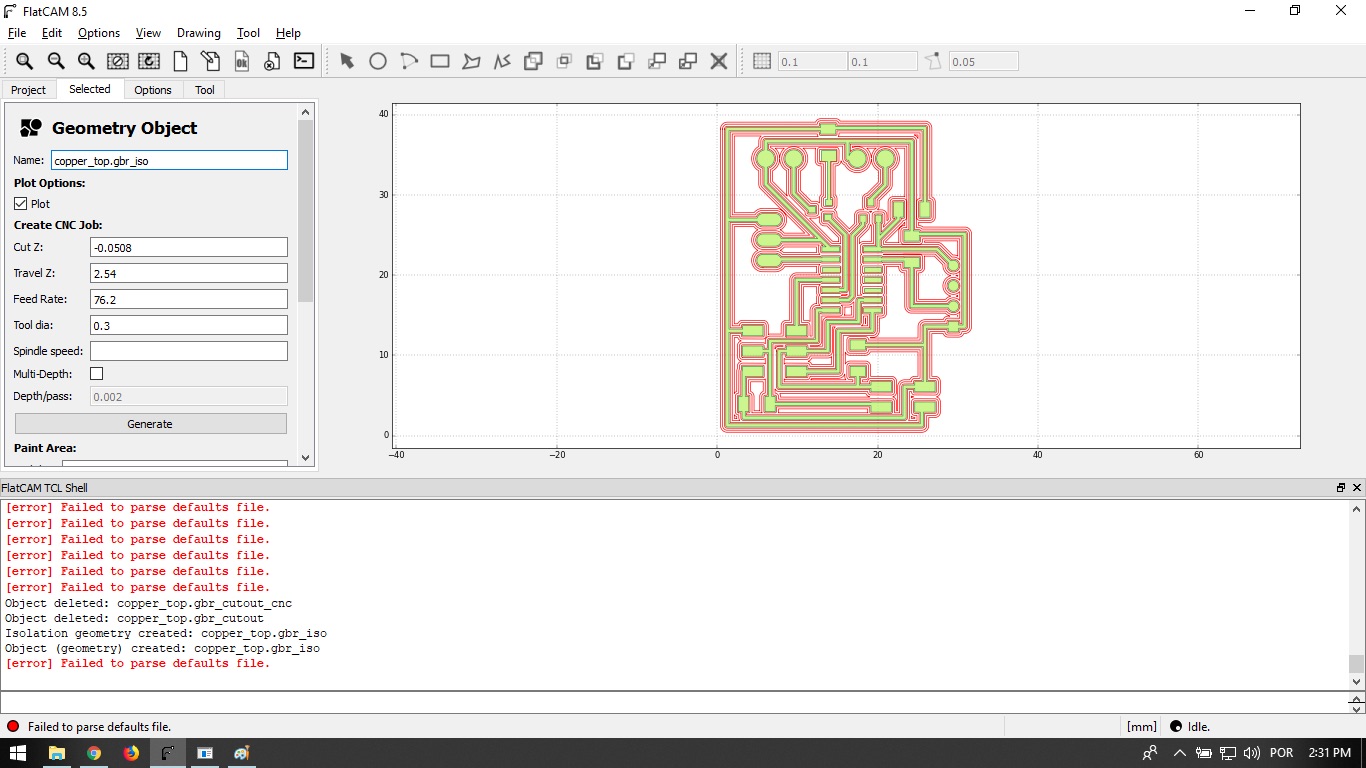

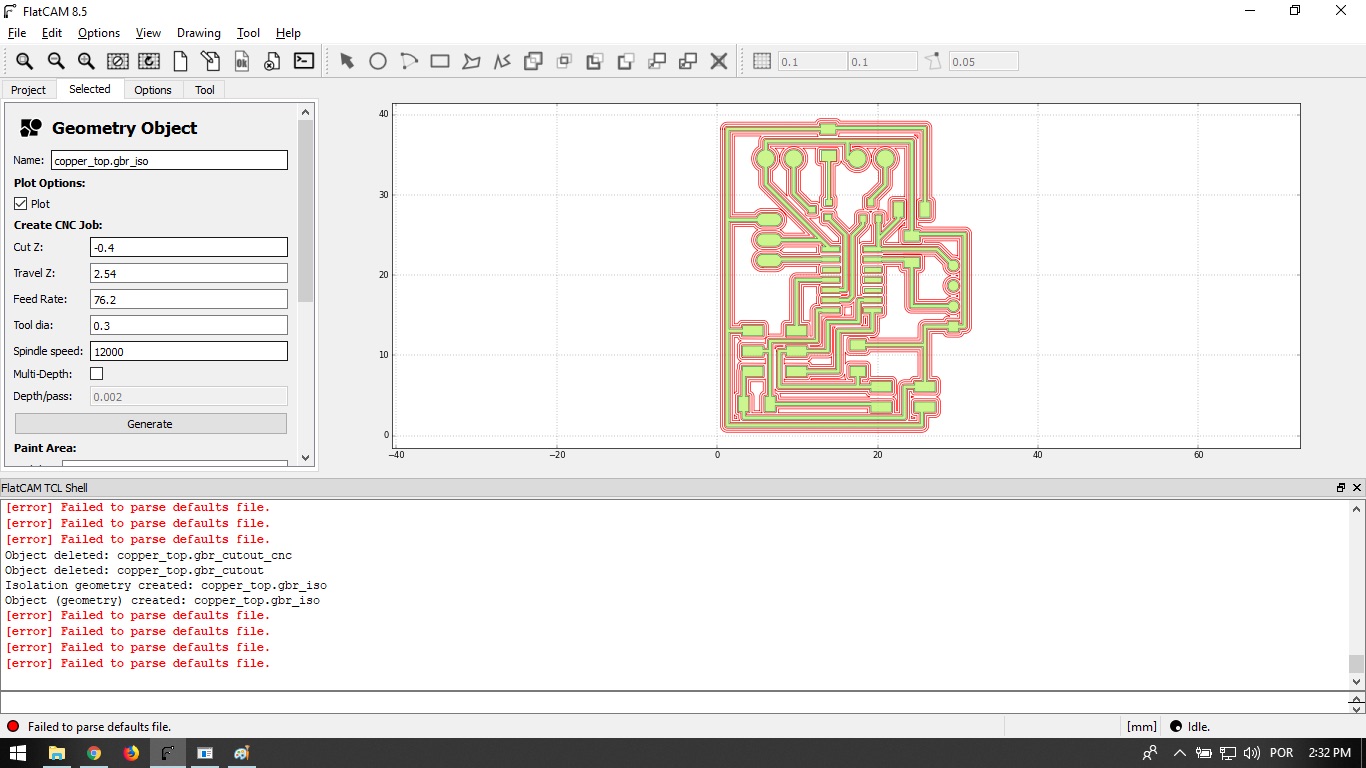

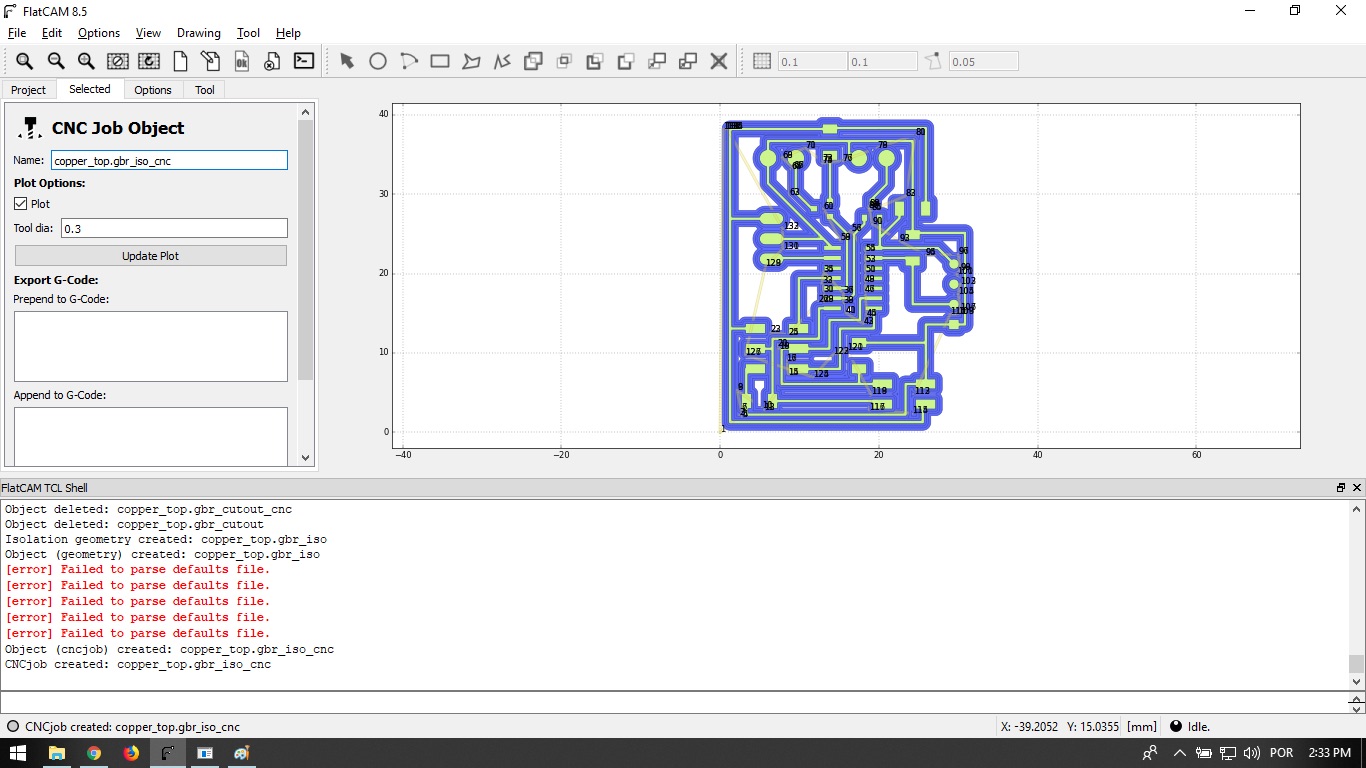

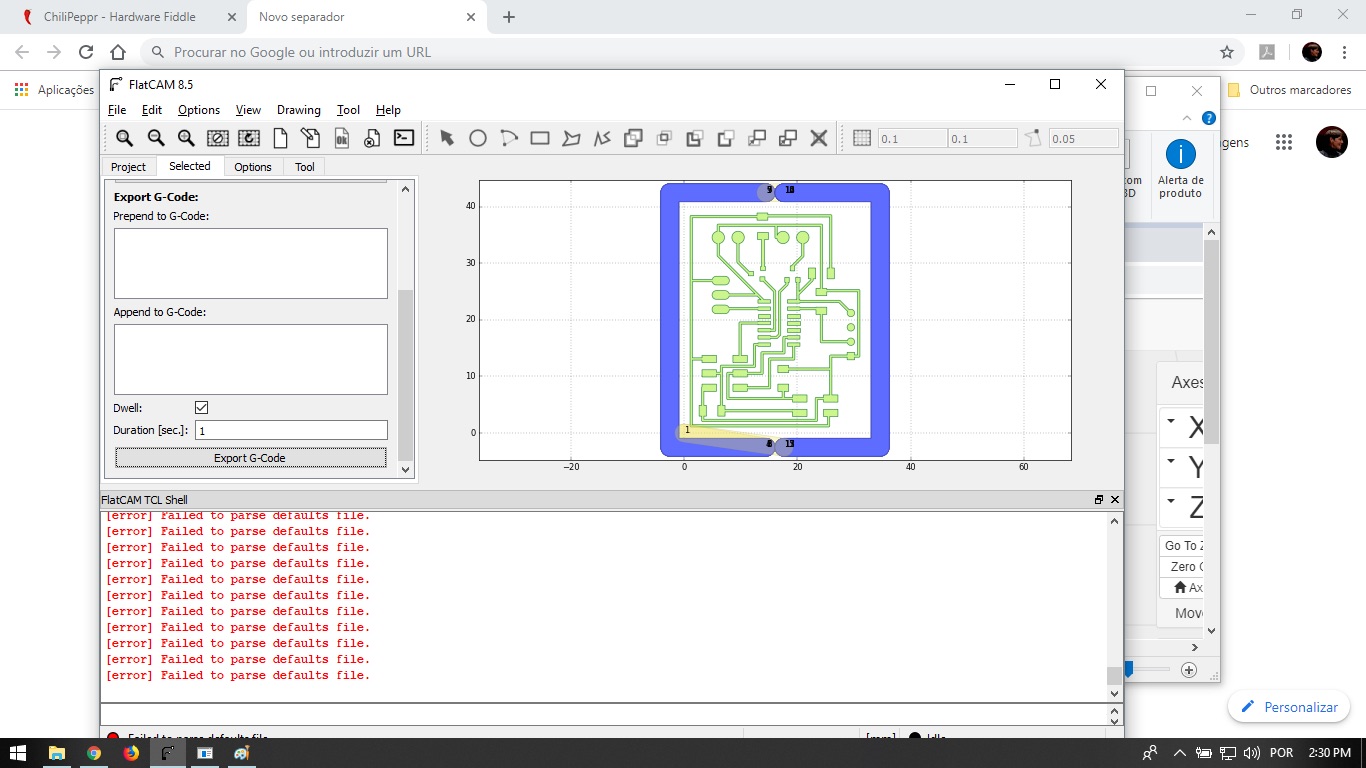

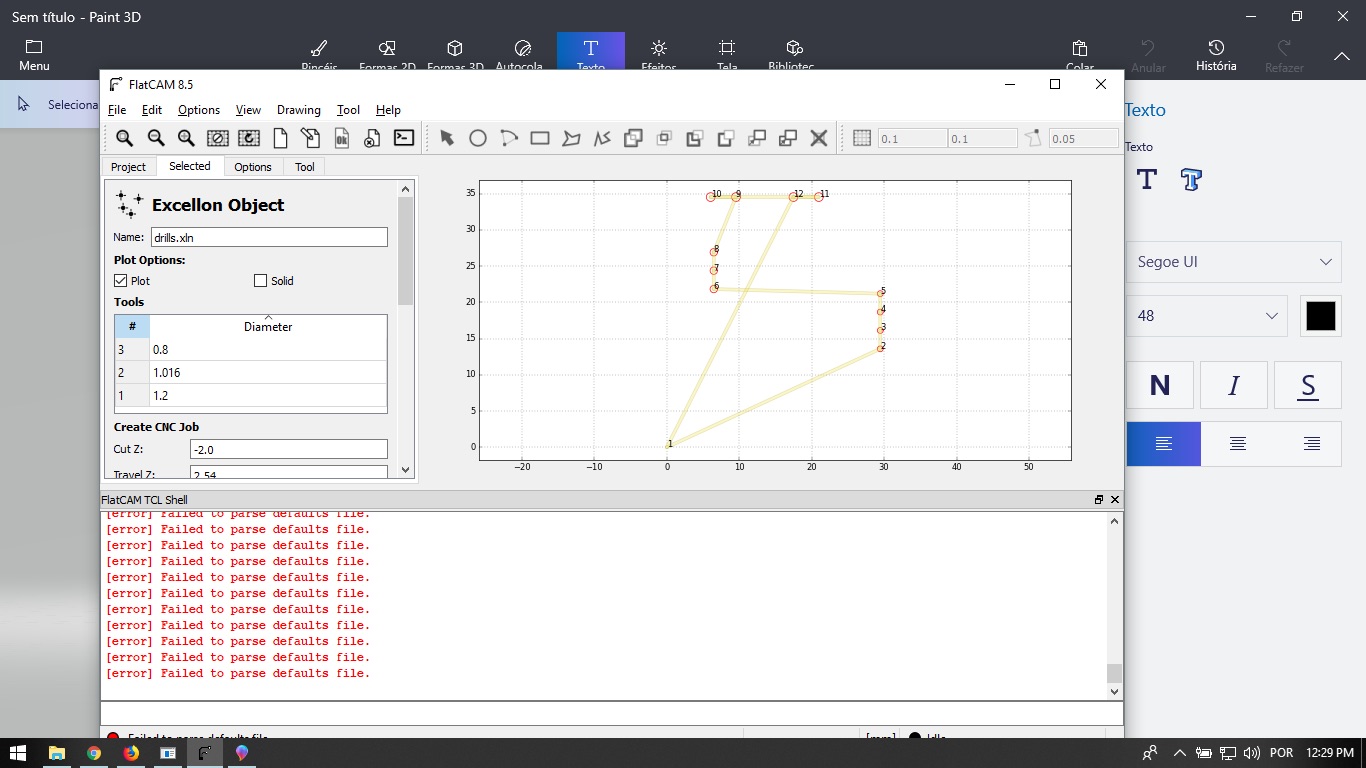

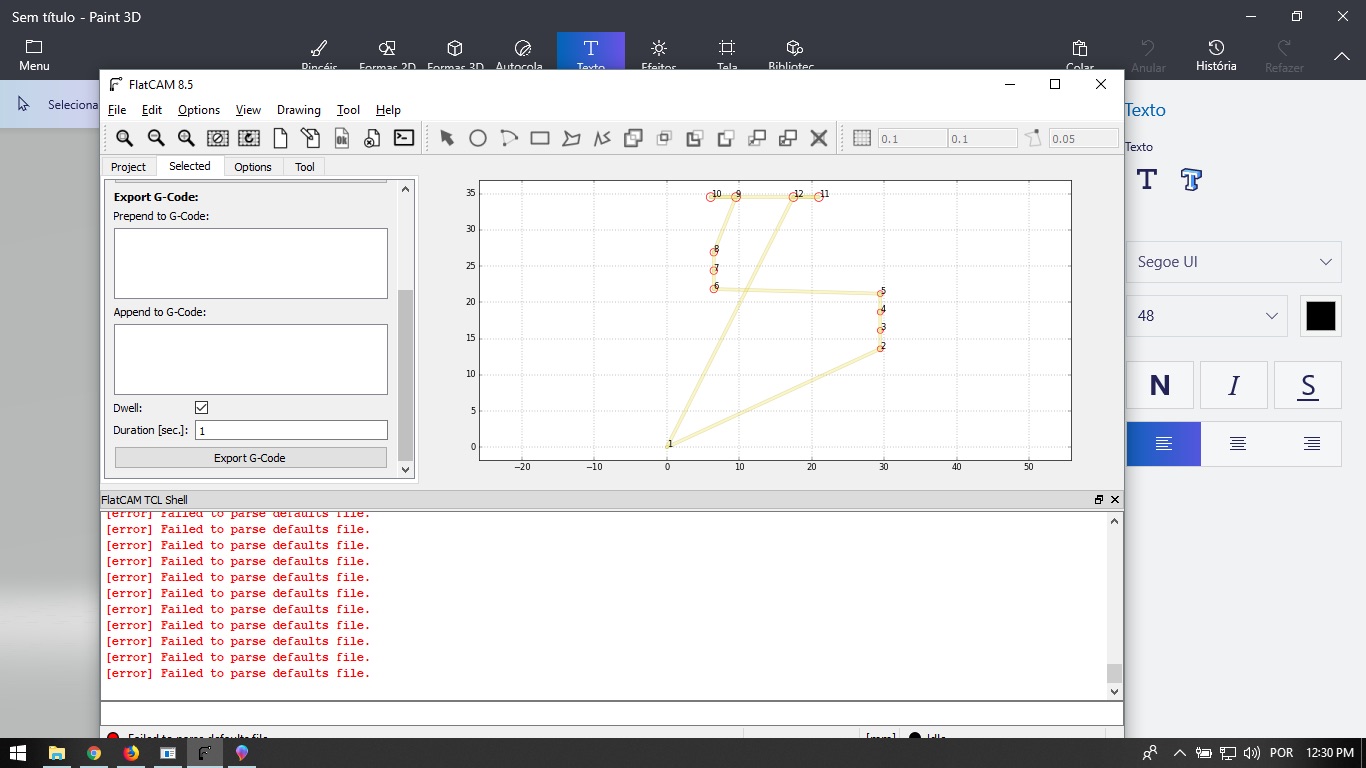

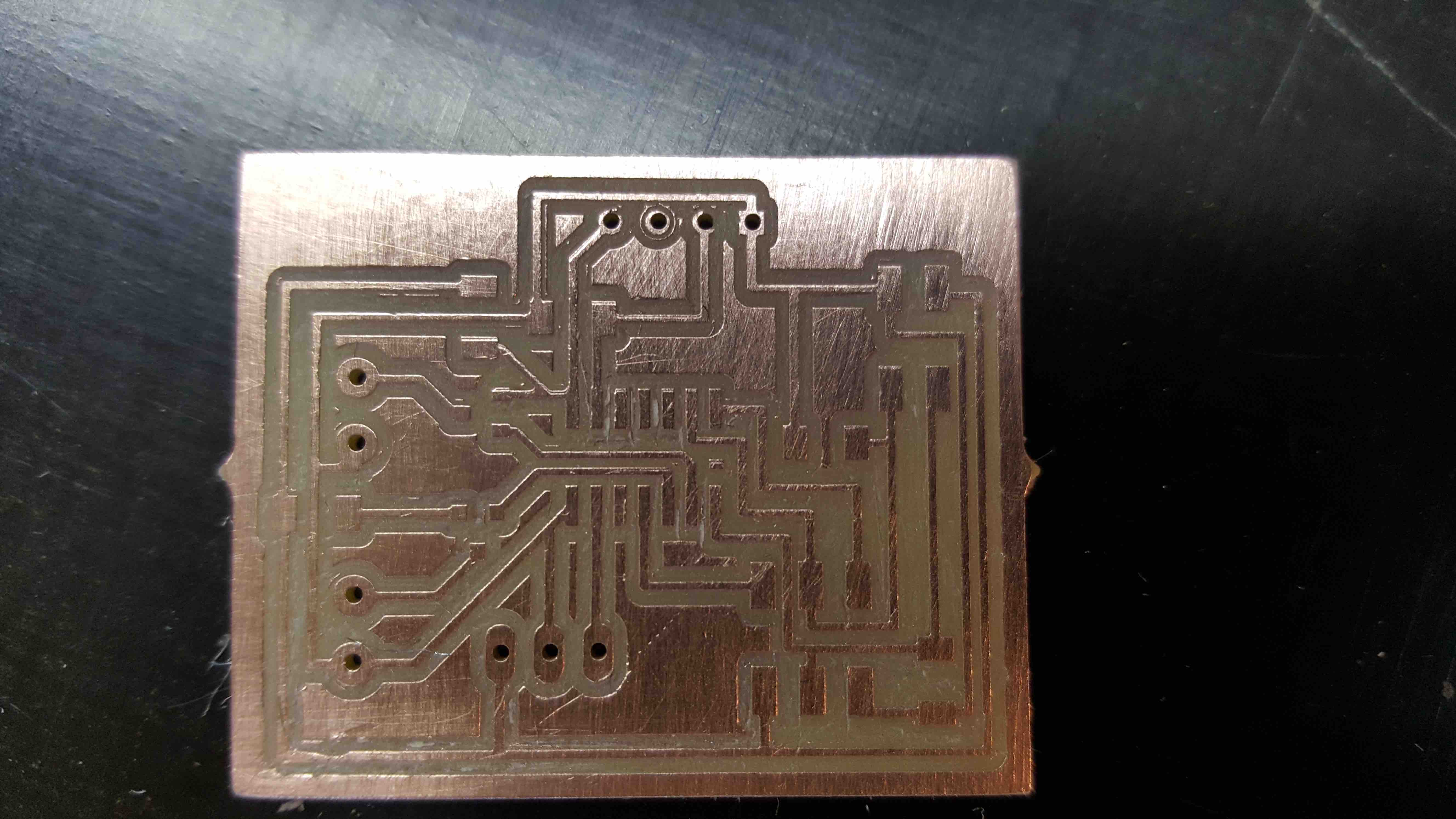

