Mechanical And Machine Design

Task Requirments:

- Explain your individual contribution to this project on your own website

This is a Group Assignment where the whole lab should design and manufacture a machine and post all the process on the Lab Page and every one of us should document his own contribution on his personnal website.

We decided to make a pen plotter machine, for more details please visit the Lab Page.

My Task:

I was assigned to design and fabricate optical endstop for the machine Axes.

Idea:

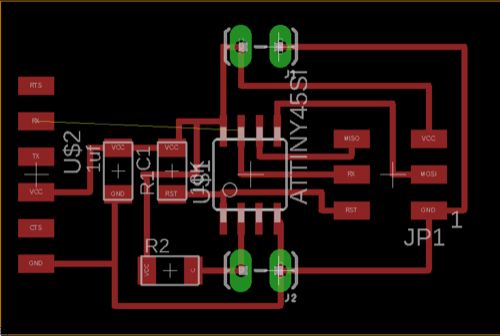

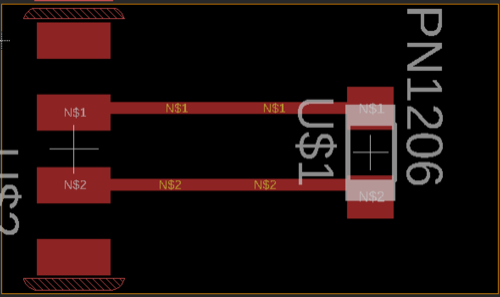

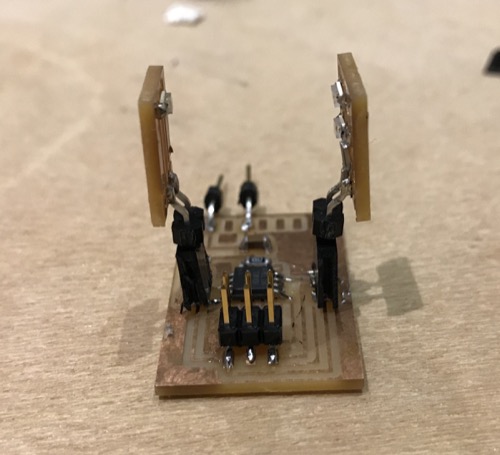

The Idea is to make a 3 boards one with the MCU and the Pin heads for connections and one holding two leds and one holding the Phototransistor sensor, then connecting the 3 boards where the led board is facing the phototransistor board, then making a case with a space between the two boards so any object passing between the led and the phototransistor will change the value of the sensor. we will use the change in the value of the sensor to send digital signal to the main board of the machine to act as the end stop signal.

Bill Of materials:

