Back to Mónica Pedro ←main page ←Assigments

individual assignment:

- design and 3D print an object (small, few cm3, limited by printer time)

that could not be made subtractively

- 3D scan an object (and optionally print it)

group assignment:

- test the design rules for your 3D printer(s)

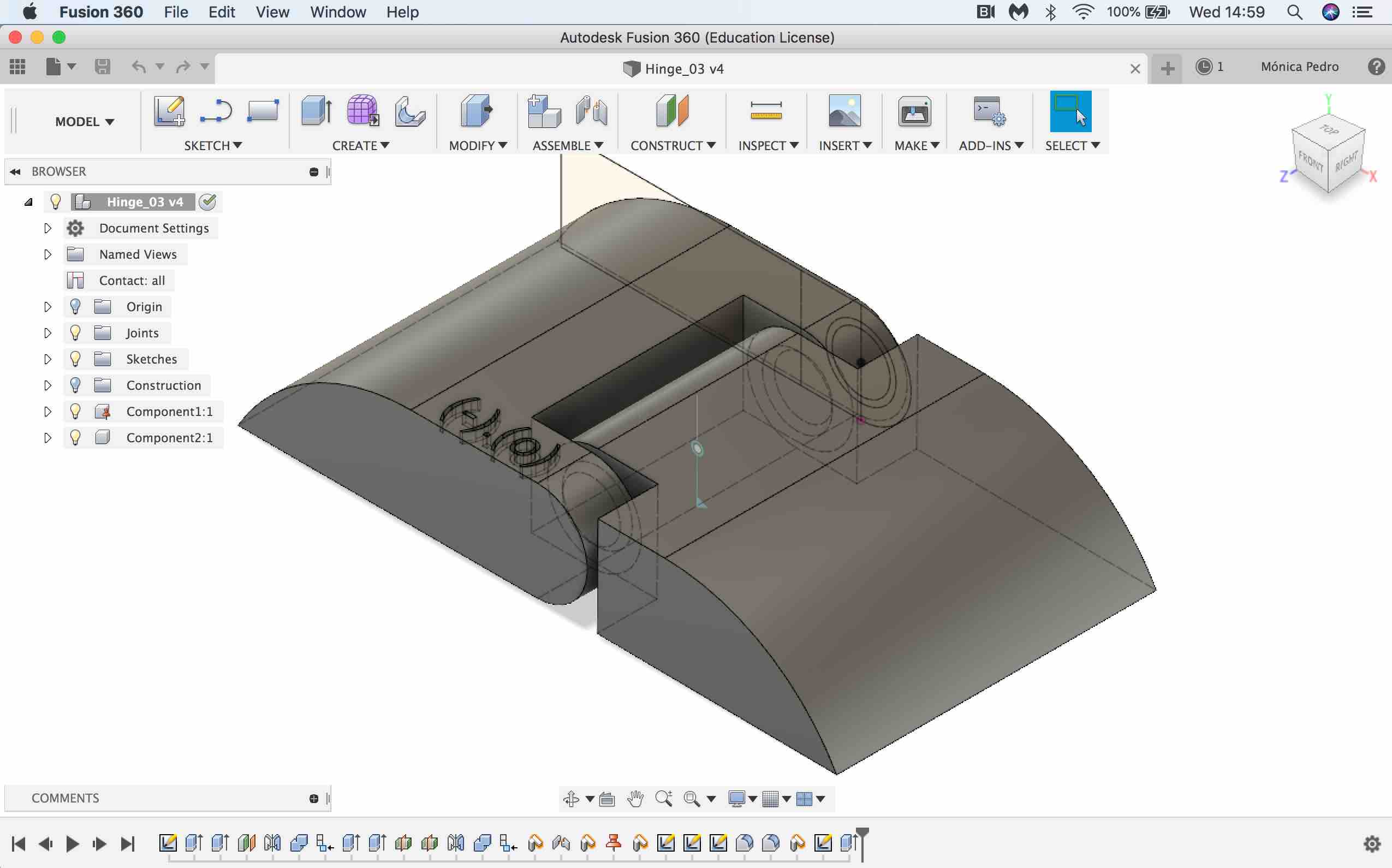

Fusion 360 model to download

Fusion 360 model to downloadthem I went to print it...

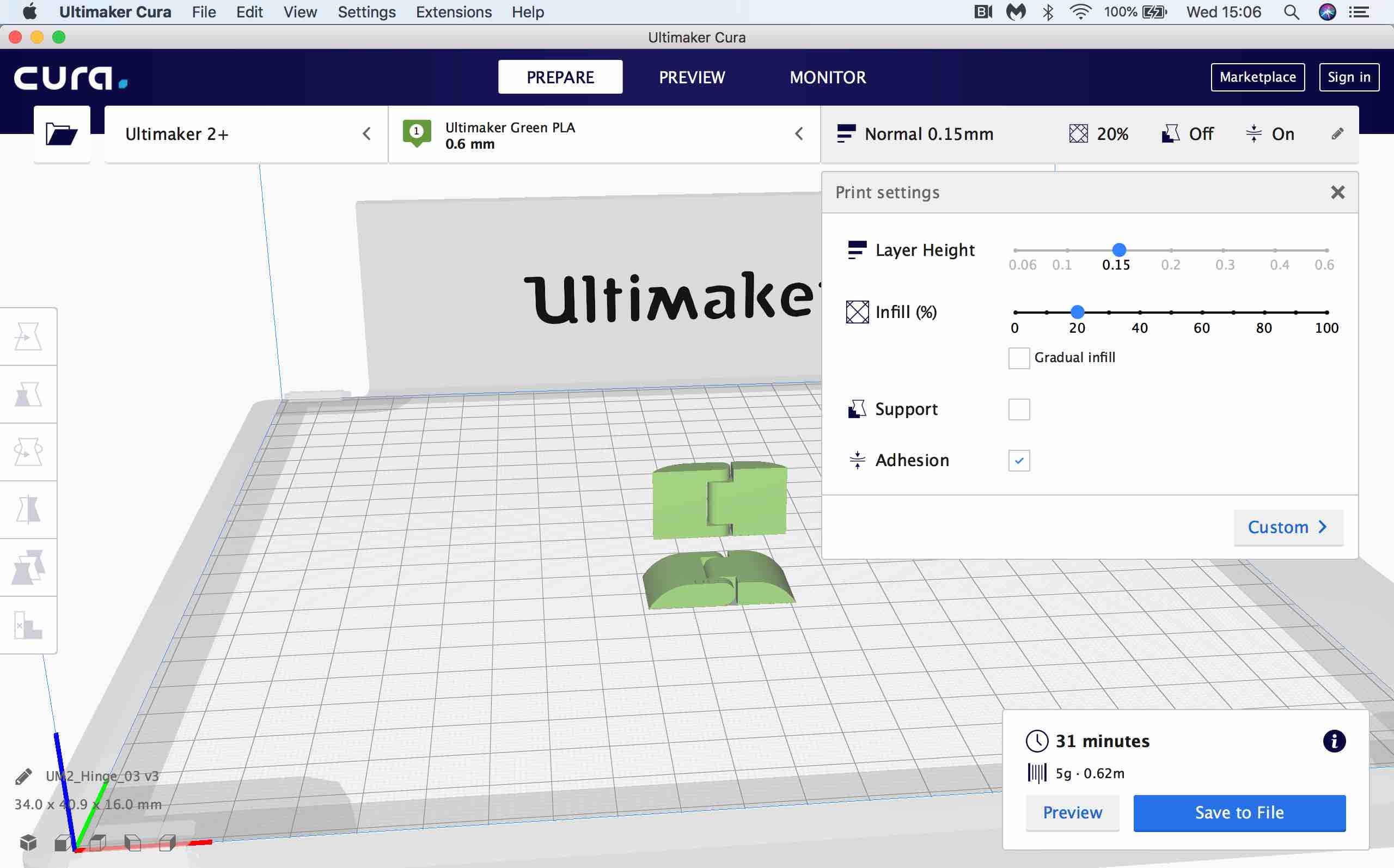

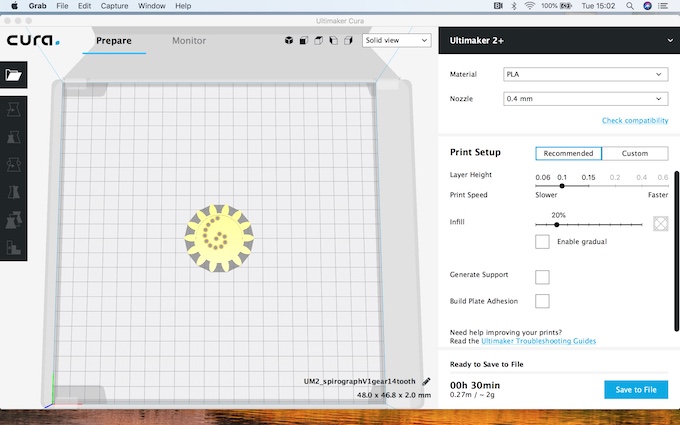

Exported the 3D model from Fusion to STL and through Cura generated the Gcode...

So tried two positions for the same model... and got this conclusion...

.... which is: It should be printed flat, since only this version works as hinge, the version printed top does not move...