After the Hardware design in Eagle, exported the File as CAM and worked the files in

Them I generated the Cutout as fallows..

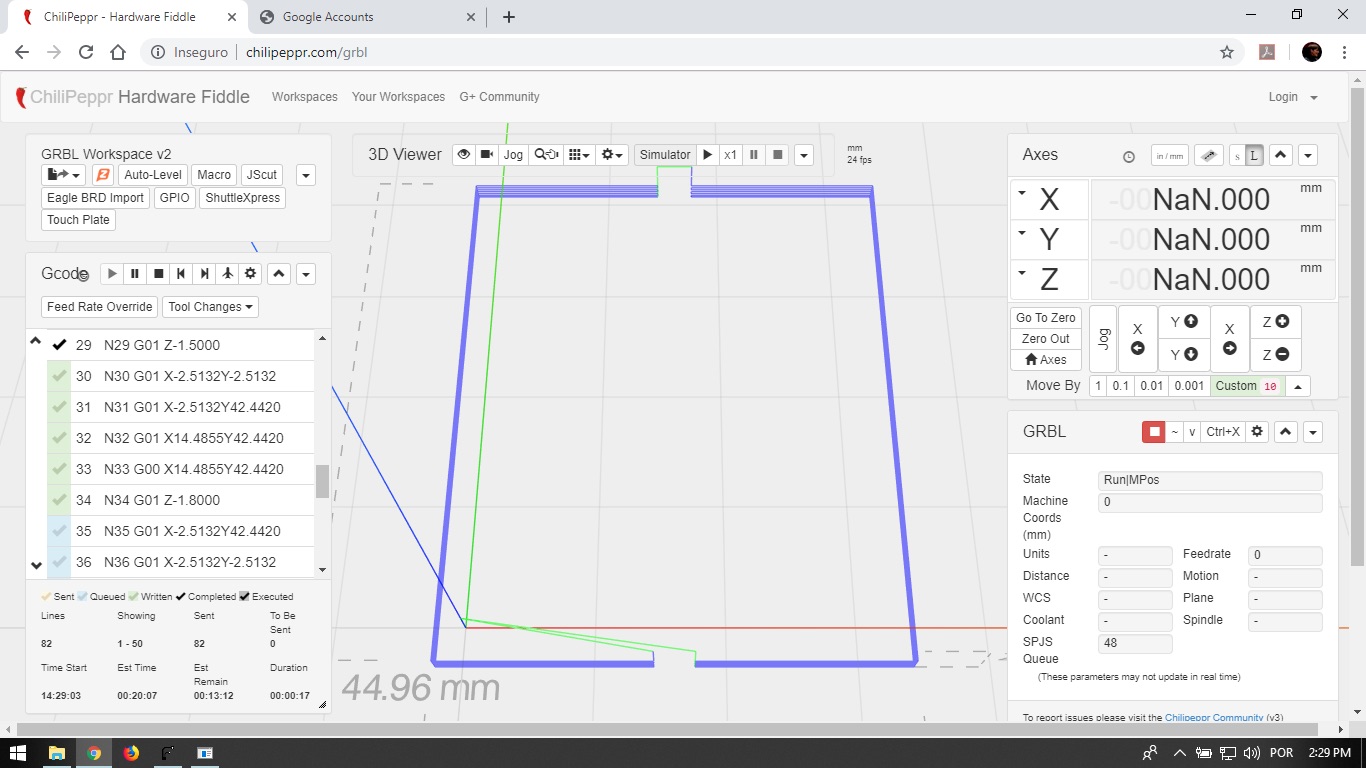

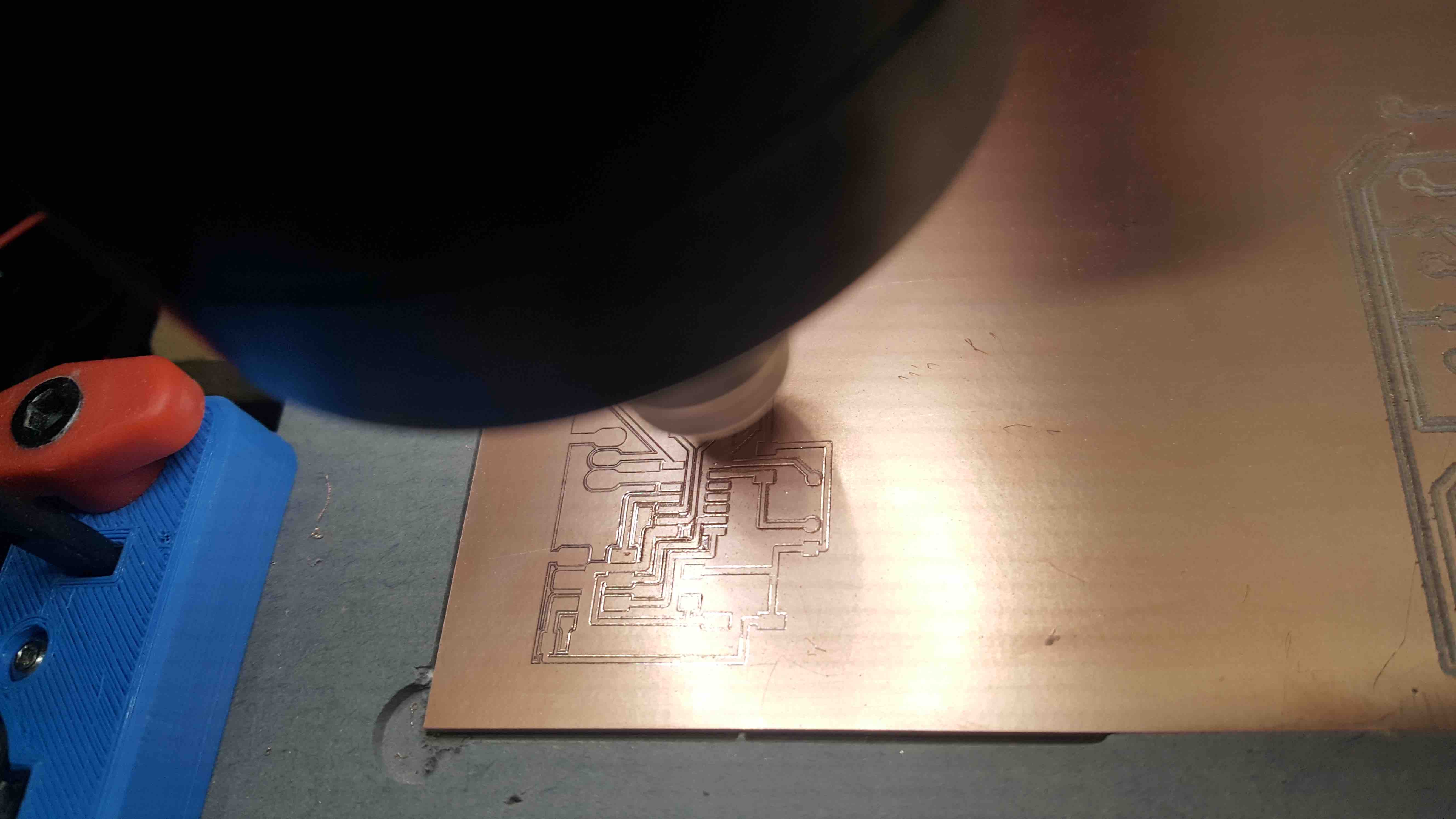

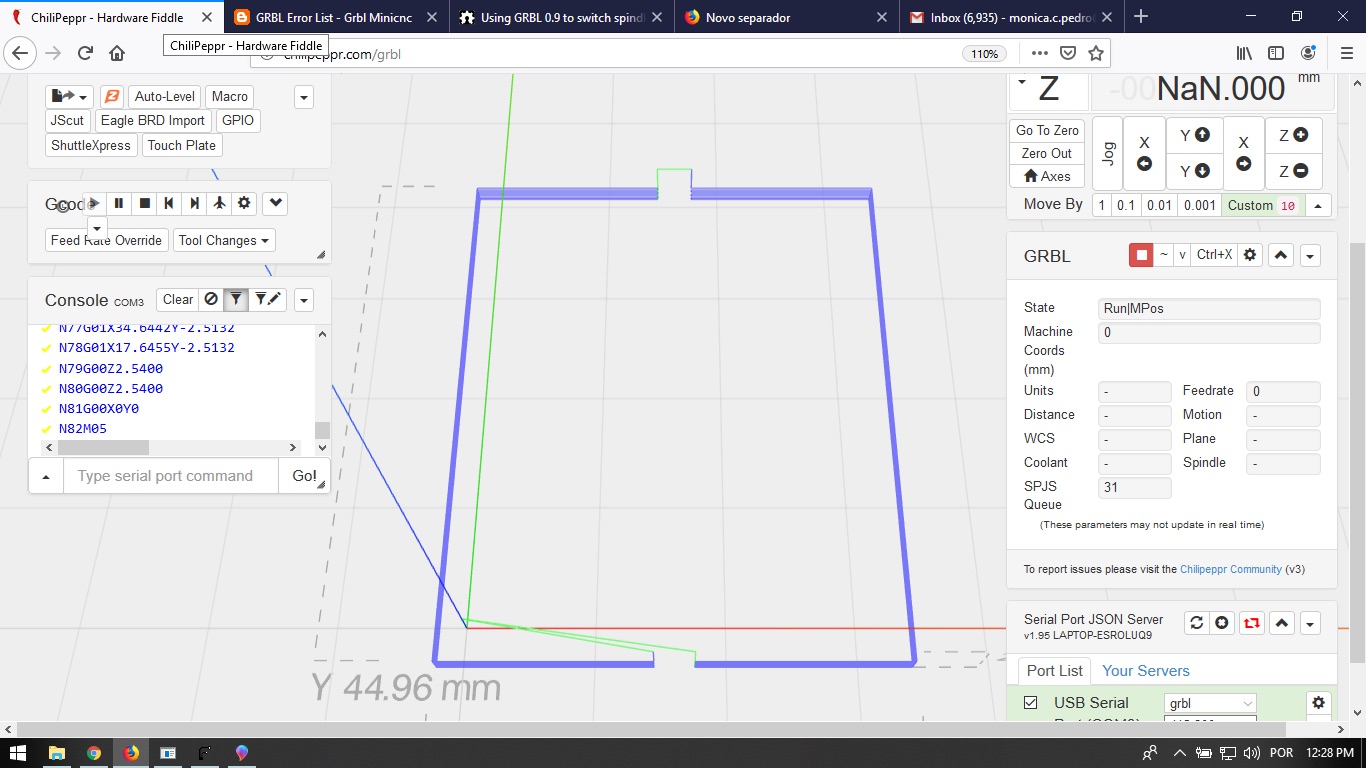

Them in the Chilipepper...

