Week 4: Computer-Controlled Cutting

Assignment:

Group assignment:characterize your lasercutter, making test part(s) that vary cutting settings and dimensions.

Individual assignment:Cut something on the vinylcutter design, lasercut, and document a parametric press-fit construction kit, accounting for the lasercutter kerf,which can be assembled in multiple ways.

From this week onwards we have started working with machines. We need to use vinly cutter and laser cutter. So we need to cut something for these CNC machines, here I plan to use Inkscape and Autodesk inventor.

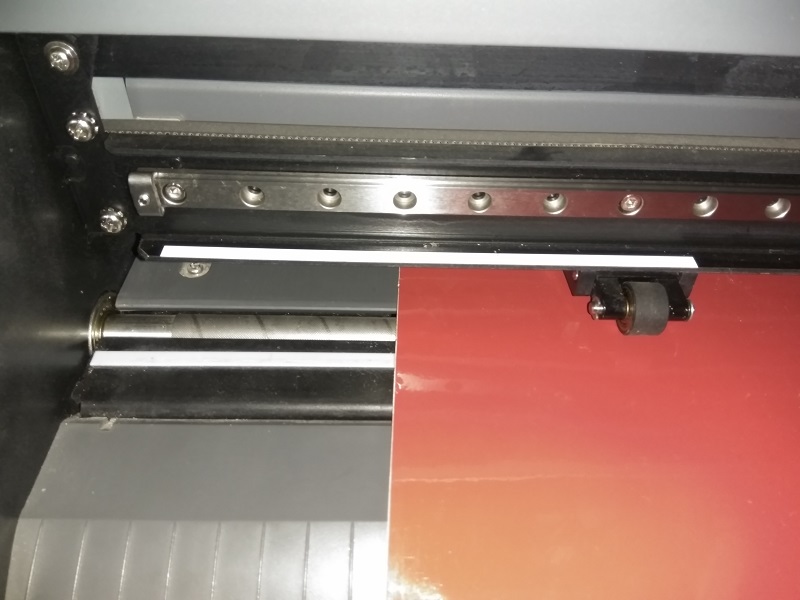

Vinly cutter

Vinyl cutter is a computer controlled cutting machine, used to cut vinyl sheets and copper sheets. Here we are using Rolland Gx-24. It has a blade which is mounted on a bearing which can rotate. The blade can rotate on its axis, and the bed has rollers for moving the sheet back and forth. The sheet is cut by moving the blade over that.

Machine Setting : we need to follow certain steps

- Load the vinyl sheet,select the type of sheet (piece or roll) accordingly.

- We need to take care while loading vinyl, it must cover the IR sensor then only the material will be detected. We should align the material according to the reference lines in the vinyl cutter.

- We see that there is a certain white sticker on the top of the rollers. There are knurling done with the rod, below on which the vinyl roll need to keep, or else the vinyl would not get a grip on the rollers, and it won't pushed out properly.

- We need to select the input material roll/piece or edge, Based on this it would give the overall X and Y lengths available for cutting.

- To set origin, we need to press origin and use movement key to set origin point and then press and hold the set button. Use force button to set force; we can set force between 90 to 140 g for this machine.

- We need to check the force of vinyl cutter, so we perform test function, test cuts a circle with a square inside. So that we get a sample cut if that cut can easily remove the circle without peeling square, we can confirm that force is perfect and the blade is perfect. The machine is perfect for use. From here we got the force need or cutting is 110g and velocity is 2.

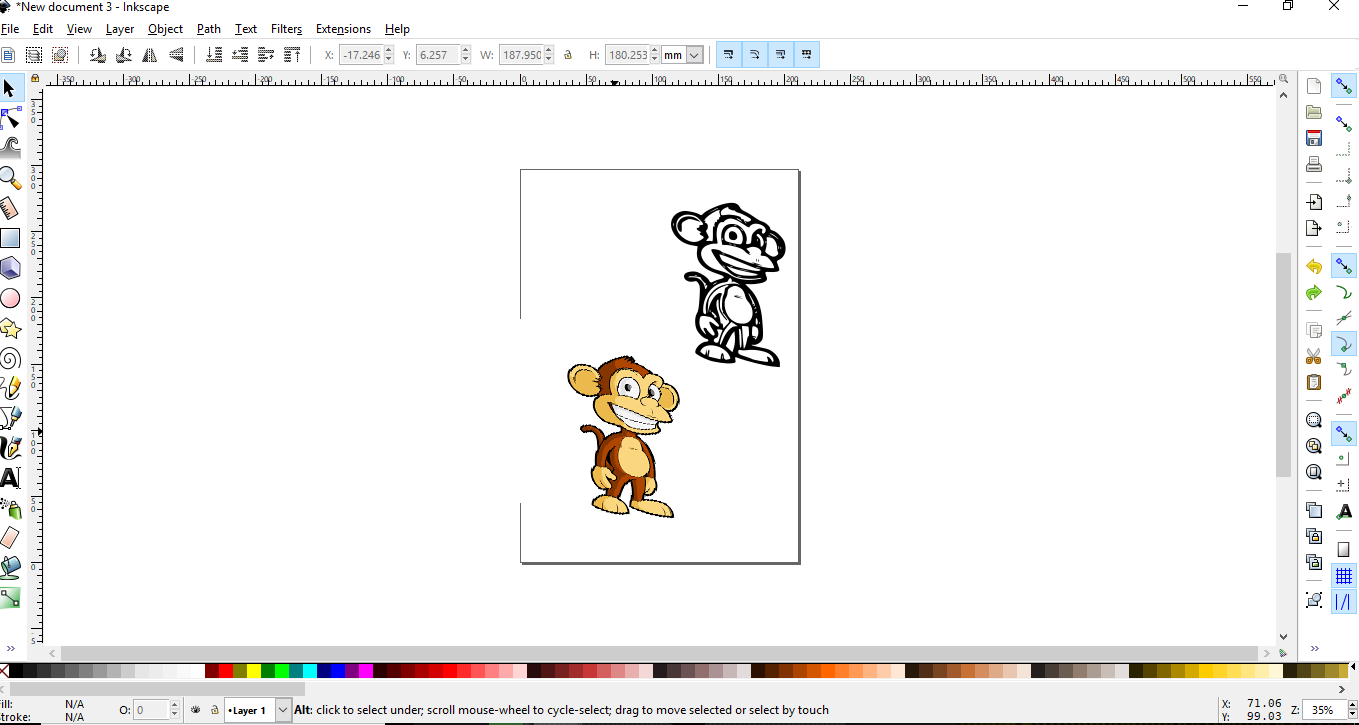

My Work

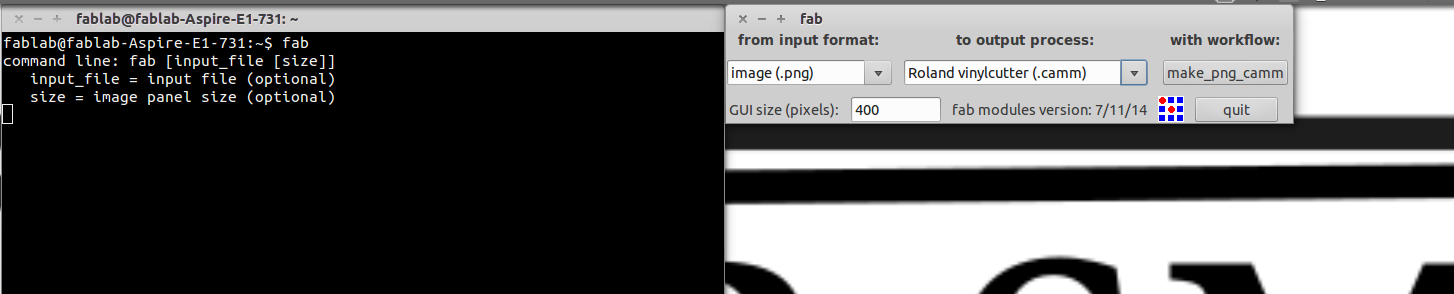

First, need a design so I used Inkscape to create a design file and save this file as a png image, the Grayscale image does not work with this. First, I download a cartoon image of monkey from the internet and use Bitmap techniques in Inkscape and save it as a png image