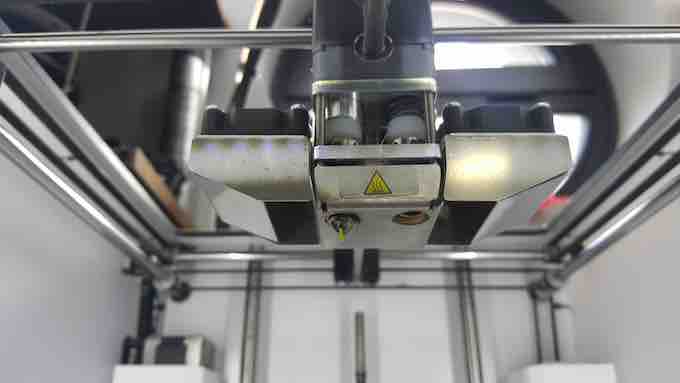

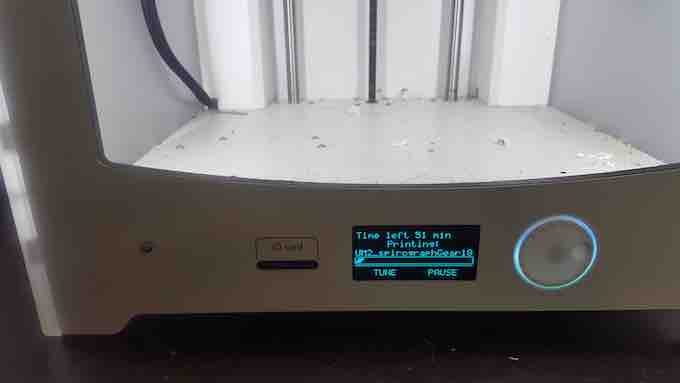

The Lab printer is a Ultimaker 2+

needed to instal Cura

and the process to print was:

and this are the first prints to know how to operate the machine

configuration for the first prints...

finaly some objects to play with Geometry...

---------------------------- (-).(o) -----------------------

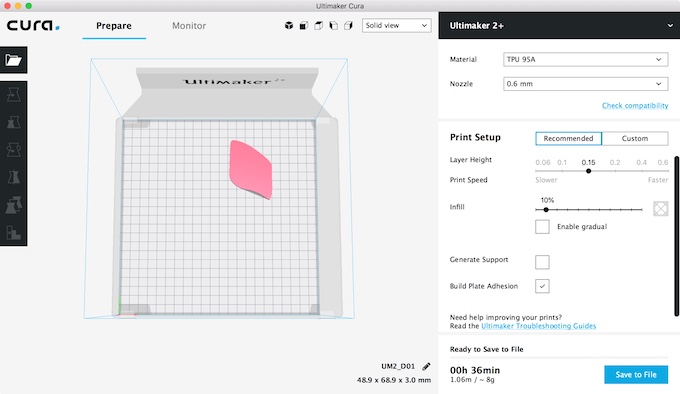

I'll try the Flexible Filamente using larger NOOZLE, to evaluate both the material and the viability of such product

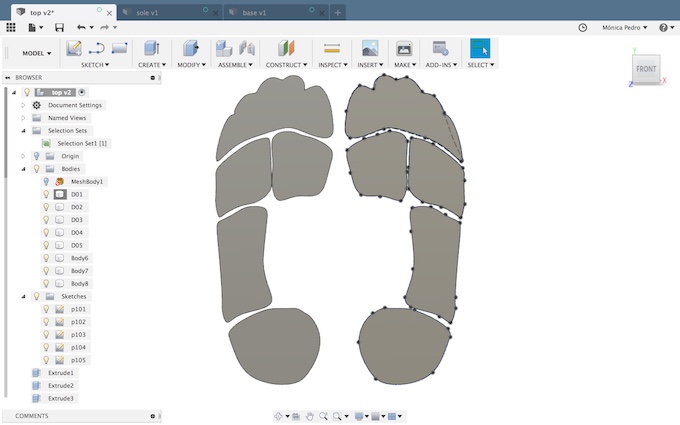

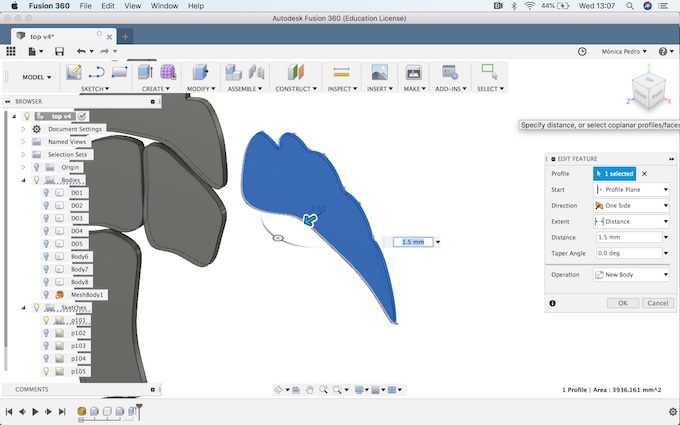

I'd decied to design a ergonomic modular sole so that the Printer tests would be quiker ;-)

Thikness of the sole: 3mm

steps:

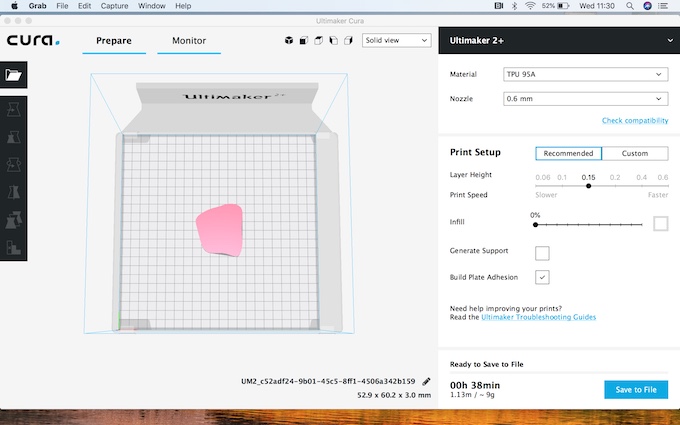

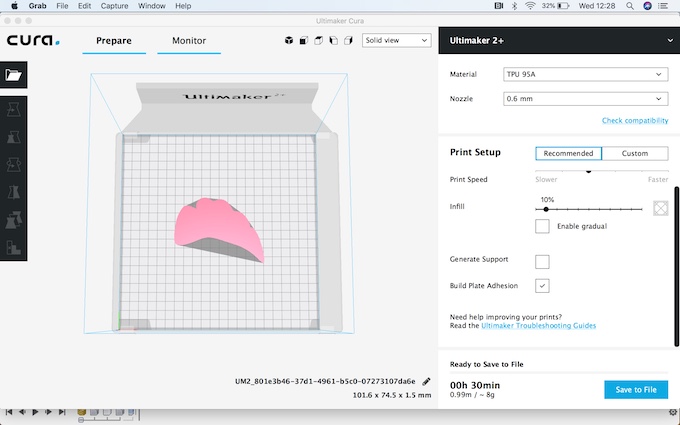

Configuring CURA for the new material

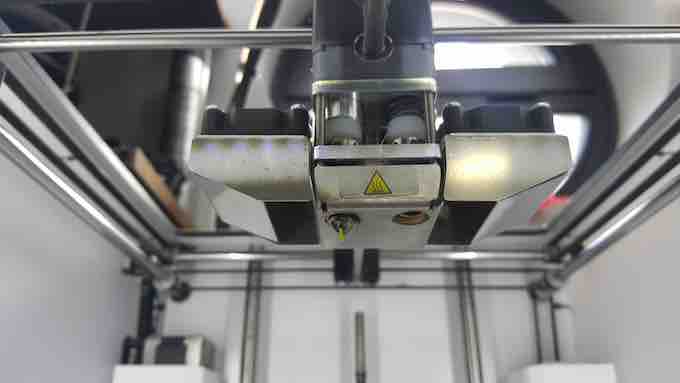

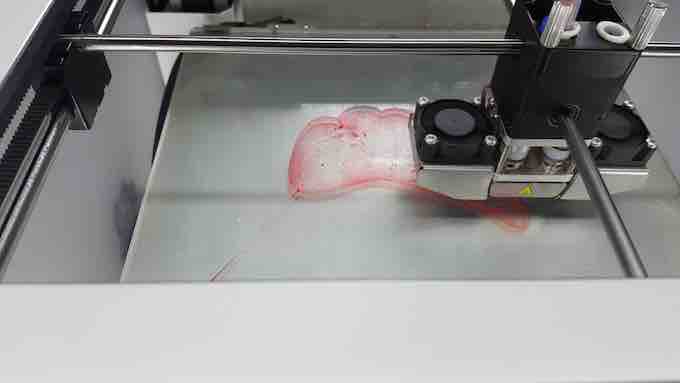

When printing.....

Final print... its not very bad, but NOT GOOD for the purpose...because it's not flexible and soft enought to give a "no Shoo sense"

I'll try a print without Infil...INFILL = 0

and the Printing becomes quite strange....

