Week 17. wildcard week - composite

Assignment

- group assignment:

produce test coupons for your composite fabrication process(es) - individual assignment:

read the safety data sheet (SDS) and technical data sheet (TDS) for the resins that you're using

design and fabricate a 3D mold (~ft2) and produce a fiber composite part in it, with resin infusion and compaction

group assignment

see FabLab Kamakura's group assignment page.

introduction

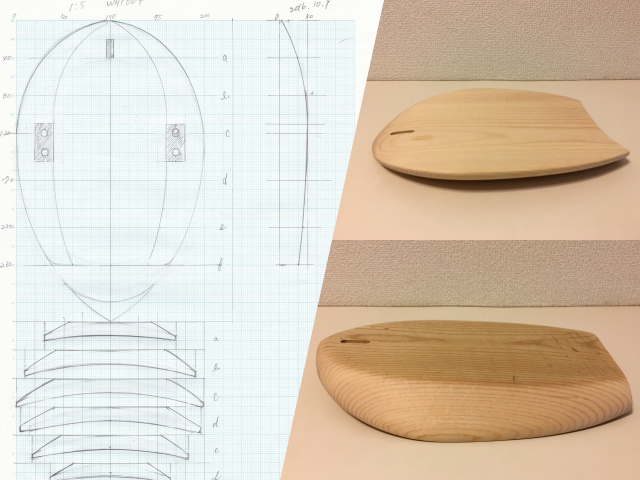

I wanted to coat my surFABoard with a resin, which I made in week 8, but I don't have a big plastic bag enough to compress after the resin infusion. So, I made a handplane.

A handplane is a smaller version of a surfboard that you attach to your hand using an adjustable strap, which allows you to easily ride waves better while bodysurfing.

modelling

I designed a 3d modelling based on a schematic which a friend of mine designed shown as below.

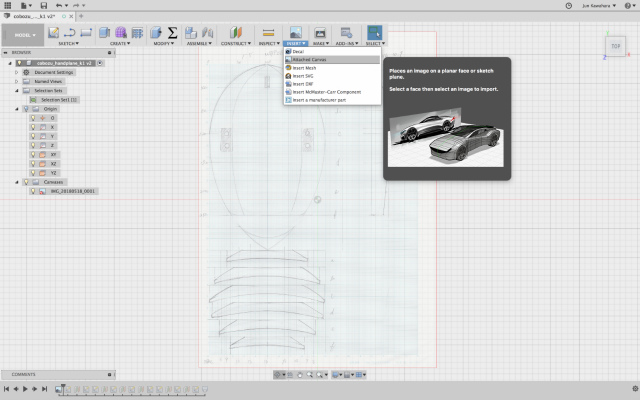

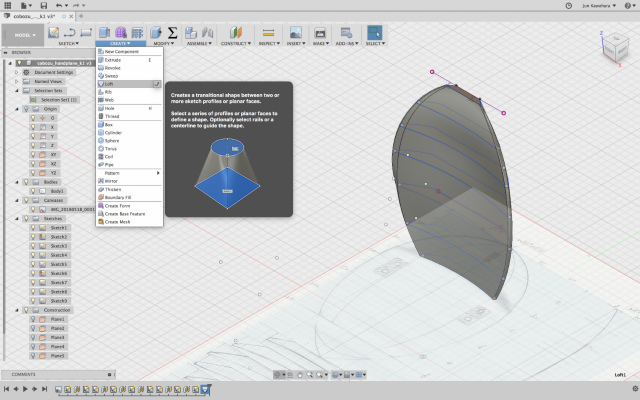

Start Fusion 360, [INSERT]>[Attached Canvas] and select a schemtic.

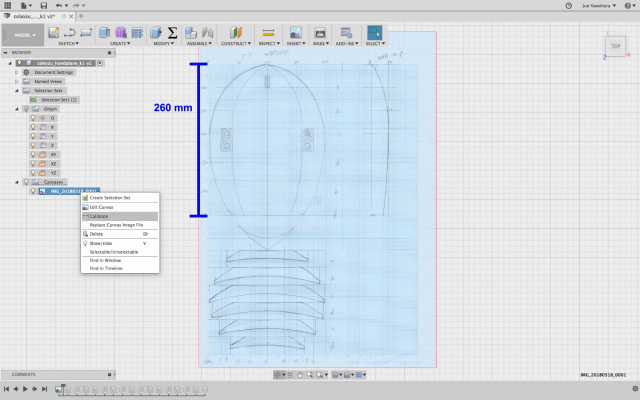

Right-click the attached canvas and select [Calibrate]. Put points at either end of a length. In this case, the length of a handplane was 260 mm.

