This week is to work in a team to make a machine. This week is more in making the mechanical parts.

My goals are to finish my task and to help others in making their tasks.

In the beginning, Wendy and Hashim divided us into two teams and they gave us two ideas. The first one is X-Y Plotter and the second is hot wire cutting machine. The two teams must pick an idea and then search for the component, function, and whether we can make it in two weeks. My team took X-Y plotter and we started searching we also searched individually for many ideas but we decided on making the X-Y Plotter cause all the component that we need in the lab and also the previous student in the fab they make a similar machine so we will benefit from their experiment. Here is our group assignment.

My task was to design two boxes that contain the bearing of the axis and the leadscrew. The two boxes one for the Y-axis which will hold the servo and the other for the X-axis which will hold the bed.

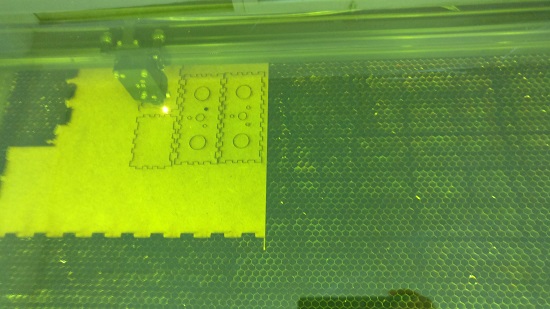

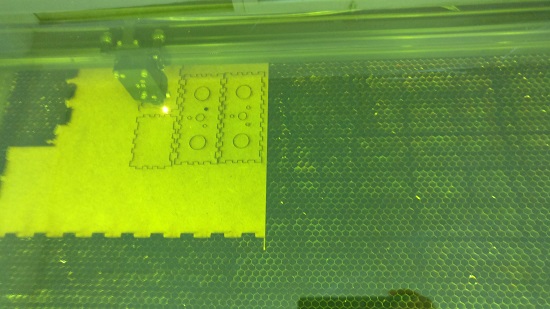

I started to design the box in fusion 360 I make the design in order to be press kit-fit. The team thought of making it from acrylic 3mm but we don't have much. So I thought of using MDF to make sure the hols of the screws of the leadscrew are good and the hols on the bearing. After the first try, the location of screws hols wasn't good also the box didn't press fit.

Then after many tries, I fix the location of the screws by measuring the distance between them and I make it press kit-fit.

After that, I moved to 3mm acrylic and I knew the kerf will be different but the important thing is the location and diameter of hols are good. I cut the first piece and I notice acrylic is much sensitive than MDF because when the laser beam cut through it. The laser takes out the material it cut also the material near the beam it melts or in other word bend little bit and of course, this becomes less whenever we put thicker acrylic. MDF is better than acrylic at this point.