Look fuzy... but it has its qualities.. flexible... soft

I'll try with lower thikness of the sole...EXTRUDE = 1.5mm

sent it to Cura

and then this was happening in the printer

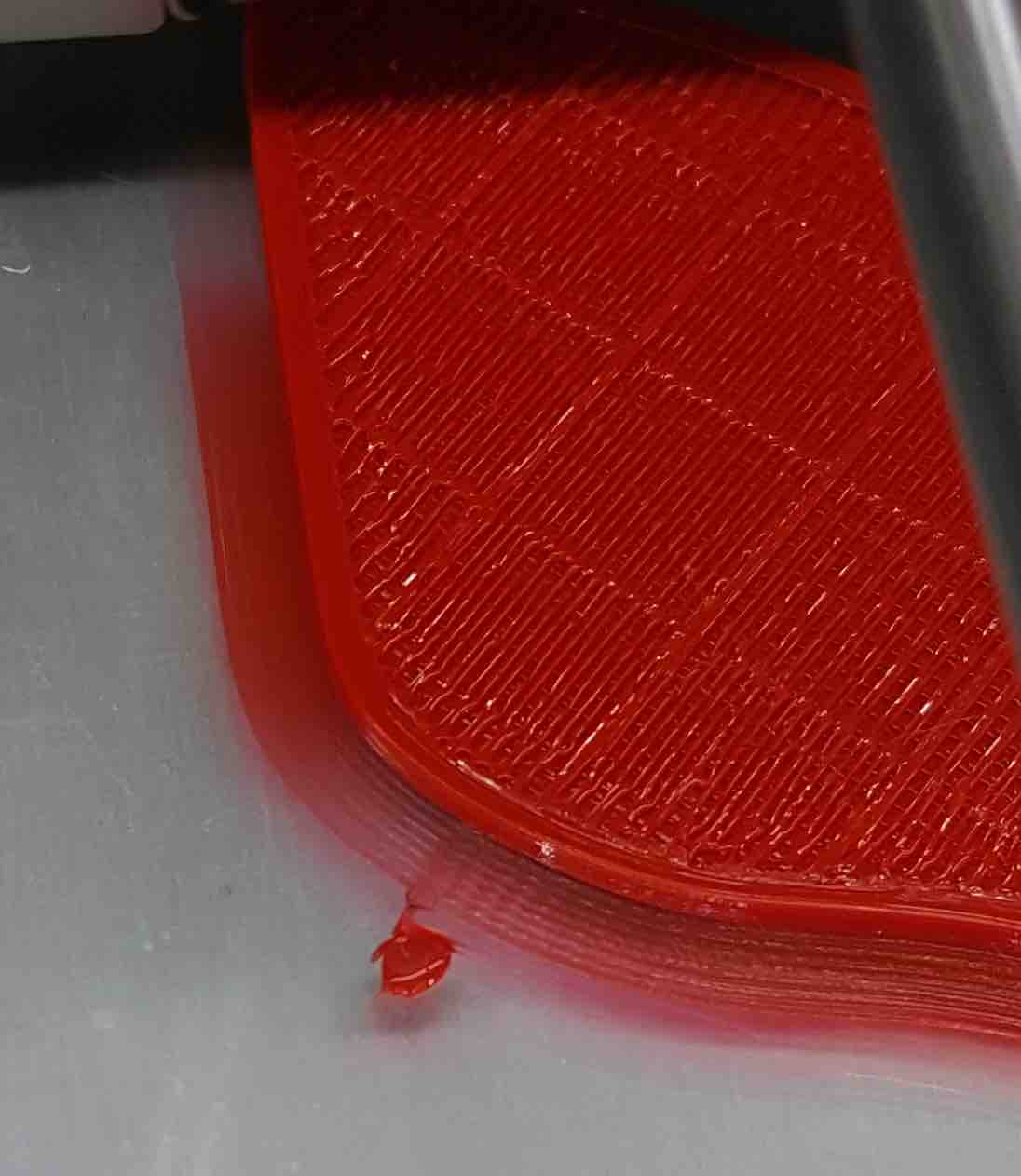

the BAD RESULT

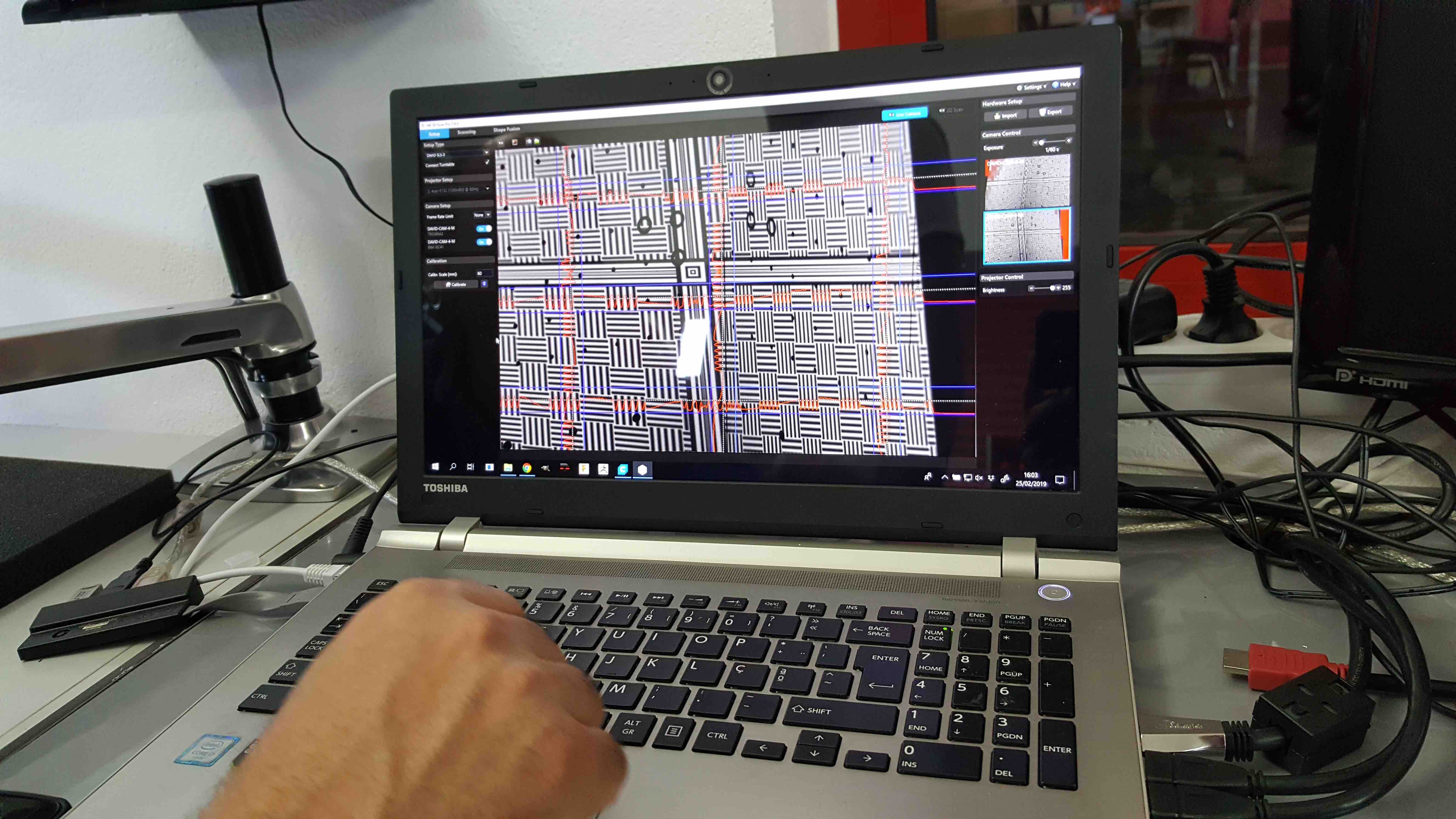

