Input Devices

Magnetic Sensor

For this assignment I decided to build an electronic board equipped with a magnetic sensor that can detect magnetic fields.

DataSheet

This is the datasheet of the magnetic sensor.

My Hall Sensor Board 2

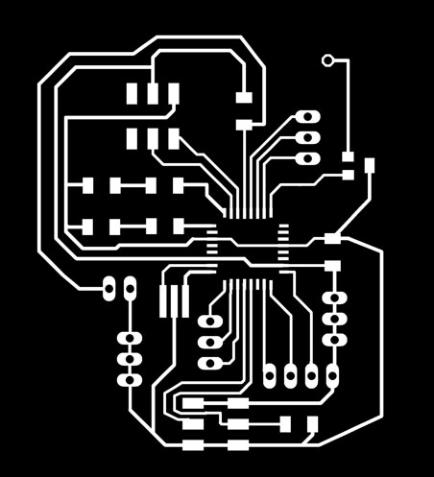

As I have learned in past weeks, to create my electronic board, I have used the “ Eagle ” software to prepare the schematic (fig.1) and the electrical connections named Board (fig.2). For this board I decided to have more pins available for further development, for example to use it in my final project. I think it is useful to multiply the power and ground pins in more contacts and also have extra pins available.

1 Eagle Schematic

2 Eagle Board

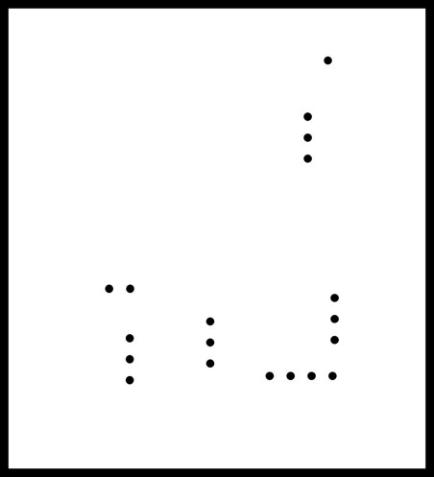

fig.3 “Traces”

fig.4 Outline and holes

Program the Board

To program my electronic card I have used the “Arduino ide”. Before proceeding with the programming I verified that the card hardware was fully functional. I used avrdude to establish the contact with the card and verified that it was working and ready to receive data. My USB-tiny programmer help me in this operation.

The Components

I chose ATMega328p TQFP card because it has many available pins. This choice comes from the fact that I would like that my card would be ready for possible other use and expansions, ( e.g adding other sensors, servo motors ecc)

Partlist exported from C:/Users/UTENTE/Documents/eagle/HALL SENSOR 2/HALL SENSOR 2.sch

Qty

Value

Device

Package

Parts

Description

1

PINHD-1X1

1X01

JP4

PIN HEADER

1

PINHD-1X2

1X02

JP2

PIN HEADER

4

PINHD-1X3

1X03

JP3, JP5, JP6, JP7

PIN HEADER

1

PINHD-1X4

1X04

JP1

PIN HEADER

2

PINHD-2X3-SMD

2X03SMD

DEVICES, FTDI

PIN HEADER

2

100 Hom

RES-US1206FAB

R1206FAB

R2, R3

Resistor (US Symbol)

2

100nF

CAP-US1206FAB

C1206FAB

C1, C2

1

10K

RES-US1206FAB

R1206FAB

R1

Resistor (US Symbol)

1

A1302LH

A1302LH

SOT23-W

IC2

Linear Hall Effect Sensor ICs

1

ATMEGA88-THIN

ATMEGA88-THIN

TQFP32-08THIN

IC1

2

LEDFAB1206

LEDFAB1206

LED1206FAB

U$1, U$2

LED

1

RESONATOR

RESONATOR

EFOBM

U$4

Control of readiness of the Device

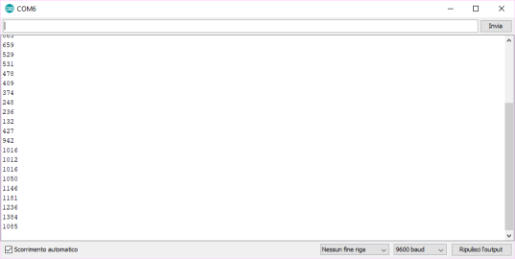

Having connected the electronic board to the “Usbtinyisp” programmer (built in the first weeks of the fablabcourse) the “Avrdudess program” confirms that everything is ready for programming. At this point, I start the “Arduino ide” and start typing the code of my software. When the code is written, I connect the hall sensor board to the “usb to ttl serial converter”. Doing so, I can test the data coming from the magnetic sensor.Baud rate? unexplained mystery…

At this stage I encountered a very unusual problem .... I studied that in the serial protocol the transmission and reception’s speed should be the same. The speed is measured in baud rate. Usually, the default value is 9600 with bit 8 no parity, bit stop 1.. Unexpectedly, when I connected my card programmed with a baud rate 9600, the arduino serial monitor did not receive any data! All was set to 9600, even the usb to ttl serial converter.

however

it

did

not

work

...

the

serial

port

was

transmitting

but

the

computer

did

not

receive

the

data.

Then

I

installed

a

serial

port

monitoring

software

to

figure

out

where the problem was...

Unbelievable ...