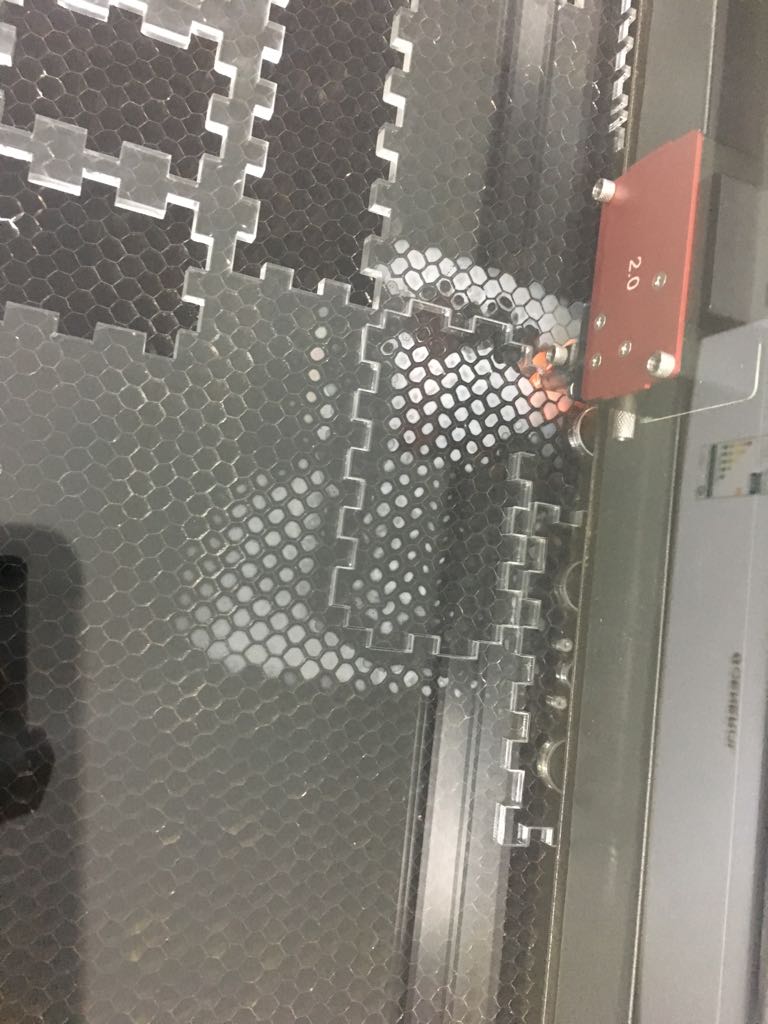

I hated to work with 3mm acrylic it was annoying because it's too sensitive I nearly finished one box all the parts fit just still the last part when I cut the last part it didn't fit. Although it has the same laser setting as the previous parts. I lost hope so I went to bring any tool to use it as a hammer then Zubair told me: chill I will do it.

Zubair tried his best but he couldn't then he gave me the parts. Then Darshan came to help.

Also, he lost hope and start to hit the parts to make them fit. I left the fab late that night without finishing my task. I loast time but I learned a lot.