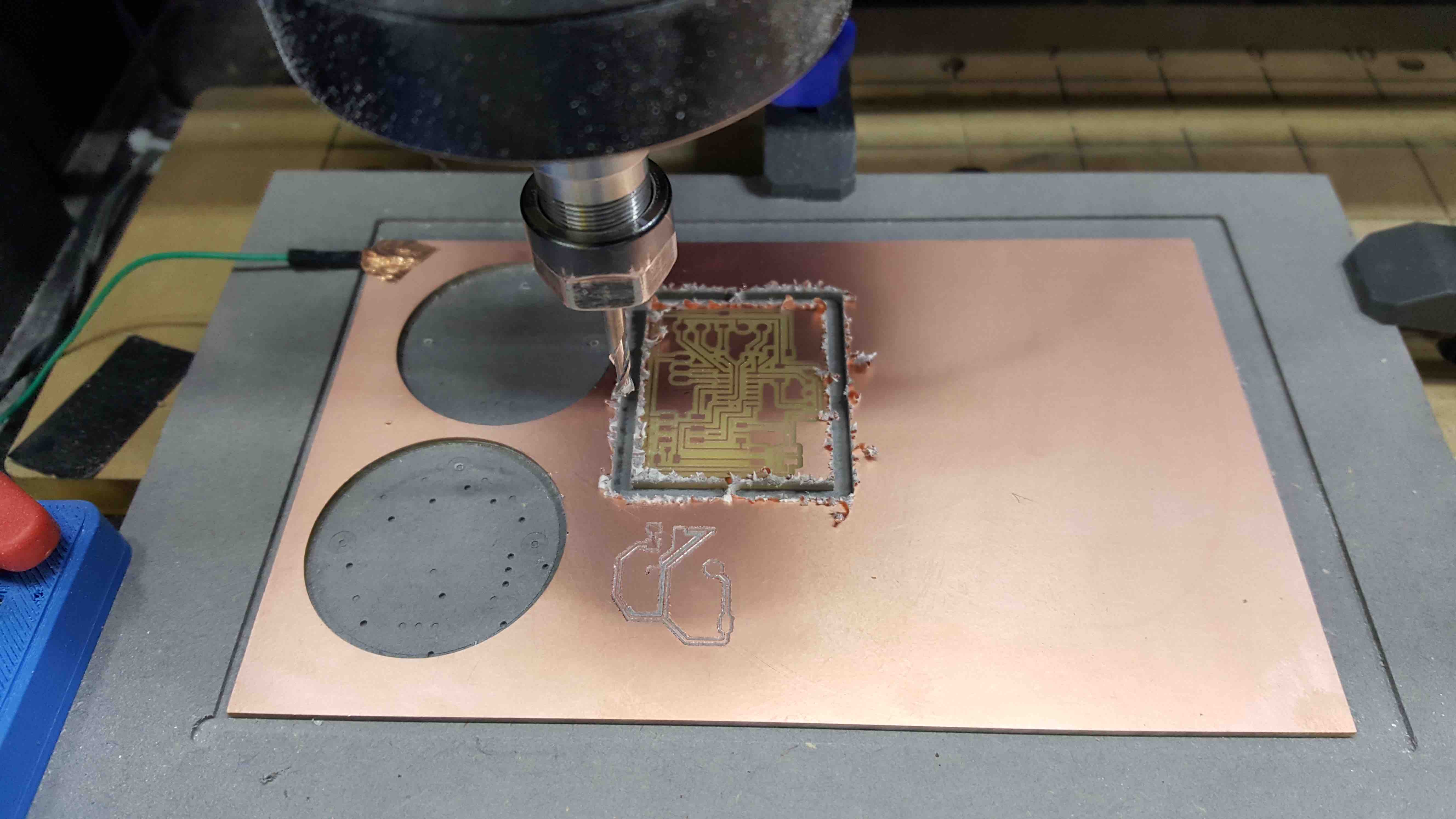

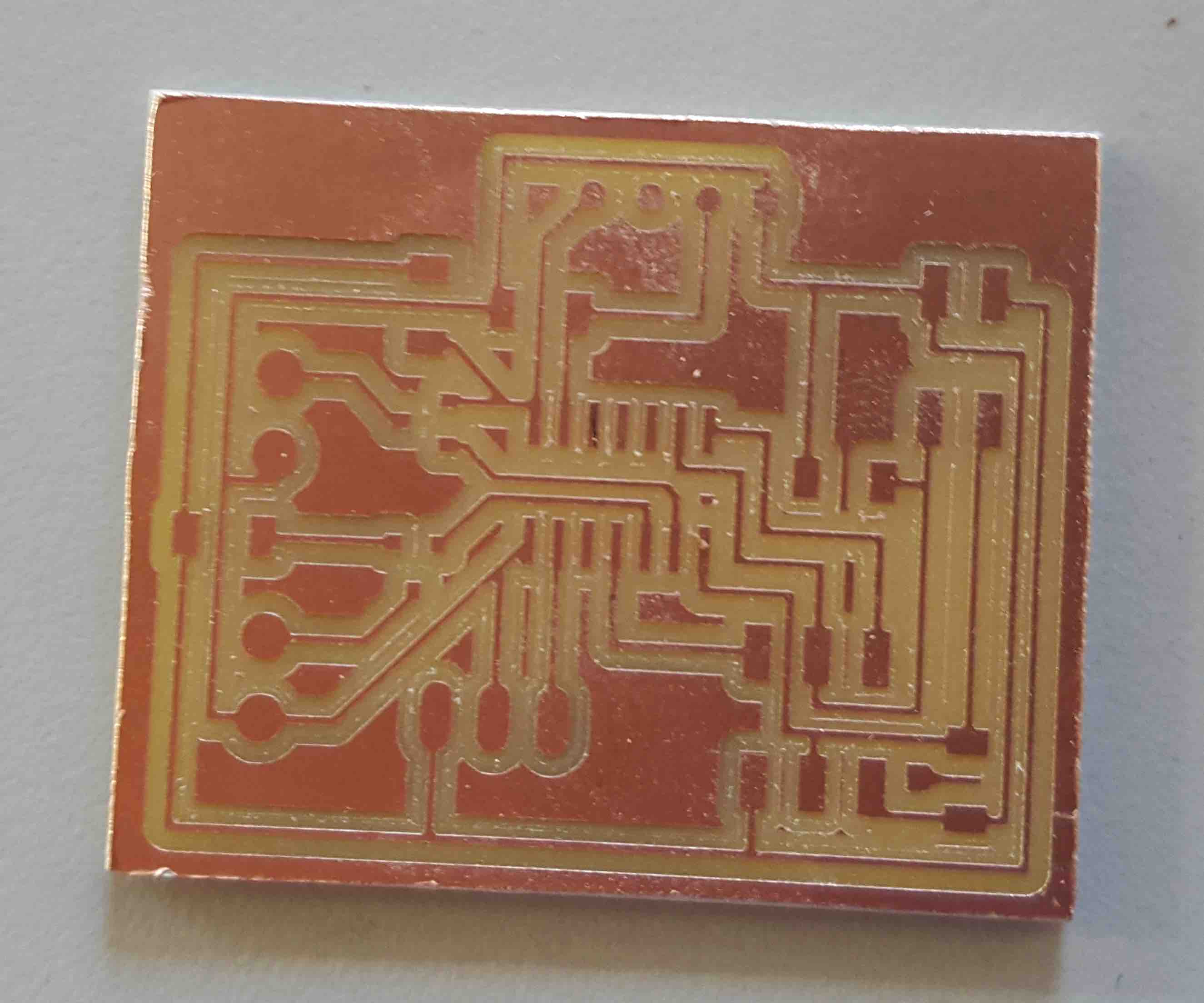

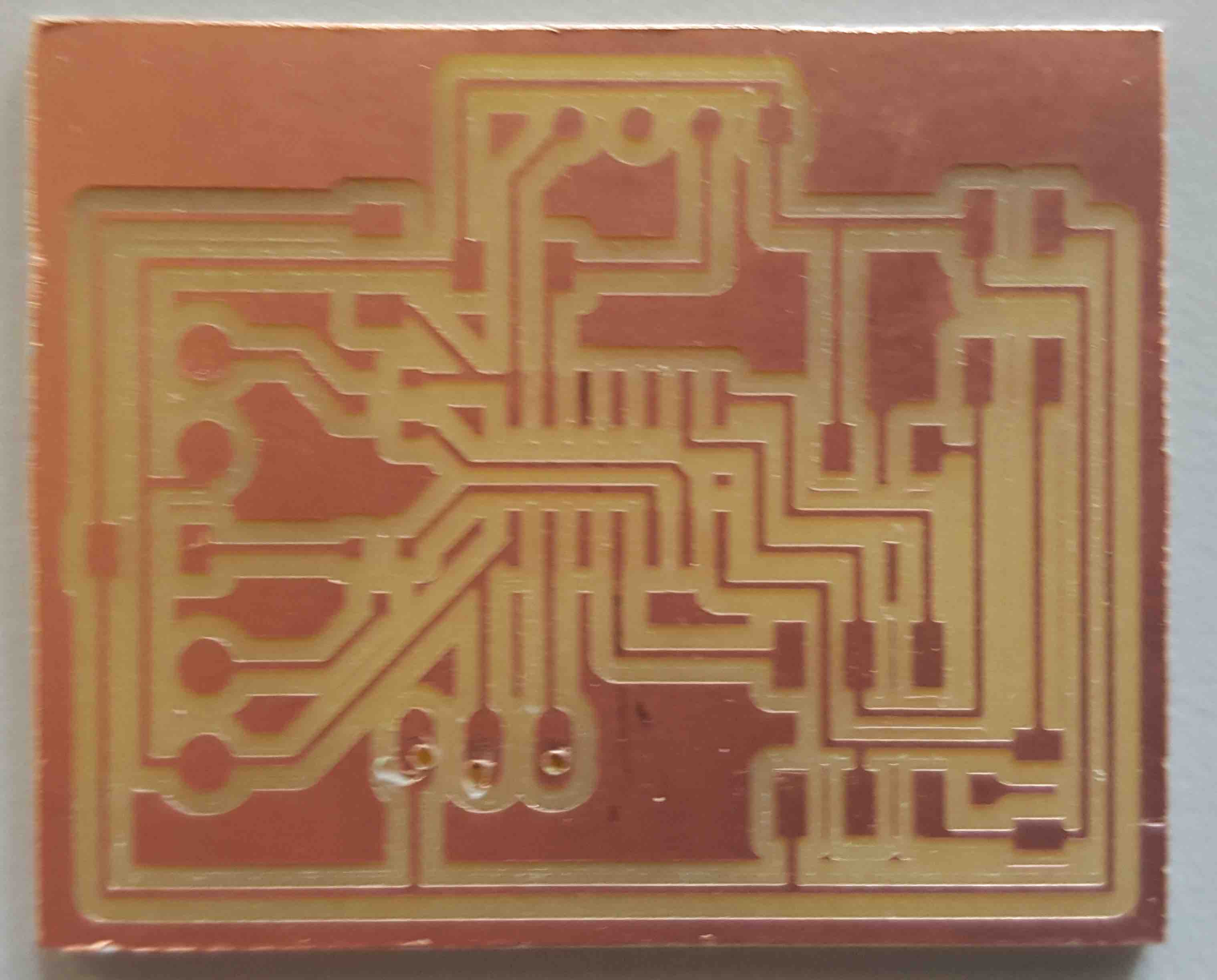

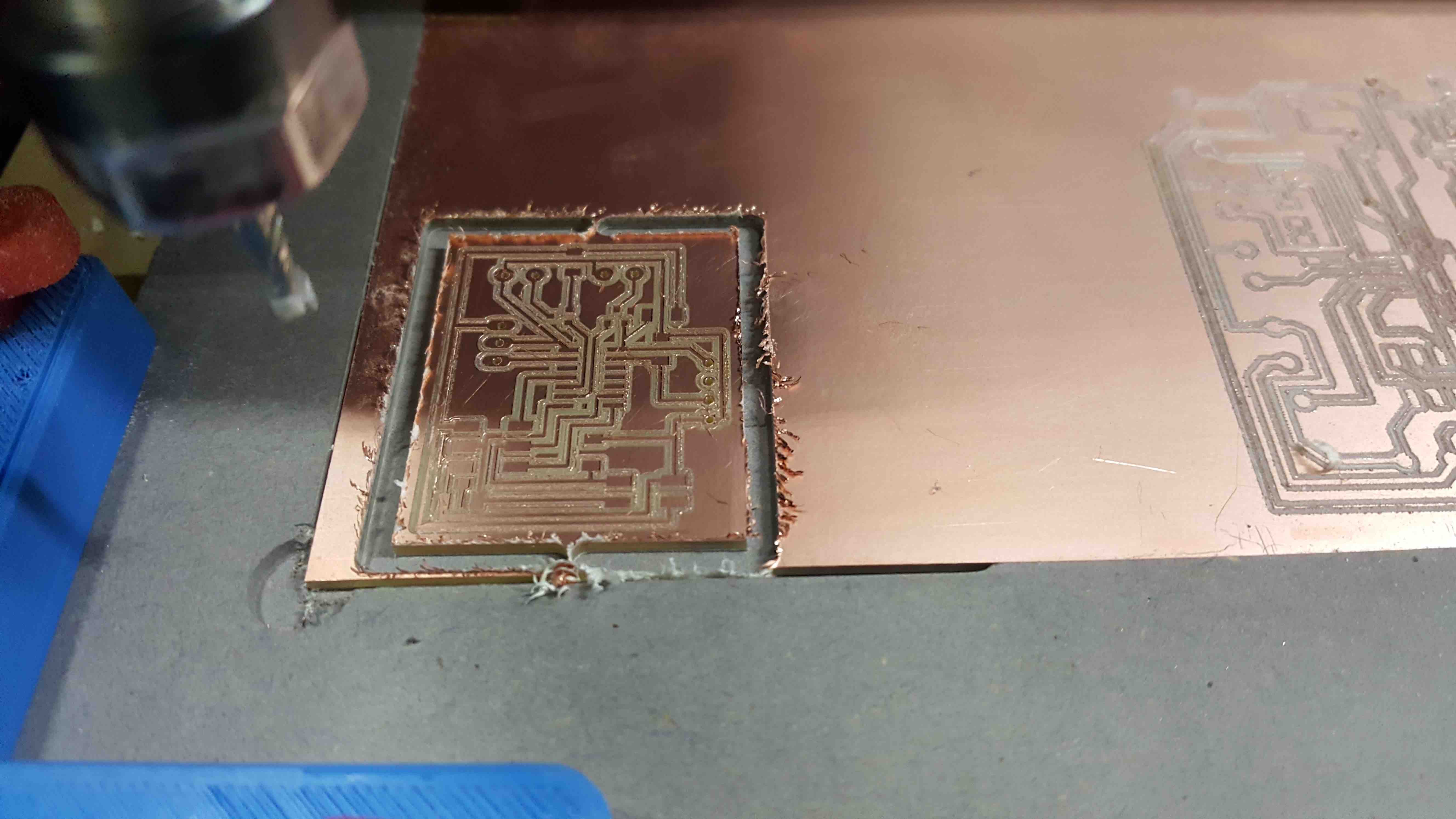

and the final Milling

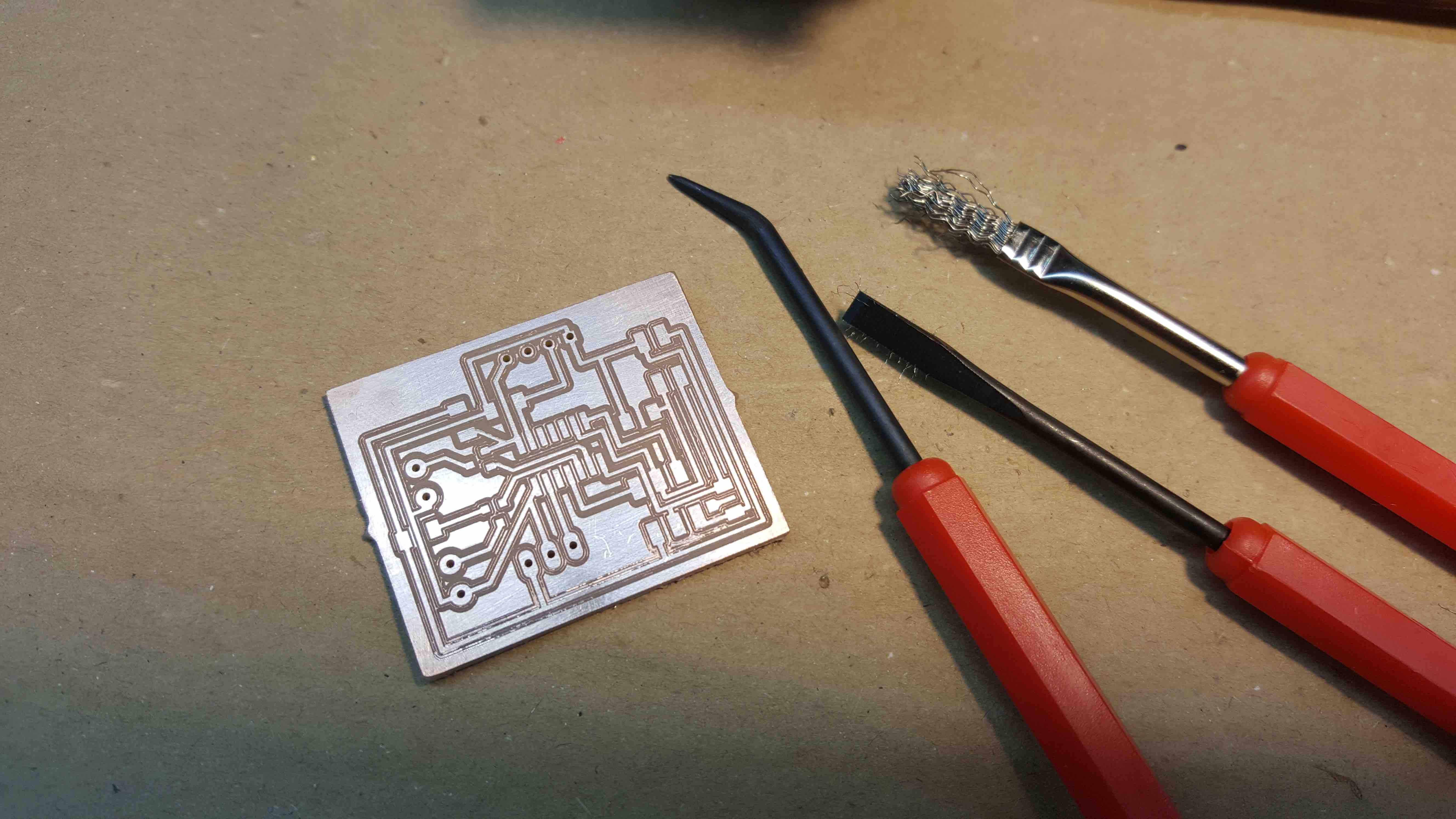

But the I Forgot the Holles and tried to make it by hand... which resulted very BAD

first attemp is goind wrong again, now the problem was with Chilipepper...

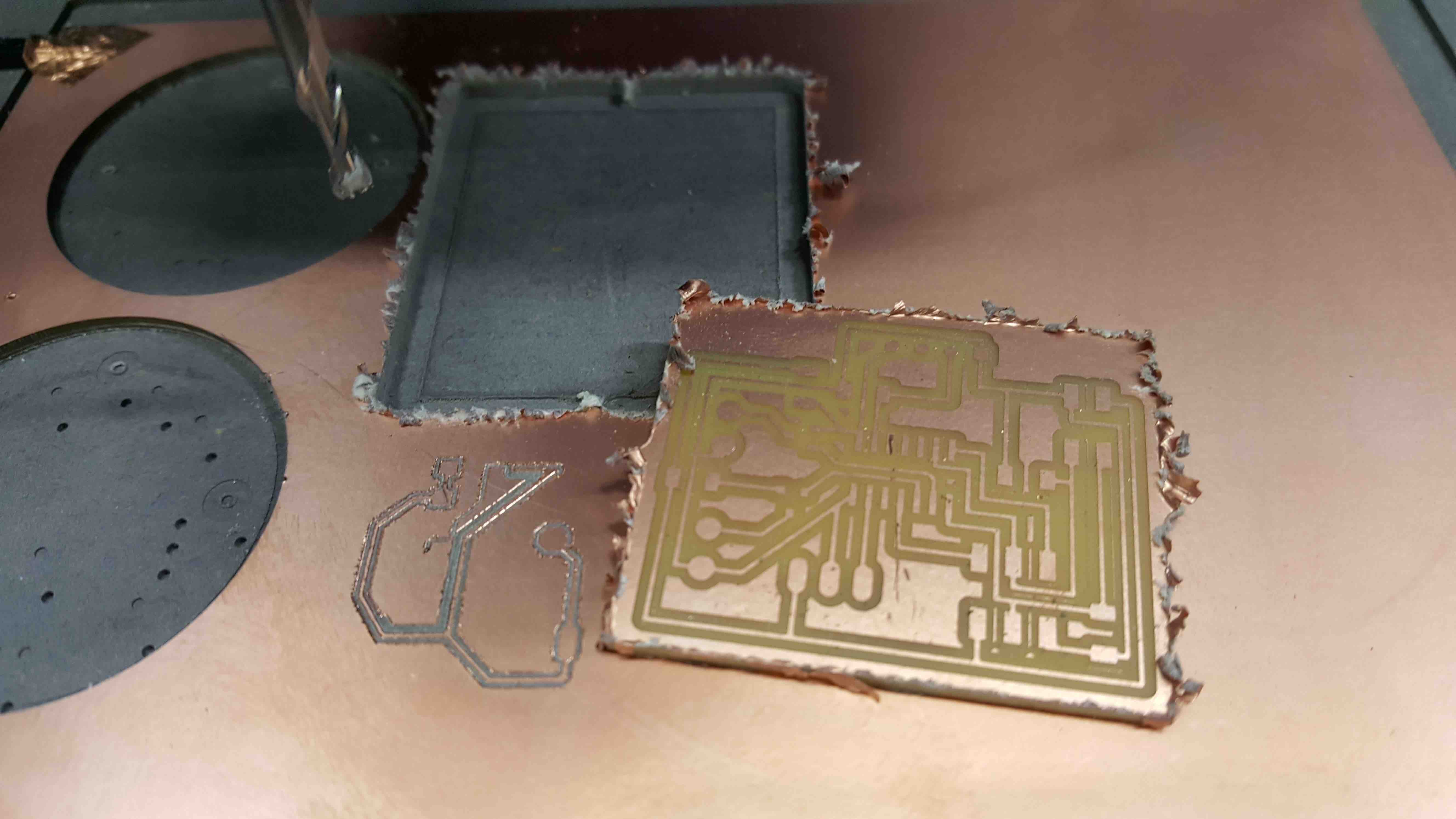

It seams that the Drill was too hold, so after changing the drill to a new one... it worked

them moved to Chilipeper and made made the final cut

but I notice the need to clear the pass between the wires, so....

