Week6 : 3D Printing

Chain Mail

Download files

Resources

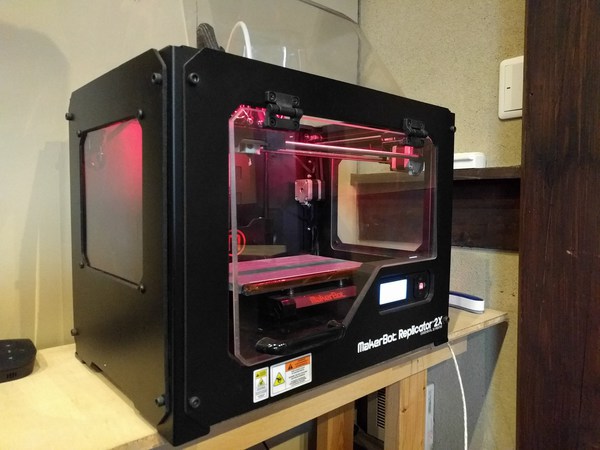

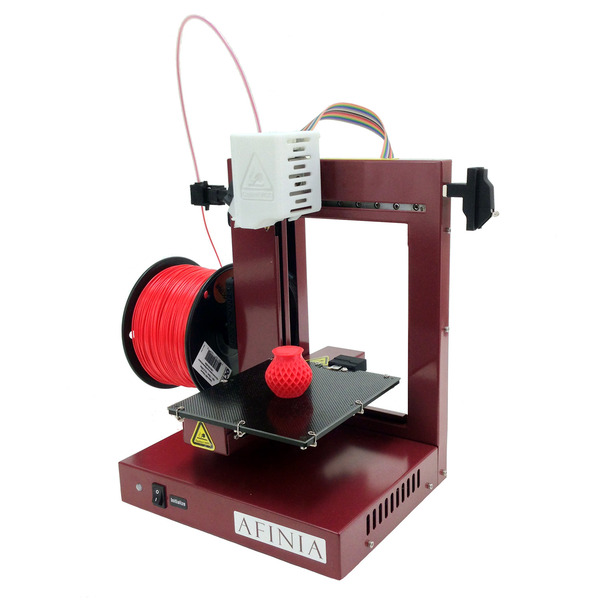

Printers in our lab

- Makerbot Replicator 2X

- Afinia H480

- Afinia H400

Test printers

Check out what we tested as a group:

Group page

To characterize our 3D printers, we picked test model from Thingivers.

Test data : All In One 3D Printer test by majda107

The set of filament material and printer we tested :

- PLA with Makerbot Replicator 2X

- ABS with Afinia H480

In our lab setting, we usually use Replicator for printing big stuff (larger than approx. 100mm square), and Afinia for small stuff that requires accuracy.

Although ABS has high degree of flexibility and accuracy, it often curves as it cools down (we tackle this problem by adding raft or pre-heating the platform), and this curve gets worse if the model size gets bigger. That is the reason why using ABS for only small things, and Afinia Studio and the slicer setting on Afinia is optimized to the use of ABS. Its build volume is smaller than Replicator too.

In contrast, Replicator has big build volume (24.6 L X 15.2 W X 15.5 H cm) so we are using it for printing large things with PLA. PLA filament has less deformation after printing (it is also less flexible and difficult to do after processing)

Results

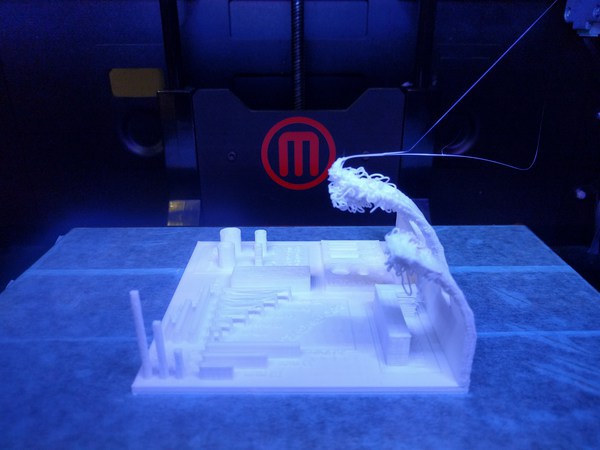

Makerbot Replicator 2X

Filament : PLA (bonsailab/white/1.75mm)