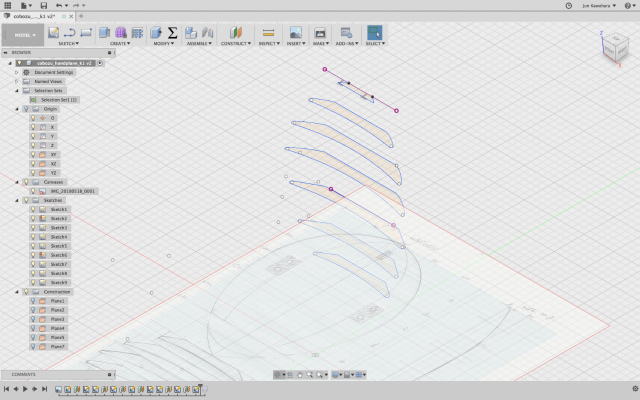

I created offset planes, [CONSTRUCT]>[offset plane], to draw a cross-section on each offset plane

[CREATE]>[Loft], select each plane and press OK. Then, right-click the part and "save as STL."

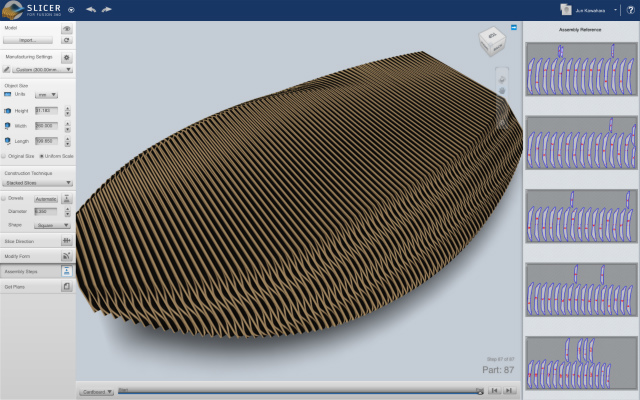

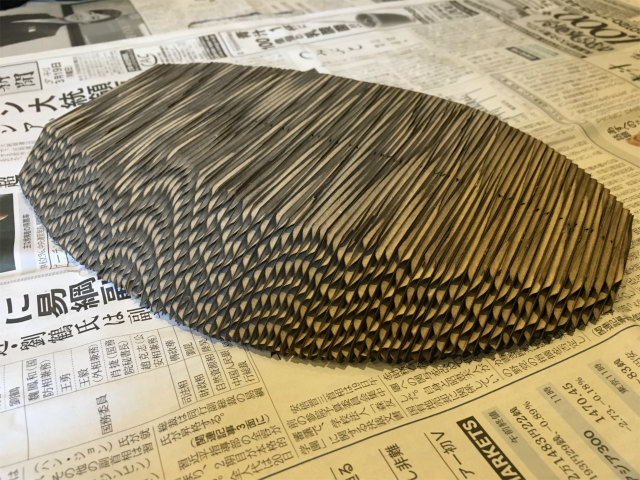

I made a handplane with stacked slices of cardboard. I started SLICER for fusion 360, imported an STL file exported earlier. I Chose "Stacked Slices" as Construction technique. Material size settings were followings.

- Units: mm

- Width: 300

- Length: 600

- Thickness: 3

I set a slice direction perpendicular to the longer direction.

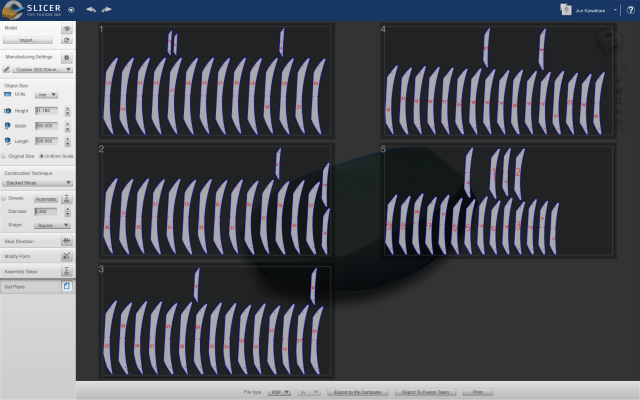

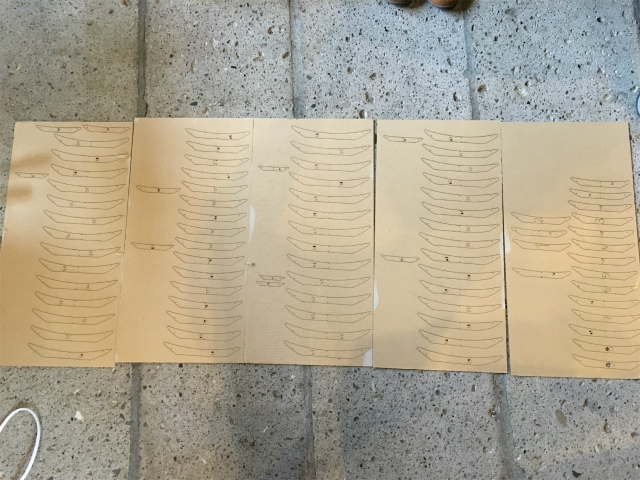

Press "Get Plans" and "Export to My Computer" as a file type "PDF." Then, I cut cardboards with laser cutter based on this schematic.

