3D Printing

FDM Printed Parts

3D Printing is an Additive Manufacturing technology that turns digital design to tangible 3D objects.

You can see more details on how I learnt about this technology in the 3D Printing Week. The machine I used is the Ultimaker 2+.

I have designed multiple parts in my final project to be manufactured using 3D Printing.

The first part I decided to print is the back part of the box that carries the water tank and electronics.

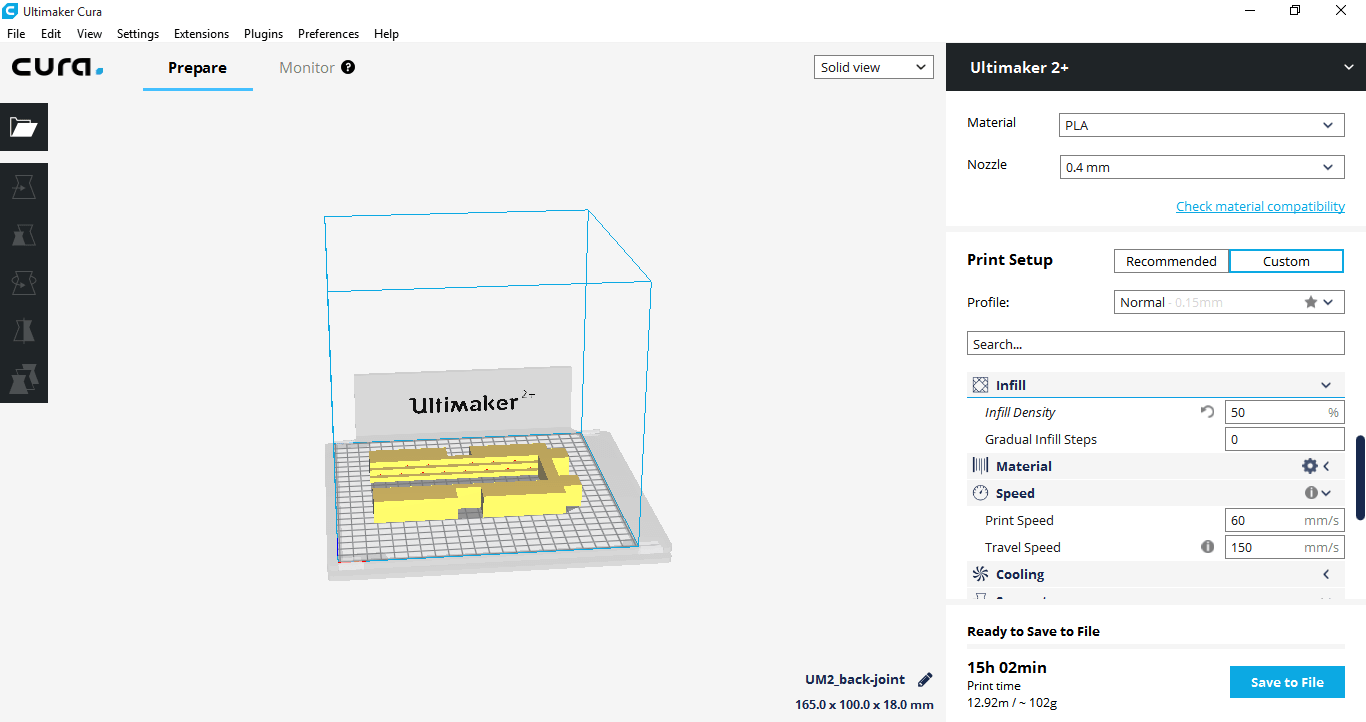

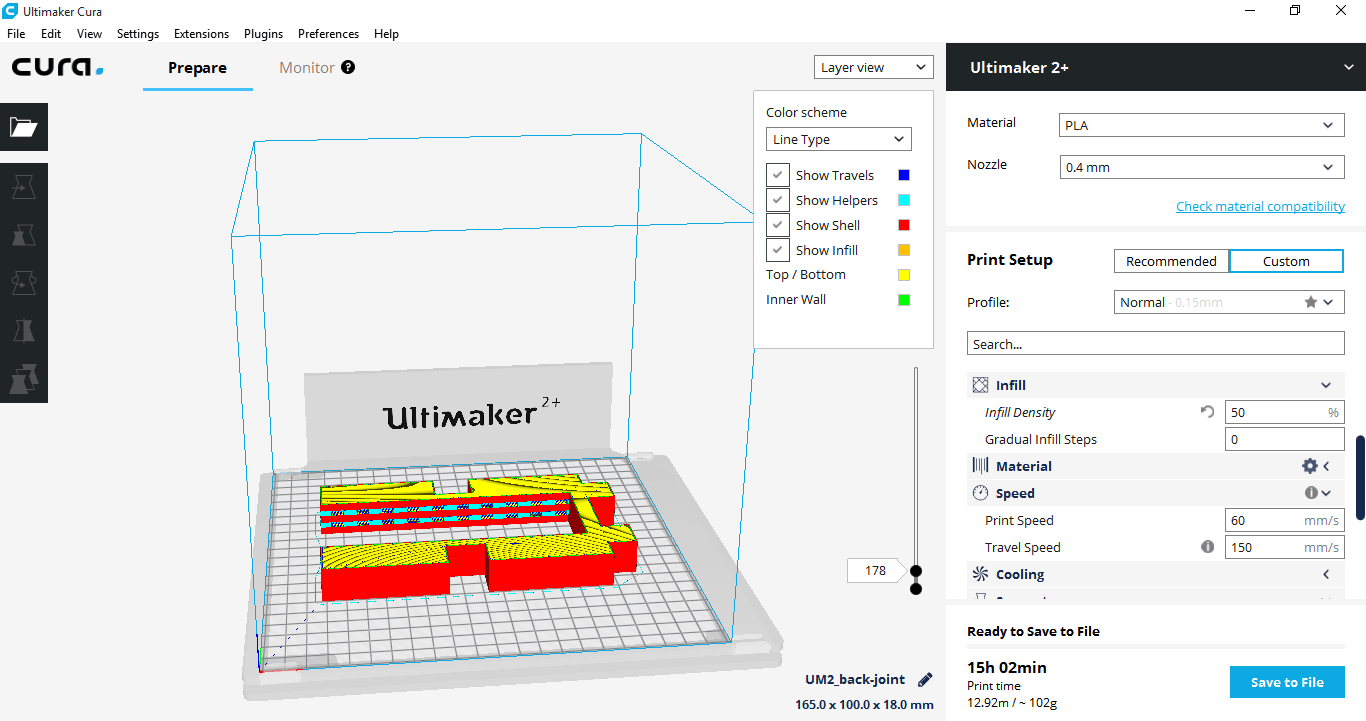

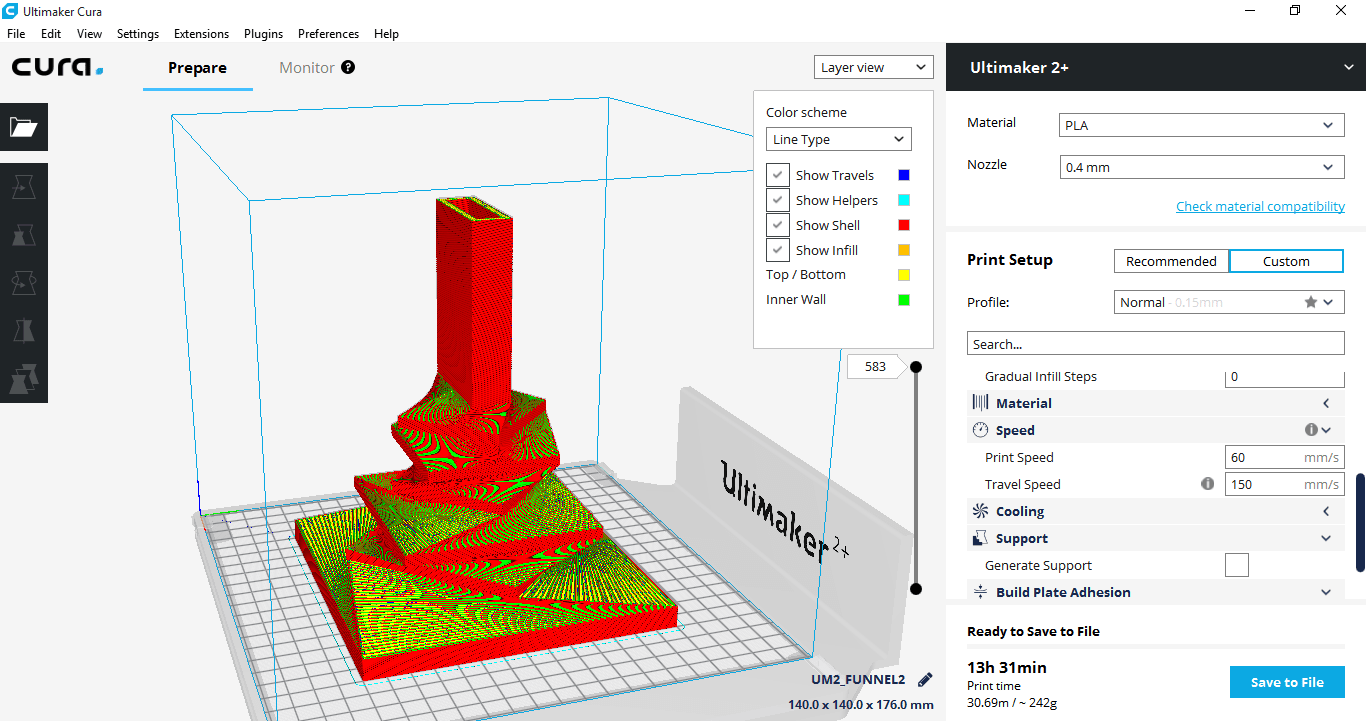

After I saved the file as STL, I opened it with Cura. I used the following settings:

- Layer Height: 0.1mm

- Wall Thickness: 0.8mm

- Top/Bottom Thickness: 0.8mm

- Infill: 50%, infill dictates how rigid your print is

- Print Speed: 60mm/s

- Material Used: PLA

- Printing Temprature: 215

- Nozzle: 0.4mm

- Print Bed Temprature: 60

- Support was enables and set to everywhere becuase I have tracks for the acrylic.

- Support Pattern: Zig Zag.

- Support Density: 5%.