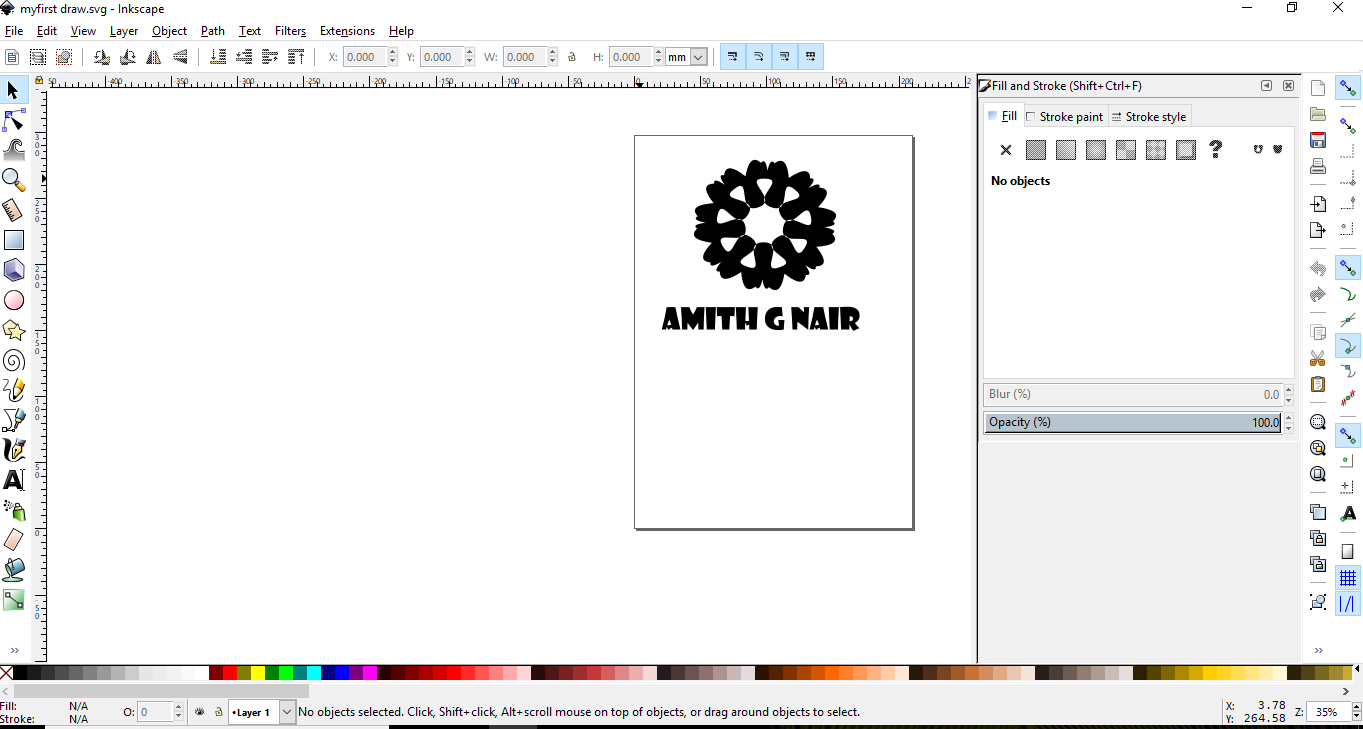

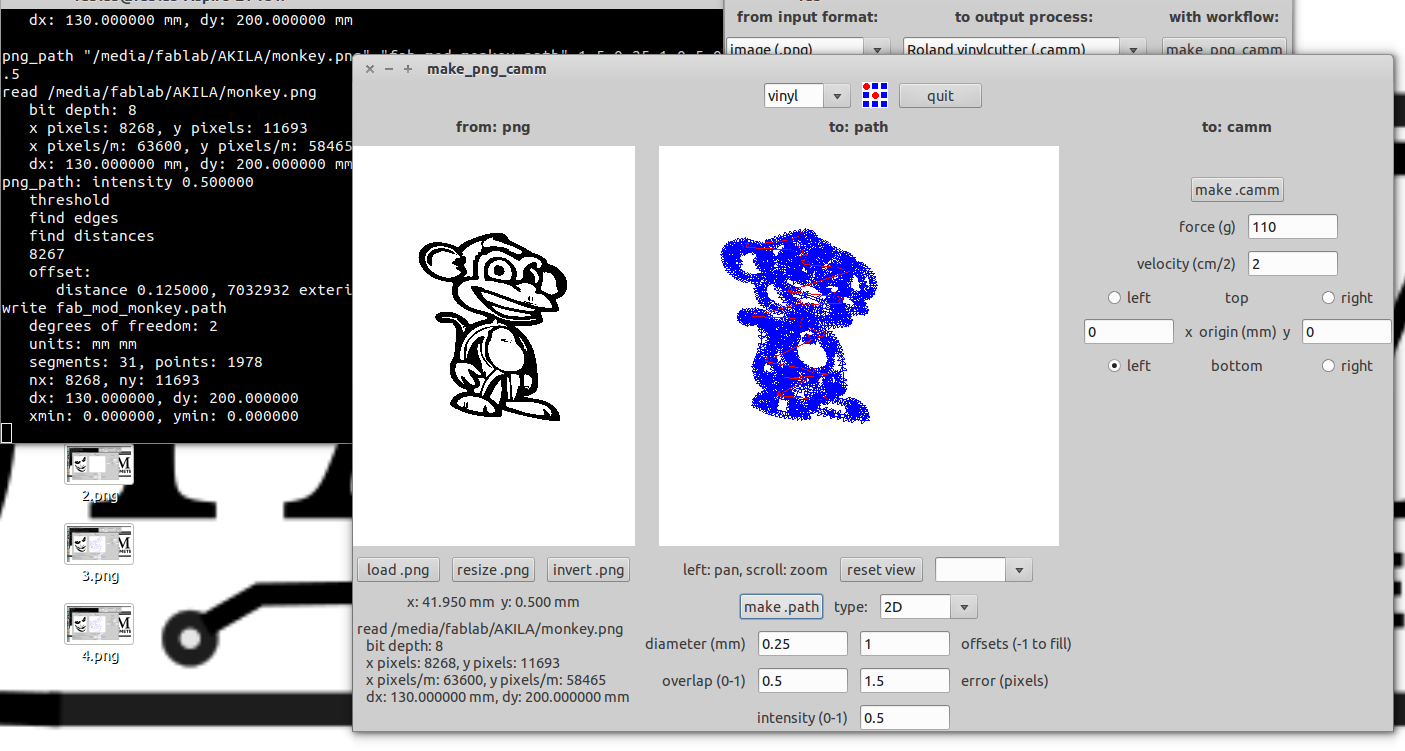

Second, draw a simple design, it's my first attempt I draw a 6 angle pentagon, circle, and star and adjust its spoke and got this design and save it as png

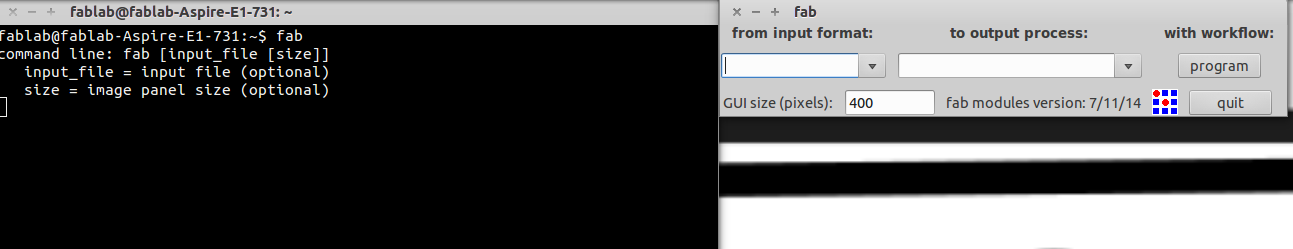

Then I load vinyl sheet on Rolland machine by following the steps mentioned above after loading, then go to pc connected with Rolland and open terminal and type fab and hit enter, which opens fab module. Go to the fab module and select the input format as png. Next the output process as Rolland vinyl cutter and click make_png_camm. A new window will pop up.

Now click the load png button and select your image. Now your image will be displayed. You can resize the image to the size you want and click make path. Now you can see the cutting path of the tool.For cutting vinyl, I changed the force to 110g,and Velocity as 2 and keep rest as default ,Click make .camm button and click send it, now the machine starts cutting.

Fab module settings for Vinyl cutting.

Diameter(mm)= 0.25 ,Overlap = 0.5 , Offsets= 1 ,Error(pixels) = 1.5 ,Intensity = 0.5, Force = 100g, Velocity =2

After cutting the vinly , i simply remove the unwanted parts, apply masking tape directly then clean my laptop surface and paste it on there.