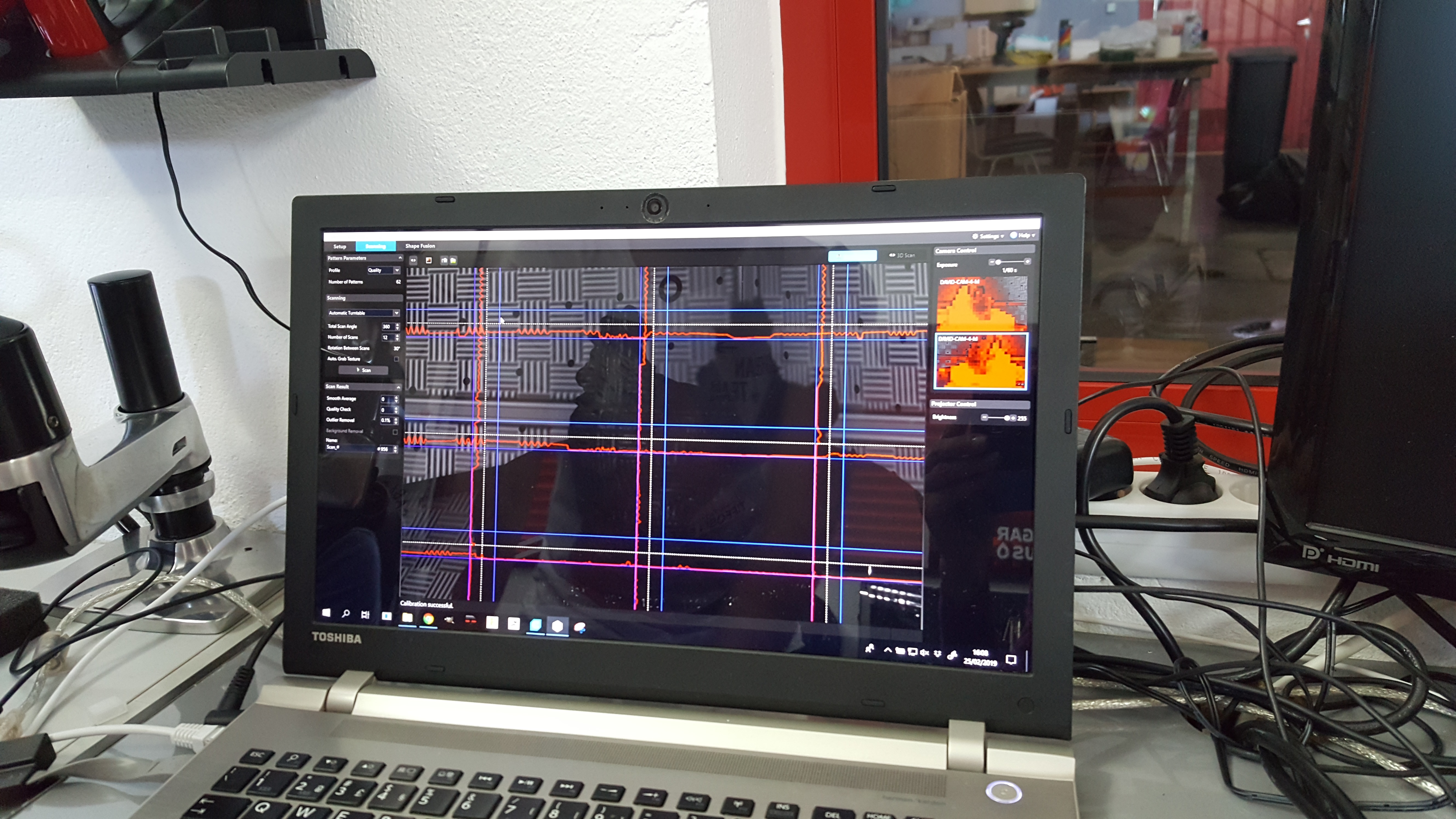

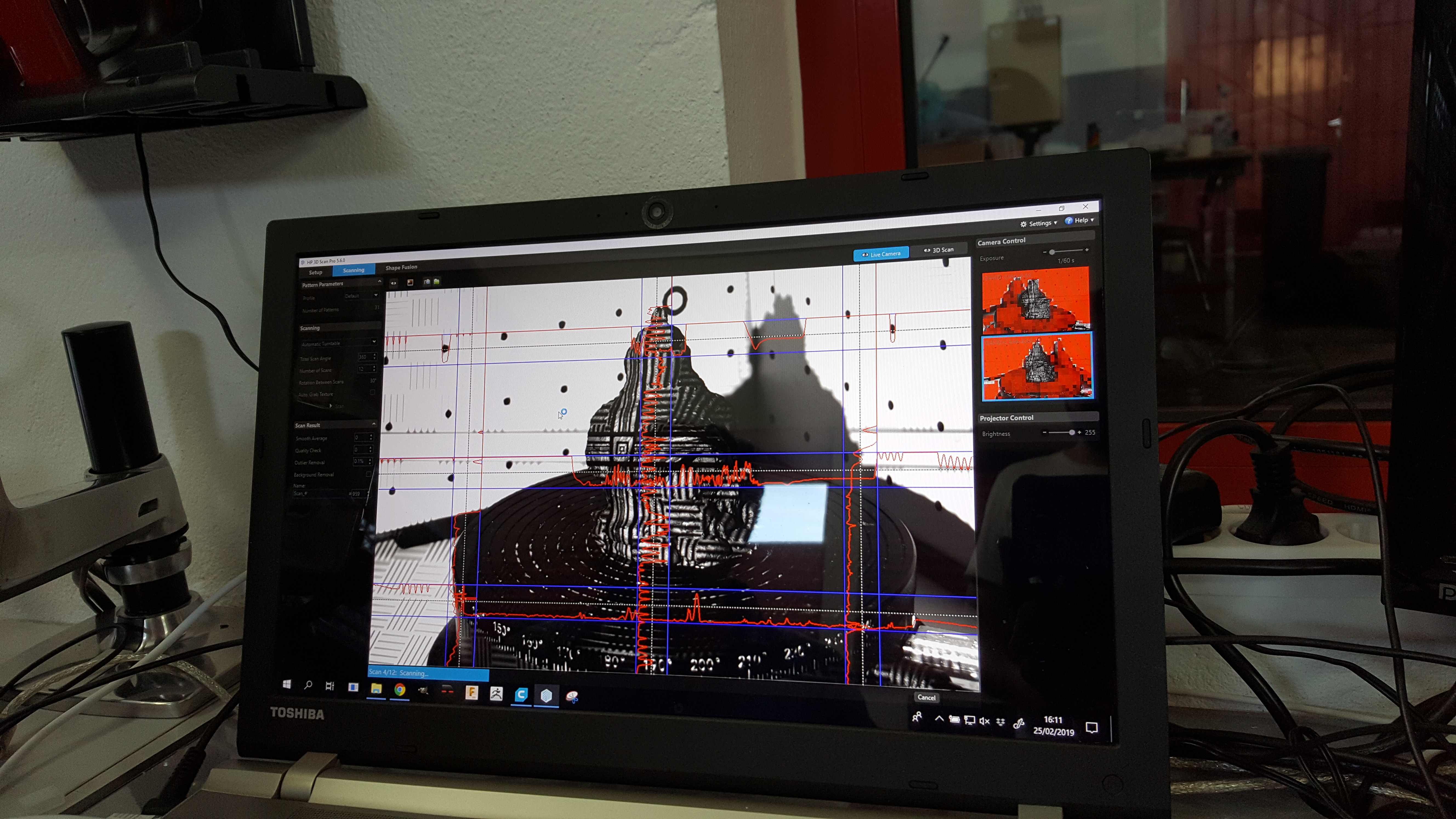

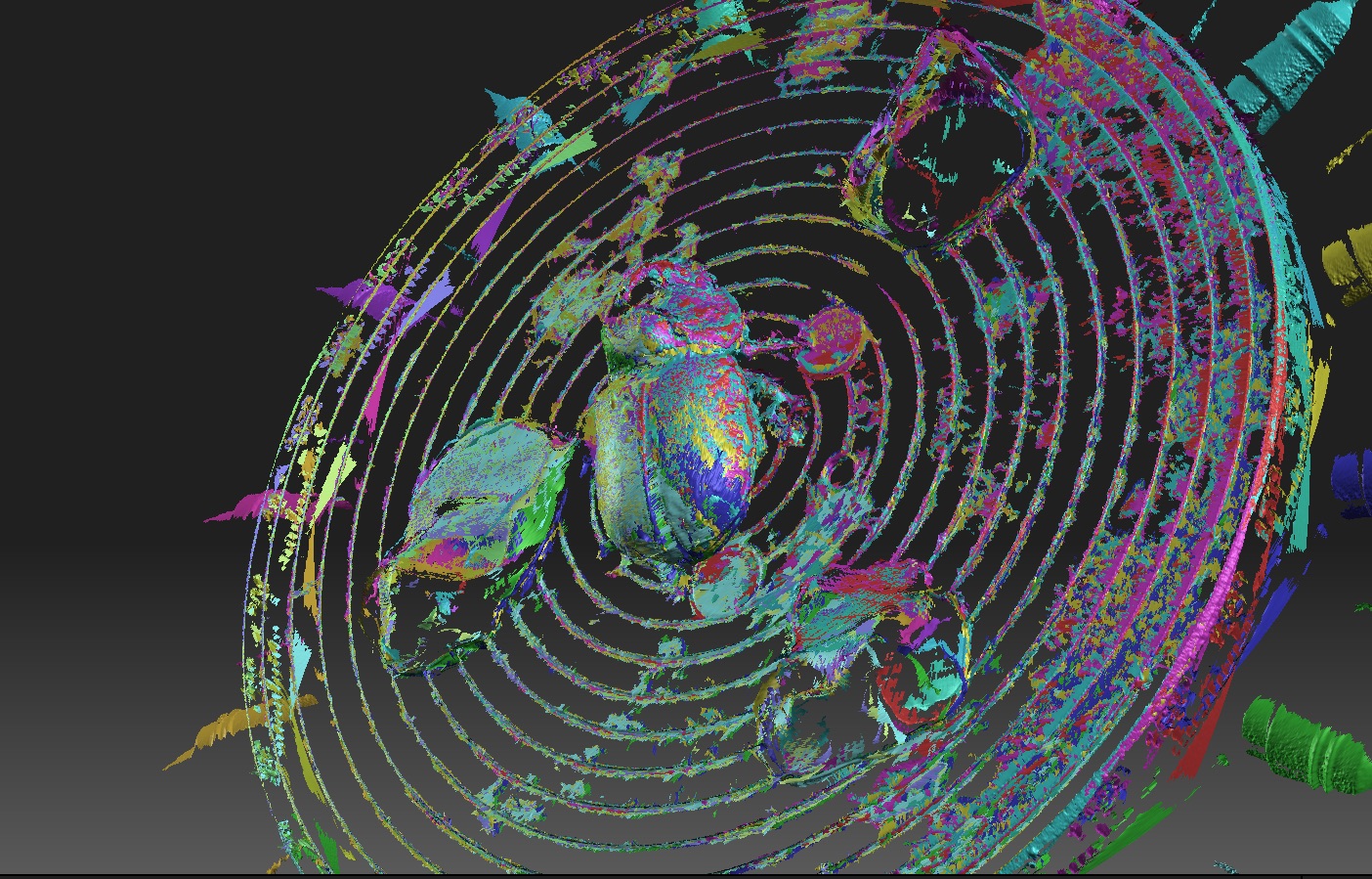

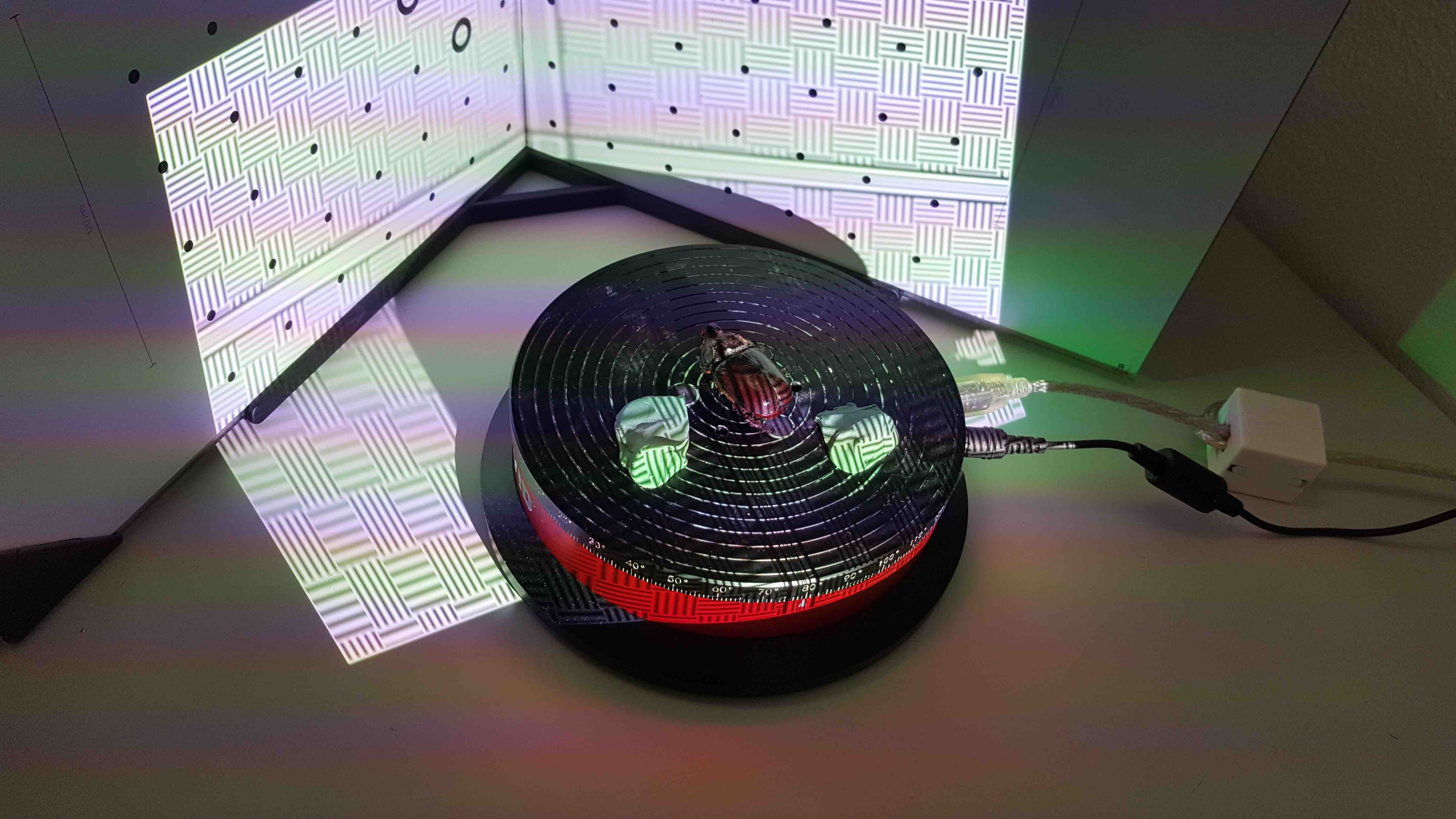

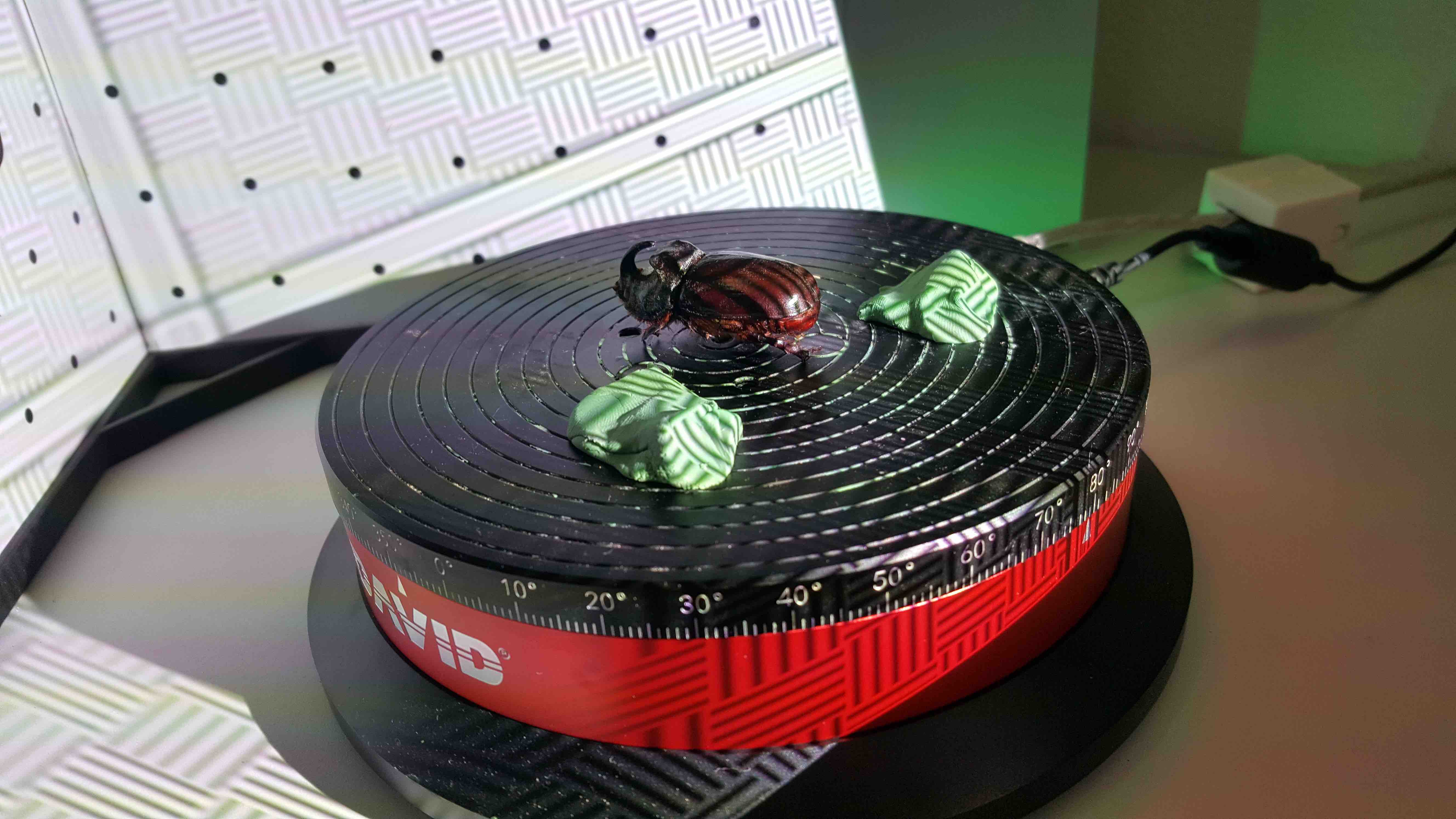

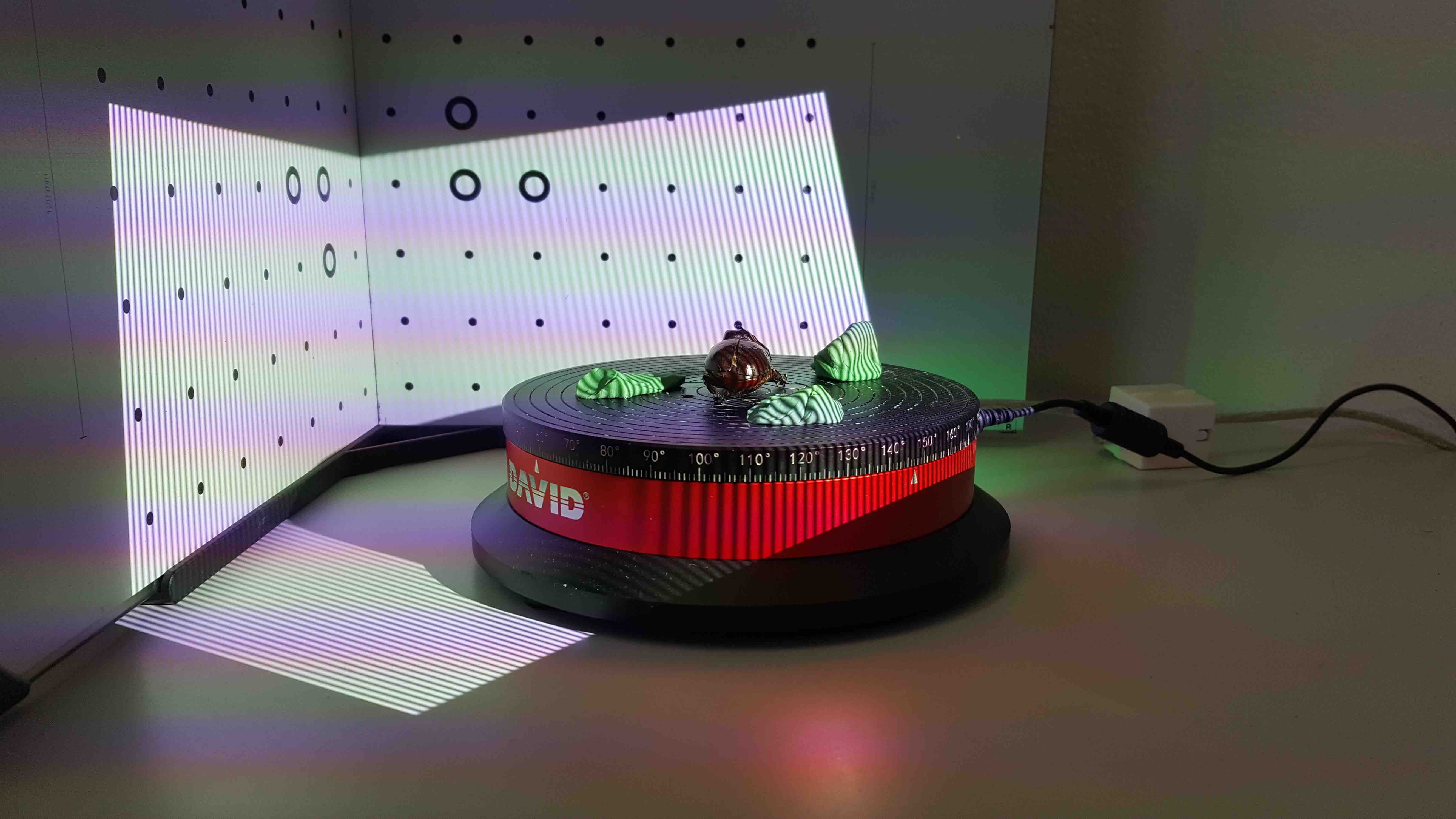

