Assignment 6: 3D Scanning and Printing

Assignment:

Group assignment:

- Test the design rules for your 3D printer(s)

Individual assignment:

- Design and 3D print an object (small, few cm) that could not be made subtractively

- 3D scan an object (and optionally print it)

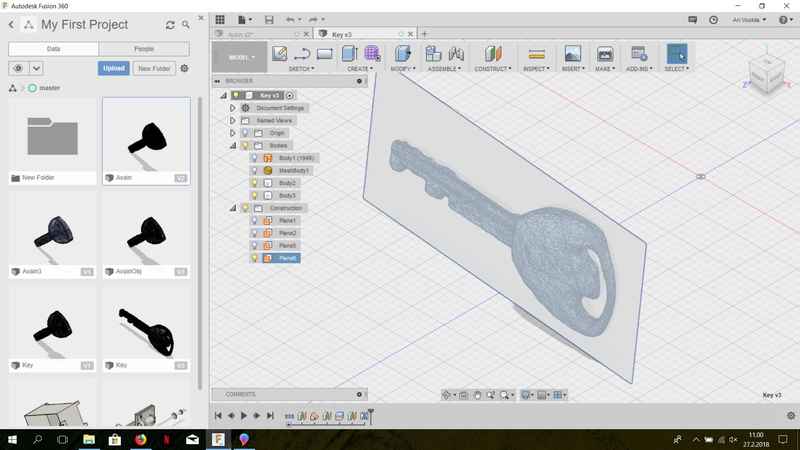

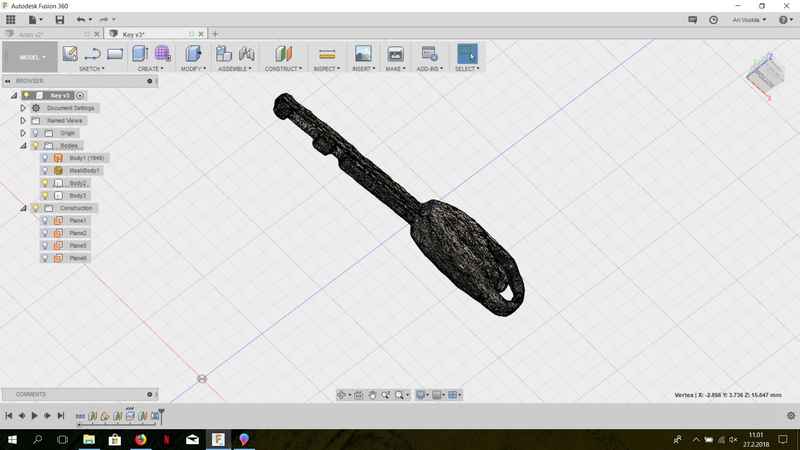

3D Scanning

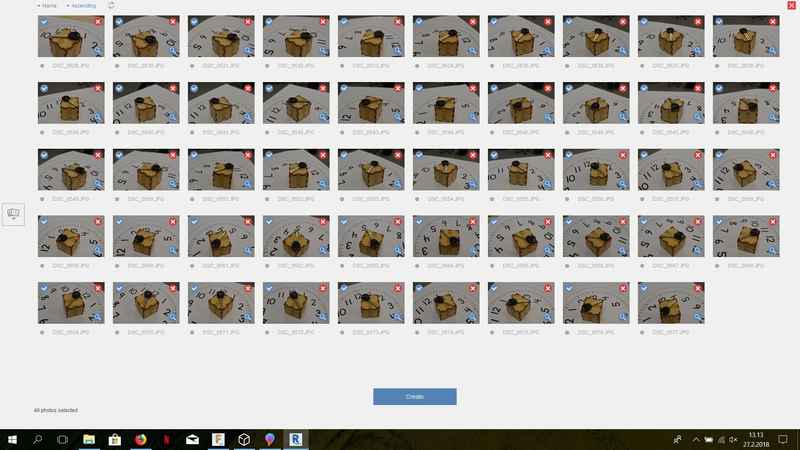

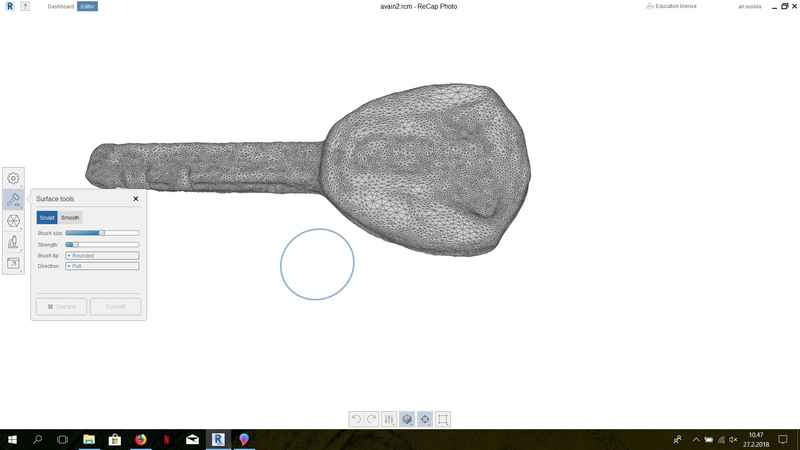