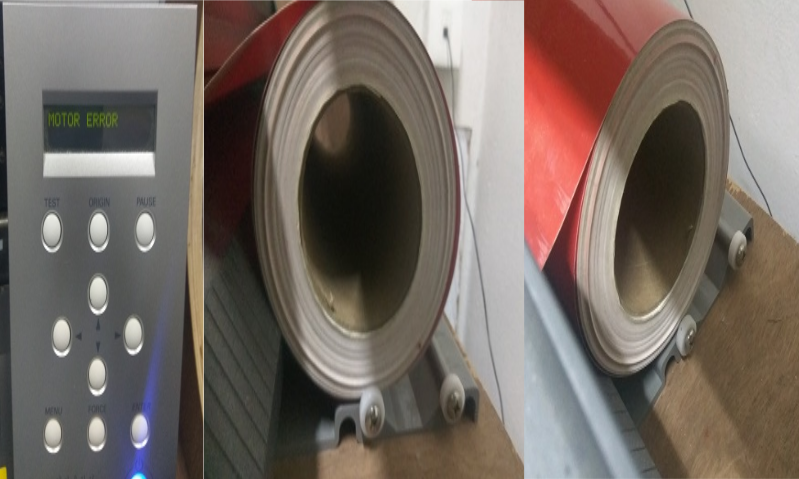

Error Occurred

After cutting our desgin we need to push vinly sheet to front in order to cut out the sheet from machine but when we press the forward button machine shows motor error which means roller is out of bed so due to friction between sheet and surfac,so motor cant pull the sheet anymore.We need to place roller on bed and do once again it works.

Laser Cutter:

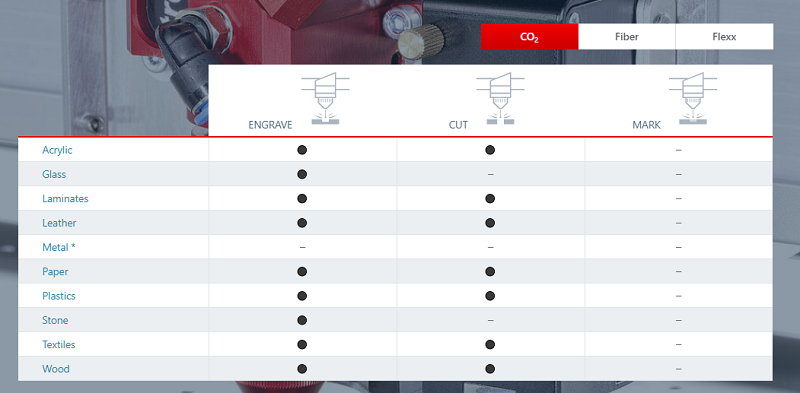

At the FabLab Trivandrum , we have a Trotec Speedy 100 ,60watt laser,which is a entry level CO2 laser cutter.Informations are collected from this source

Laser cutting is a technology that uses to cut intricate parts such as press-fit,gears etc. Our lab instructor Lancy started with the brief lecture on Laser and how a laser cutter works. When a laser beam is focussed to a point the material that gets vapourised which means Laser Cutter cuts because it burns. We can do Vector cutting, vector engraving and raster engraving on the Laser Cutter.

He explained about the importance of focusing of laser beam . An unfocused laser may cause unexpected results like burning too much or other hazards and also we may take care of lens while loading and unloading the cutting material. A laser is a very dangerous and we must use it very carefully. One should not leave laser unnoticed, which can trigger fire.

From Internet I found that this laser is a class 5 type which means its output power can be greater than 500mw, so even it may fall into our body severe, permanent damage to eye or skin .while using this laser cutter we also check the heat concentration of material whether the material can handle it or not.

Machine Setting : we need to follow certain steps

- Trotec Speedy 100 we can load cardboard,acrylic or plywood of dimensions of 600mm x 300mm.

- After that we need to focus the laser by using the spacer provided, hang the spacer on the notch in the cutting head and slowly raise the bed until the spacer falls off.

- After focusing we need to switch on the filter , while laser performing cutting it emit hazardous fumes that may cause health problem, filter is filled with active catalist it absorb the fumes and emit clear air outside.

- Using Inkscape we load the .dxf file and then change the stroke colour,RED is for cutting and BLACK is for engraving.

- After changing the settings we would go to print then a new window named job control is opened.

- In job control window we need to set the material type , power of laser, frequency and speed and after that we click on ready.

- When we click on Ready button it takes feed back from laser cutter regarding the orgin of laser after that we can press play to cut

Important : Never leave the Laser cutter unattended, dont perform cutting before switch on the filter.after cutting door will open after 10 to 15 seconds.Use manul for material list dont use matrial other than that for cutting or engraving