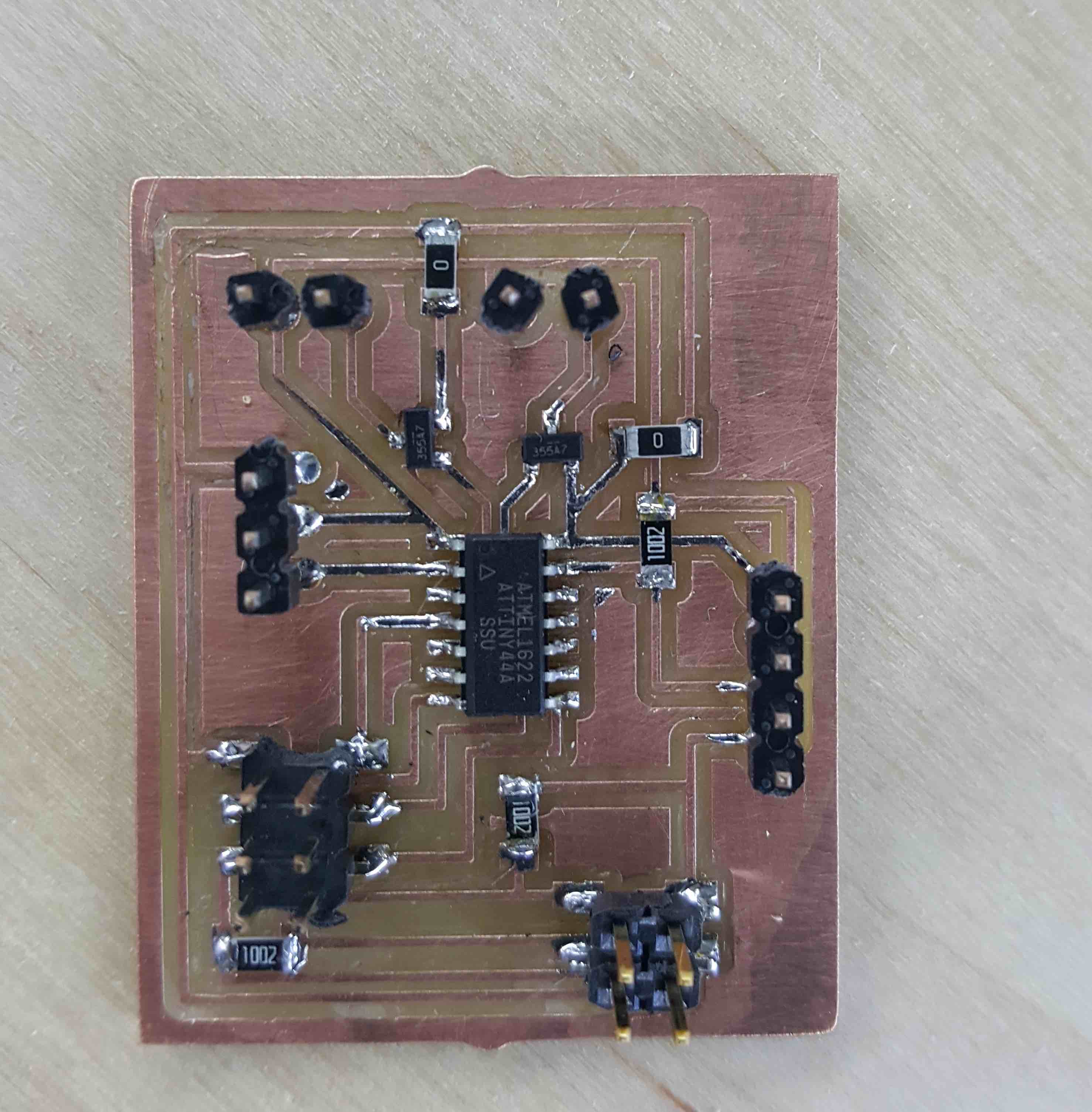

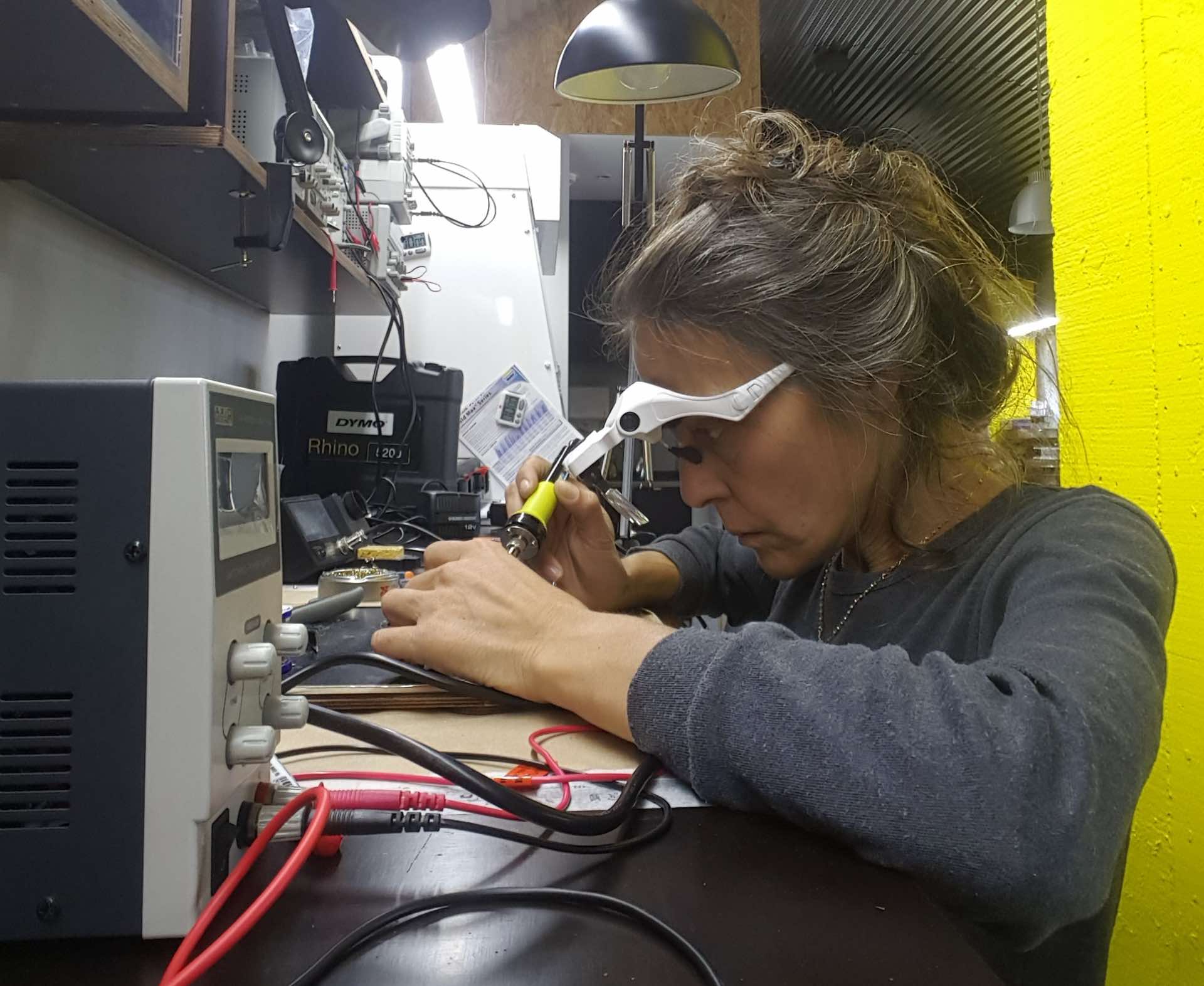

And then the soldering... with a new par of Glasses

Download GCode files :

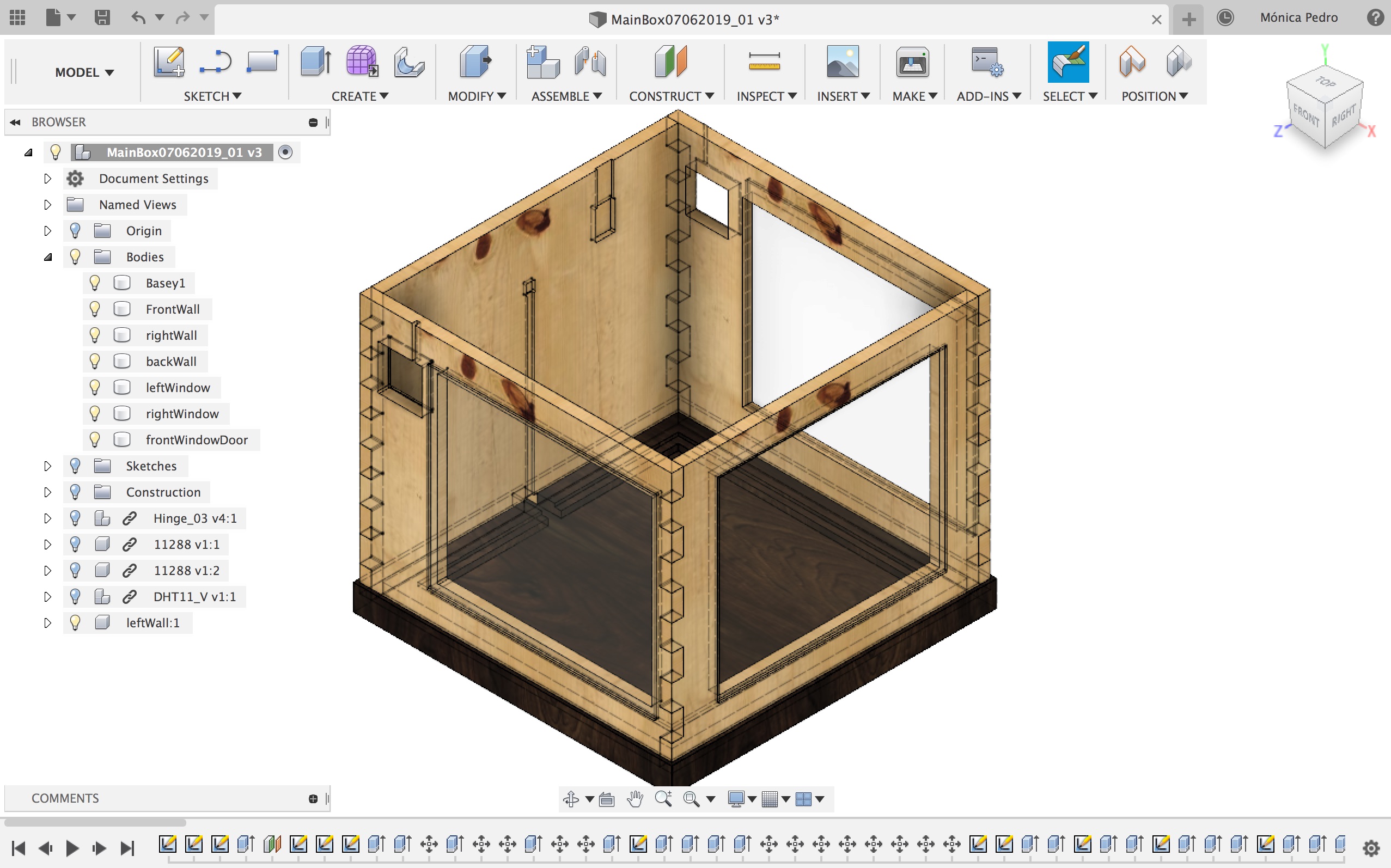

So the main box will have three different materials:

It will have:

Started by the BackWall....