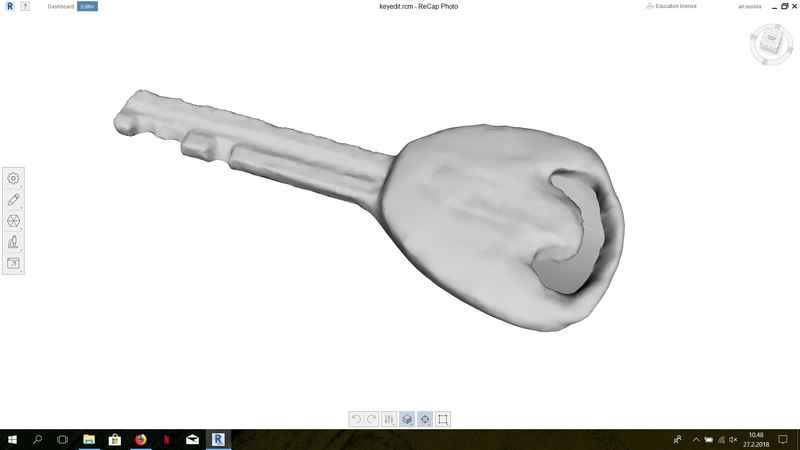

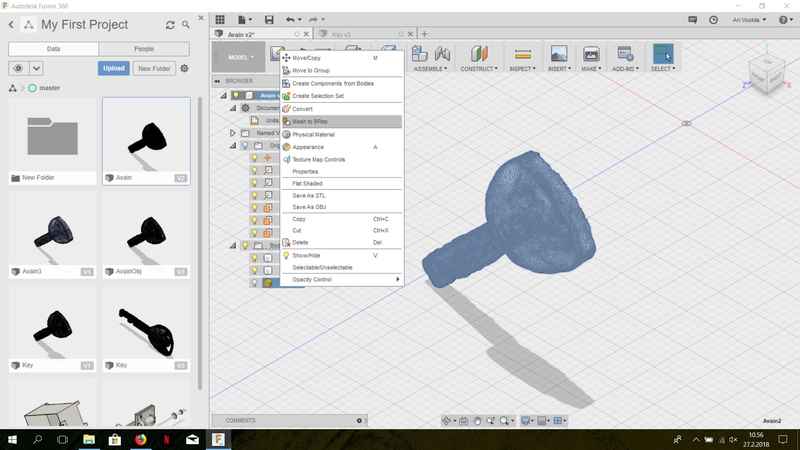

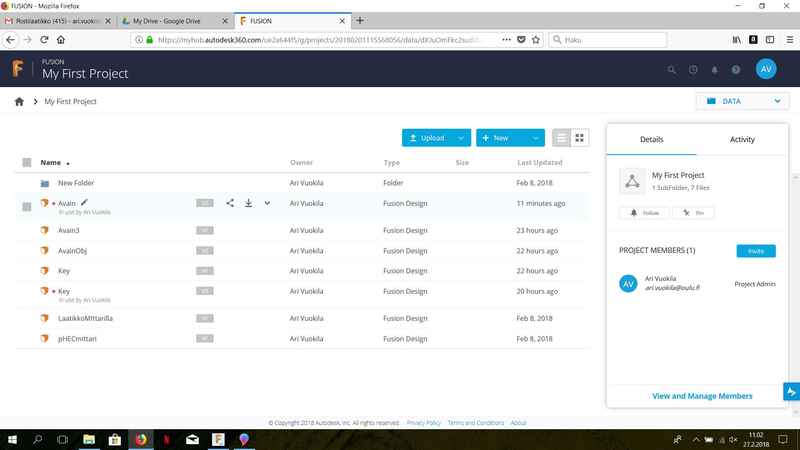

We started to practice using the 3D printers and 3D scanning with our whole group at 10 am at 22.2.2018. We went through a guide of which program to use for the scaninng and how. I chose a key for the scanning. There was a clock face below the key and a box under it to lift it up from the table.