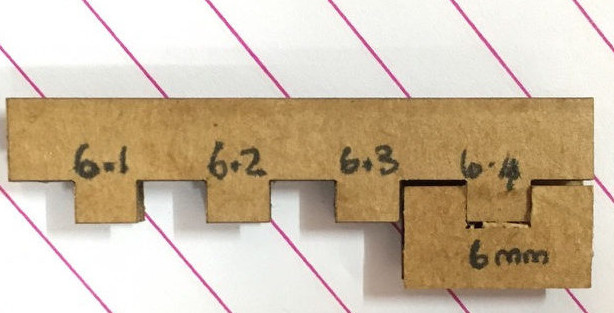

Group Assignment

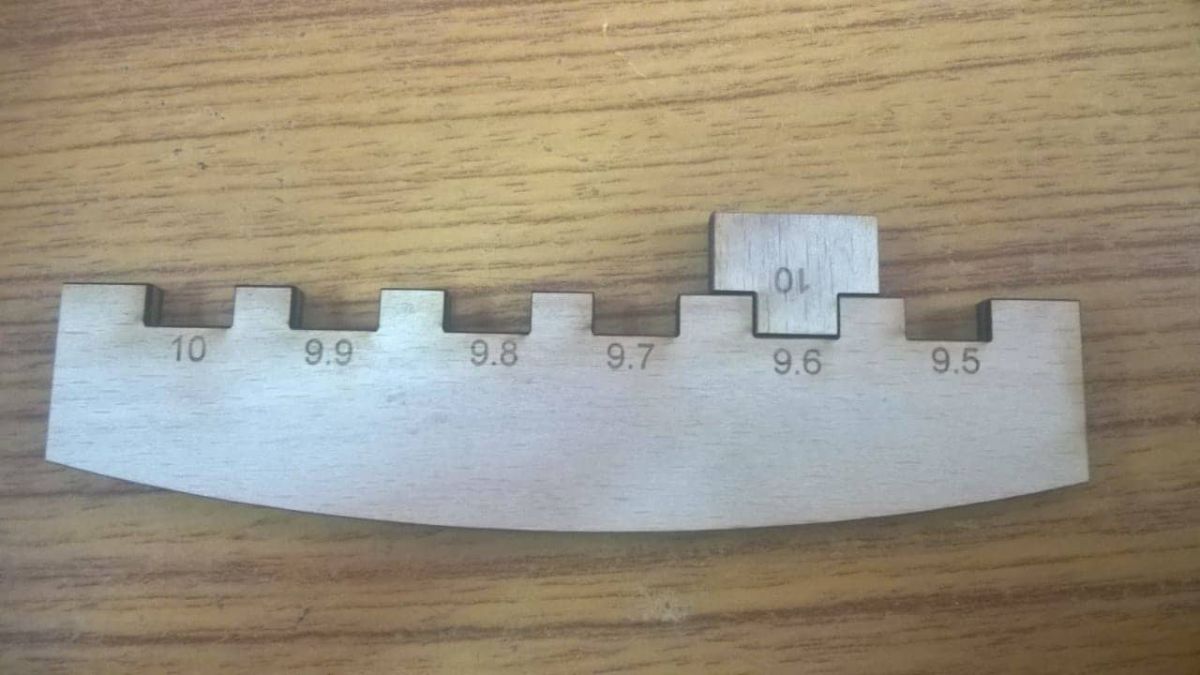

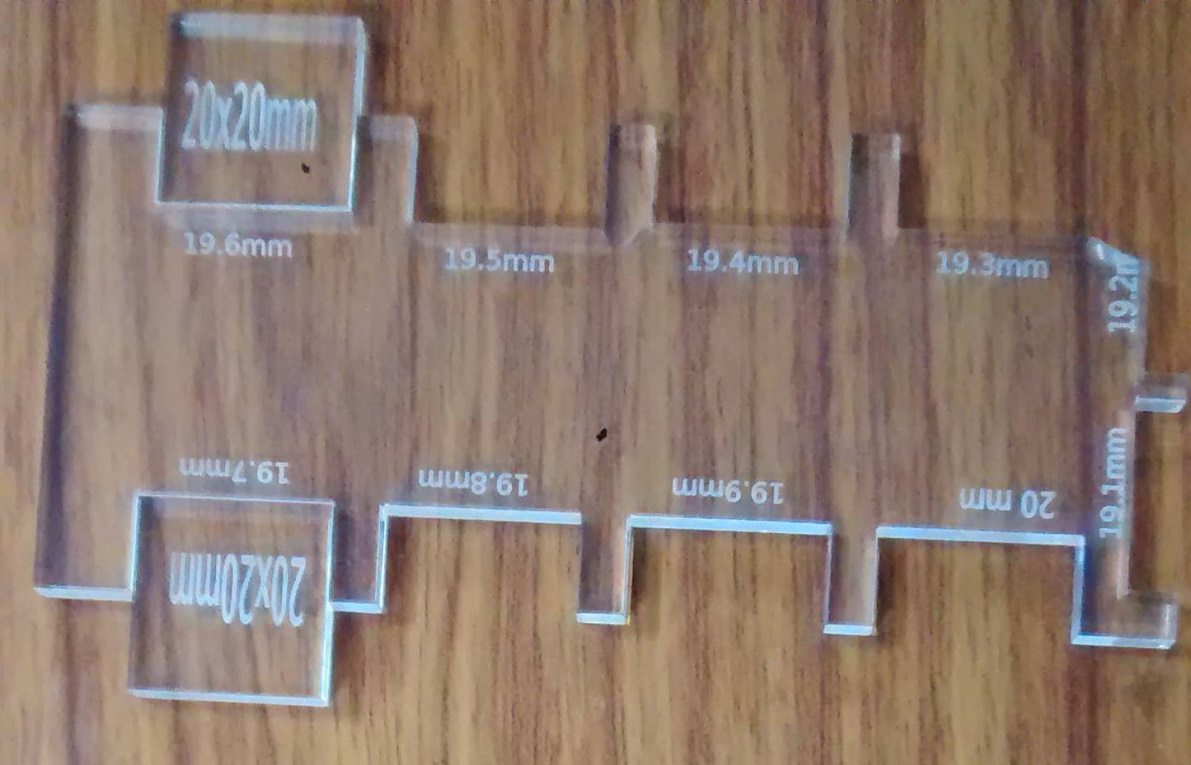

After this we go with group project,here we need to calculate the kerf.Kerf is defined as the width of material that is removed by a cutting process, as I told laser to perform cutting by burning some material.

To find the proper fit for each of the materials in the Lab, we set out to do as a group, each one taking a different material and finding out its loose fit and tight fit. For my part of the assignment, I had worked on acrylic. I developed a parametric comb in Fusion 360, making 20x20mm square and comb starting from 19 to 20, each increased with 0.1mm thickness. Also, make similar for 3mm acrylic using 15x15mm. Now, I exported the file as .dxf file and opened on Inkscape to give a print to the laser cutter.

After perfom the cutting ,we measure the kerf of each test parts.kerf for wood kerf is 0.3mm, kerf for cardboard is 0.2 and Kerf for acrylic is 0.3mm.

Laser cutting settings we found that In our lab material available are beach plywood of 3mm, Acrylic sheet of 6mm and 3mm and Paper of 3mm.

- Engraving : Power : 80 velocity : 55 Frquency: 1000

- Cutting :Power : 100 Velocity : 0.70 Frquency: 2500

- Engraving :Power:80 Velocity : 40 Frquency: 1000

- Cutting : Power:100 Velocity : 0.40 Frquency: 1000

- Engraving : power: 4 Velocity :50 Frquency: 70

- Cutting : power: 100 Velocity : 0.80 Frquency: 2000

- Engraving : Speed : 55 Velocity : 5 Frquency:auto

- Cutting : Speed : 85 Velocity : 3 Frquency: Auto

Acrylic sheet of 3mm :

Acrylic sheet of 6mm :

Beach Plywood of 3mm :

Paper of 3mm :

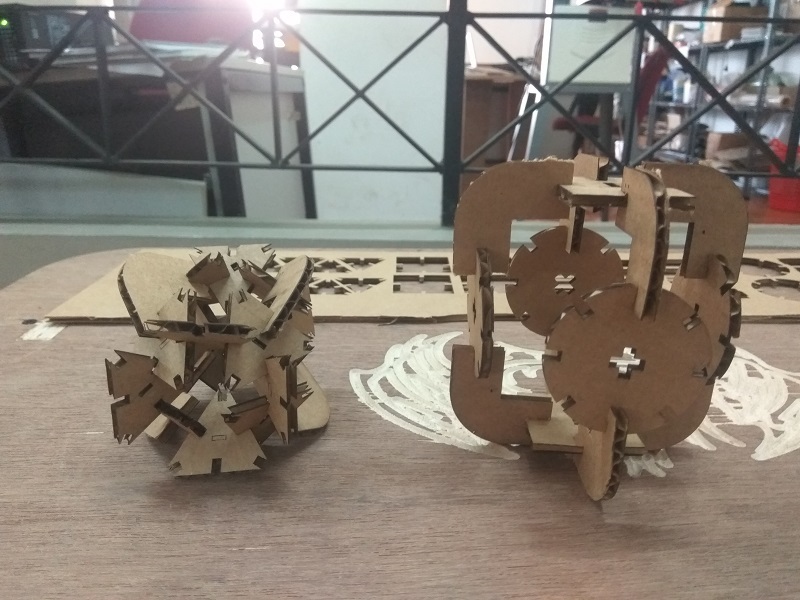

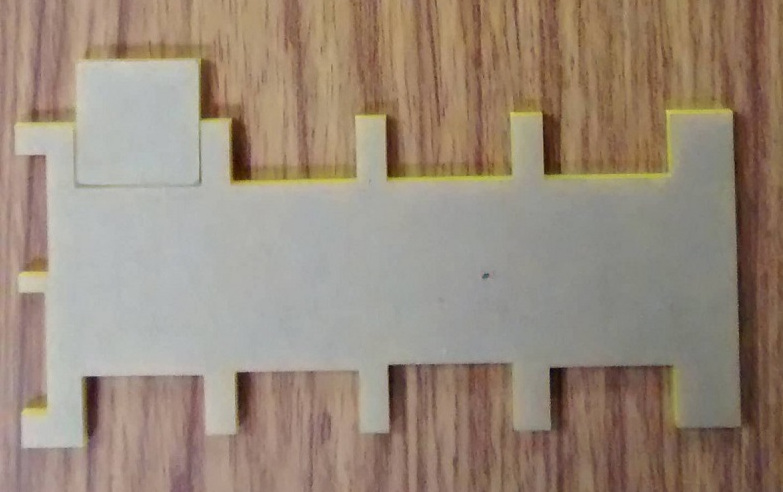

Parametric Press fit Constructionn kit

This week assignment is used to make a press fit construction kit.Parametric design is a process based on algorithmic thinking that enables the expression of parameters and rules that, together, define, encode and clarify the relationship between design intent and design response.