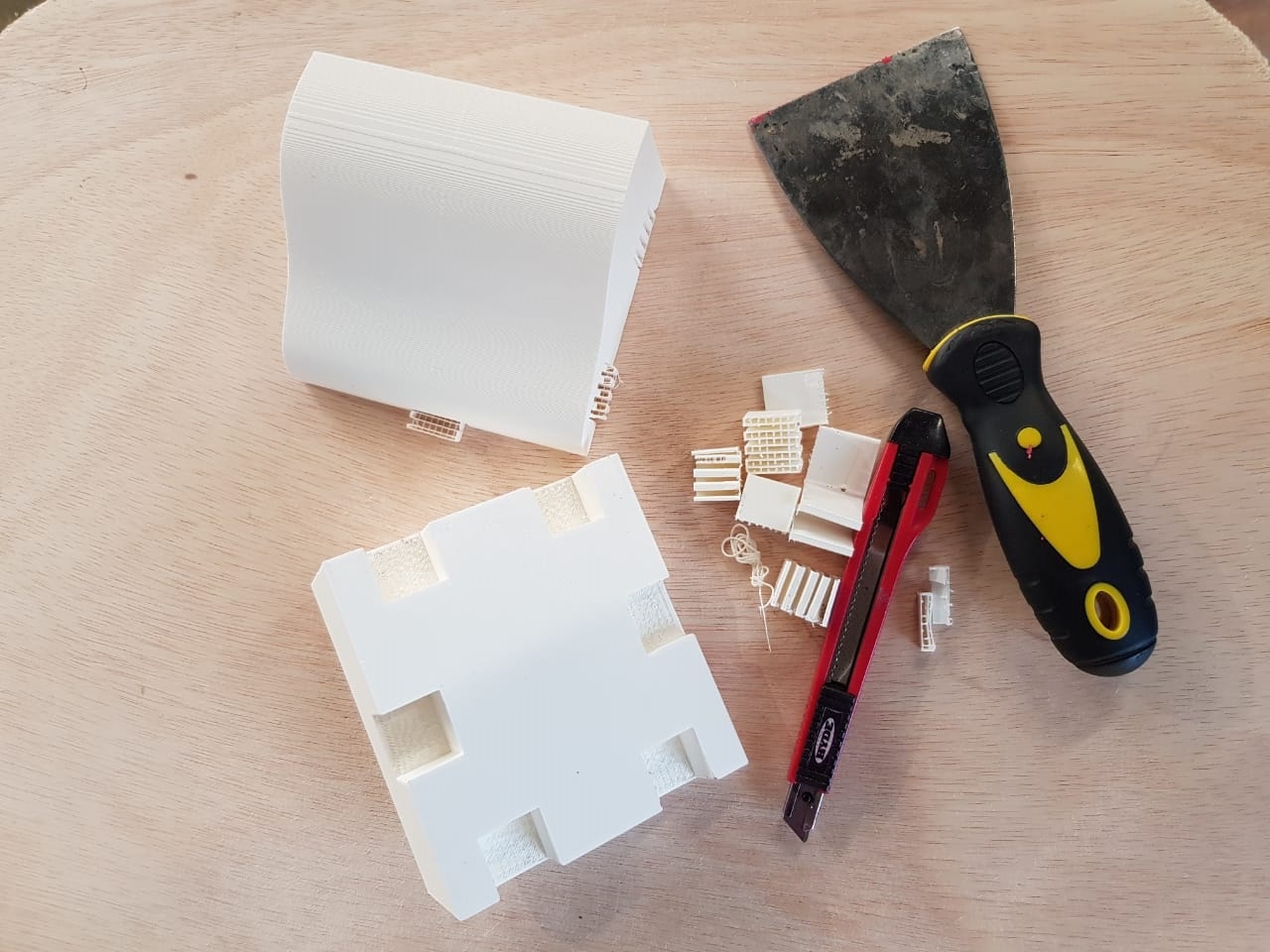

The print took 15 hours and needed 30 minutes of post processing to be able to remove the support generated in the tracks.

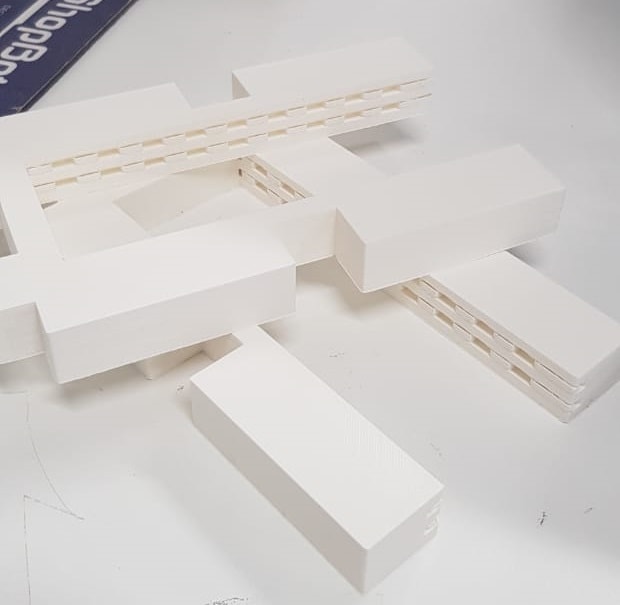

The next part I printed was the left and right joints. I also used Cura asn set the same settings.