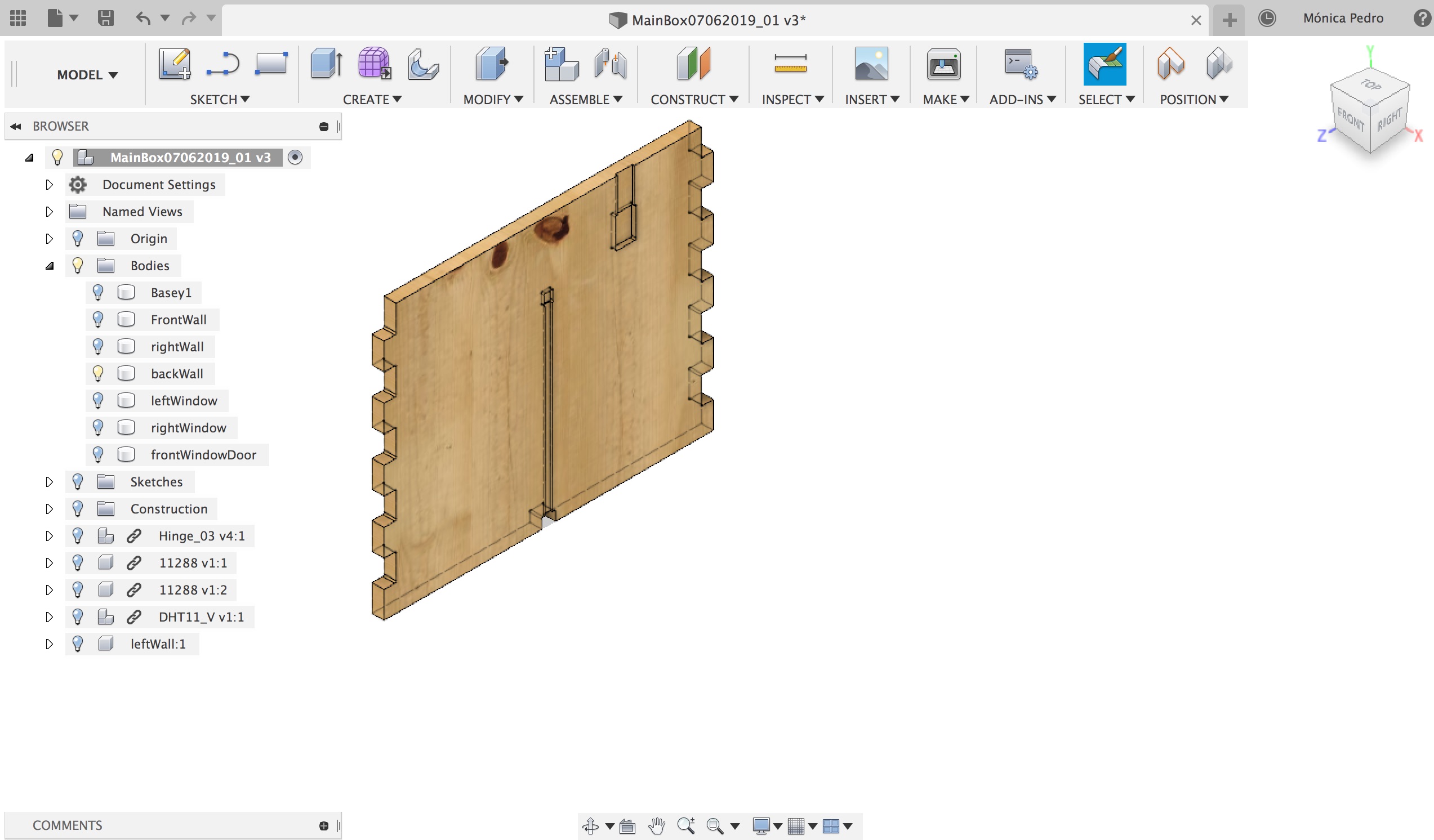

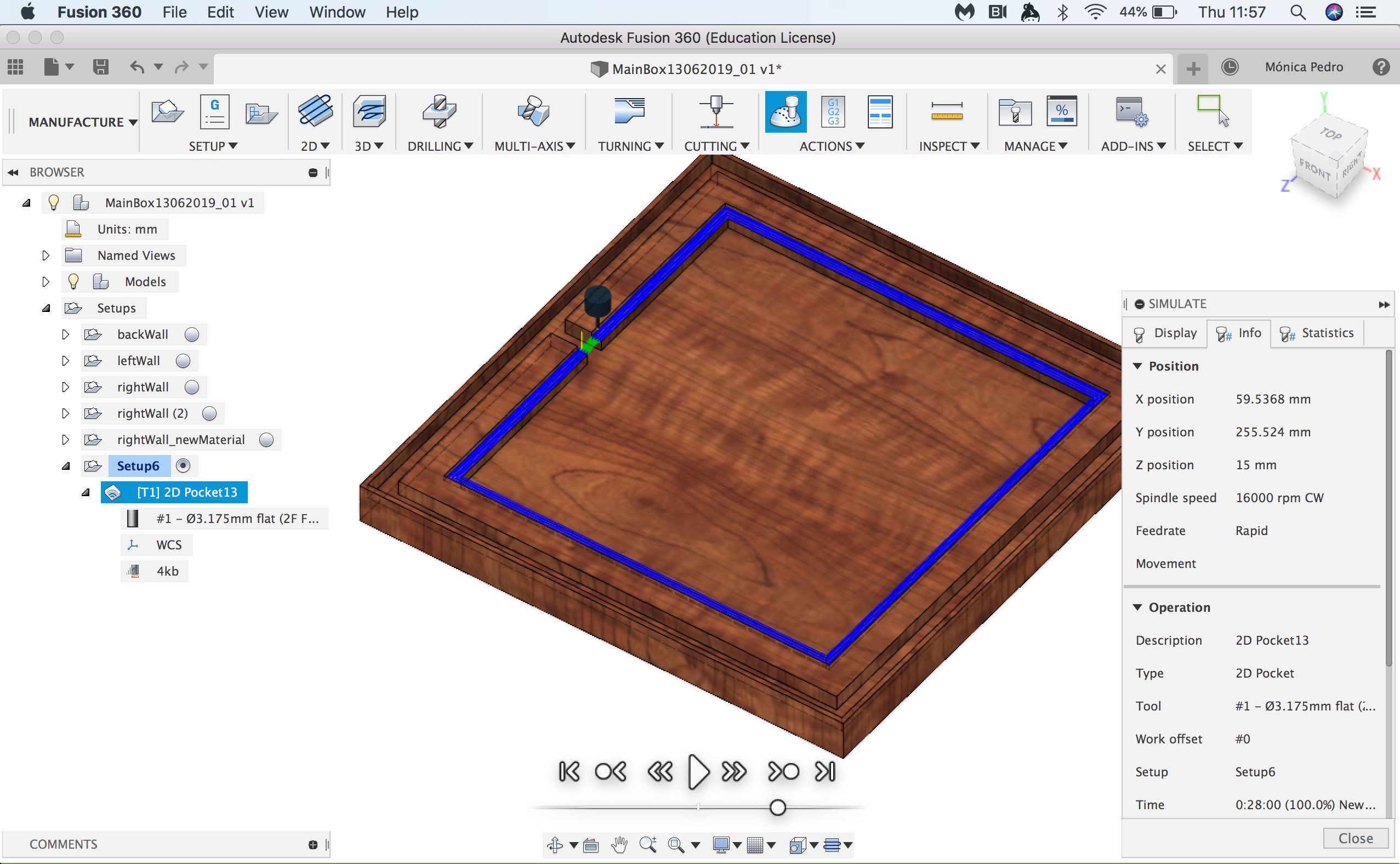

... so in Fusion 360 hide all except the BackWALLL

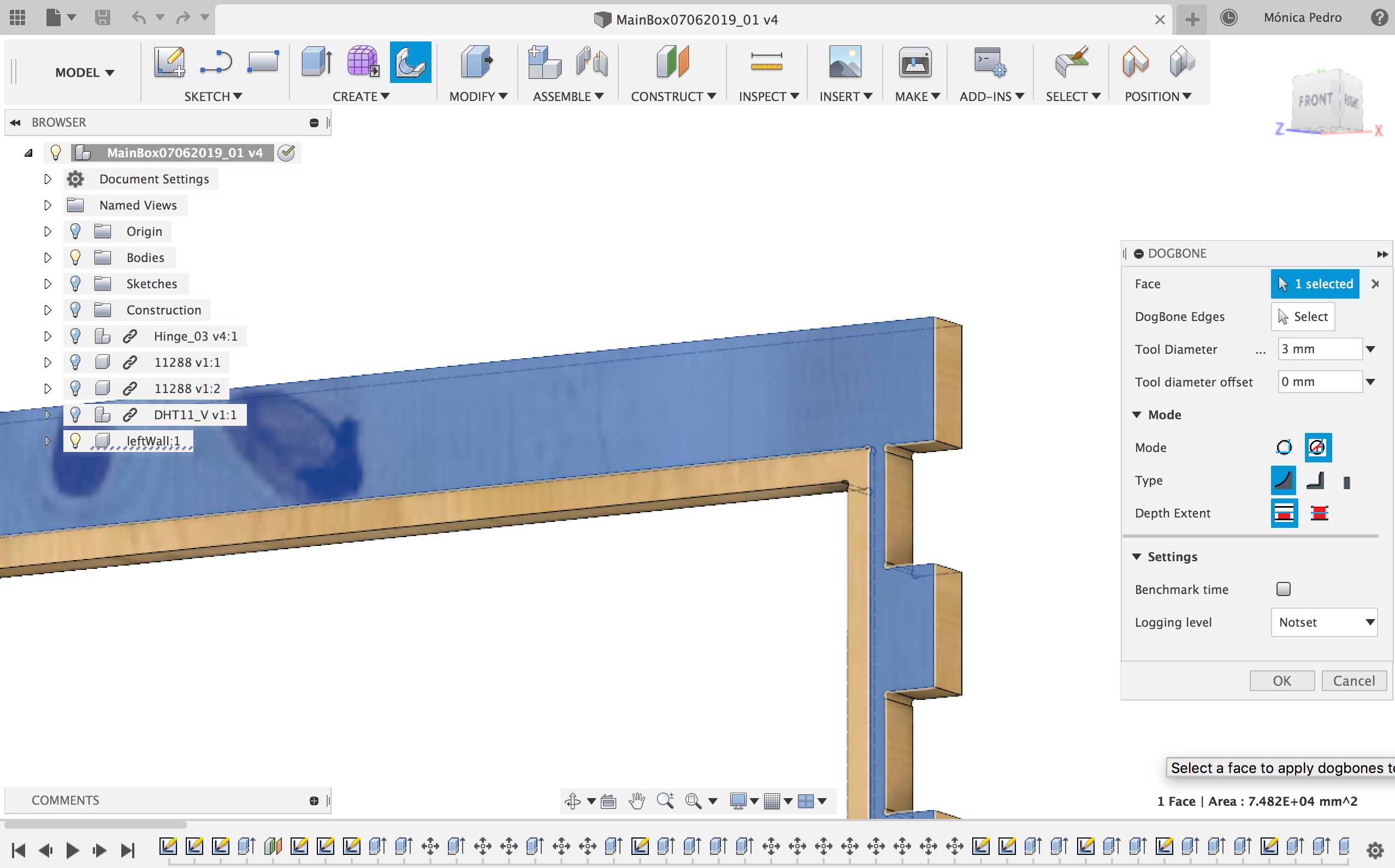

to prepare it to right Fit I made the DogBones using the Fusion 360 function available in MODEL workspace, specifing the Tool Dimension which is 3mm

I'll use the Inventables bit of 1/8 inch

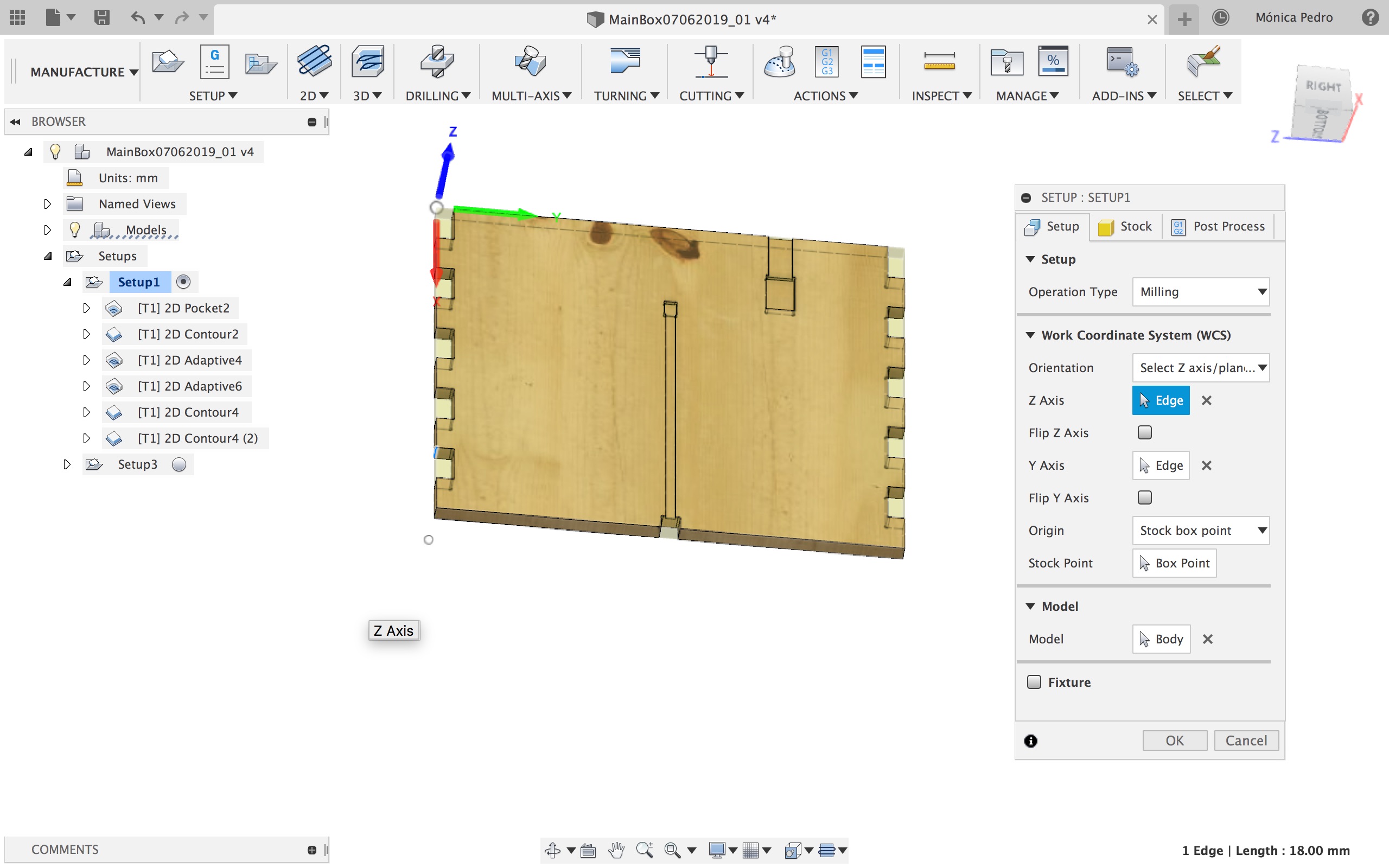

then, with the Back Wall only visible, i Went to MANUFACTURE workspace...

and created a new Setup...wher is important to set:

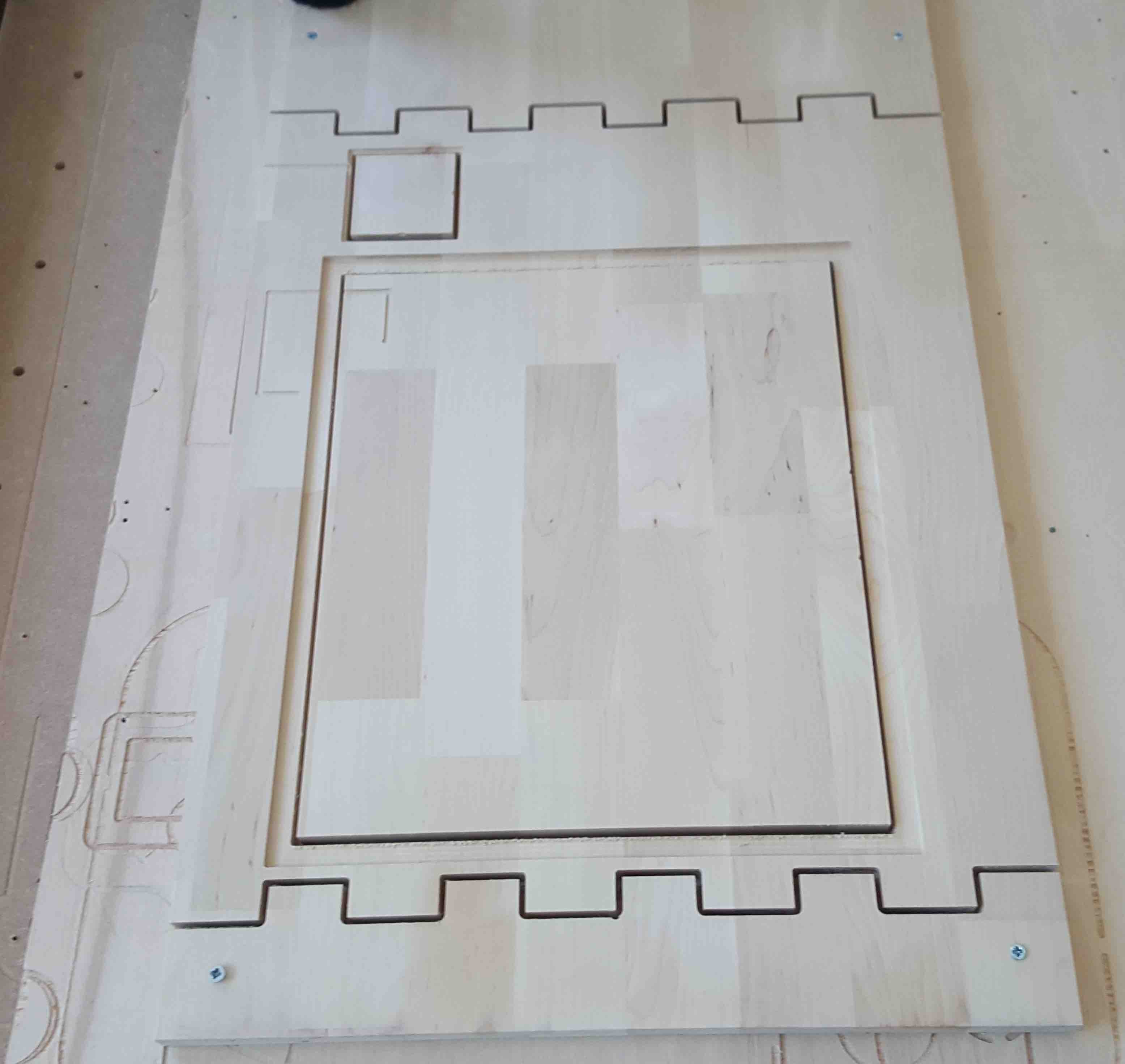

Back Wall Cutted nicelly

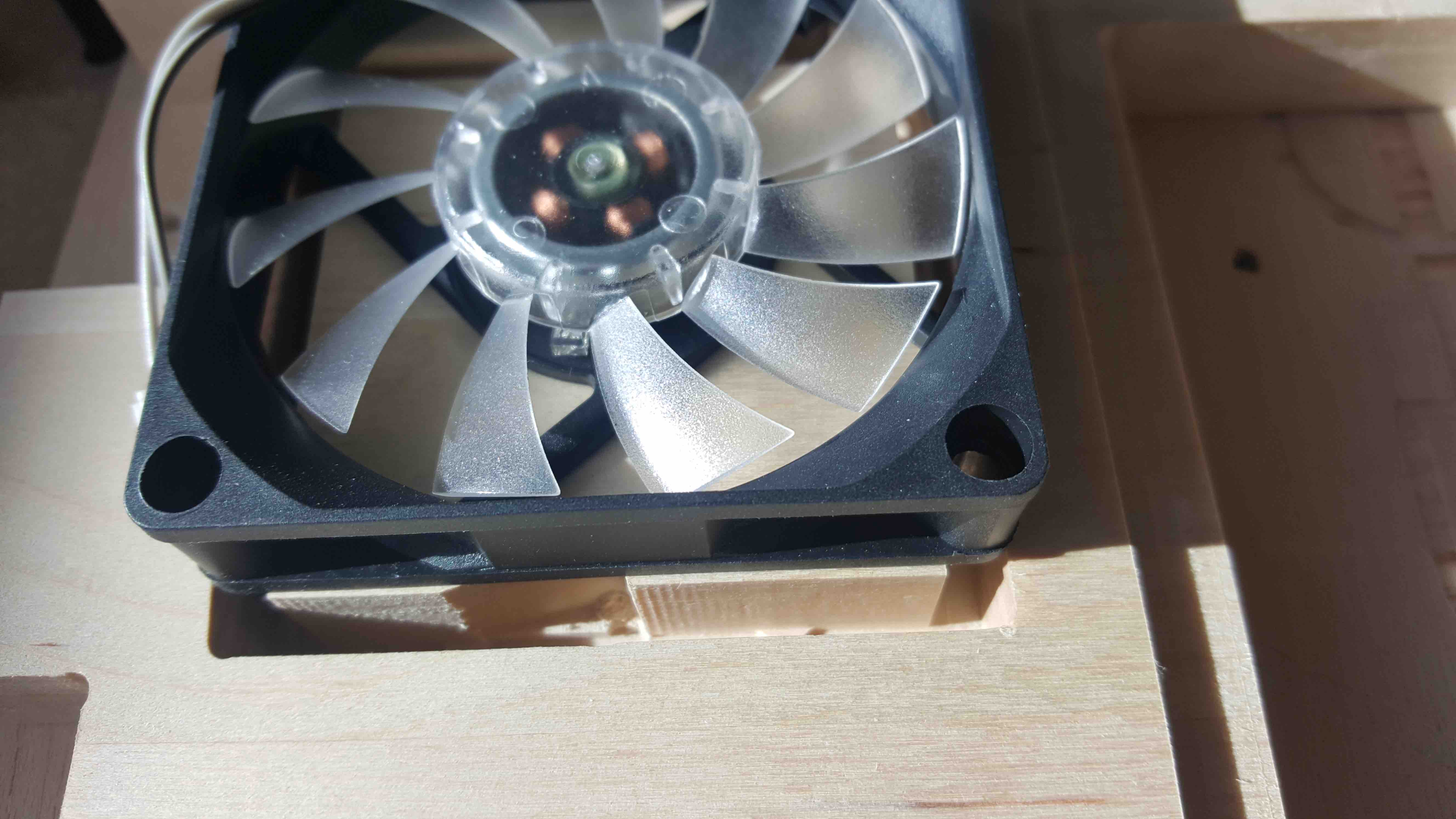

but the LEFT wall does not work well, it had not cutted trhough all the space for the FAN....

i even tried to take it back to the CNC machine but there was no way to align it again...

So I decided to proceed with the right door and see if I would latter recover this one...