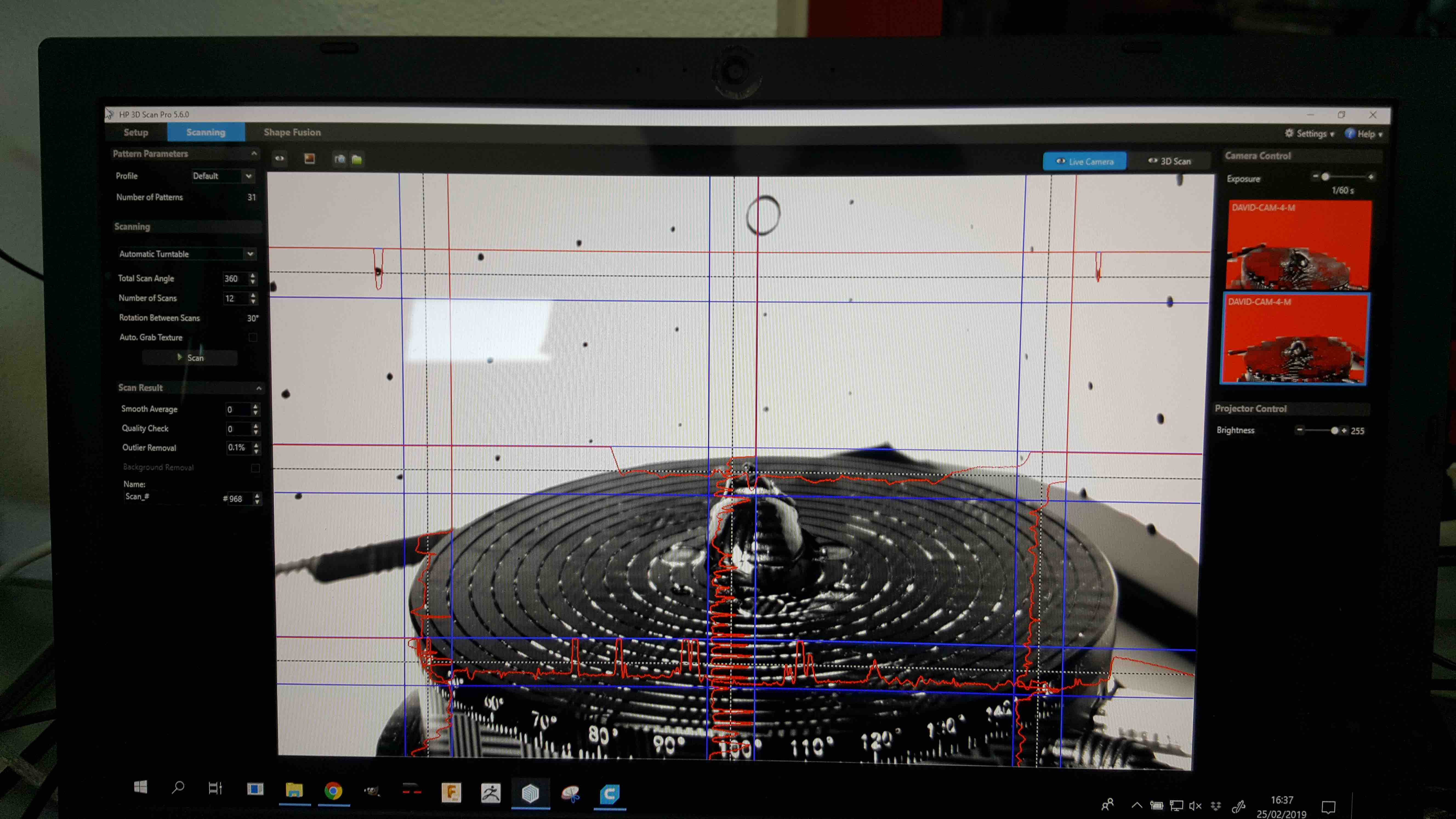

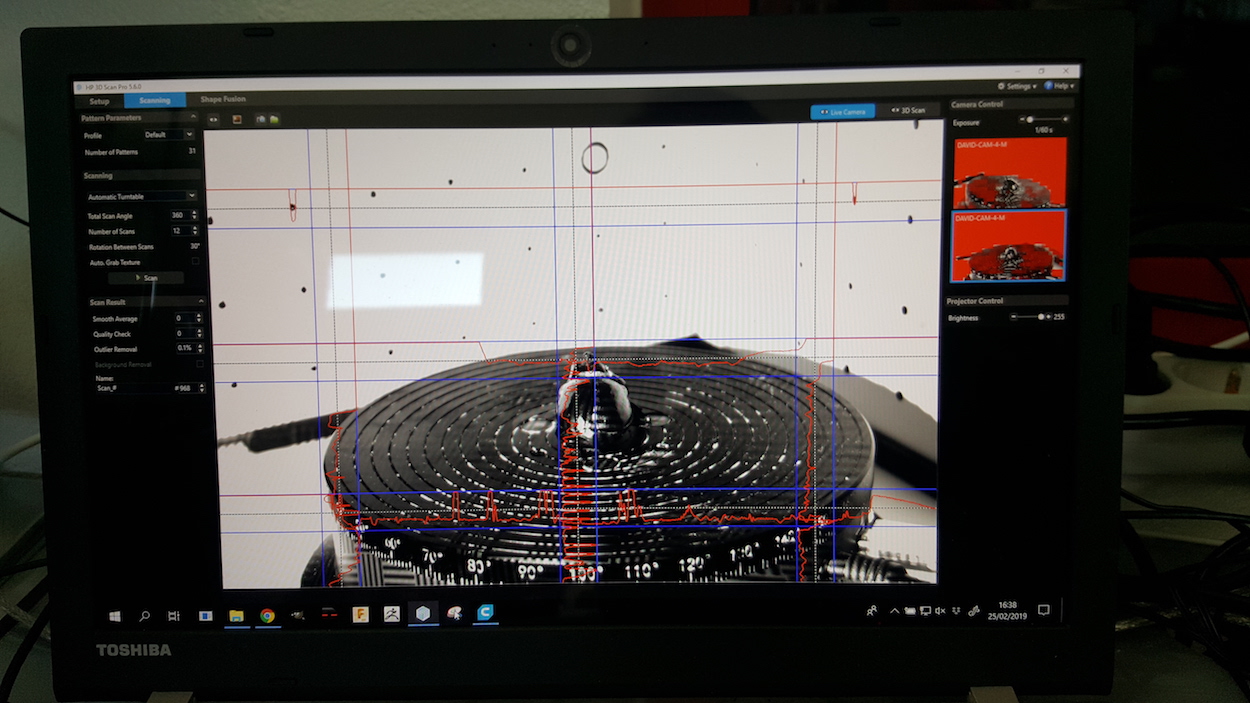

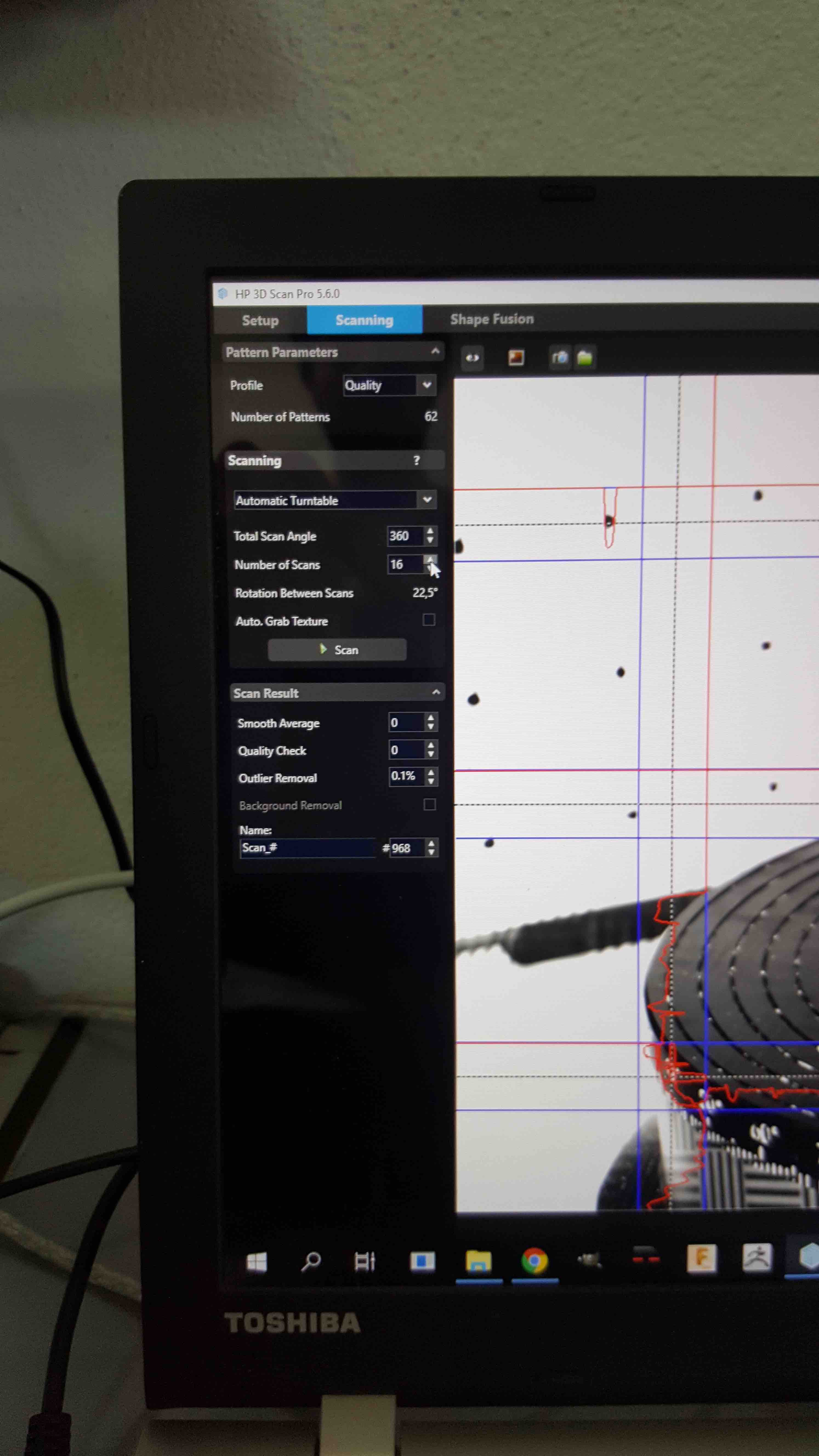

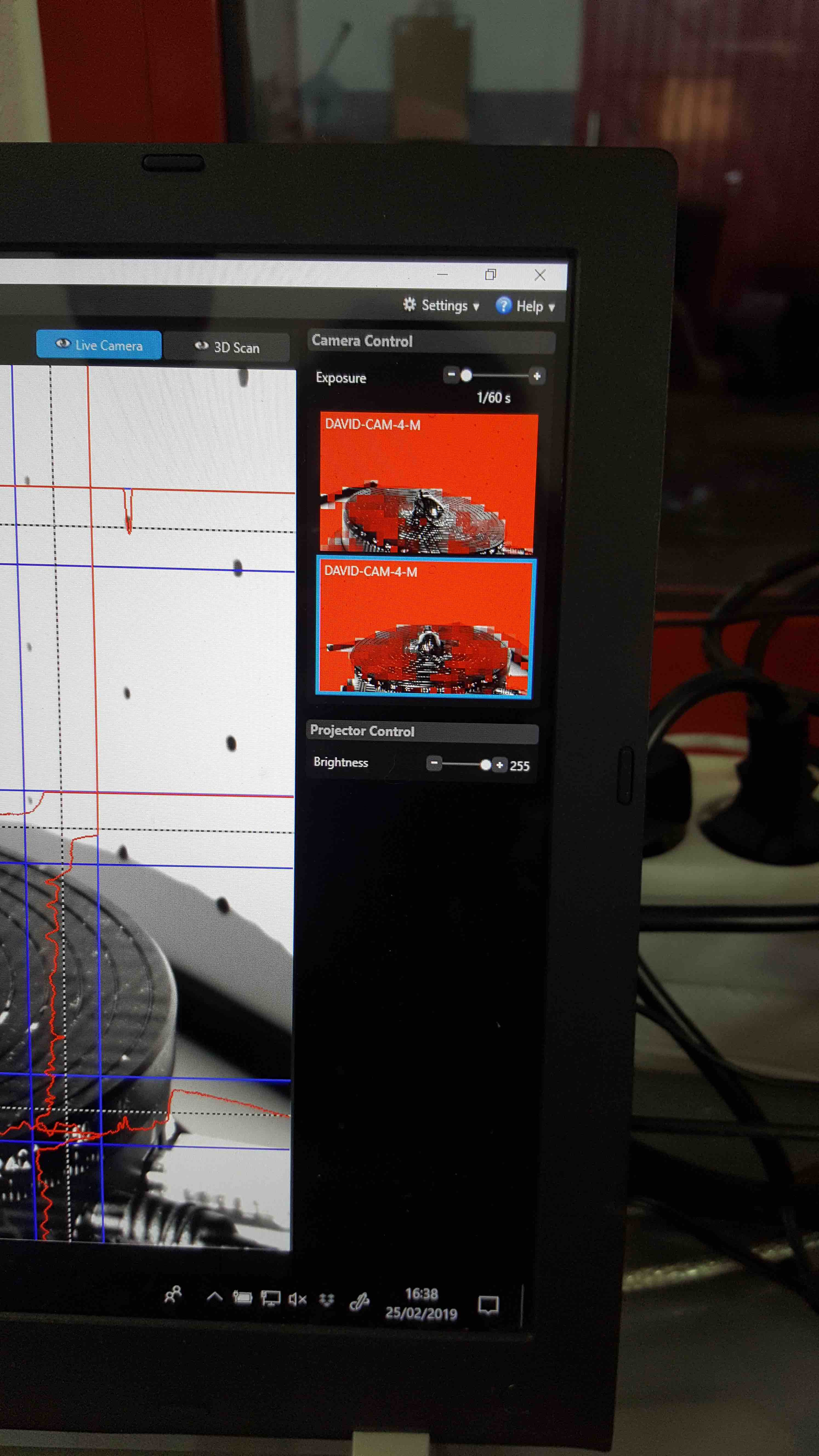

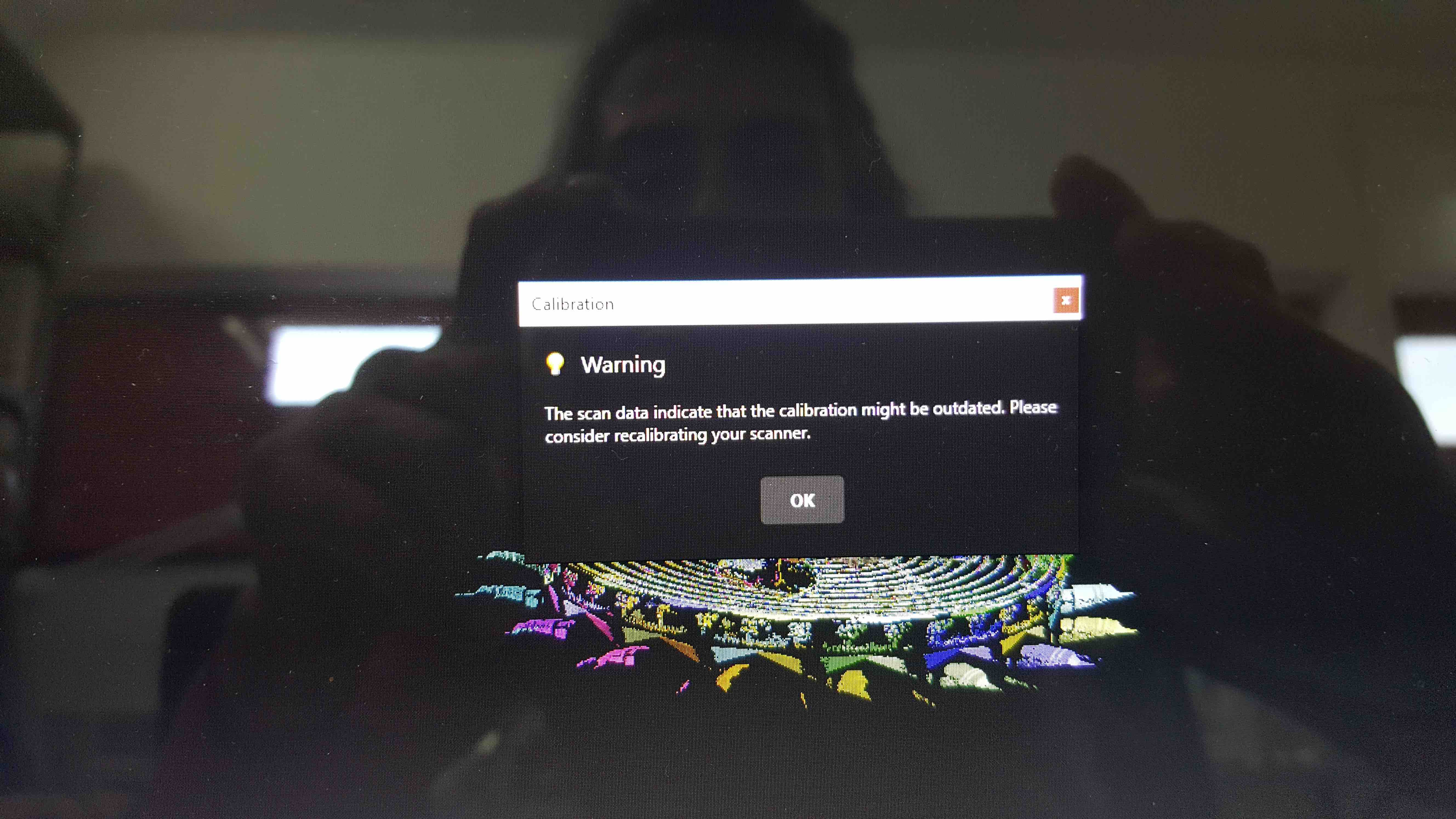

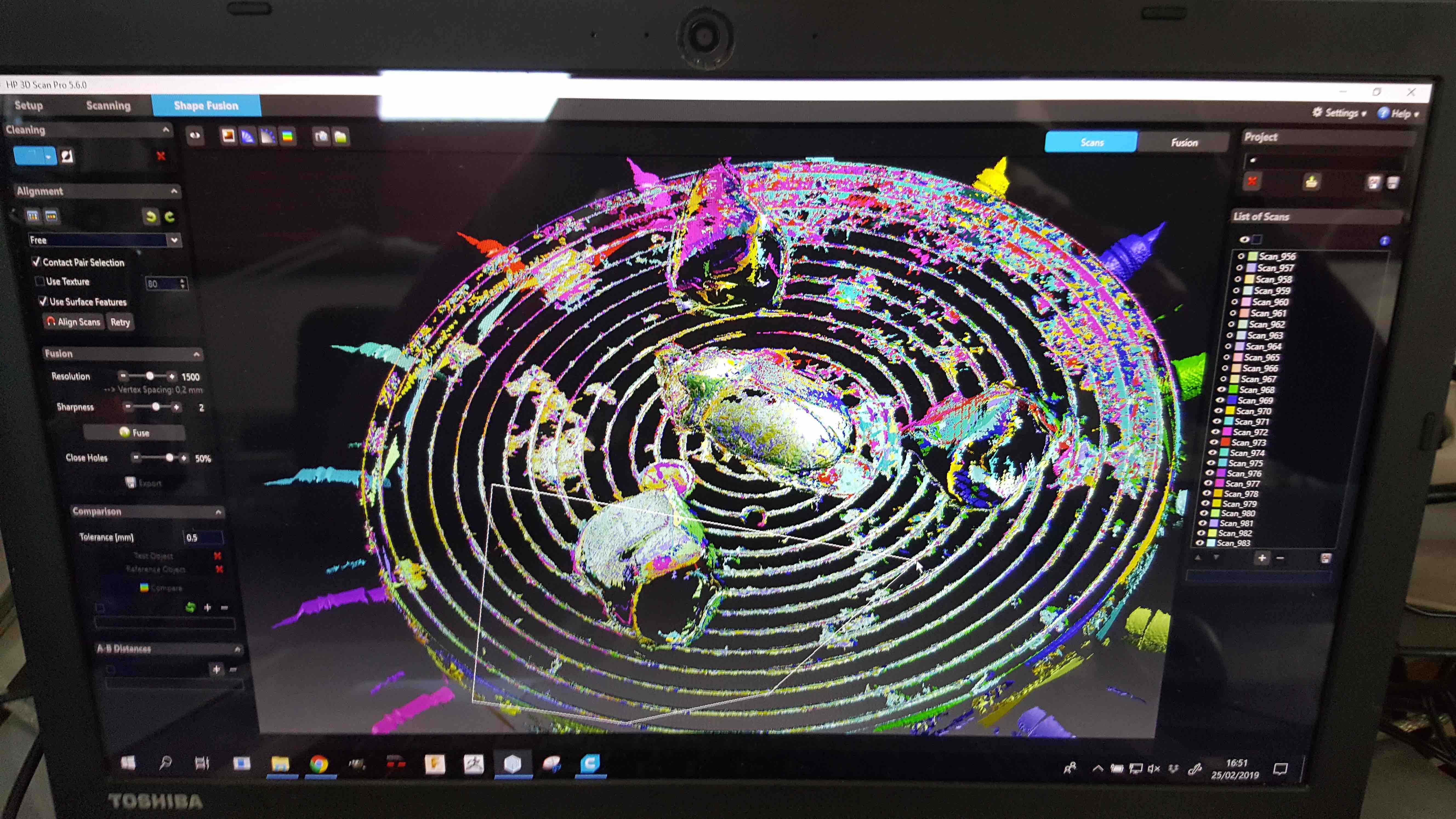