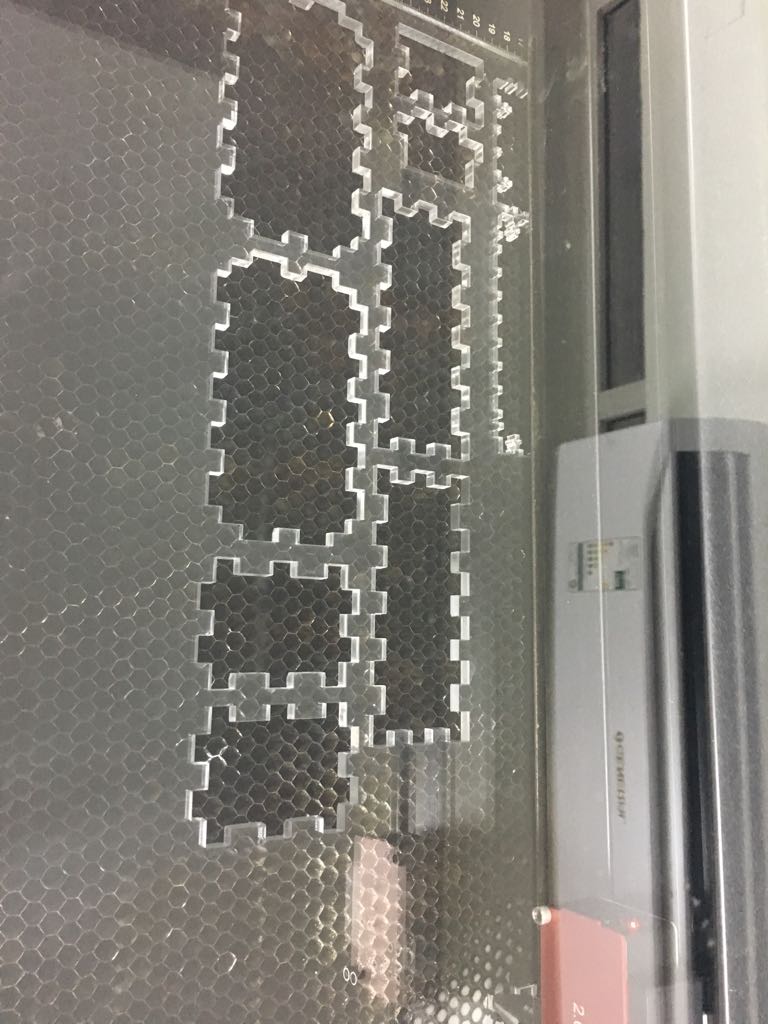

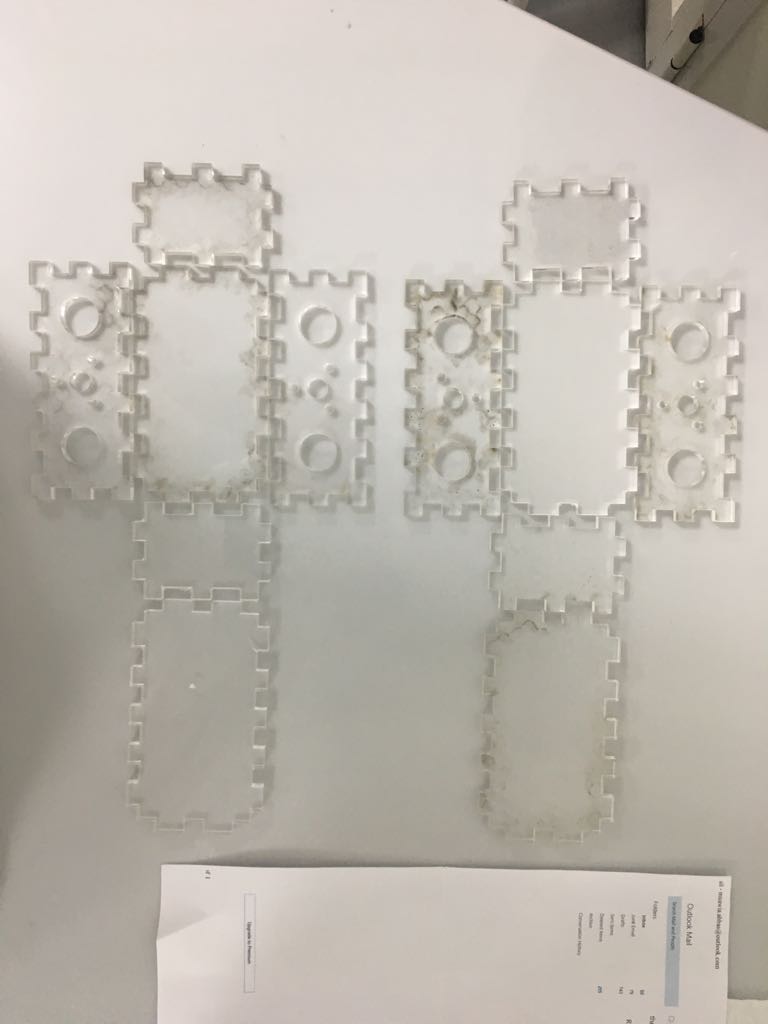

I decide to use acrylic 6mm. I prepare the file and like usual I tried three or four times until I found the kerf and it was perfectly fit. (Note: Then I added a place for stepper motor but I don't have a clear image for it)

Then I remember the servo and the bed so I redesign the upper part which is the cover. I thought of fixing the bed to the box but without using screw cause it will affect when writing. So I make four square holes on the bed and the upper part of the box and I made them parallel to fit the square column.

Here is my moving X-axis box (f3d)

Here is my moving y-axis box (f3d)

I'm very happy that we work to accomplish this machine. I didn't find time to work more because of the finals. I learn a lot about acrylic and I can now know their setting and kerf. If I hade time I will invest more time in finding a better way to fix the bed with Y-axis box.