The print took around 11 hours and the result is seen below.

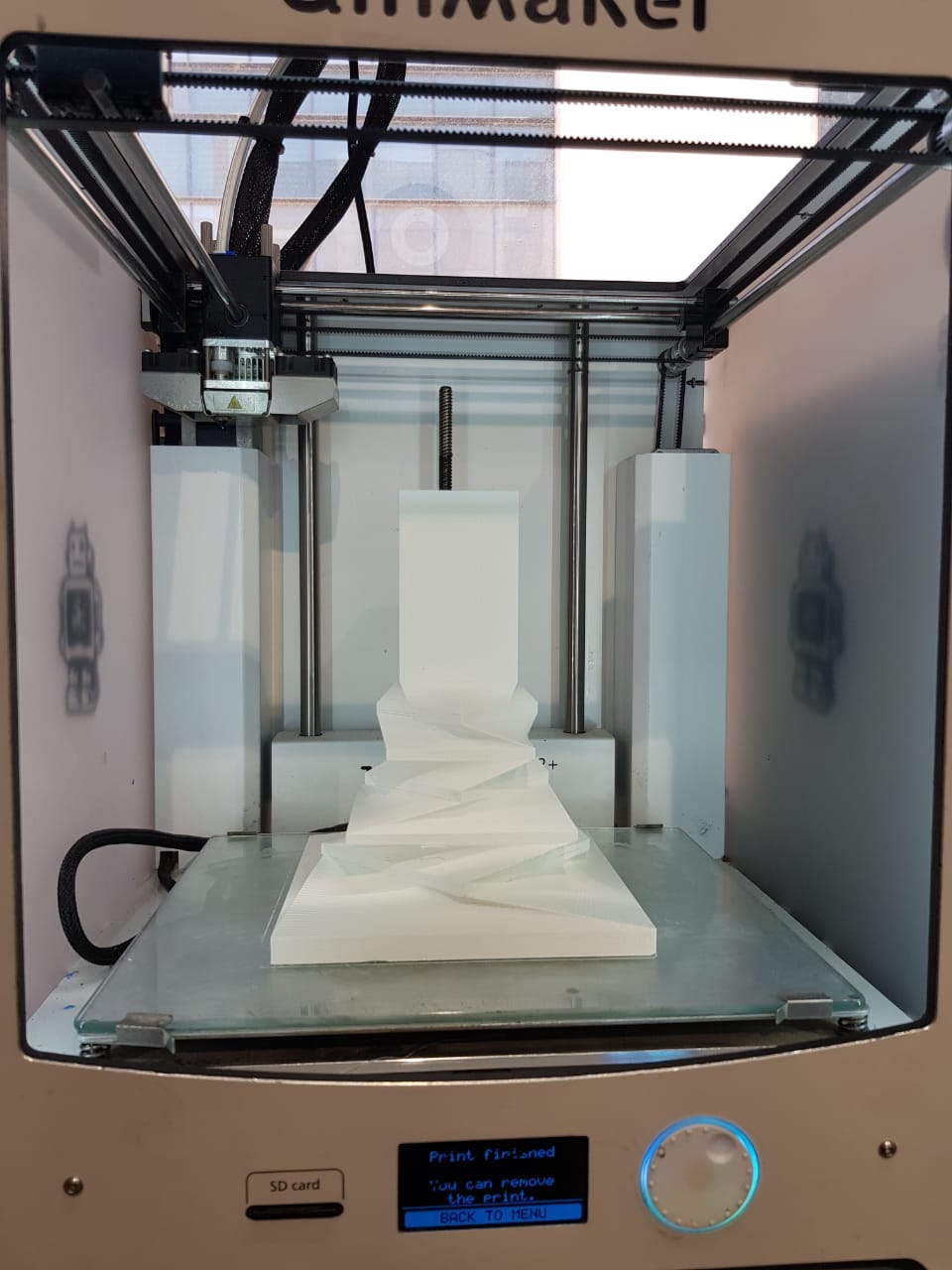

The last thing I printed is the funnel. The funnel was self supported and didn't need any support. I used the same settings as before since I used the same material and the results were great.