Photogrammetry: is the art and science of making measurements from photographs, especially for recovering the exact posotions of surface points. Photogrametry is as old as modern photography...

Objective: scan a insect that's in danger

xxxxxxxx xxxxxxxx xxxxxxxx xxxxxxxx xxxxxxxx xxxxxxxx xxxxxxxx

xxxxxxxx xxxxxxxx xxxxxxxx xxxxxxxx xxxxxxxx xxxxxxxx xxxxxxxx

xxxxxxxx xxxxxxxx xxxxxxxx xxxxxxxx xxxxxxxx xxxxxxxx xxxxxxxx

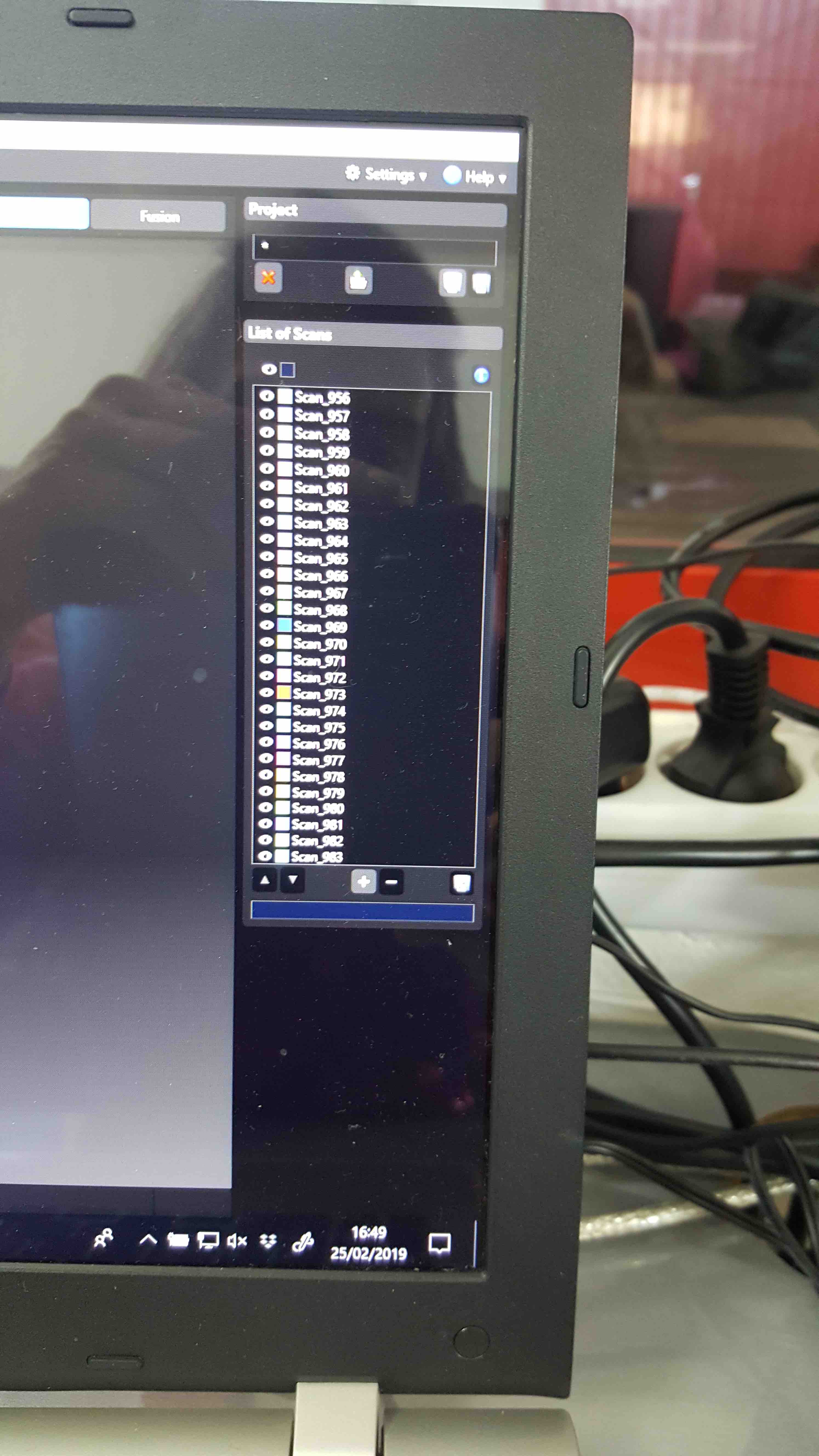

TIP: to deal with such huge file, origanly with 909 Mb, its to open it in MeshLab and apply reduse complexity