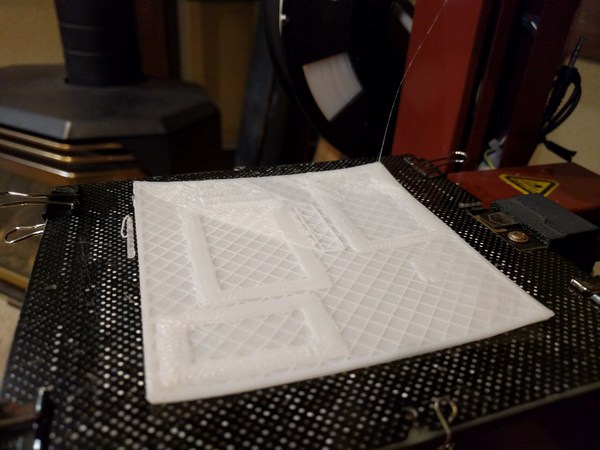

Attempt #1

| Parameter | Value |

|---|---|

| extruder temp | 210 |

| build plate temp | 60 |

| infill | 20% |

| raft | yes |

| support | no |

| layer height | 0.3mm |

| print speed | 10m/s(raft), 30m/s(model) |

| cooling fan speed | 50%(raft),50%(model) |

| filament diameter | 1.77mm |

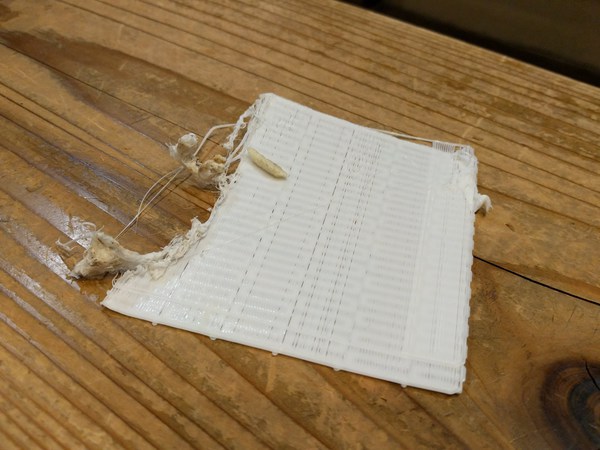

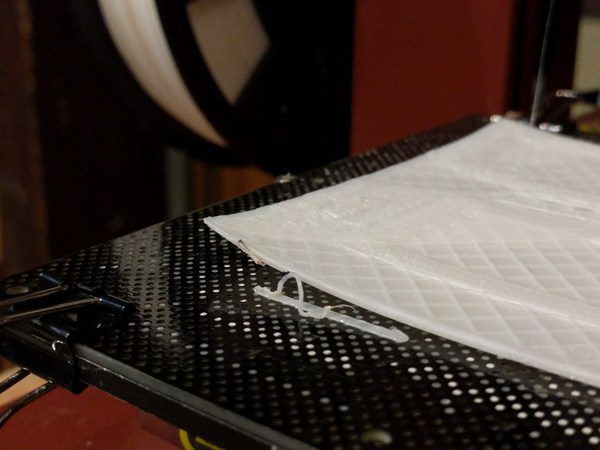

Resulted in failure

- In the first time, model

- raft pealed off

Attempt #2

| Parameter | Value |

|---|---|

| extruder temp | 220 |

| build plate temp | 60 |

| infill | 20% |

| raft | no |

| support | no |

| layer height | 0.3mm |

| print speed | 10m/s(raft), 30m/s(model) |

| cooling fan speed | 50%(raft),50%(model) |

| filament diameter | 1.75mm |

Success!!!