The result is seen below and I so much like how it turned out!

SLA Printed Tank

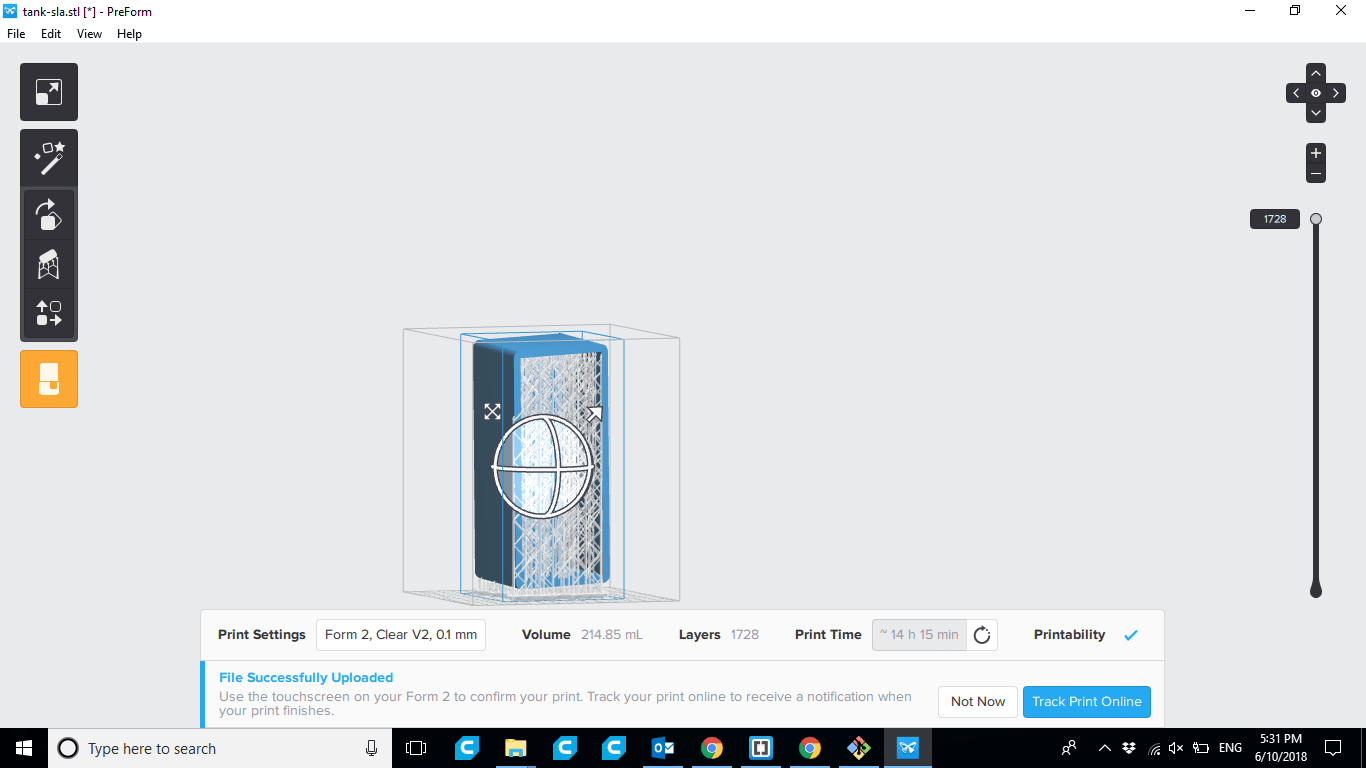

I decided to print the water tank using SLA since I want it to be water proof.

The printer available in the lab is the Form2 and I used clear resin to print the tank so I can see the water level.

The settings I set in Preform are seen below.

I tested the tank by filling it with water and leaving it over night to make sure it doesn't leak. When I came back the second day it was all good :)

You can download the STL files HERE.