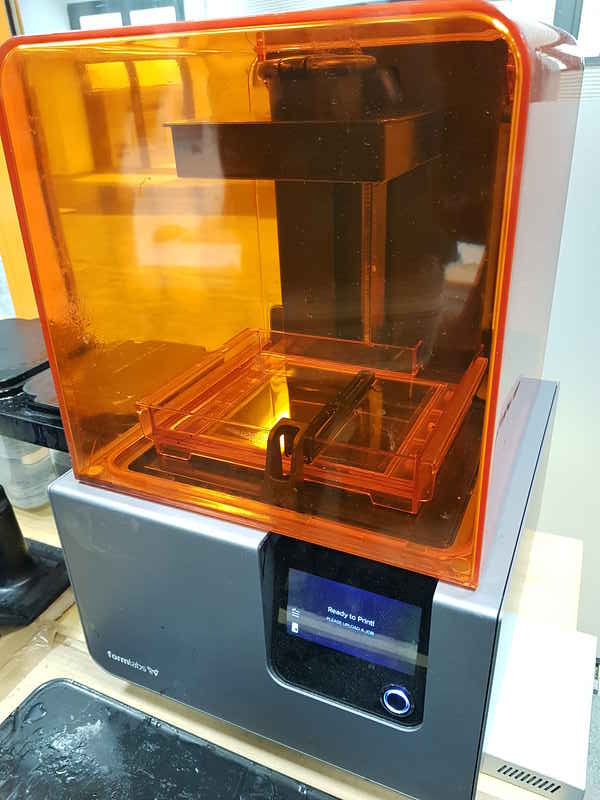

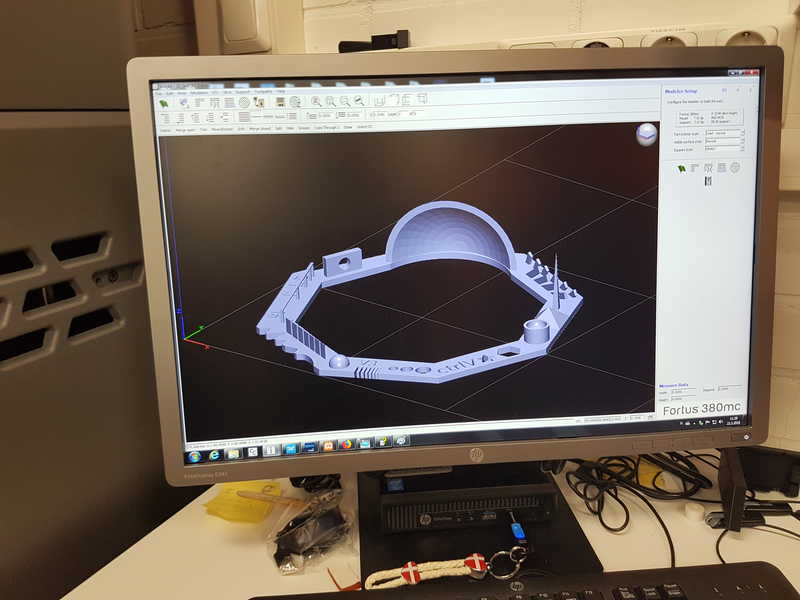

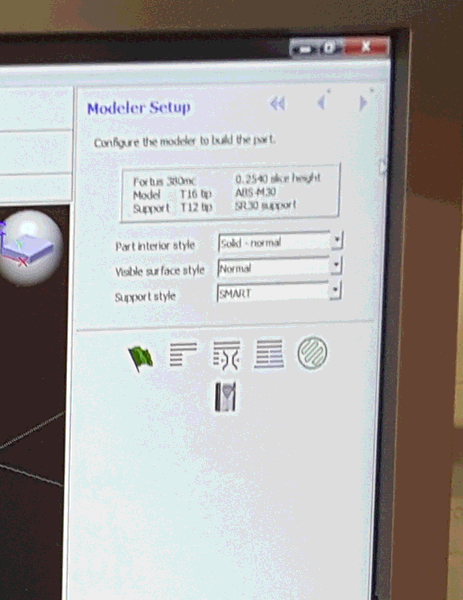

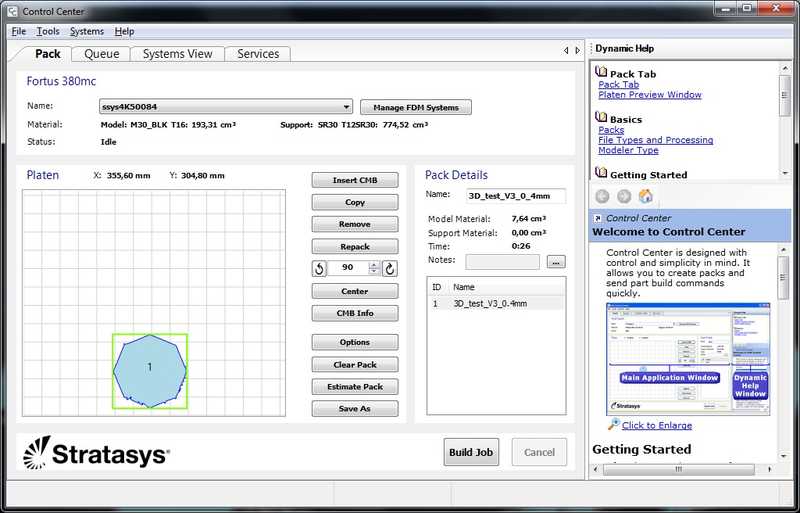

We have three 3D printers in our Fablab, which we used in this weeks assignments, Stratasys Fortus 380 mc, Sindon 3DWOX and Formlabs Form 2. I did my 3D print with Stratasys printer.