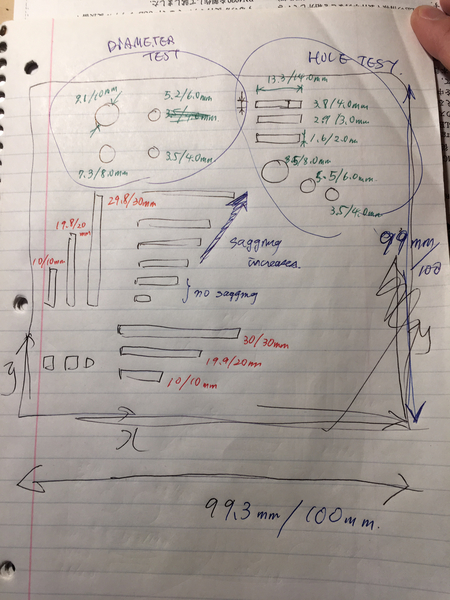

Findings

- Generally speaking, Makerbot with PLA is quite presize at paths (including straight lines, curves and corners), results in performing fantastic build with towers(thin vertical structure) and walls.

- We measured the sizes of the actual built model and compared with the model data. They all had relatively same shrinkage ratio which means the built is accurate.

- In contrast, PLA fillament easily falls off when building diagonal surfaces. Take a look at the section of “overhang test” and “bridge test” in the test model, 30 degree is the maximum lean for overhanging and you will not be able to bridge more than 5mm gap.

Afinia H480

Filament : ABS (Afinia genuine)

| Parameter | Value |

|---|---|

| extruder temp | 270 |

| build plate temp | 90 |

| infill | 20% |

| raft | no |

| support | no |

| layer height | 0.3mm |

| print speed | n/a |

| cooling fan speed | n/a |

| filament diameter | n/a |

Failed due to the distortion. I also tired printing out with raft, and with higher build plate temperature, but could not fixed the problem.

Filament material characteristic

| PLA | ABS | |

|---|---|---|

| Printing temp | 200-210˚C | 210-240˚C |

| Print bed temp | 20-60˚C (optional) | 80-110˚C (mandatory) |

| Strength | Decent Strength | Above Average Strength |

| Flexibility | Brittle | Moderately Flexible |

| Heat Resistant | no | yes |

| Biodegradable | yes | no |

| Acetone Treatment | Not Possible | Possible |

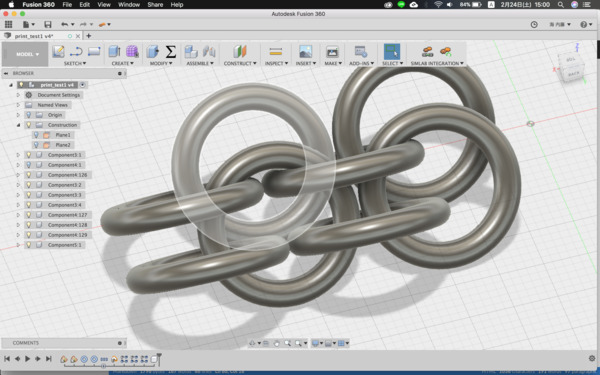

Chain mail

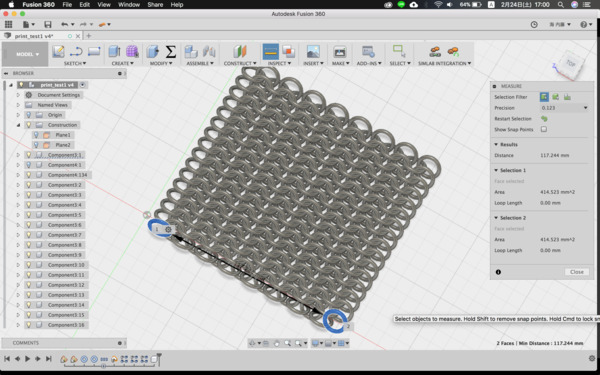

Making data (Fusion)