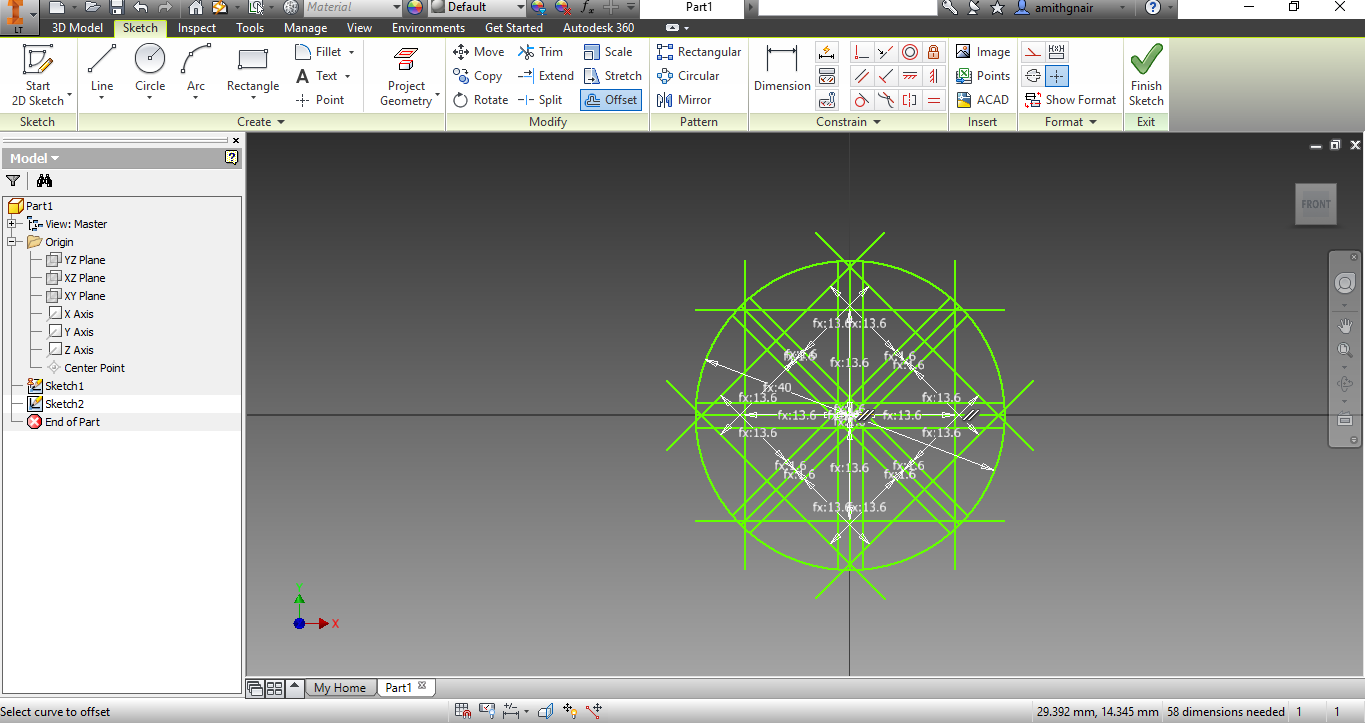

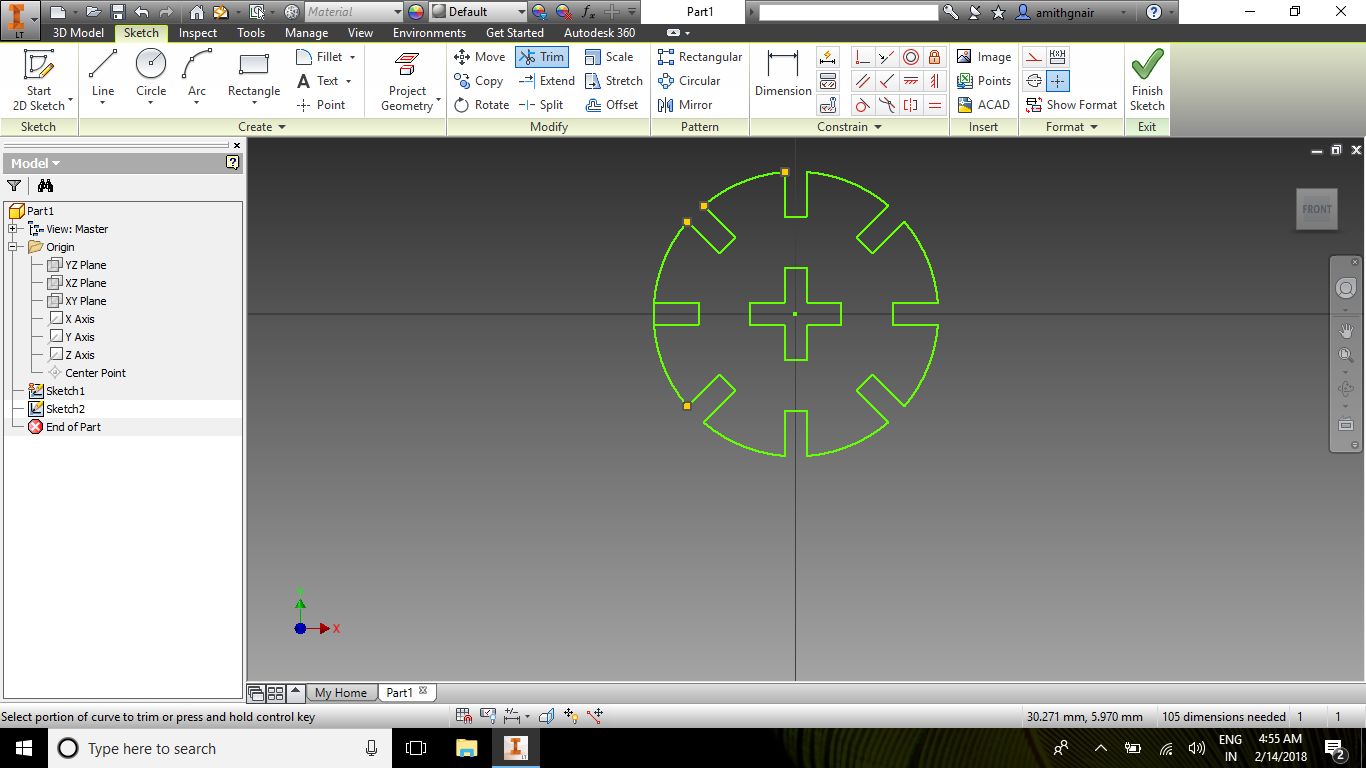

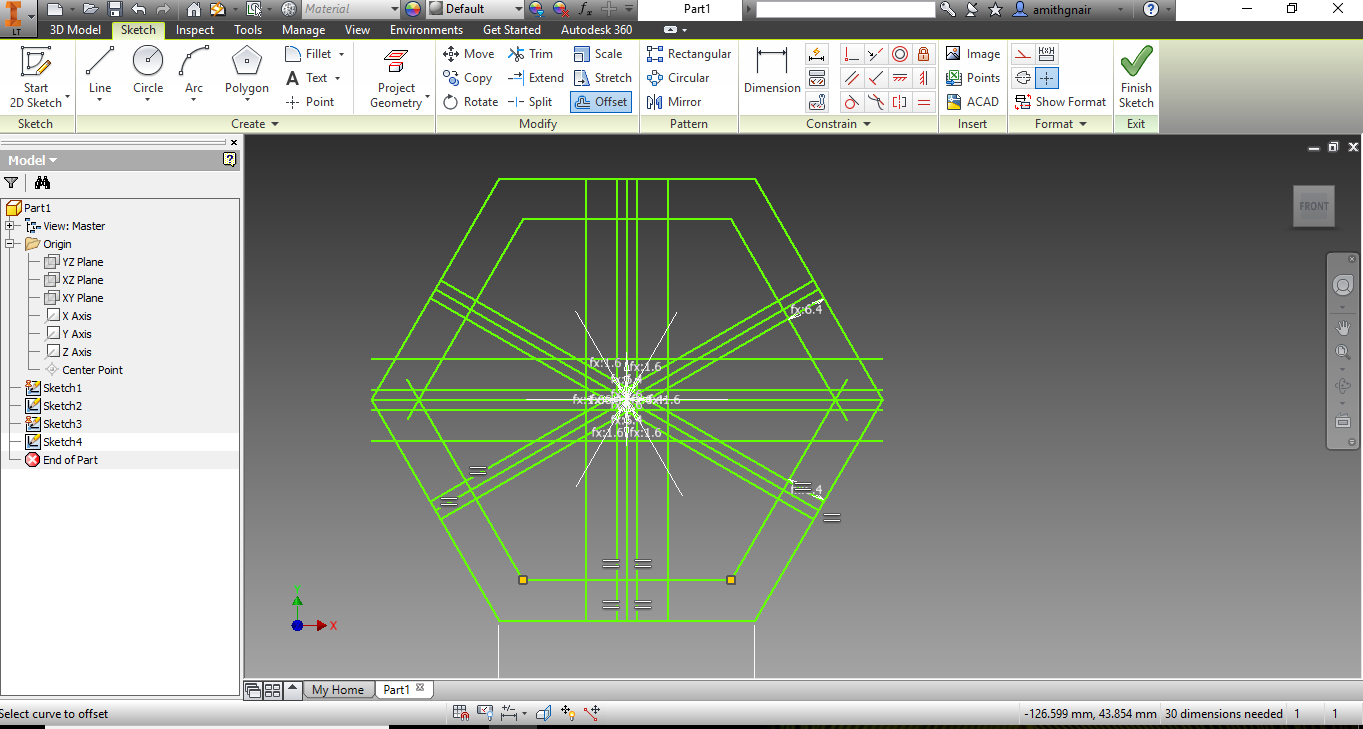

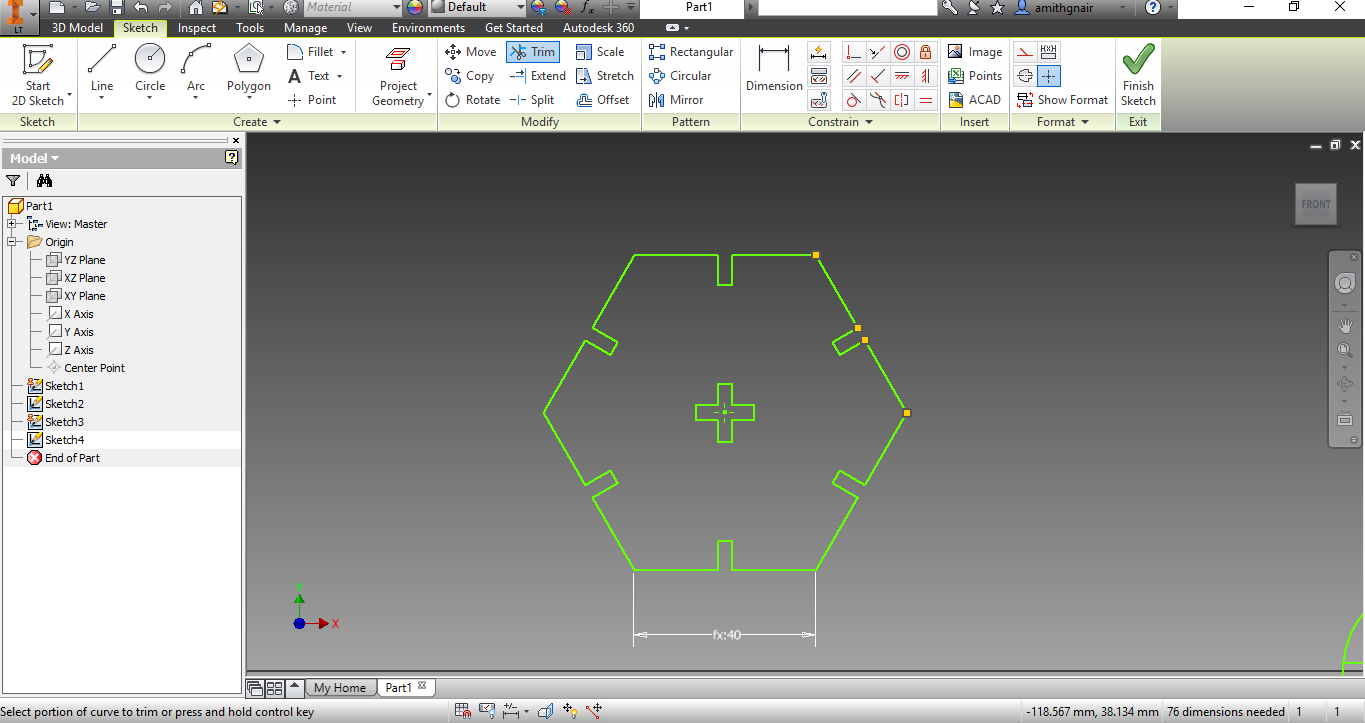