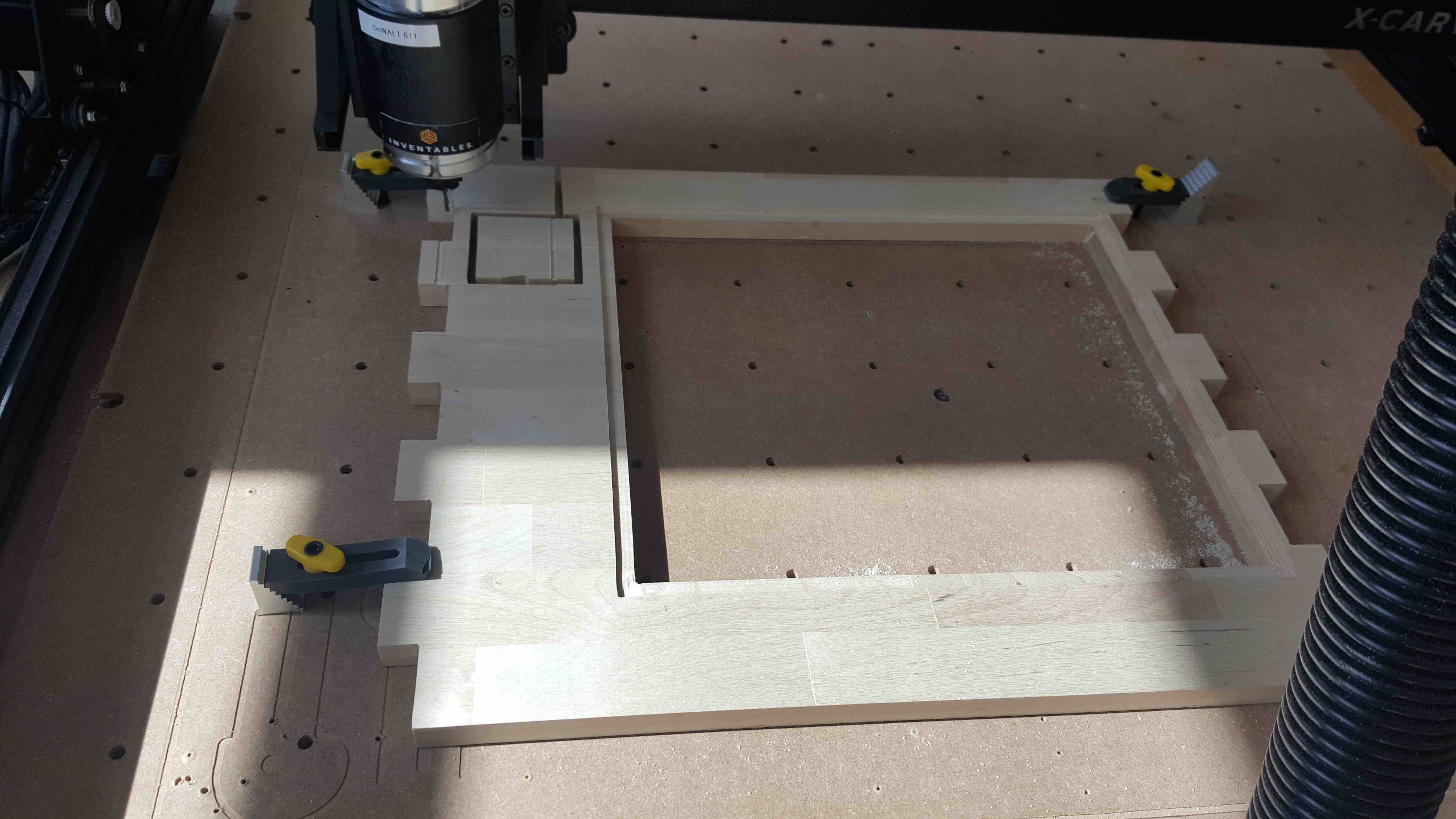

First job to test setup...

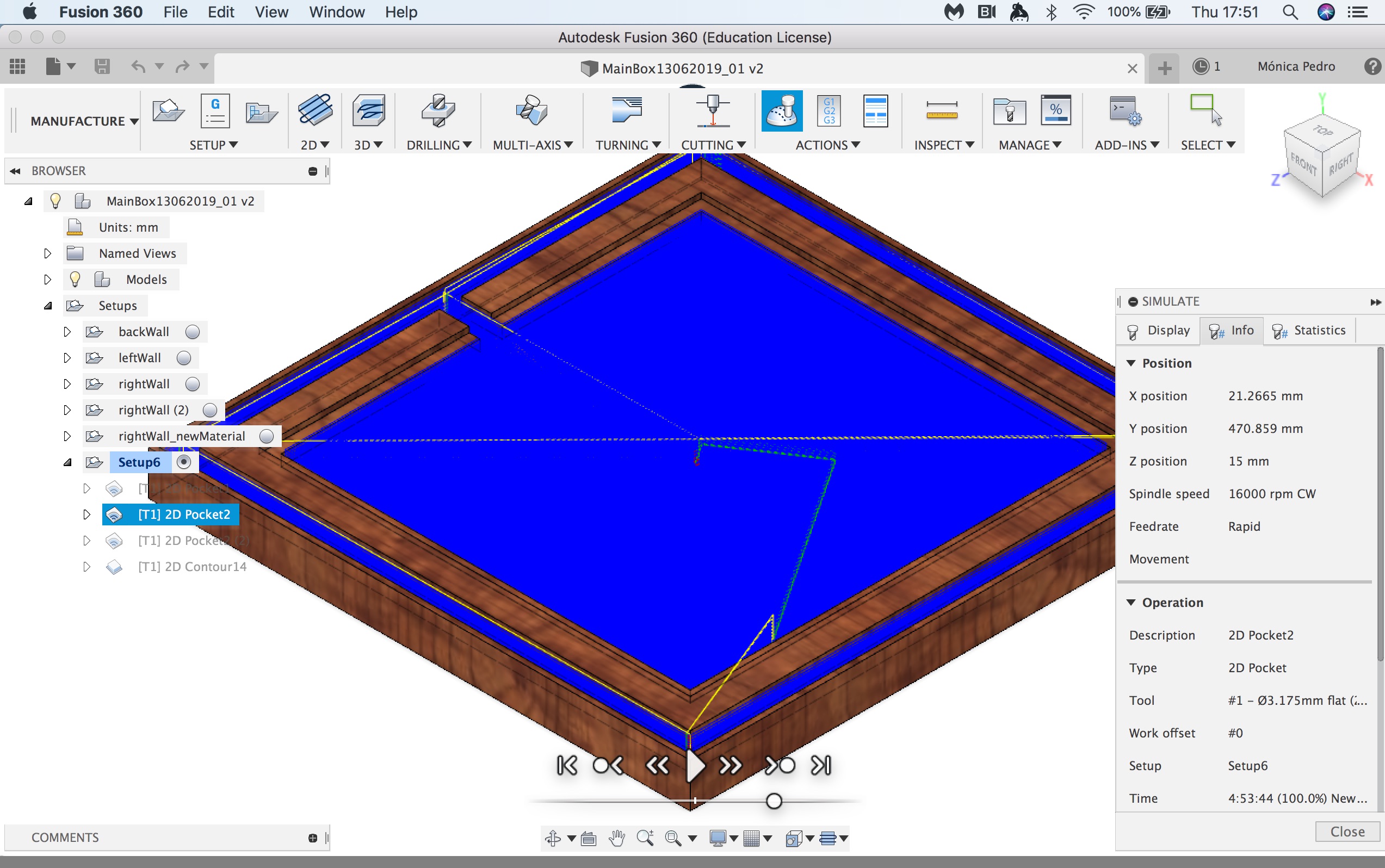

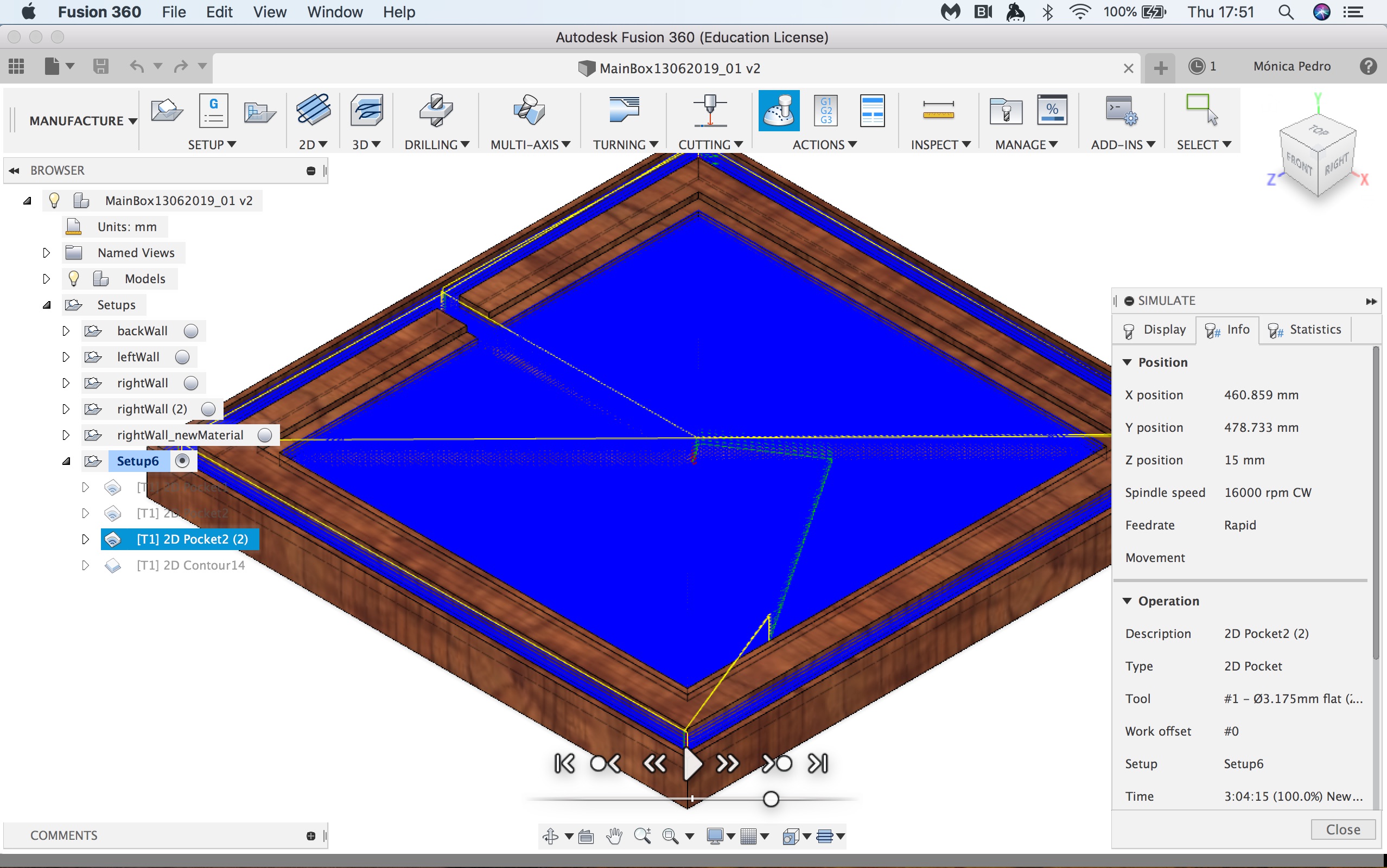

Them the main Pocket...

But it would take 5 houres and since the dust was nice and smooth, I STOPED the ongoig job in EASEL and created a new Job in Fusion360 with Higher FeedRate 3000, which reduce 2 houres the time

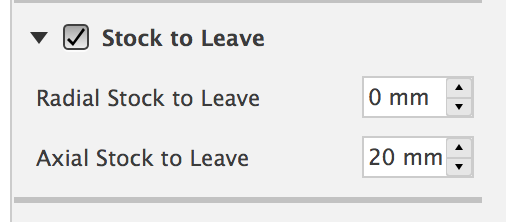

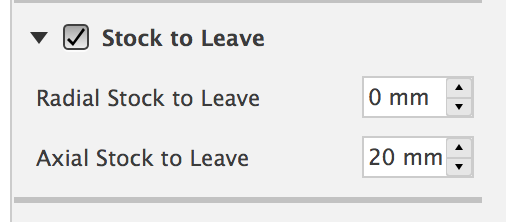

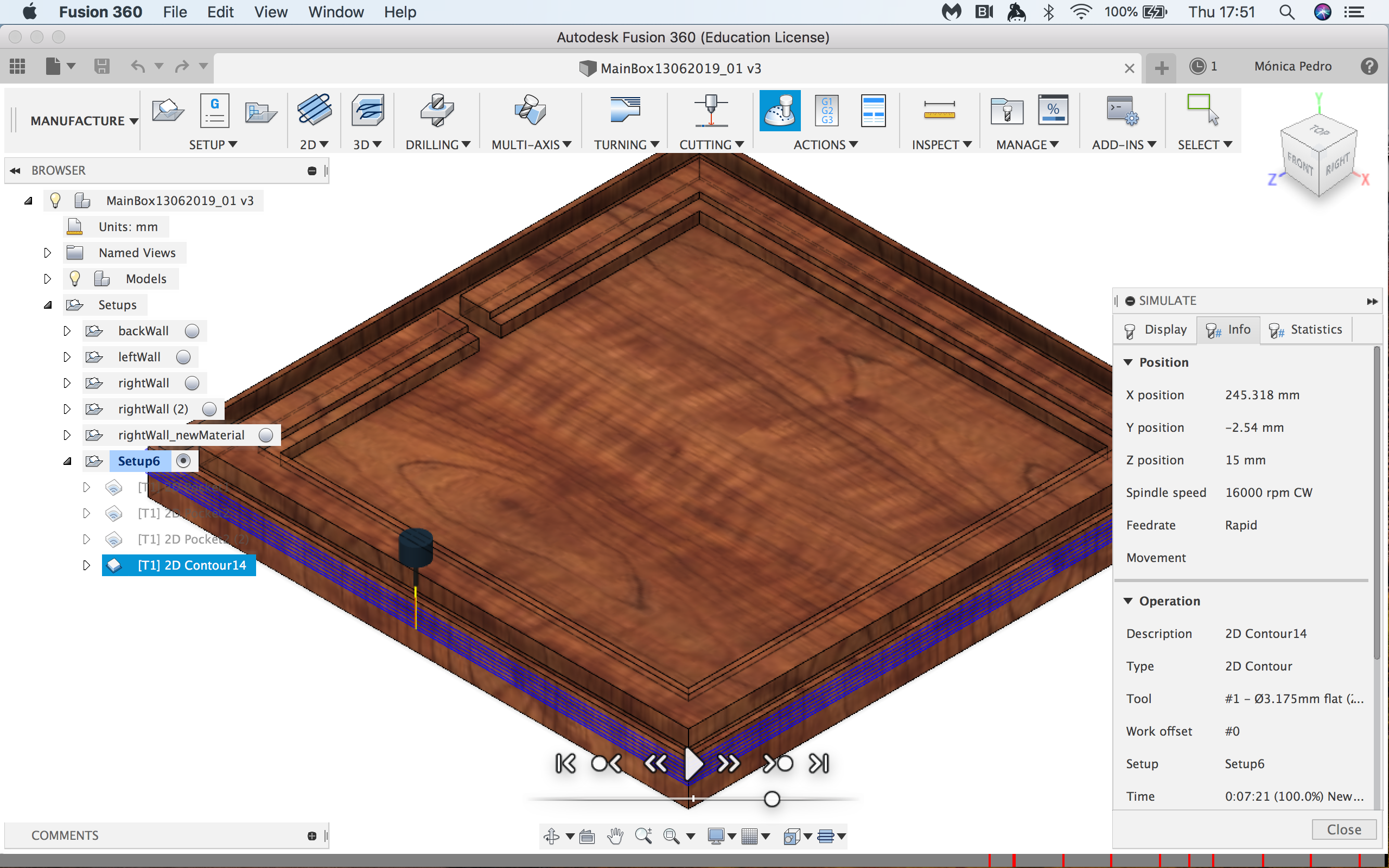

Them the Contour... but Since the just had a Bit of 3 cm long, decied to make a Contour with Stock To leave in AXial - 20mm ...