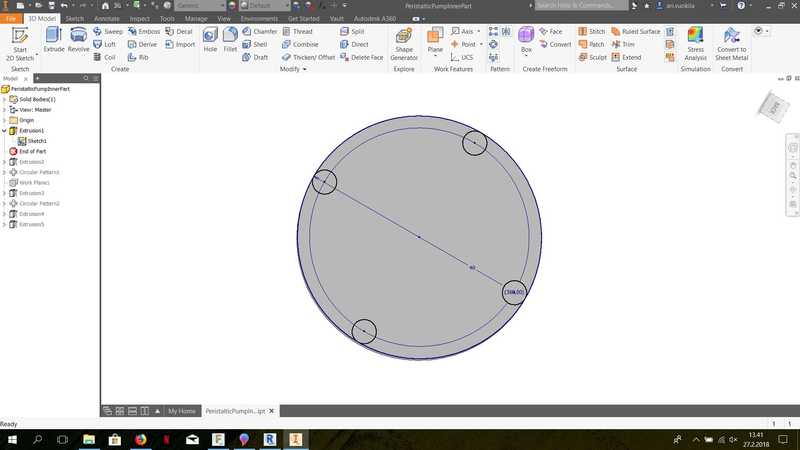

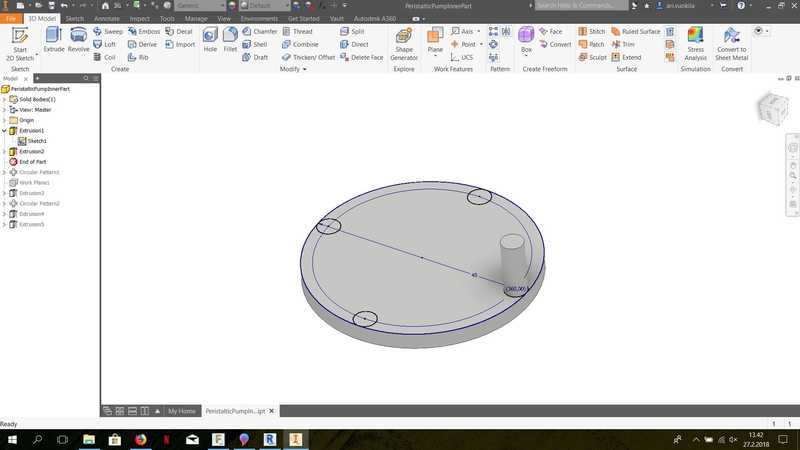

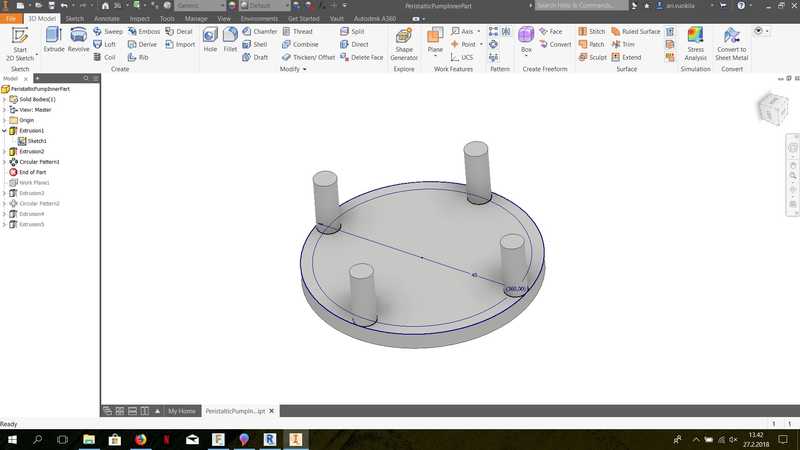

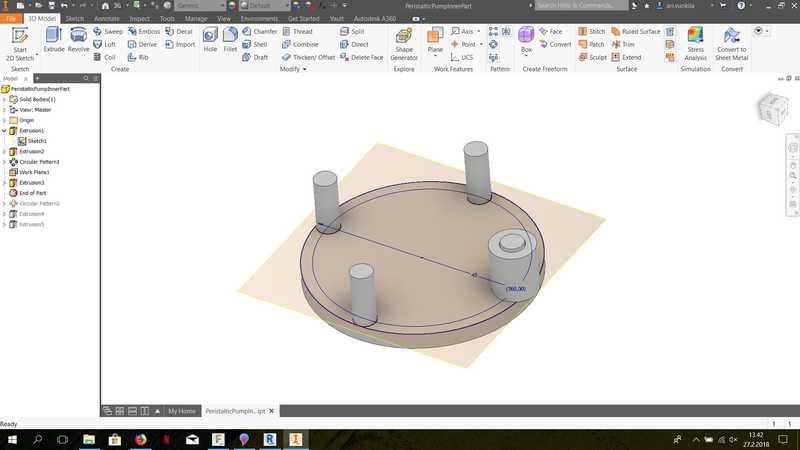

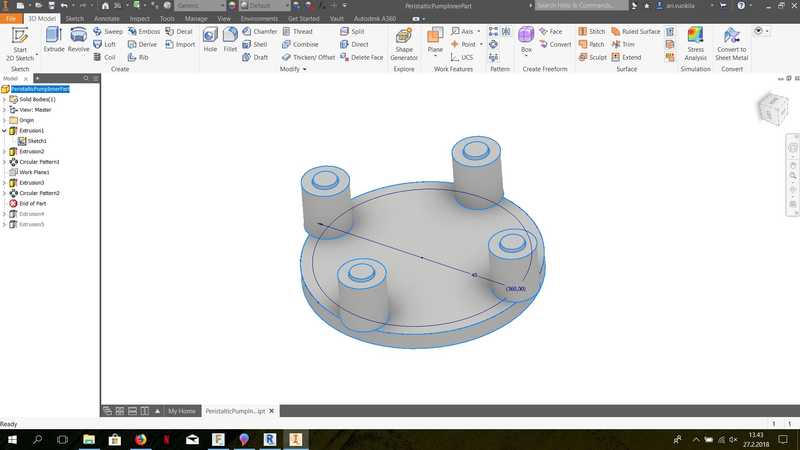

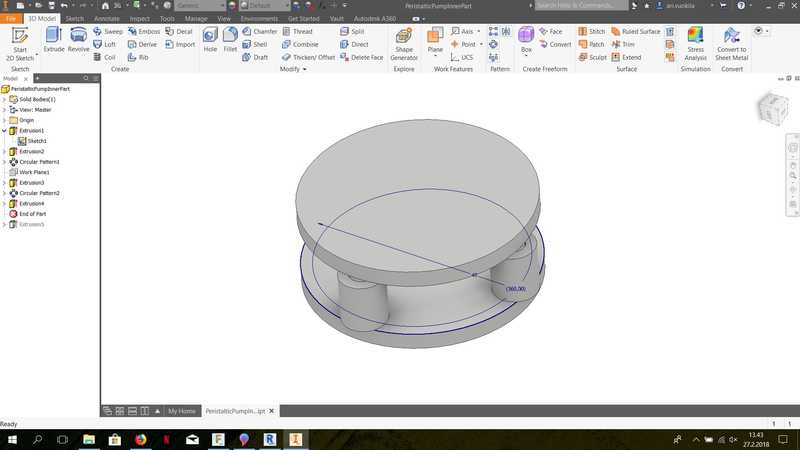

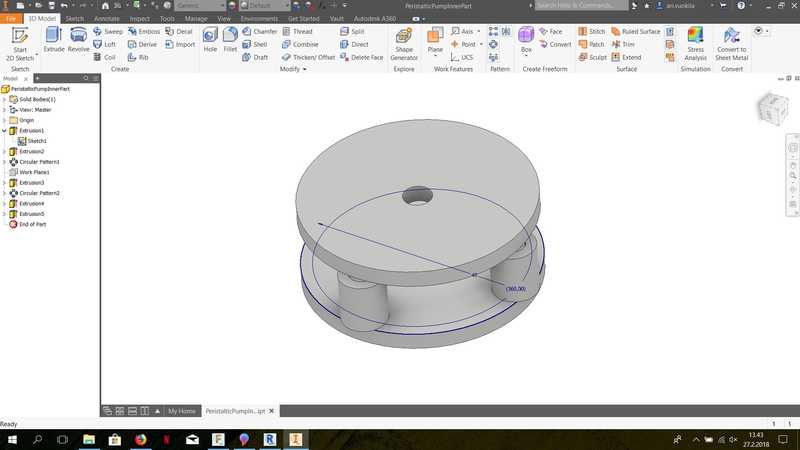

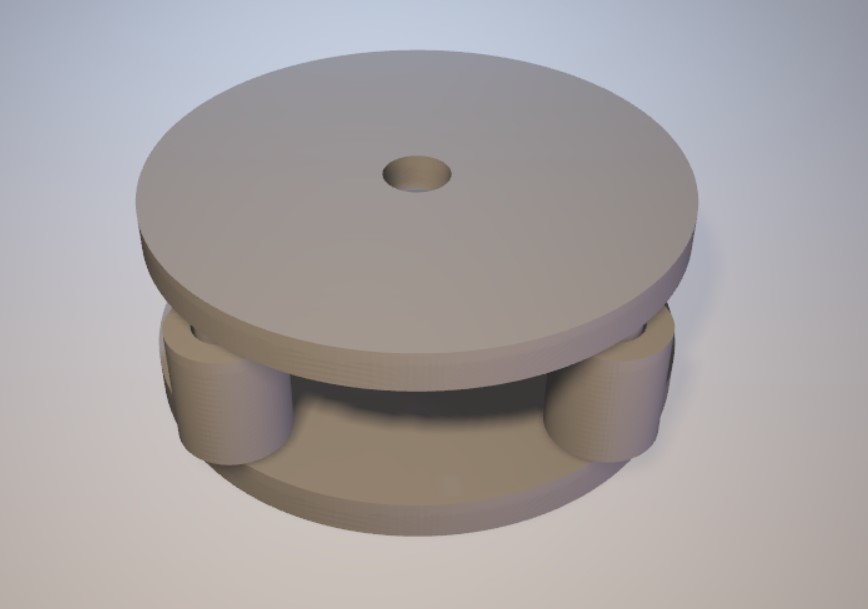

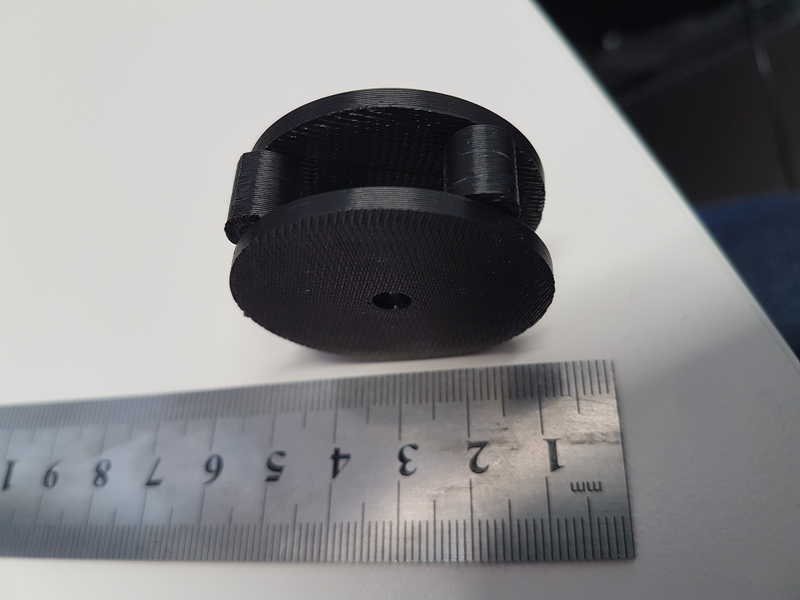

At first, I created a sketch of the wheel (diameter 4 cm) and extruded