I used double-sided tapes to assemble the slices of cardboard.

test

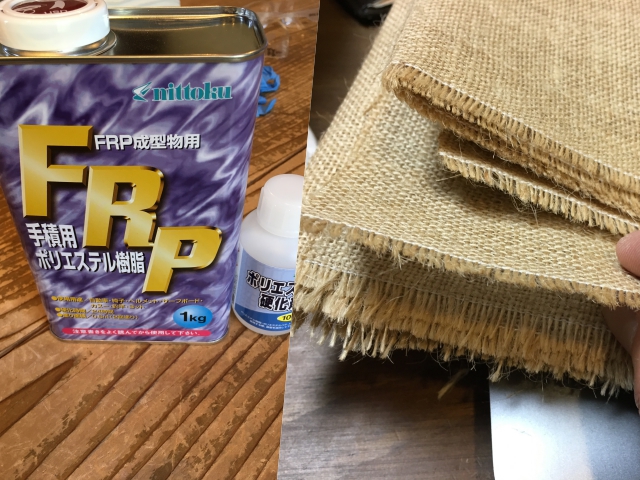

I used a cloth of Jute and unsaturated polyester as the matrix.

SDS has been provided from a supplier(in Japanse version only), but TDS was not. Matrix resin was a mixture of substances listed below, and main ingredients were unsaturated polyester resin and styrene monomer.

One of the substances, Styrene, has been classified by the International Agency for Research on Cancer (IARC) as Group 2B: The agent (mixture) is "possibly carcinogenic to humans." So, I dealt with care wearing eye protection goggles, a mask, and gloves in well-ventilated space.