I then tried to change some parameters. Changing the reception speed, I saw strange symbols appearing on the screen .... and tan error related to the frame uart ... I then understood that something was misaligned and I kept changing the values. Atbaud rate 600, everithing started to work again. Possibly the default value of 9600 was divided by 16 ... 9600/16 = 600. Taking into consideration this, I modified the transmission value accoridngly: 9600 * 16 = 153.600 and found the solution to all the problems !!! Everything was working well eceiving on the serial 9600 ... but I could not understand the reason for this problem, maybe it could be something related to the microcontroller. I haven’t understood yet.

Final Conclusions

Reprocessing the card was a good job, and despite the problem of the baud rate my magnetic sensor works very well. Obviously I tried the card on different computers and everything is fine.Upgrade! 01/05/2018

finally I solved the problem, I realized that the error was in the processor clock settings. By searching the web, I found a library for arduino that allows you to set the external clock to 20 MHZ. I have downloaded the library, reconfigured the fuses , and the card now works at 9600 regularly. Problem solved!

Supported Chips and Clocks

ATmega8/168: The chips used in early arduino boards (e.g. Arduino NG, Arduino Diecimila).

ATmega328p: The chips used in recent arduino boards (eg. Arduino Duemilanove, Arduino UNO).

ATmega168p/328: Different but functionally equivalent to the above. People sometimes buy these by mistake.

The

core

delay()

function

is

not

very

precise

for

clock

rates

other

than

external

8

and

16MHz.

The

internal

clock

should

provide

enough

precision

for

most

cases but external 12 and 20 MHz are useful only if your code does not depend on precision timing.

Install

Open the Arduino IDE preferences window and add the following URL to the Additional Boards Manager URLs list:

https://raw.githubusercontent.com/carlosefr/atmega/master/package_carlosefr_atmega_index.json

Now

go

to

Tools

>

Board

>

Boards

Manager

and

search

for

Barebones

ATmega

Chips.

Select

it

from

the

list

and

click

Install.

A

new

section

called

ATmega

Microcontrollers will immediately appear in the Tools > Board menu.

My Final Test

In this video you can see the complete test of my card. The sensor’s data are read by my software and graphically represented on the screen as red ellipses that are synchronized with a sound in relation to the value provided . See More details on the output device page.

Next

step

is:

to

export

the

images

in

order

to

be

able

to

mill

the

copper

board

with

the

“Roland”

milling

machine,

export

the

files

in

.png

format

and

prepare

them

for

processing

with

the

fab

moduls

online.The

files

are

traces

(fig.3)

and

outline

and

Holes

(fig.4).(

Gimp

Software

help

me

to

draw

the

holes and outline).

Milling machine in action!

My Milled copper Board

I Start soldering!

I like to start to soldering with Avr microcontroller, in this case a ATmega 328p, so next all other components and at last the pin header.

Pinout of ATMega328p TQFP

My Board with AVR ATMega328p TQFP

My Board with all components

My Board and my Eagle project

Original Files and Useful Links

AVRDUDESS: the card is ready!

When AVRDUDESS is started, I first chose the correct programmer model from the list. My USBtiny is on the list. The next operation is Detecting MCU connected, I do this by clicking with the left mouse button on the "Detect" button. Immediately the name "ATMega328P" of MCU appeared on the field and I am very happy because my electronic card is alive!

/* HALL SENSOR BOARD V.2.0

code written by Giuseppe Allocca

FabLab class 2018

Santa Chiara FabLab SIena Italy

*/

//leds pins definition

int powerled = 3;

//white led

int comled = 2;

//blu led

int sensor= 16;

//Analogic pin

int sensor_value=0;

int pinsound=5;

//digital pin

void setup() {

// initialize serial:

Serial.begin(153600,SERIAL_8N1);

/* my usb to ttl serial converter divide serial baud declared by 16

and so...153600/16 =9600 I really don't know why!!! */

// initialize digital pin LED as an output and pin Button as input

pinMode(powerled, OUTPUT);

pinMode(comled, OUTPUT);

pinMode(sensor, INPUT);

pinMode(pinsound, OUTPUT);

// turn LED on:

digitalWrite(powerled, HIGH);

//Board power-on

digitalWrite(comled,LOW);

//comled off

}

// end void setup

void loop() {

/* activates serial transmission and blinking led blue

when sensor value if different then normal status */

// read the sensor value from pin 16

sensor_value=analogRead(sensor);

// "or" operator to control low or high value change depending by polarity of magnet

if ((sensor_value)>511||(sensor_value)<508)

//blue led blinking synchronized to sensor_value

{digitalWrite(comled,HIGH);delay(map((sensor_value),20,1023,1,10));digitalWrite(comled,LOW);delay(map((sensor_value),20,1023,1,10));

//remap value of sensor to 1-100 scale and send the value to serial port

Serial.println(map((sensor_value),13,450,10,900));

//sound zone

digitalWrite(pinsound,HIGH);delay(map((sensor_value),20,1023,1,10));

//start beep

digitalWrite(pinsound,LOW);

//end beep

// the sound are synchronized to sensor_value than blue led

}

// end if

}

//end void loop

My Arduino code with Serial speed problem…

Useful PinOut of ATMEGA328p with Arduino pin number

Arduino plotter monitor function

Arduino serial monitor function