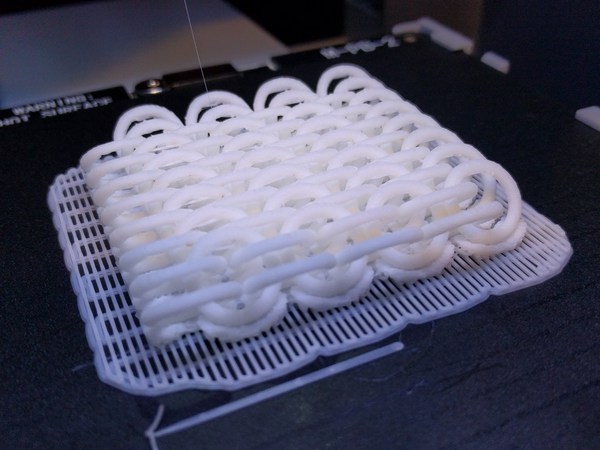

Printing

| Parameter | Value |

|---|---|

| extruder temp | 270˚C |

| build plate temp | 76˚C |

| infill | 20% |

| raft | yes |

| support | yes |

| layer height | 0.3mm |

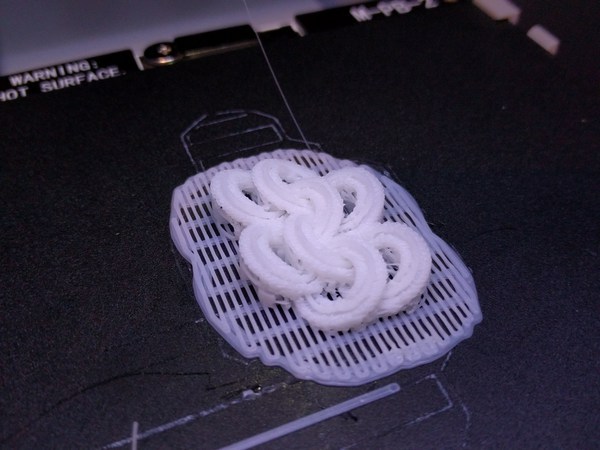

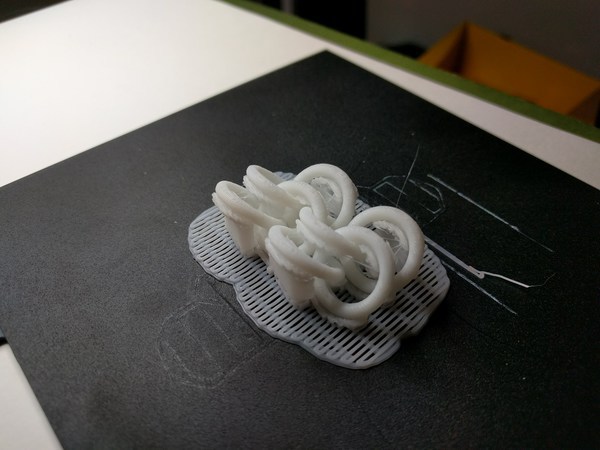

Raft and support built ok (support threshold 30˚). However, some of the rings were sticked each other as there were several interference between bodies.

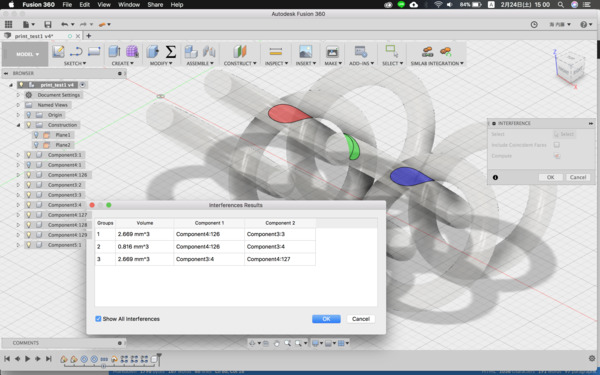

After asking senior co-work member at the lab, I discovered the inspect feature of Fusion360.

Checked interference.