it (3 mm thickness). On the surface, I created another sketch for the axle holding the smaller wheel (diameter 4 mm).

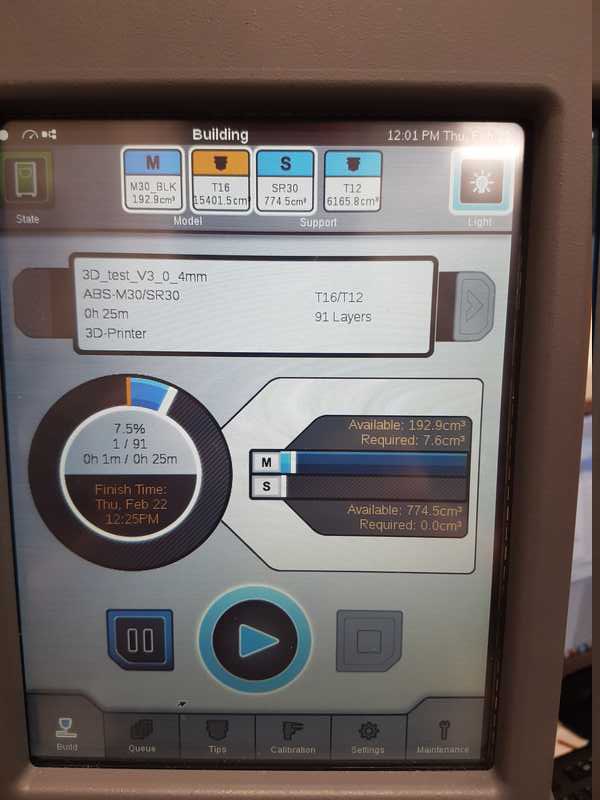

You can position your part there and press Build job when you are ready to print. This sends the file to printer.

Reflection on this weeks assignment

This weeks assignment has been really interesting and I learnt a lot about the possibilities of 3D scanning and 3D printing. Advantages in 3D scanning are that you can use camera or 3D scanner to reproduce an object and move it to a 3D modeling software for post processing and you have possibility to replicate an object. It seems that it is used a lot in statue replication and also to create 3D room views. In the 3D scanning the limitations are that it is time consuming (good images from high number of angles, processing images to 3D scanning) and you don't see the results until the images are made in the 3D scanning and even if the results seem ok, you have to make a lot of post processing. In many cases, it would be faster to use 3D modeling software and a measurement tool to reproduce the object. 3D scanning of a full object from each side is extremely hard. As a conclusion, I would say that 3D scanning of simple geometries is not efficient and the 3D scanning of complex objects is hard and very time consuming.