| chemical name | CAS No. | wt.% |

|---|---|---|

| unsaturated polyester | NA | 50 -60% |

| styrene | 100-42-5 | 44% |

| silicon dioxide(SiO2) | 7631-86-9 | 0.7% |

| phthalic Anhydride | 85-44-9 | 0.7% |

| ethylene glycol | 107-21-1 | 0.2% |

| Cobalt Naphthenate | 61789-51-3 | 0.2% |

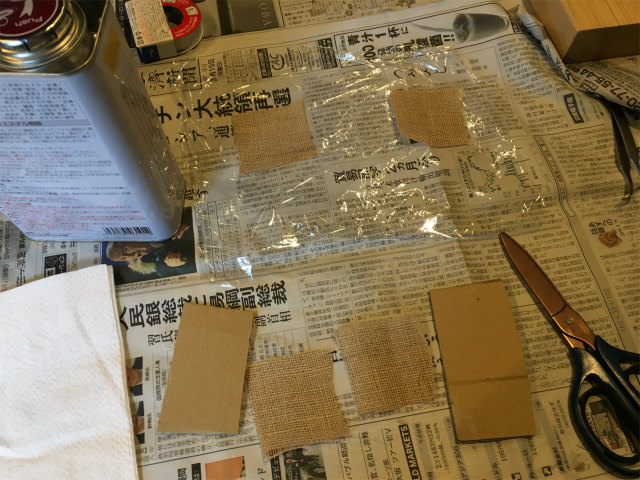

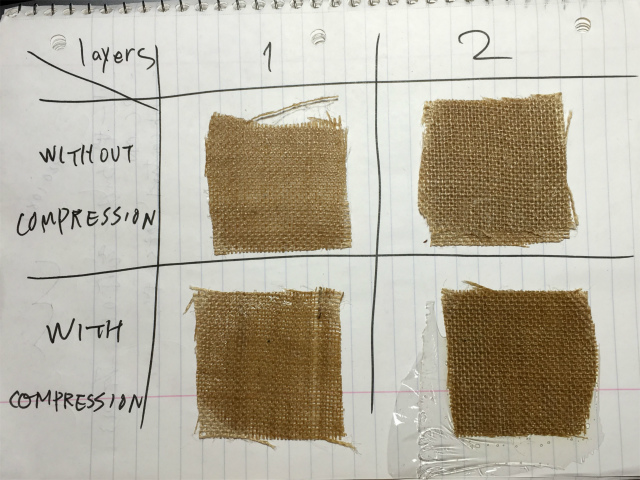

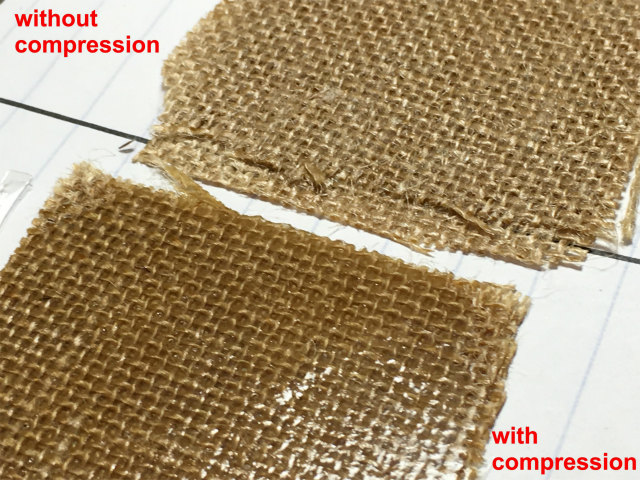

As a test, I prepared two one-layer and two-layer samples. One of which was compressed and the other was not compressed.

result

Two-layer of Jute was stiffer than one-layer, of course. I couldn't tell the difference of stiffness between the with or without compression, but the appearance was different. Without compression, the surface looked like Jute itself because, I guess, the resin infused through the fiber before the resin has hardened.

With compression, surface texture was smooth and gloss.

composite

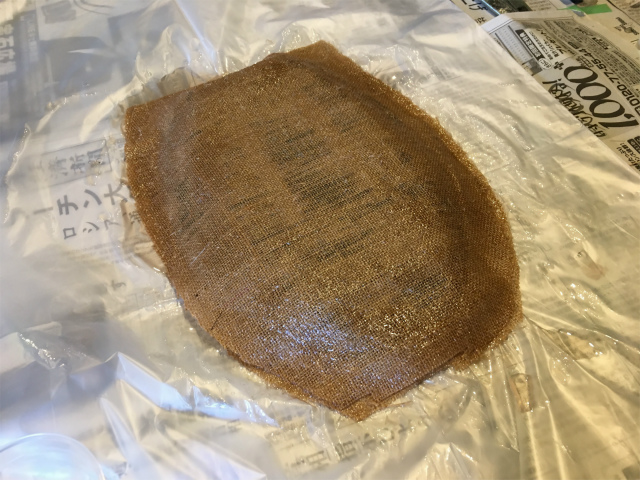

I put a layer of Jute from the top and the bottom of cardboard handplane. After I mixed matrix resin and a reaction accelerator at the ratio 100 to 2 (by weight), I poured it onto a handplane. As cardboard was paper and a porous matrix, it sucked up a lot of resin.

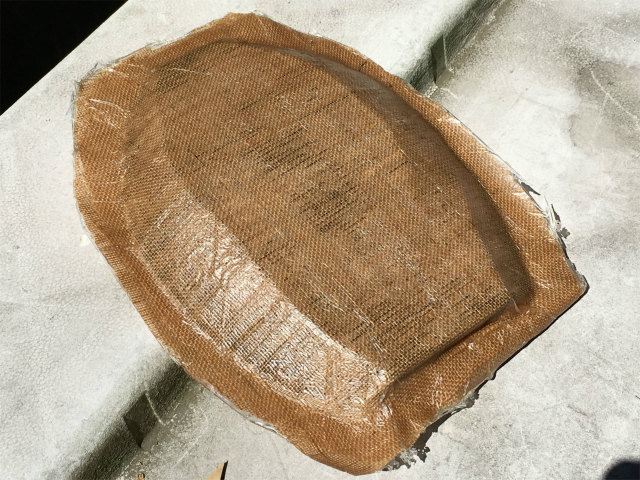

After I wrapped a handplane with a usual plastic bag, I put it in the plastic vacuum bag for compression.

I sucked the air with a vacuum cleaner.

I have pushed out the air thoroughly and left still for hours.

18 hours later, I took it out of a vacuum bag. The composite has hardened reasonably enough but still smelled a bit.

I removed the flashings with a fret saw and a sander. I was pretty happy with the result!

files

handplane 3d model: Fusion 360 format (.f3d)

handplane 3d model: STL format (.stl)

stacked slices of a handplane: SLICER for fusion 360 format (.3dmk)

laser cutting date: pdf format (.pdf)

MSDS for unsaturated polyester resin and curing agent: archived format (zip)