- 1 X ATtiny 45

- 1 AVRISP

- 2 X 10Kohm Resistors

- 1 X 1uf capacitor

- 1 FTDI pin header

- 2 X female through hole pinheads

- 2 X LED

- 1 X Phototransistor

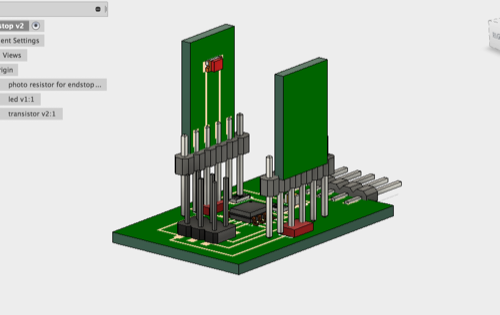

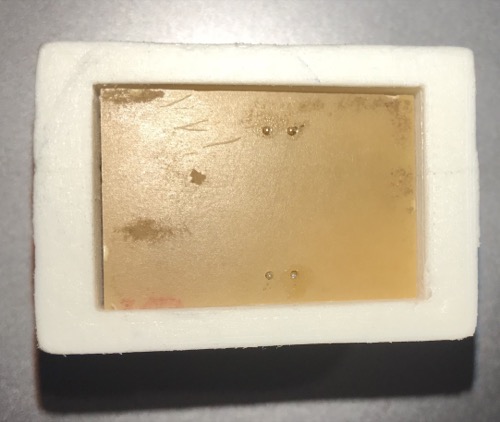

Making the Boards

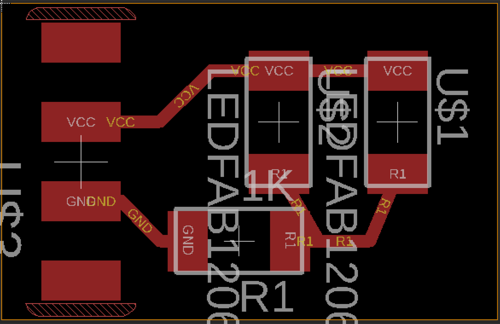

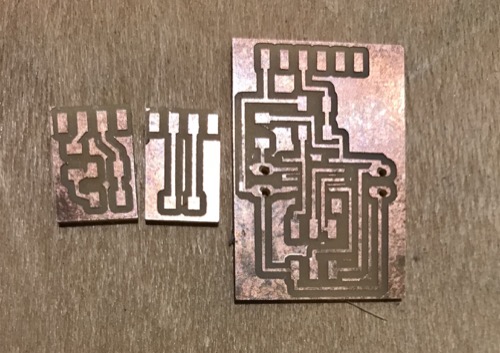

I designed the boards on eagle and fabricated them on the modela MDX20.

I soldered the three boards and connected them.

Designing the Sensor Casing:

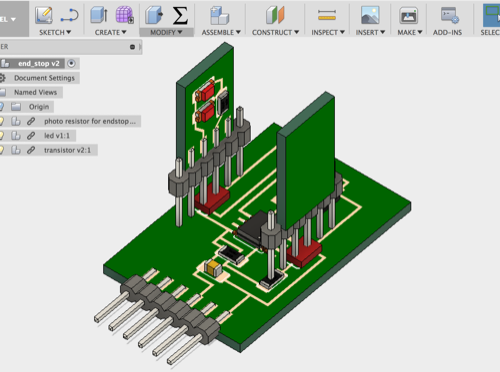

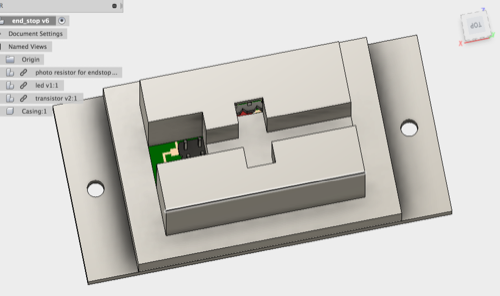

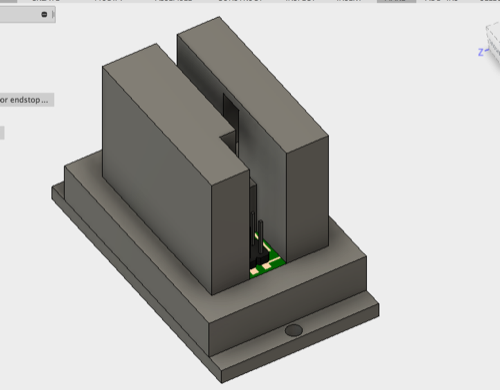

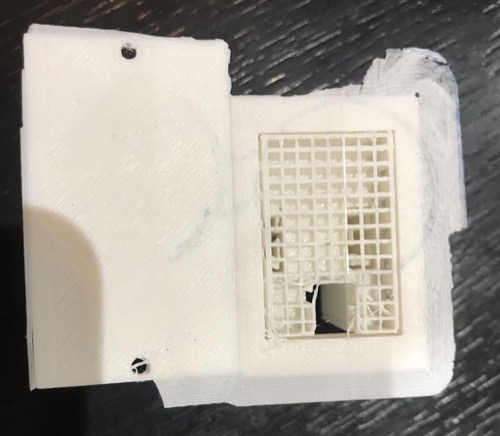

I have linked the boards from eagle to a fusion project and assembled the three of them to design a case for them.