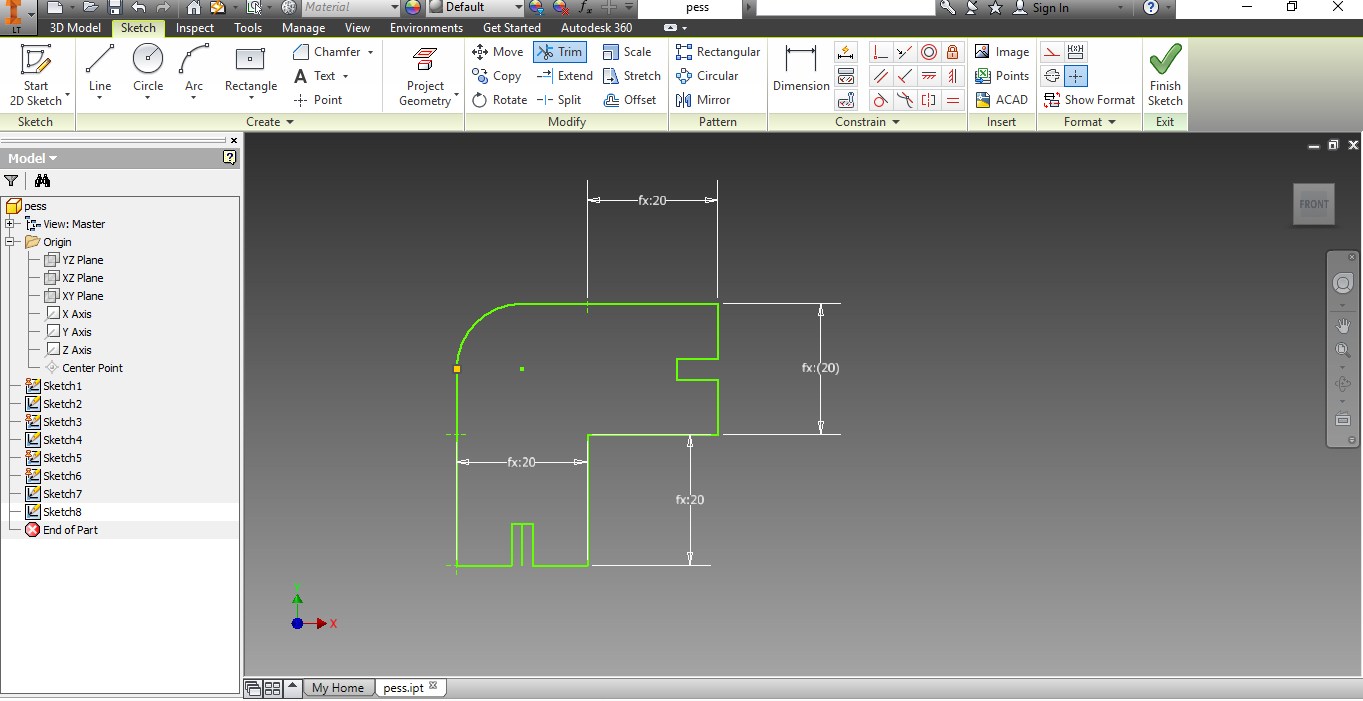

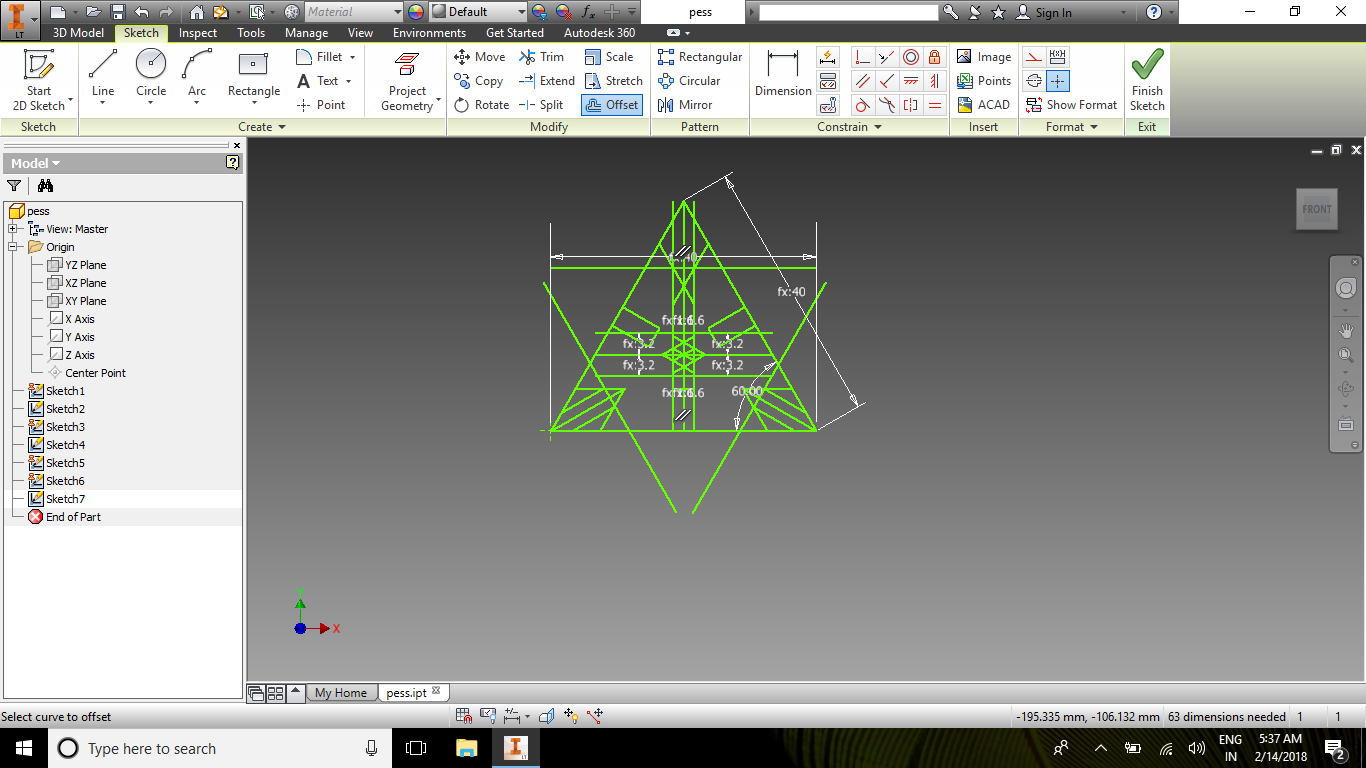

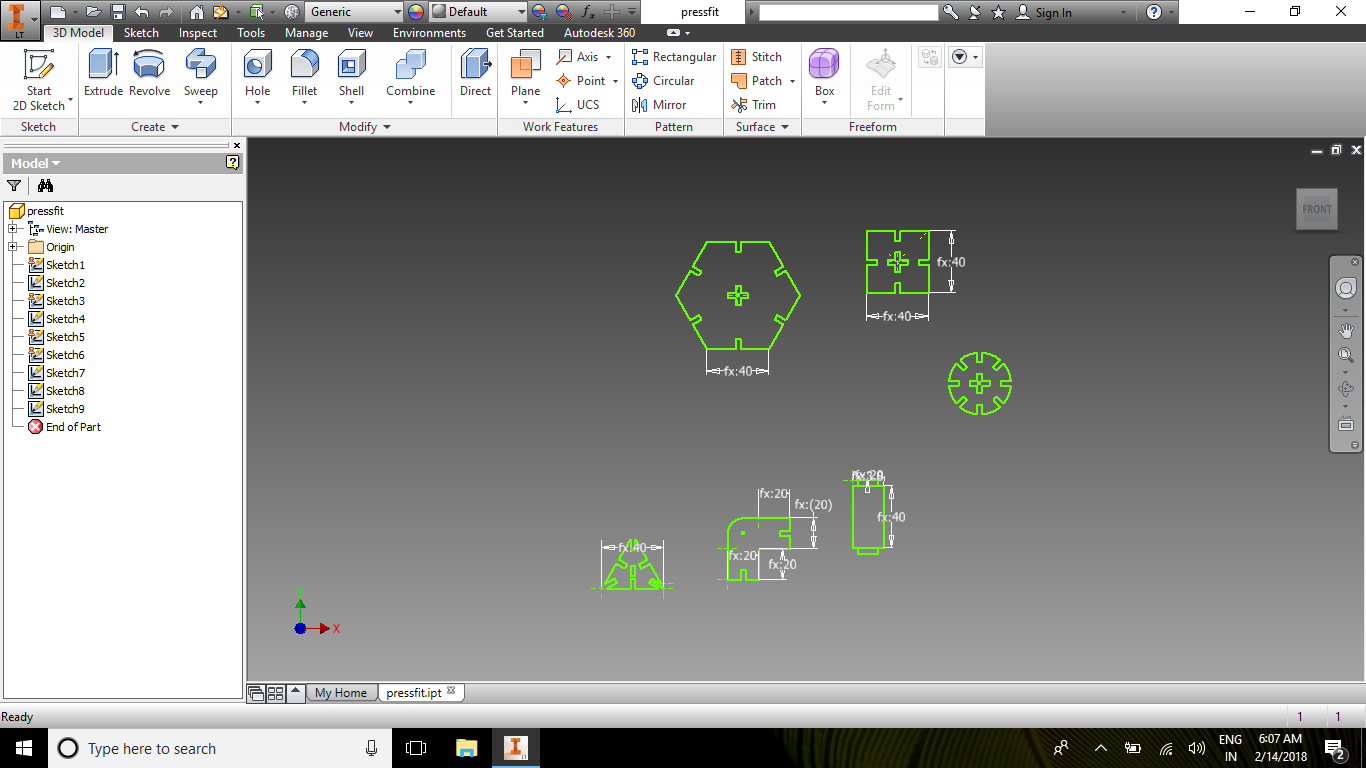

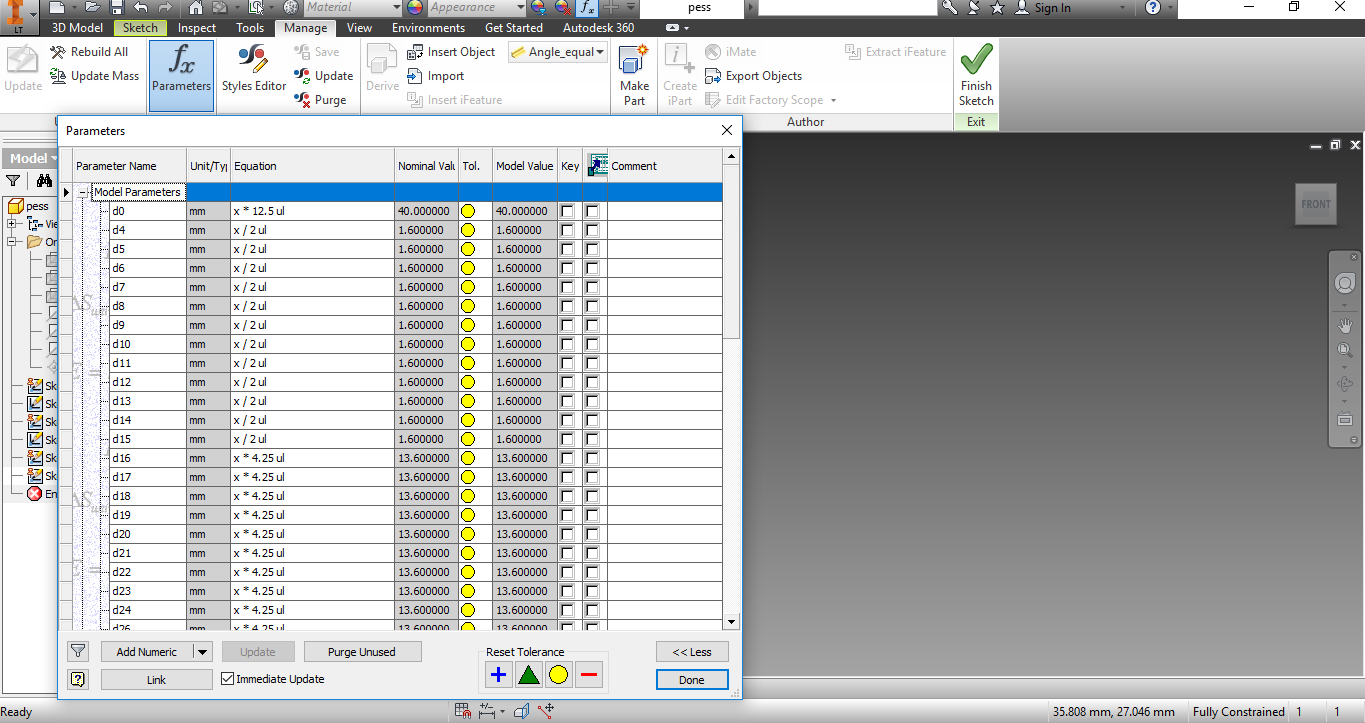

I used Inventor to create the model.After finding out the kerf of 0.2 for cardboard and we have 3.7mm tickness cardboard.I Place 3.2mm as the base and draw the models

