Week16 : Machine Design

group assignment

Visit project group page for full documentation

- actuate and automate your machine

- document the group project and your individual contribution

Last time, we made

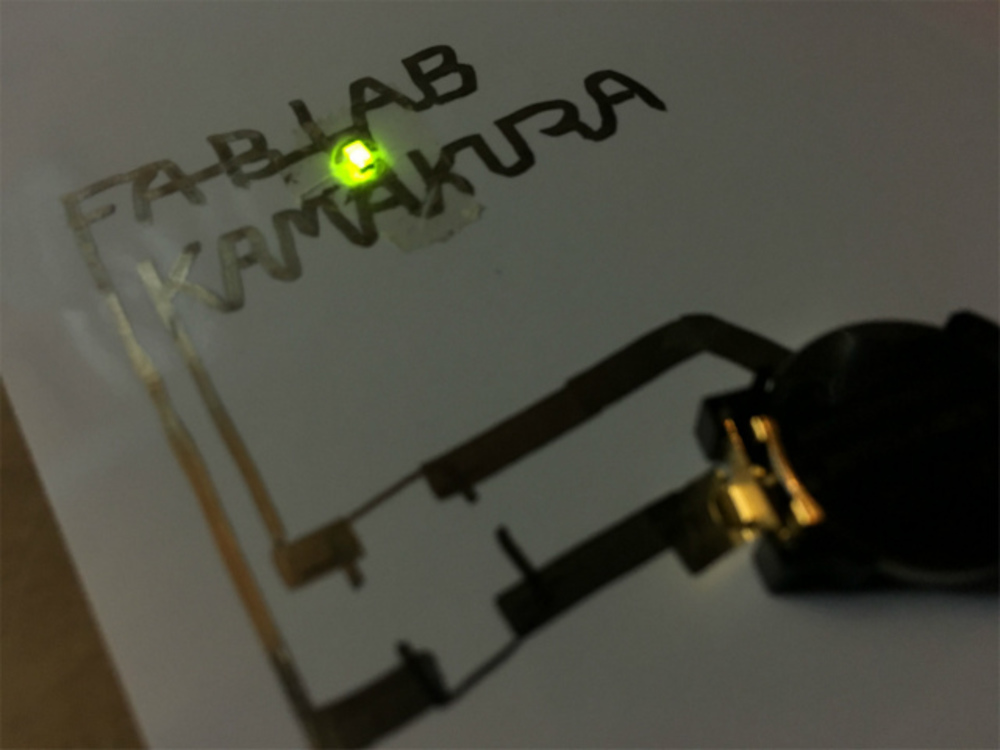

Circuit Plotting Machine Using Conductive Ink (Agic)

We had three problems left:

-

tilted pen: pen tilted during plotting.

-

mirrored image: plotted image was mirrored.

-

fragile housing: housing beams were thin and fragile.

This week each of us addressed to the individual problem. I was assigned to fix the housing.

Here I leave this brief document to report what I did this week.