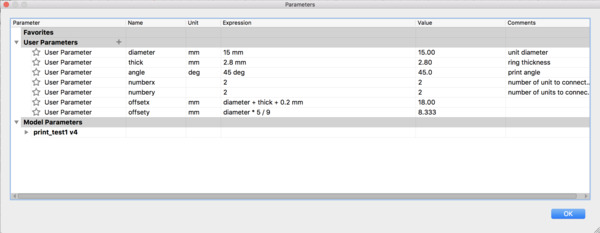

I tweaked the parameters.

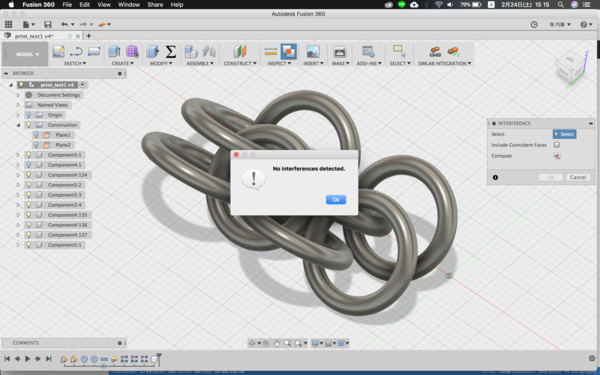

Making sure there are no interference…

Took a second try

Success!

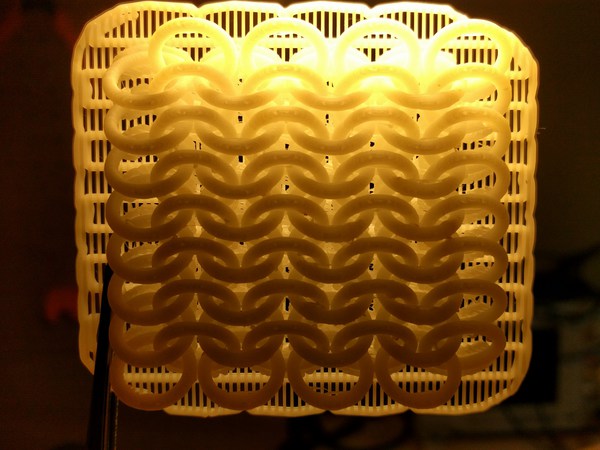

Scaling it up!

After the trial and the refinement on parametric data and the printer setting, I wanted to scale it a bit more.

The problem was time. A slicer told me that it will take 9 hours and 20 minutes to print the whole thing.

I took 2 means to shorten the build time.

Firstly, excluding support, but to do this I had to check how far I can go with out support.

Due to the placement of the each ring (placing to interlocking position with out touching each other), it was difficult to change the angle and the thickness of the ring. Therefore, I picked diameter as a parameter and tested three patterns shown in the picture below.

diameter ø7, ø10 and ø15mm.

It turned out that within this range of scale, support didn’t really matter.

As I wanted to make it as small as possible to reduce materials (the second mean for shortening build time), I decided to go with ø10mm ring. The ø7 ring was too small, some filament fell and losing shape.

Adjusting other parameters, check interference and start print.

Done.

Further ideas

Scanning

Hardware

Tools I tried

-

[Autodesk ReCap Pro for mobile]d(https://itunes.apple.com/us/app/autodesk-recap-pro-for-mobile/id1095833461?ls=1&mt=8)

-

Autodesk Recap

Windows only -

Qlone

Put an object on the dedicated paper with marker.

Accurate, but takes time and bit difficult to scan bottom part near the ground.

Has nice AR feature. -

Trnio

app available on iphones only -

3DF Zephyr

Windows only

Scanning a foot

I have been planing to make flip-flops for CNC milling week of Fabacademy. The shoe sole will be made of wood. By milling the surface of the wood according to the three dimensional shape of my foot, it should perfectly fit. Now, I need 3D scanned data of my foot…

I ended up scanning with Sense2 scanner, which turned out to be kind of satisfactory.