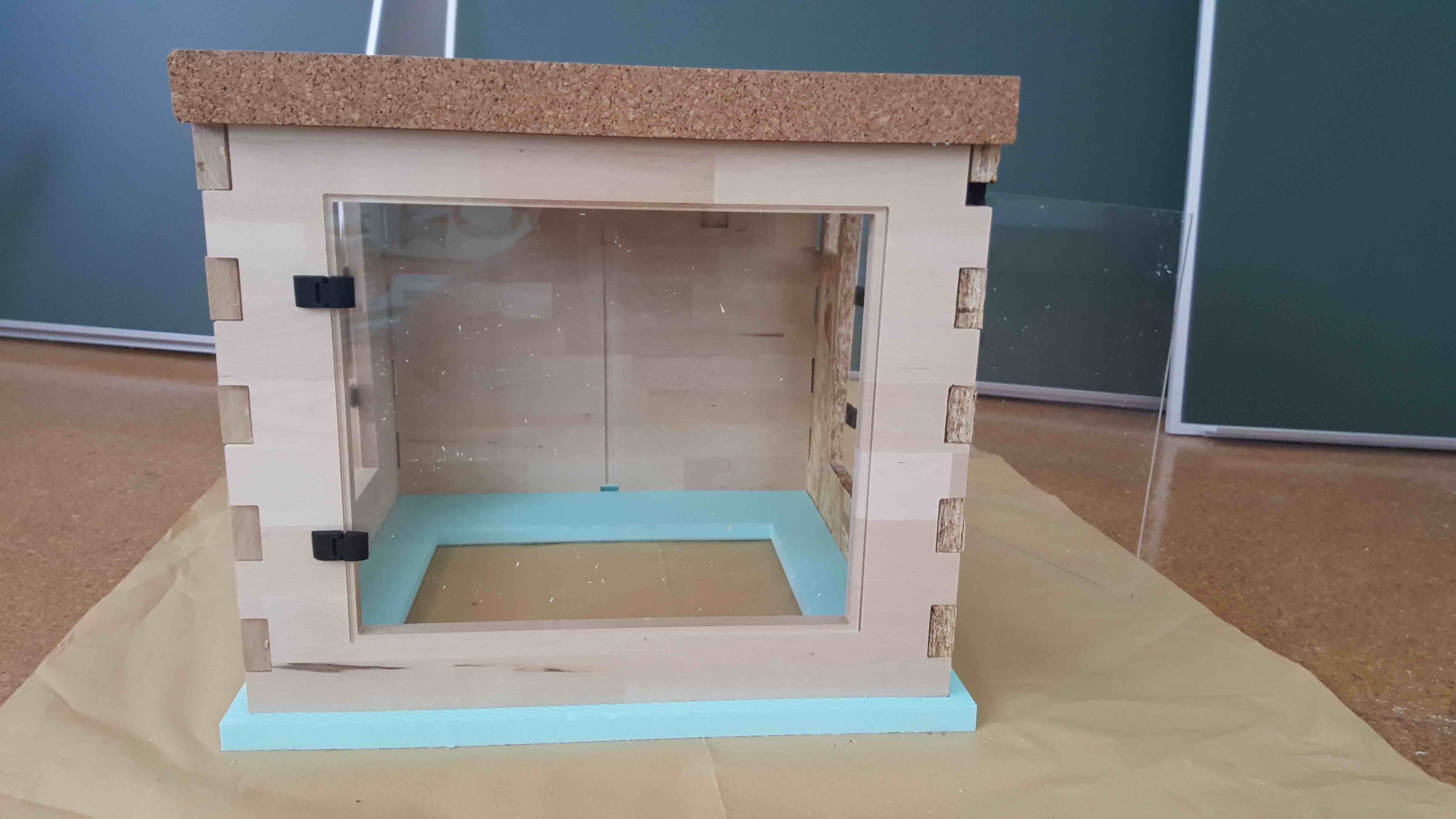

So went to assemble all this parts... and It fit very well

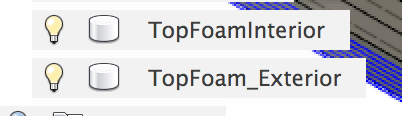

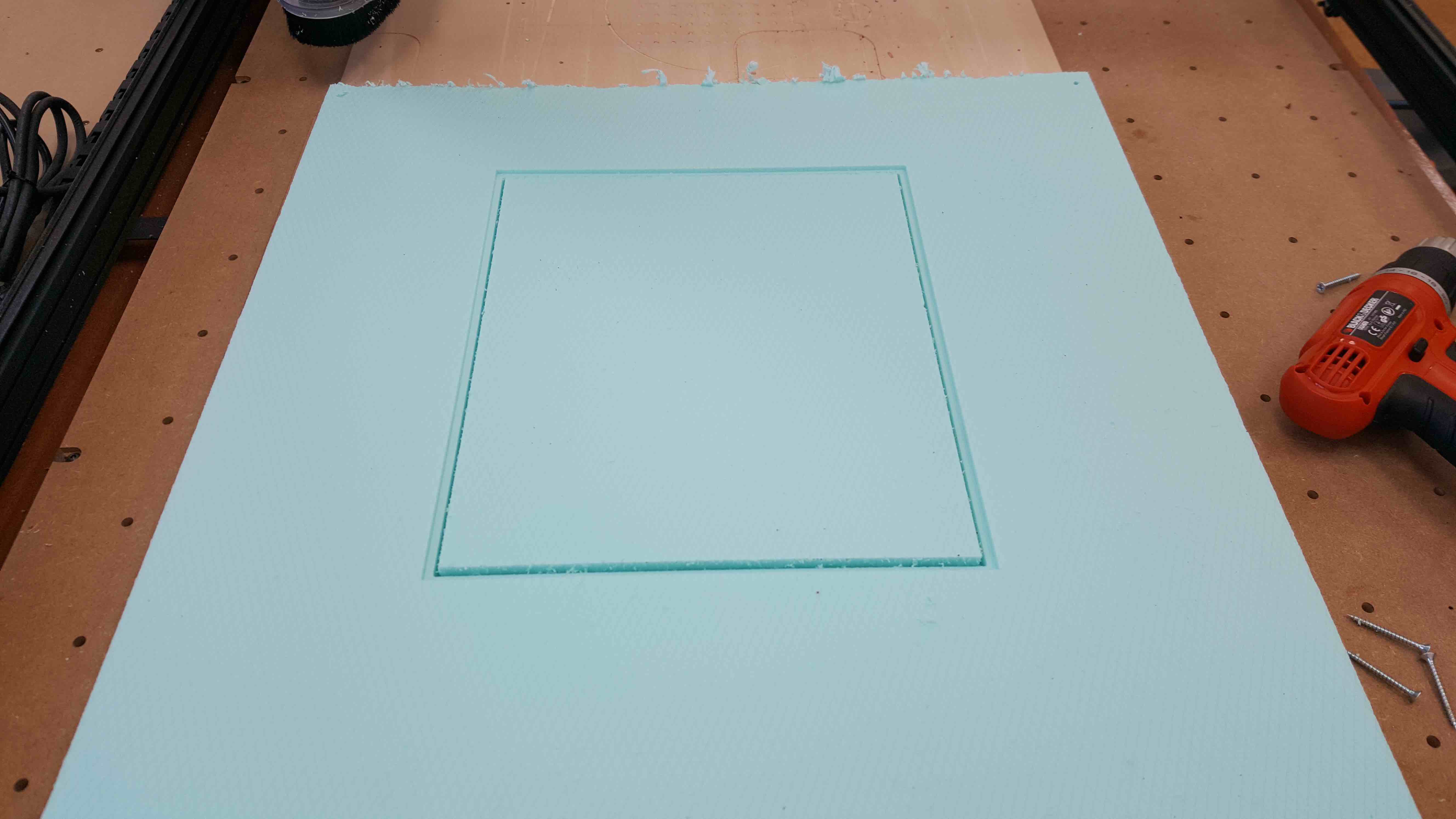

Now I need a top, but there's no more wood on the Lab.. .and I need to try the functionality of this box part...so I cuuted in Foam

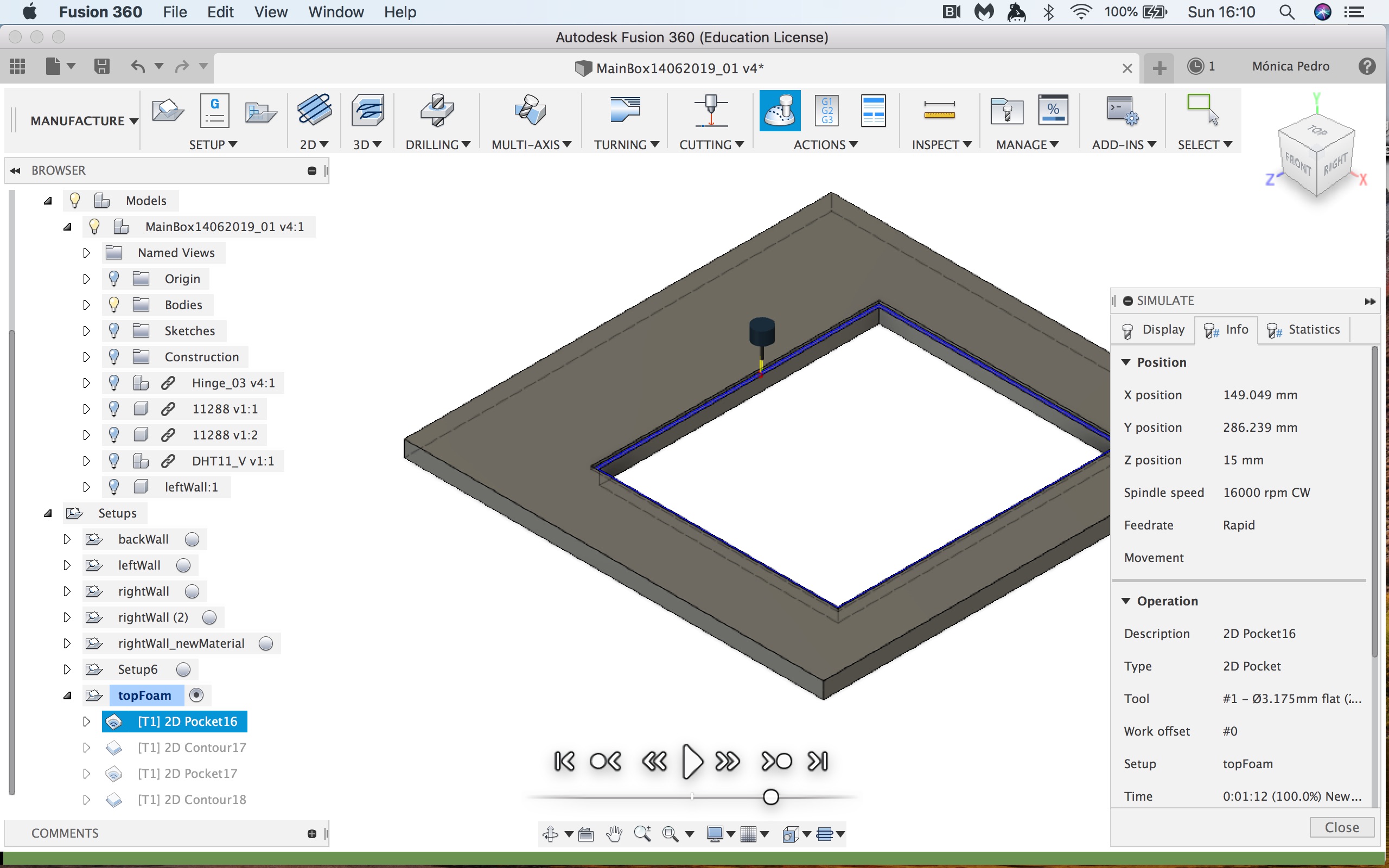

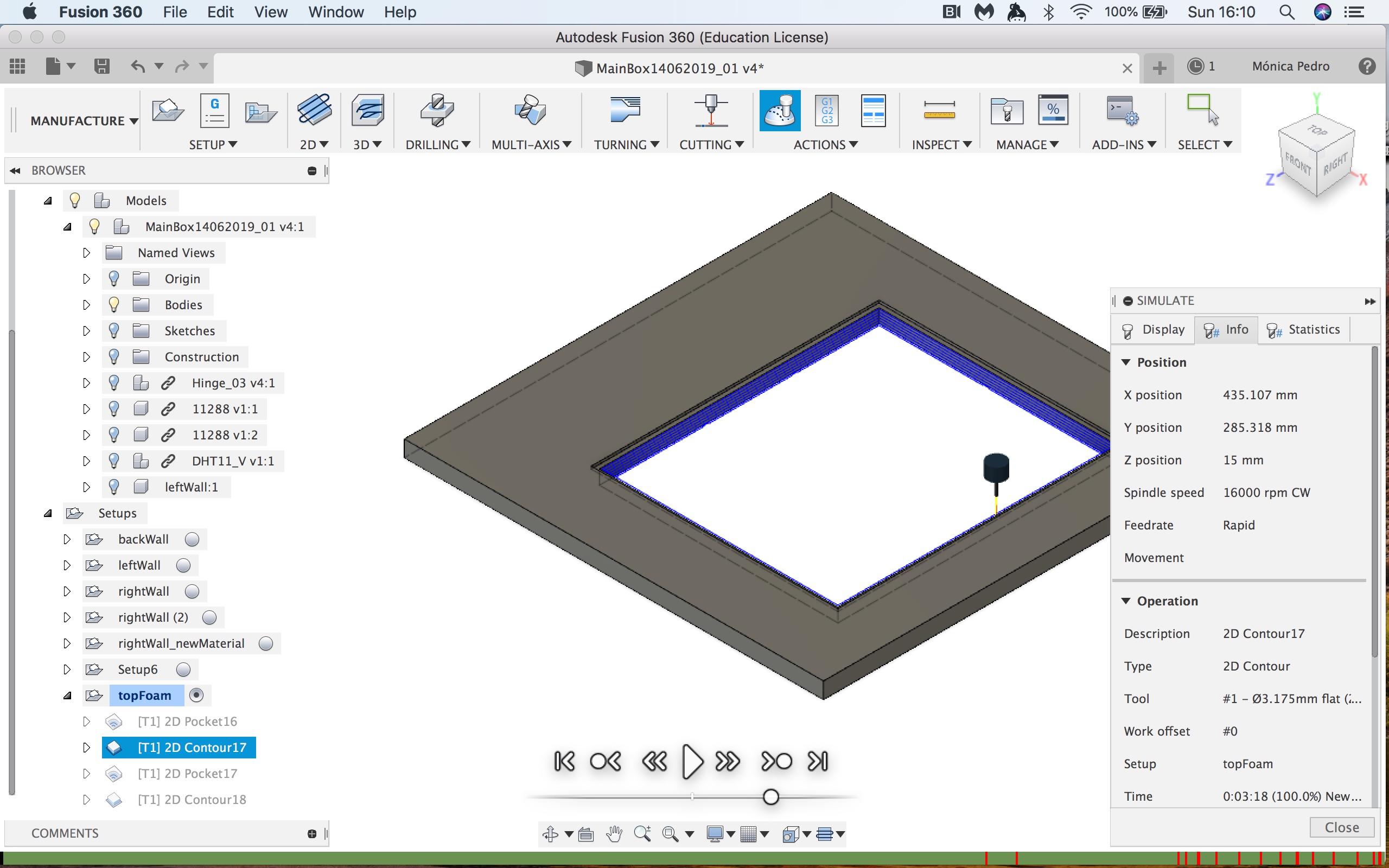

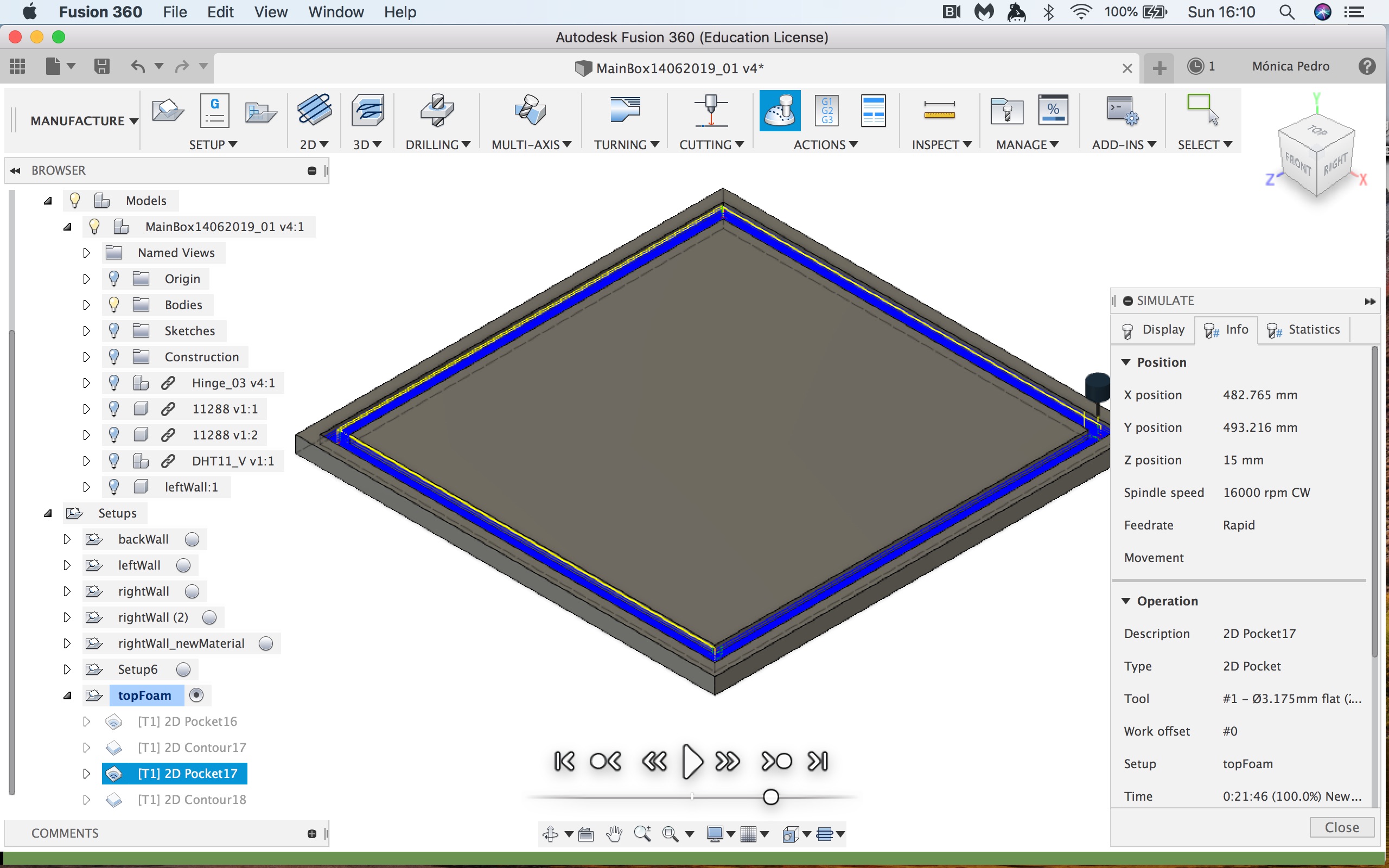

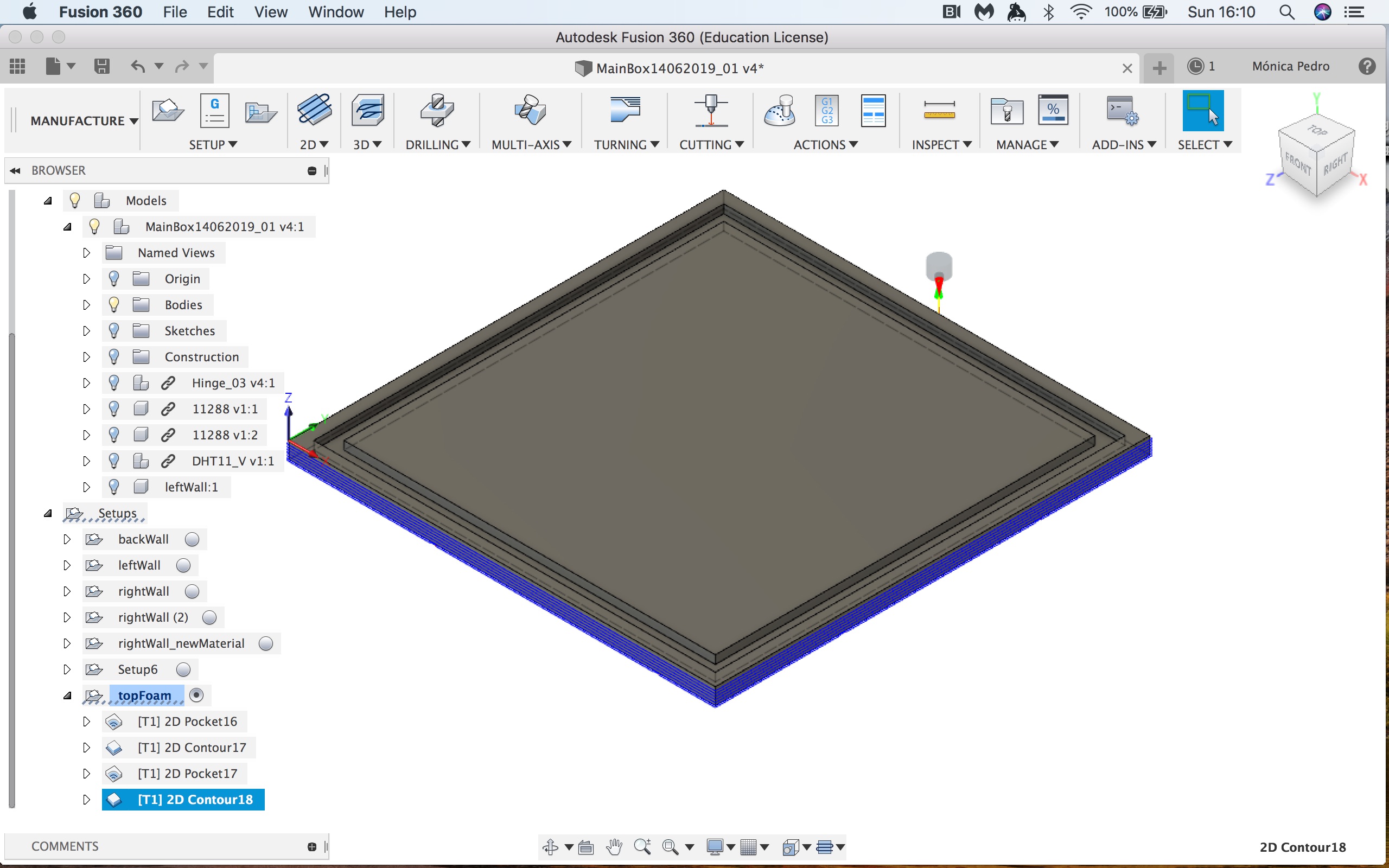

So in Fusion360 I made 2 bodies, one for the interior and another for the exterior so that I could use the Cutting in both sides of the same material...