Download data

Problem

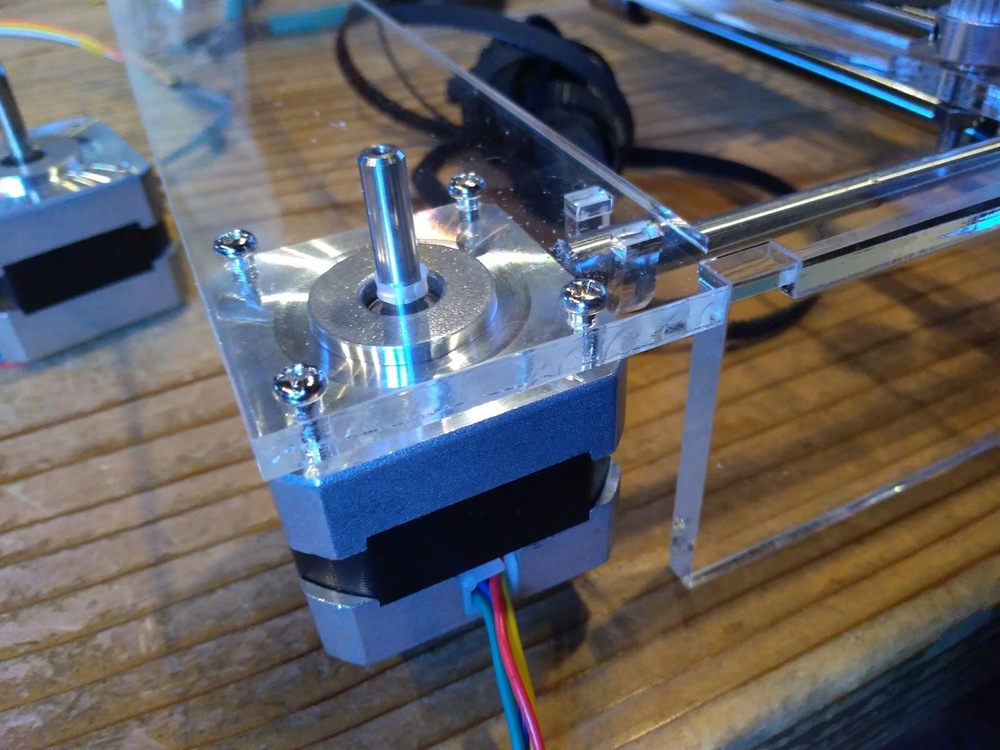

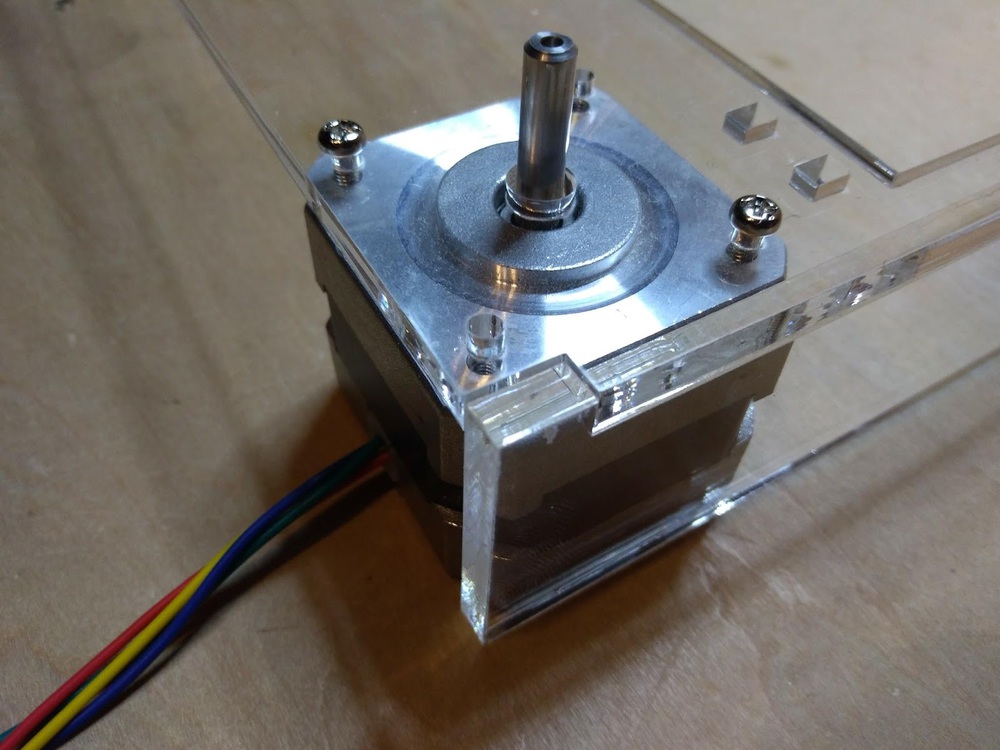

The belt tension and the weight of the motor itself concentrate at the very narrow gap between the wall and the workspace.

Solution

Before revision.

After revision.

By adjusting the height to place the motor on the ground and extend wall to support weight of the motor, there is no longer concentration of stress on the corner.

Hero shot of our machine

Further step

-

It would be interesting if the machine can draw its own circuit on the paper and reproduce itself.

-

We couldn’t get to the point of demonstrating an advantage of “flexible circuit” and “ondemand rapid fabrication of circuits”.

-

In the process of circuit making with Agic pen, installation of SMD chips is the most troublesome part. You may simply stick it with a scotch tape but it will lose contact when it is bent. In those cases you need to use conductive bonding agent to ensure the contact. What else could be used to mount components?