First i start with Design a circle of radius 40 mm and design slot of 3,2mm

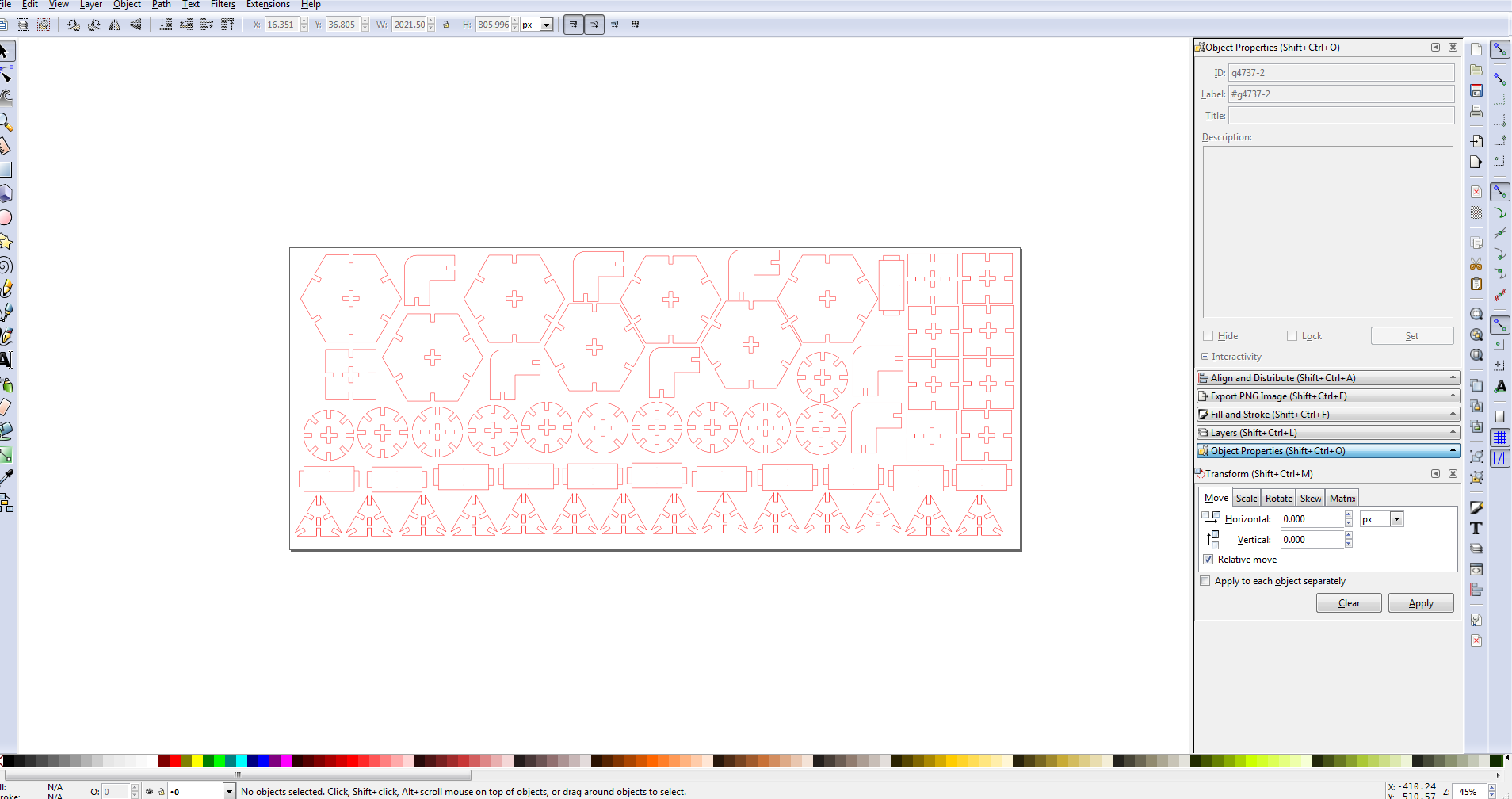

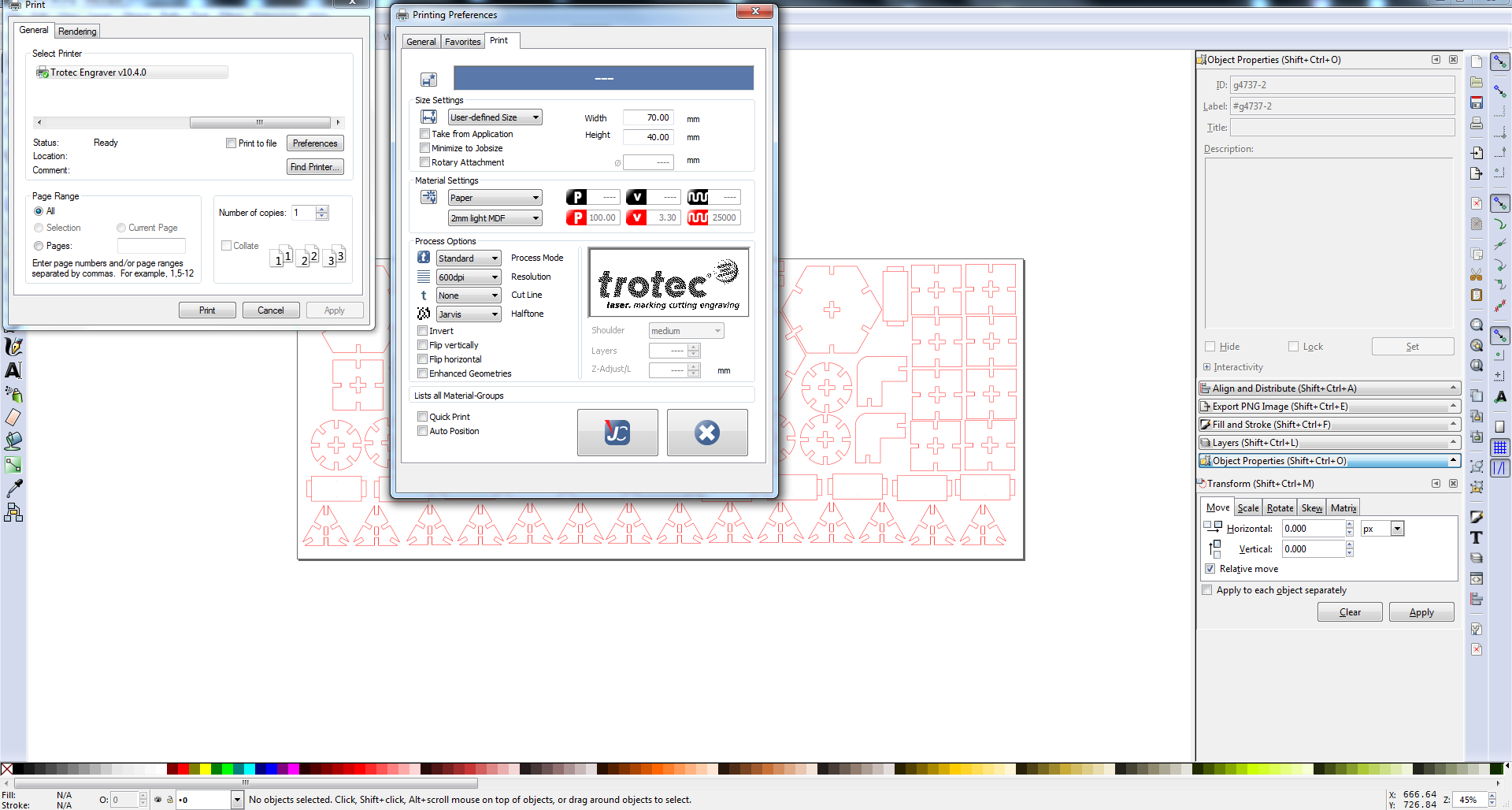

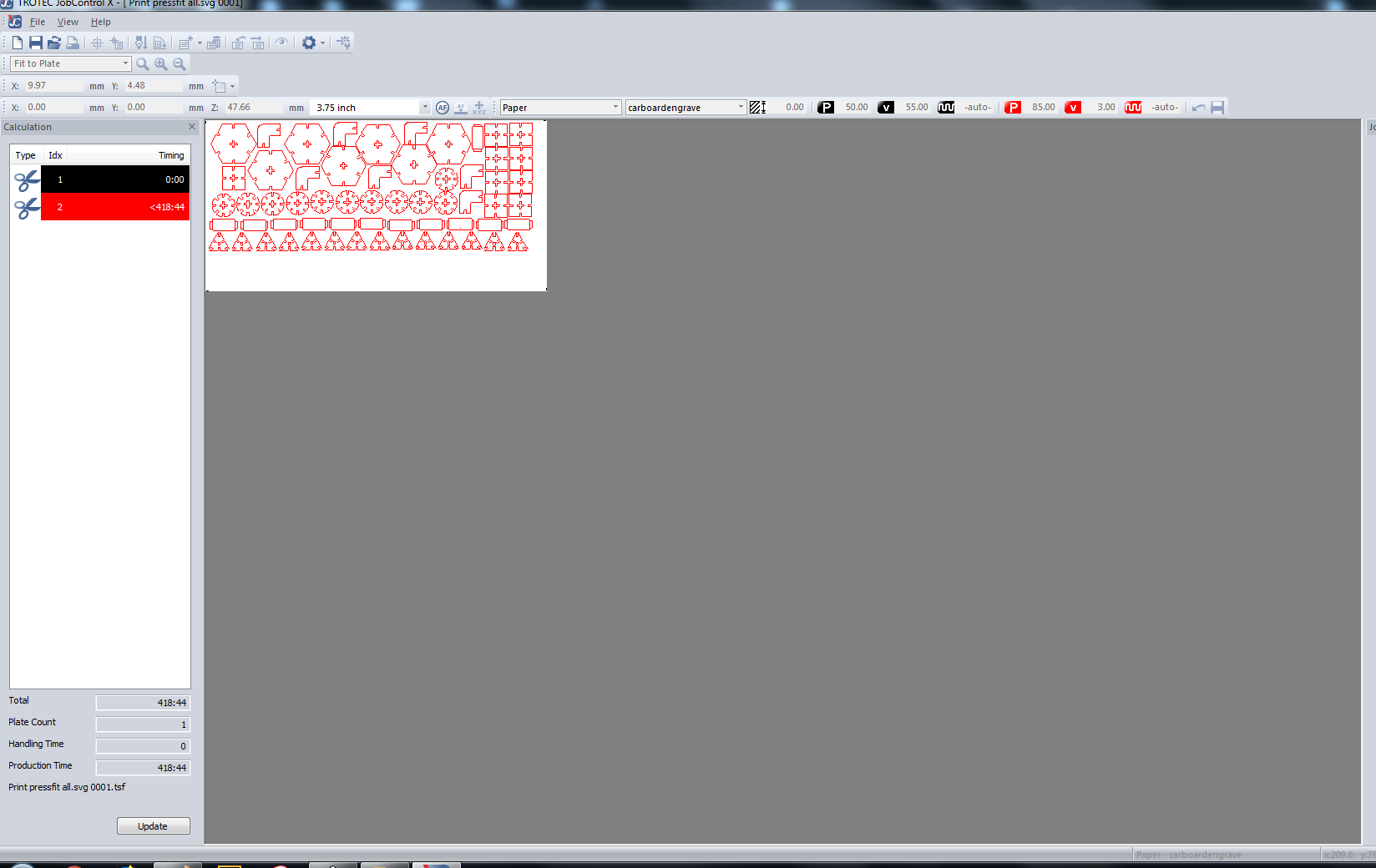

After Design process , i export the design file as .dxf and open it in inkscape and change stroke colour to red ( red is for cutting) after that we go to printing by click ctrl + P

It open printer setting and open the preference and choose printer and choose the matrial and then click on apply button it send job to tortec software

then image will open on job control.In job control we need to set the power as 85 , speed as 3 and frequency as auto .After we estabish the communication with cutter and perform cutting

After cutting , remove the waste part and construct different models using that.