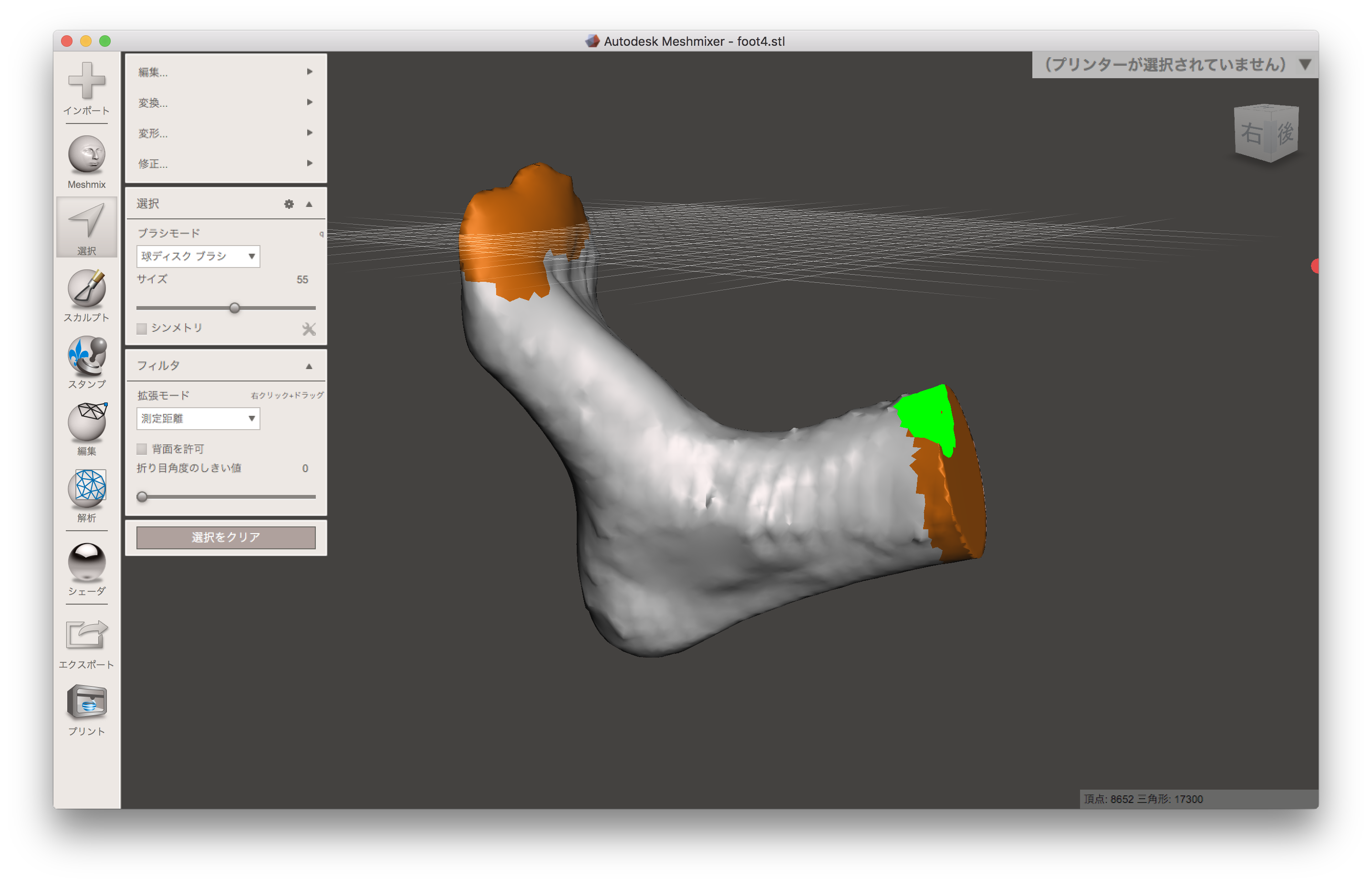

After scanning with Sense2 and generic app, I (actually my classmate) retouched the data with Autodesk Meshmixer to close the geometry and make a solid model.

By doing it, I can 3D print model or make a milling data.