I designed the around the board to be 3d printed putting into my consideration to make the openings of the sensor and the leds close to each other to reduce the effect of the ambient light.

I exported the design as STEP file and sent it to Ibrahim to integrate it with the machine design.

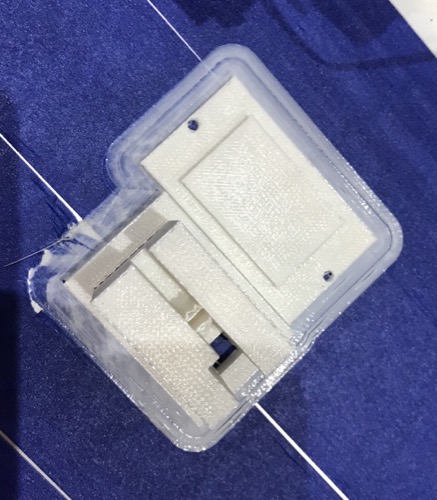

Manufacturing the casing

I printed the the 2 parts in one job.

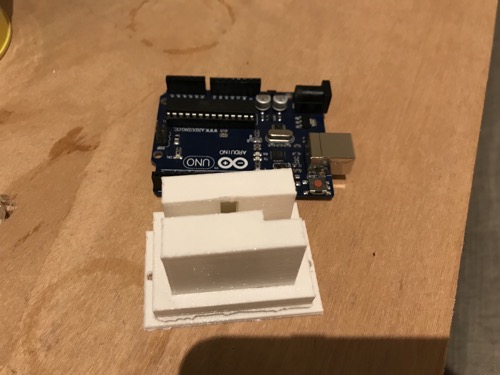

I assembled the 2 parts and added the boards.

Programming the sensor:

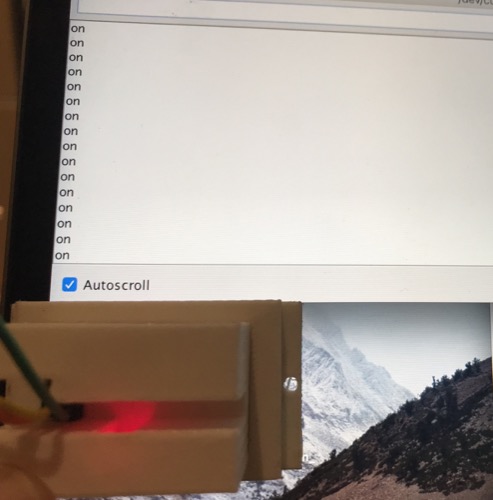

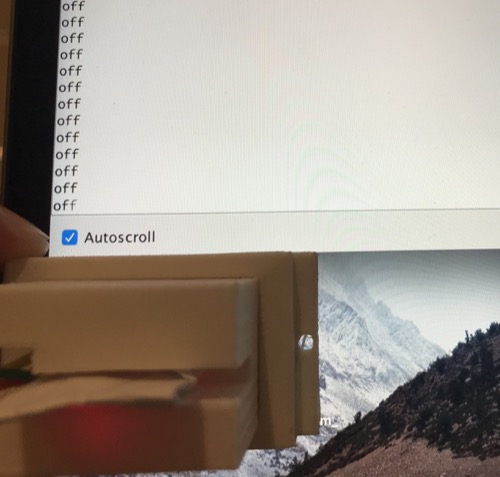

I connected the sensor to Arduino IDE serial monitor and took the sensor readings when something passes throught the sensor, it always exceeded 1000.

So i programmed the board to put the signal pin HIGH when the sensor value exceeds 1000 and also serial print OFF for debugging purpose. ELSE LOW , ON

Testing:

I connected the sensor to Arduino IDE serial monitor and placed a peice of paper inside and outside the Endstop, and it was working fine.