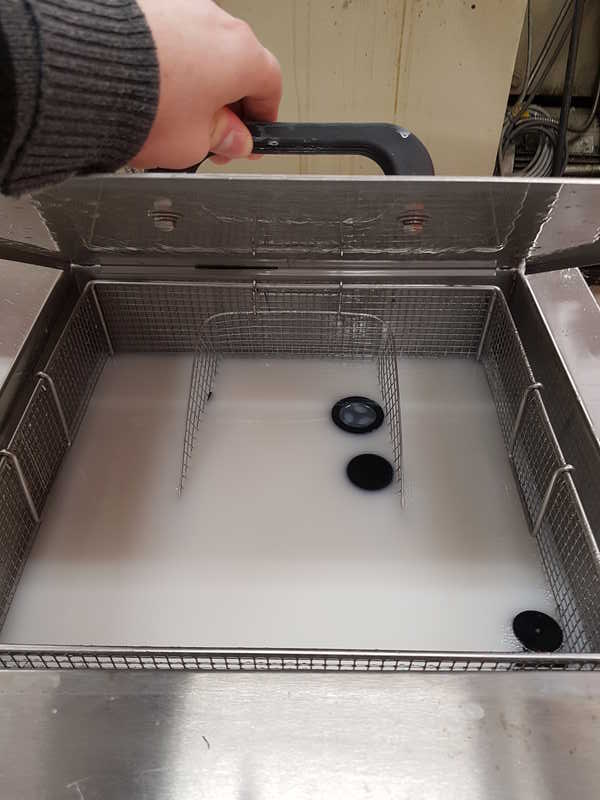

3D printing is a very versatile method and can be used quickly to produce prototypes of different kinds of objects or a part/spare part for some kind of machine. Even though many things can be made with 3D printing, it has several limitations as well. When you are considering to make bigger parts or several copies of a same part it is time consuming and in some printers the material costs are very high. In Stratasys printer, the material costs are around 300 €/l for the filament (ABS) and 450 €/l for the support material (soluble release material). Bigger pieces might cost above 1000 € and even the smaller ones cost surprisingly much. The materials for the basic 3D printers include ABS, acrylic and PLA, which are soluble in organic solvents and you have to be careful in 3D print purpose and also, if you are planning to paint them the paint should be acrylic paint. Typical printers cannot be used to print fine features, sharp angles, thin walls or walls very close to each other. The 3D printer nozzle diameter, material, 3D printing method and the fact that the filament is in molten state limits the accuracy of the print.

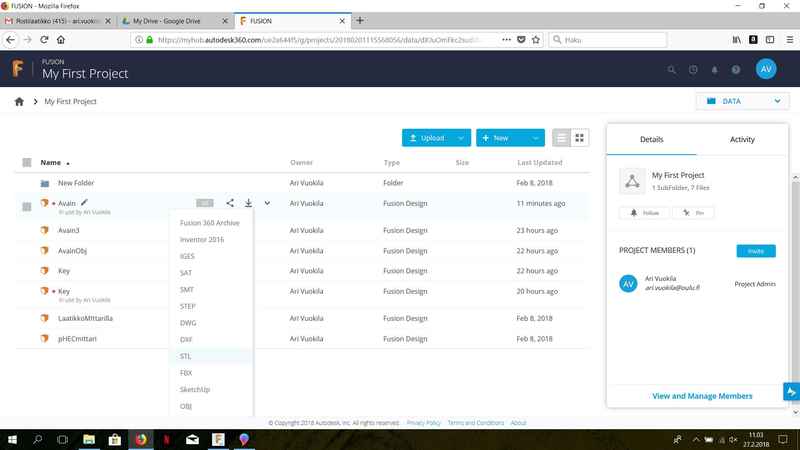

The files used in the assignment are shared below:

3DprintingFiles.zip Files for the 3D printer.

3DScanningFiles.zip Files from the 3D scanning.

Group work file from Thingverse File from the group work.

Group assignment

The group work consisted of testing the design rules for our 3D printers. 3D printing group page. I had never used a 3D printer before and I was exited to try it out and got the honors to work with the machine. Everyone else in our group had worked with them before, so they did not need the practice as much. We used a test piece, which we found from thingverse. We printed it with 3 different printers and compared the results with each other. Formlabs printer made the best quality printing, but it took almost 11 hours to print the part. We had plenty of problems working with Shindo 3DWOX, because it created filament errors four times, before we got it to print more than a single line. It might have something to do with wear of the printing surface. At least we got it to work, when we moved the hardest part to an area with smoothest surface. More on the group work can be found in our group page.