which where useful to have 4 different CNC jobs...

which resulted in this

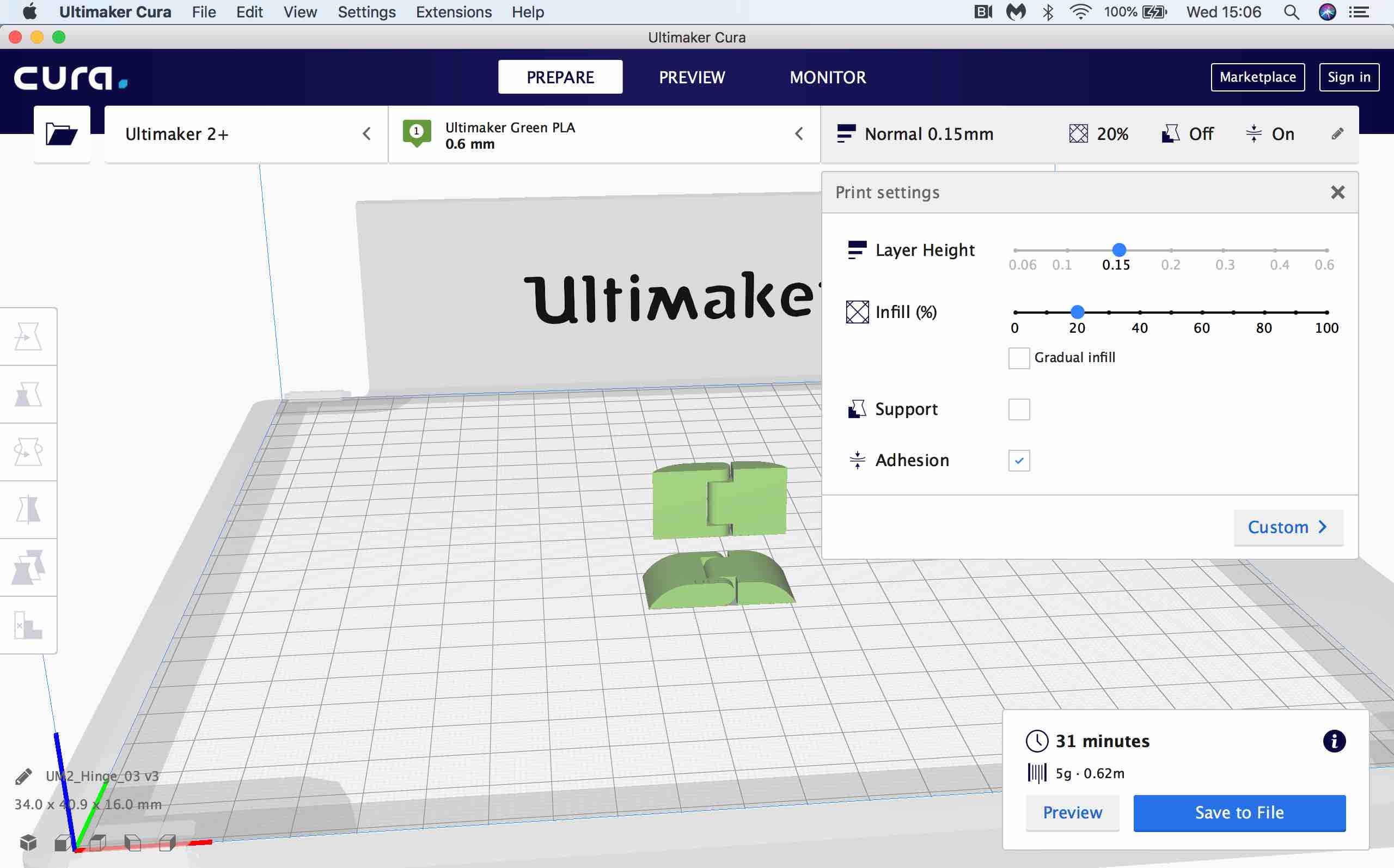

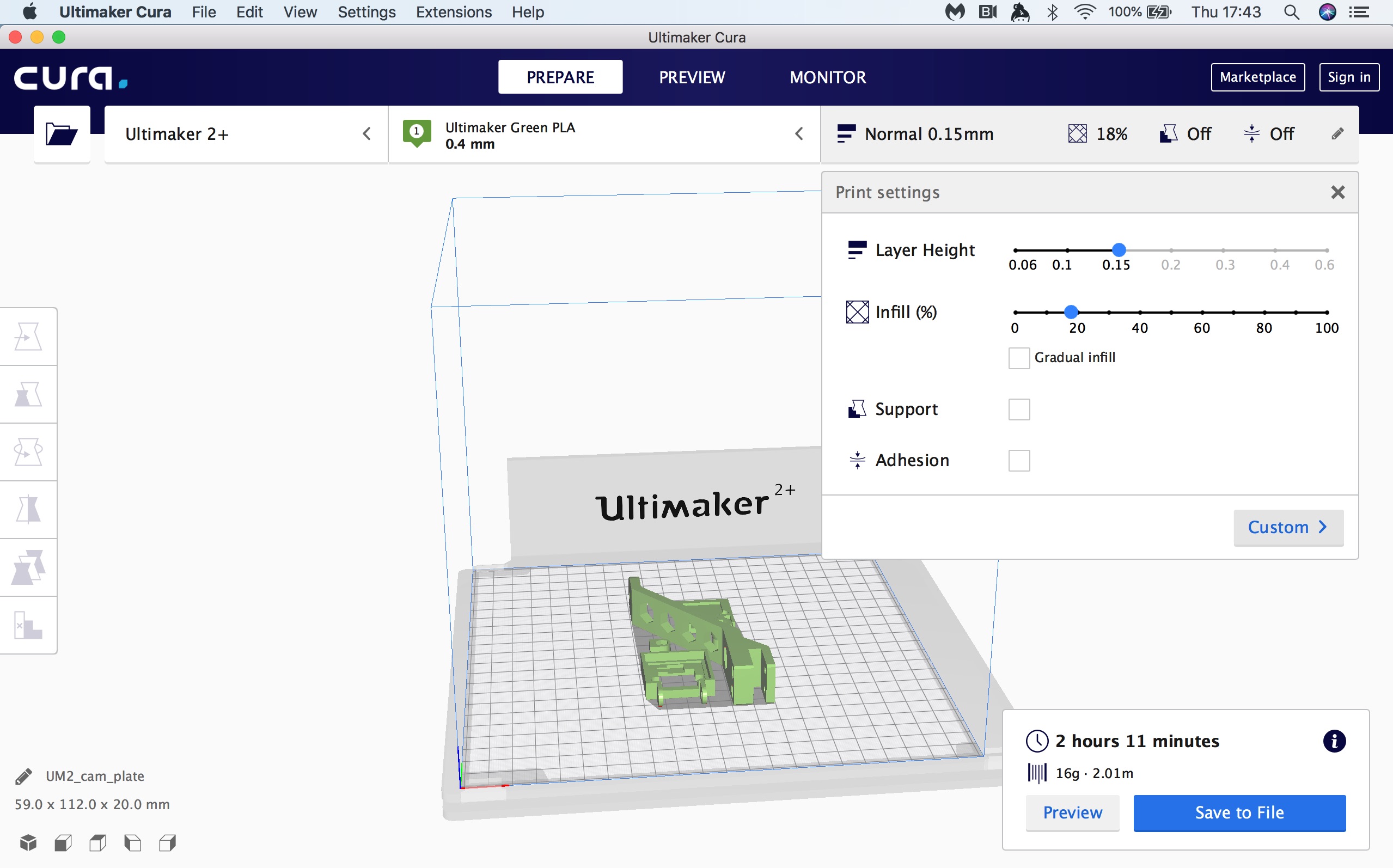

Exported the 3D model from Fusion to STL and through Cura generated the Gcode...

So tried two positions for the same model... and got this conclusion...

.... which is: It should be printed flat, since only this version works as hinge, the version printed top does not move...

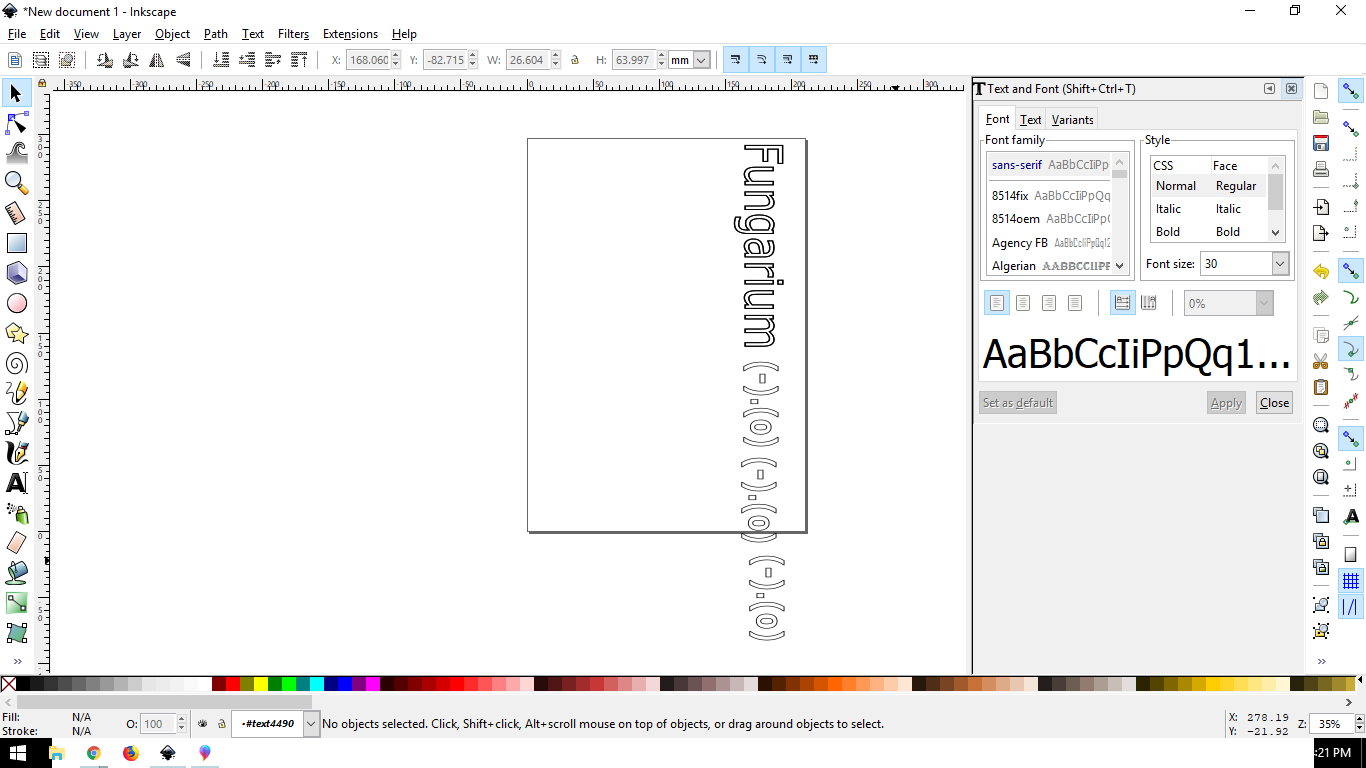

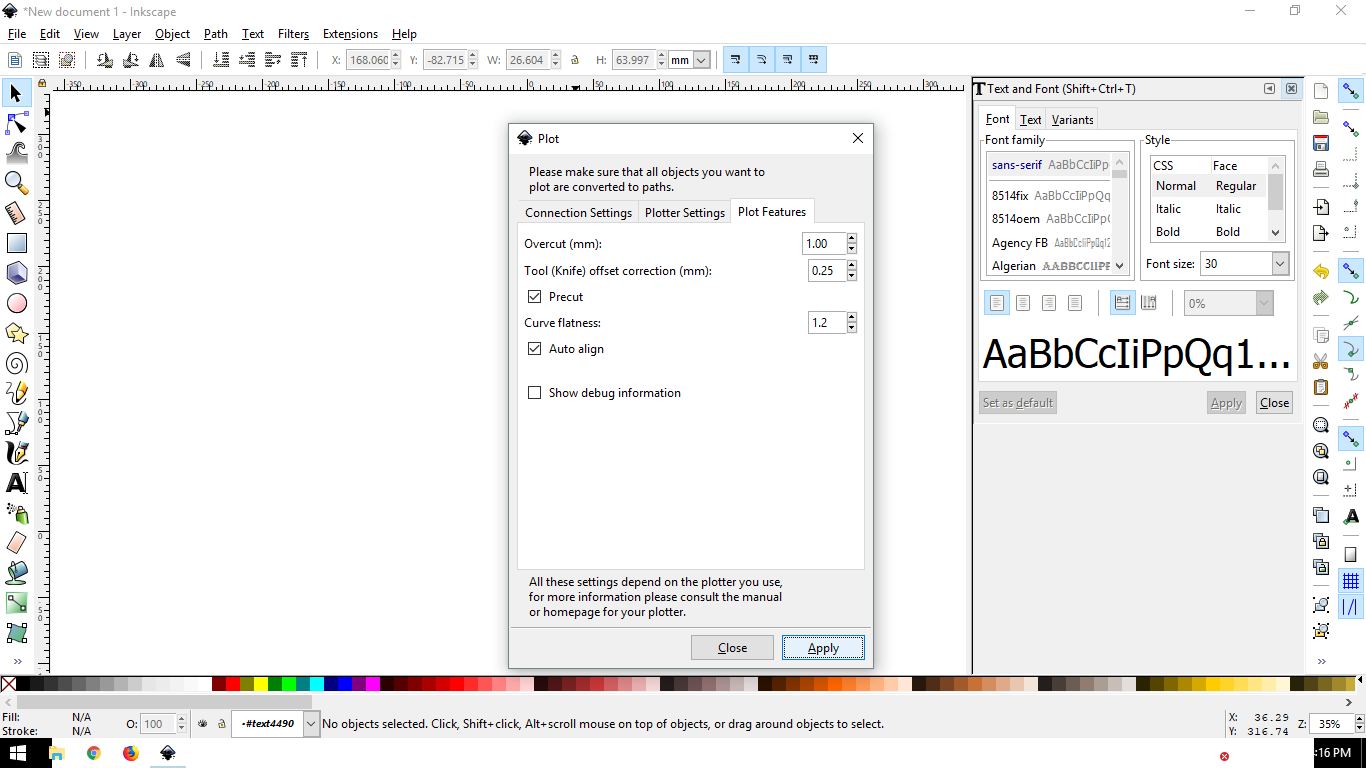

I'd design the Label in INKSAPE...

Extensions - Export - PLOT

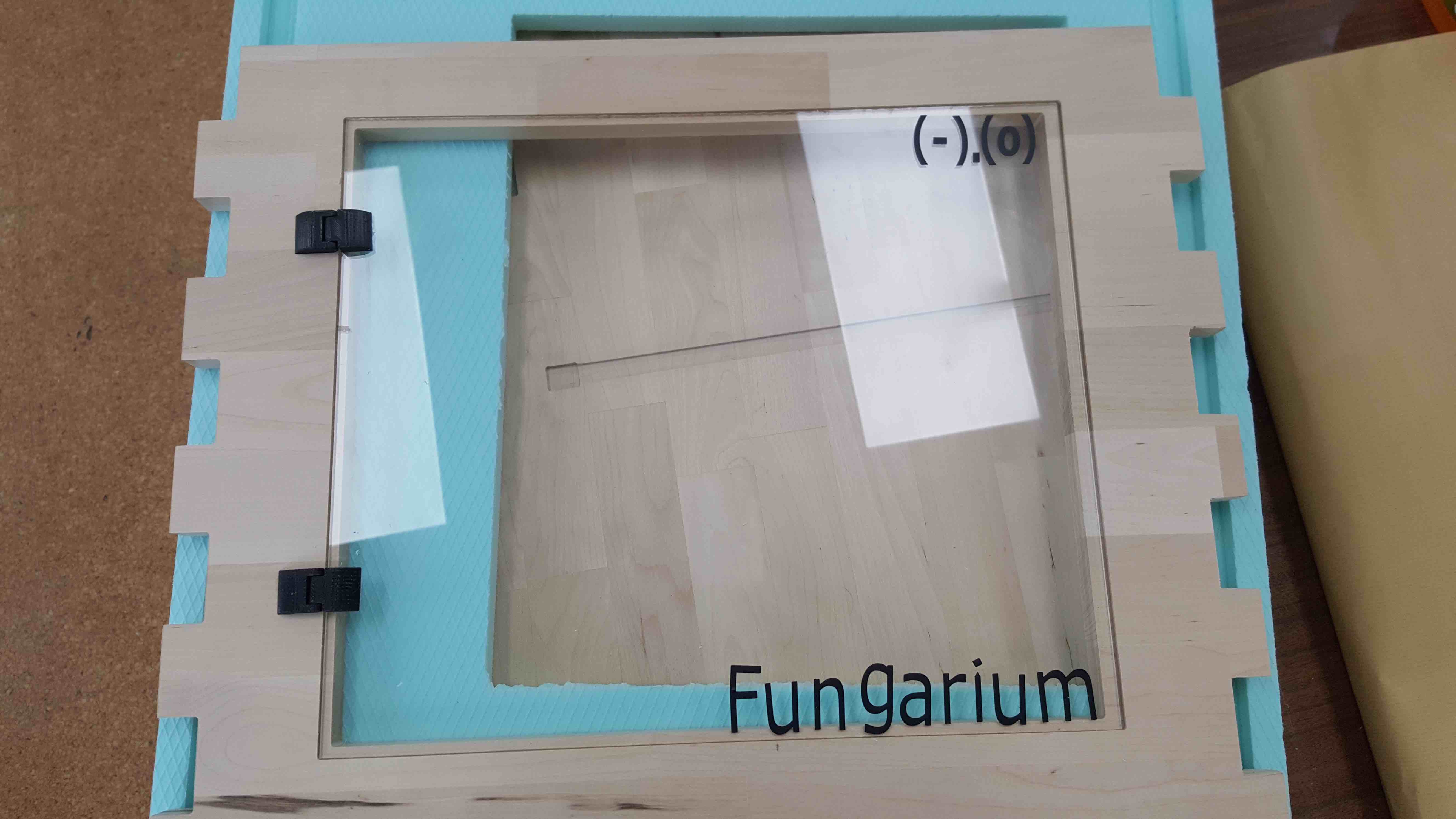

in the Ploter

Which I found in internet... Raspberry Pi camera mount for Prusa i3