MeshMixerTIP: easy to clean the extra data that does not belong to the bug

Saved to STL in order to import it in Fusion 360 and model my BUG

Youtube Video -

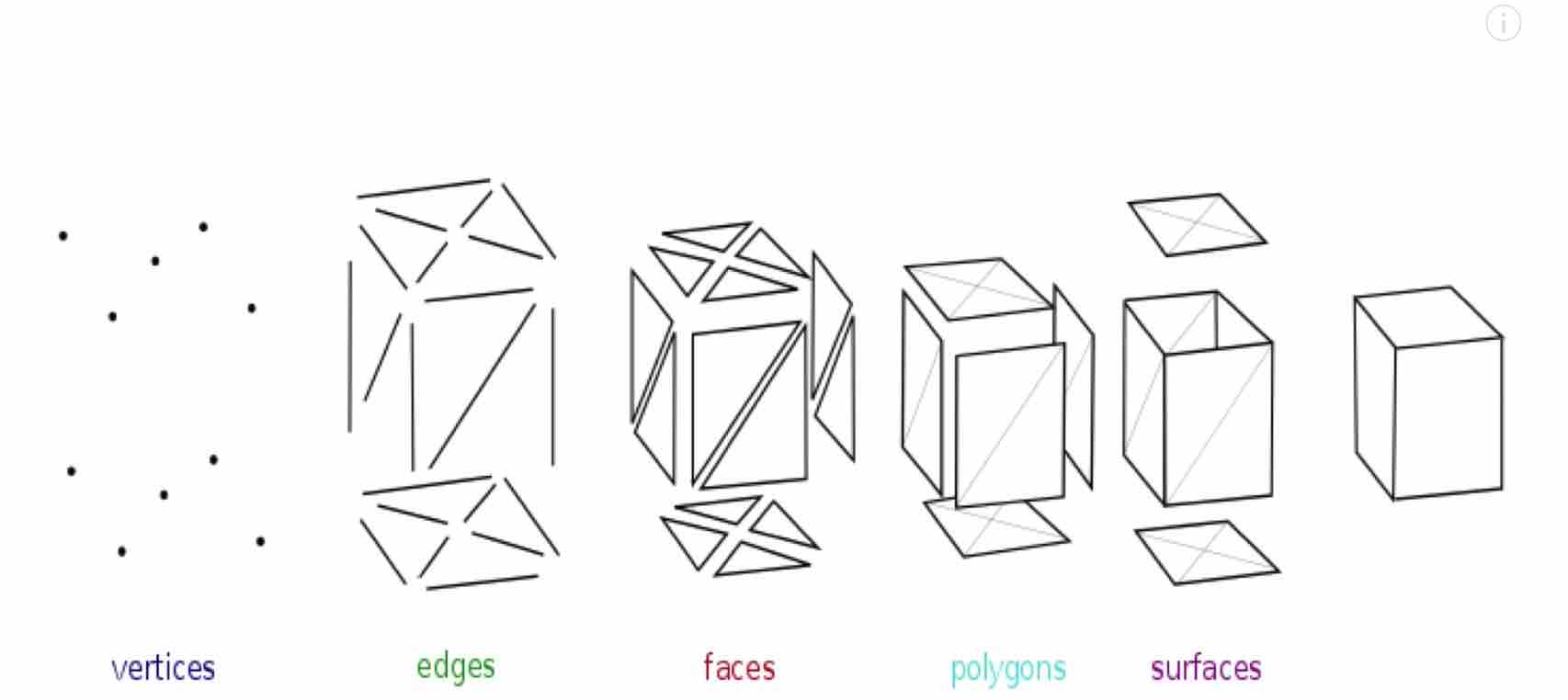

Youtube Video - important concepts: