Computer Controlled Machining

Task Requirments:

- Explain how you made your files for machining (2D or 3D)

- Show how you made something BIG (setting up the machine, using fixings, testing joints, adjusting feeds and speeds, depth of cut etc)

- Describe problems and how you fixed them

- Included your design files and ‘hero shot’ photos of final object

Idea:

The Idea is to make a desk that i can work on, i don't need a standard dimension desk as i need to use it while i am sitting on my lazy Couch.

I started by browsing the opendesk website and choose a desk that i like and i see it suitable for my modification.

Design

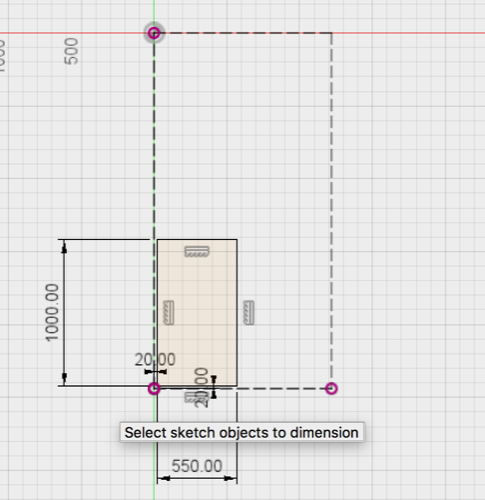

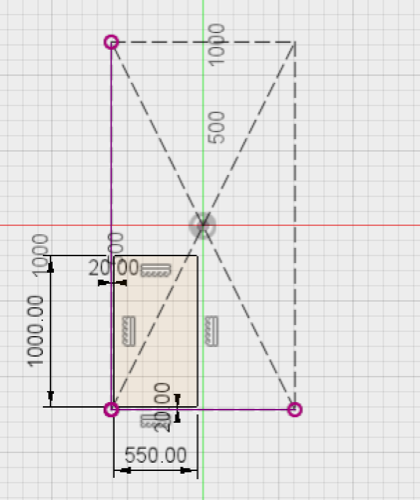

I downloaded the dxf files of a desk from opendesk to explore the desing and help me design mine, i wanted to modify the desk so i can be able to work on it while sitting on my living room coach, so i decided to make the legs shorter and offsets the front legs to the back so i can rest my back while still reaching the desk edge.

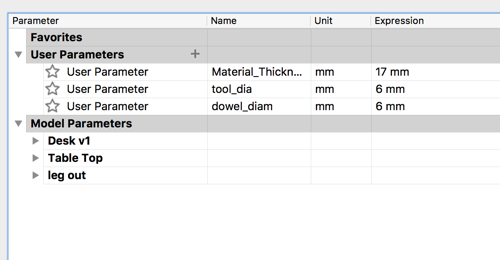

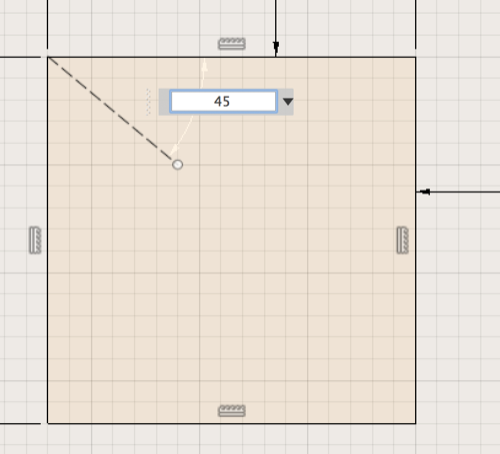

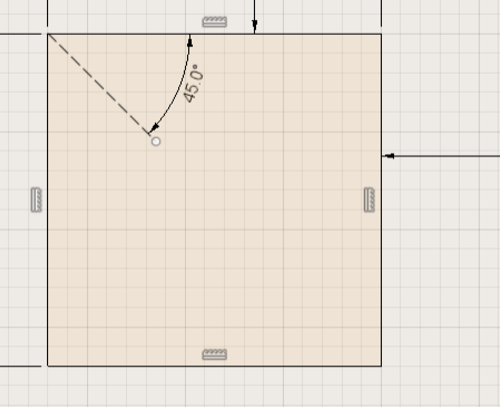

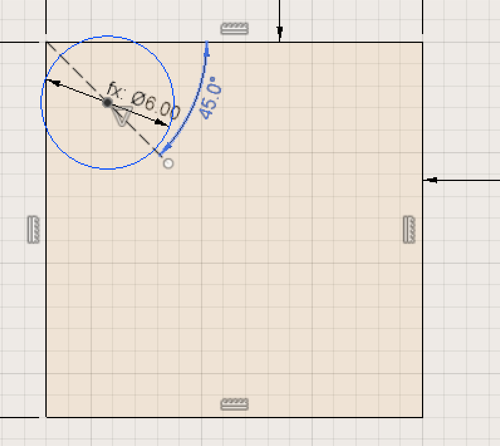

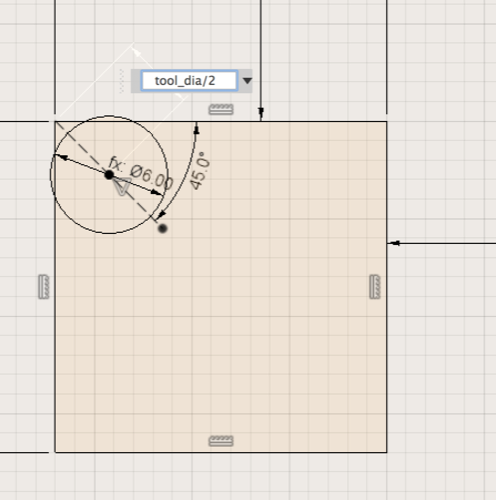

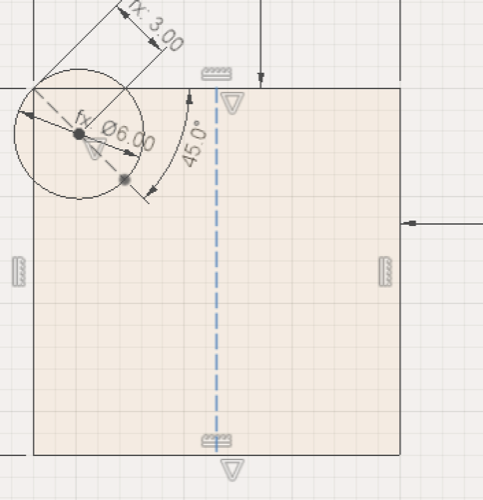

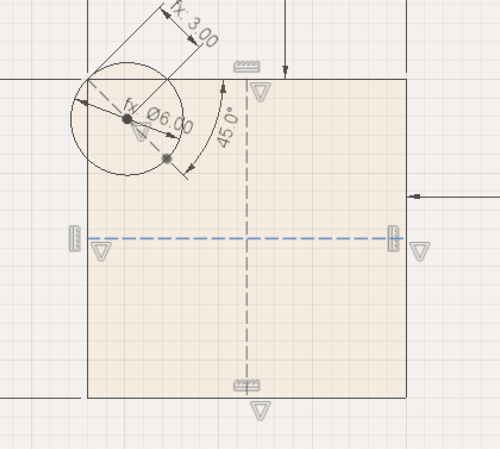

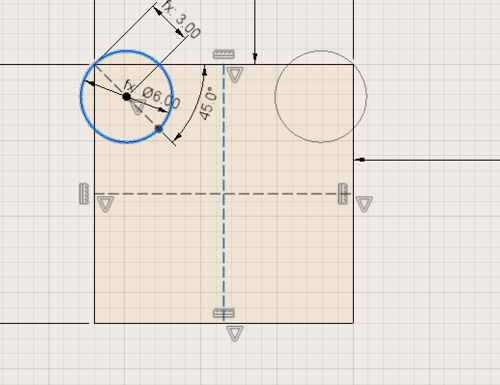

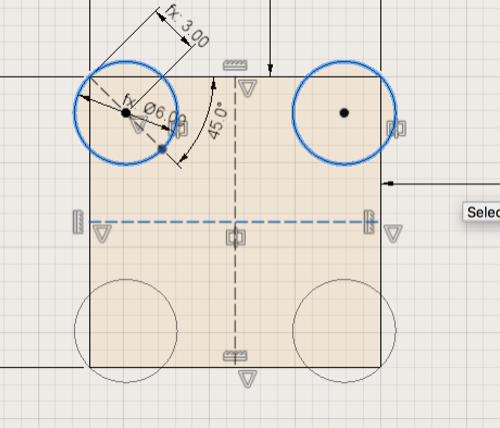

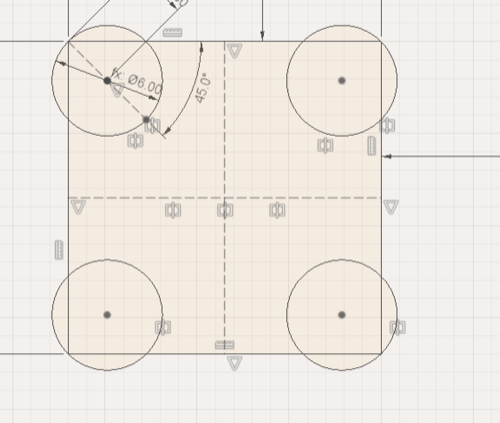

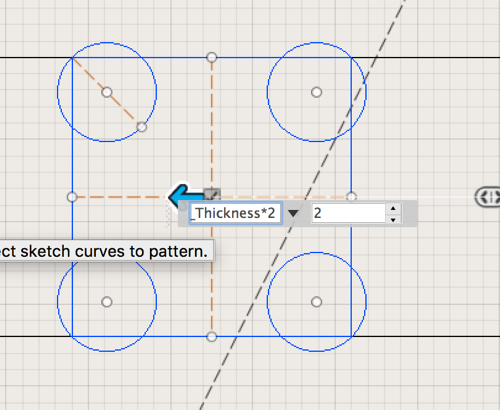

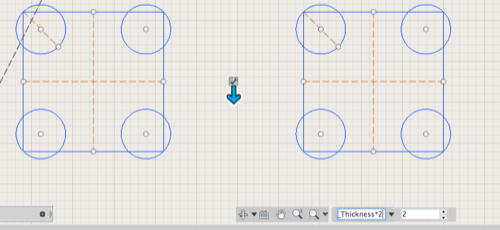

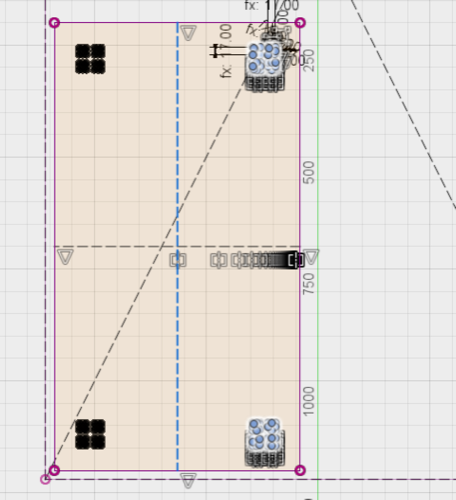

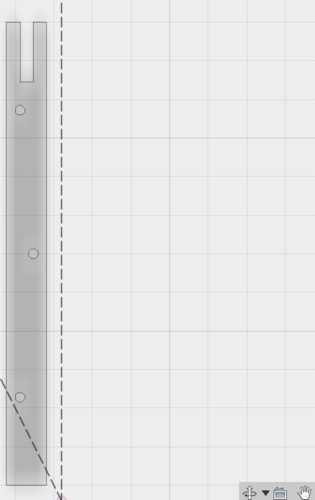

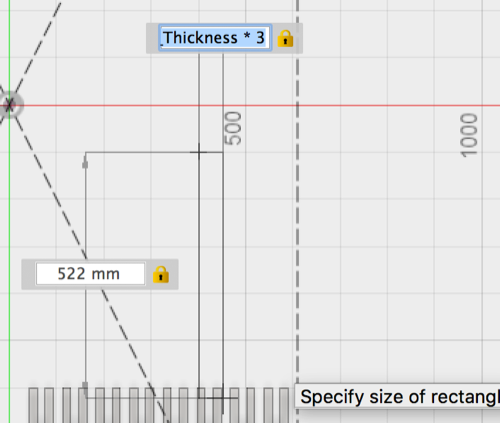

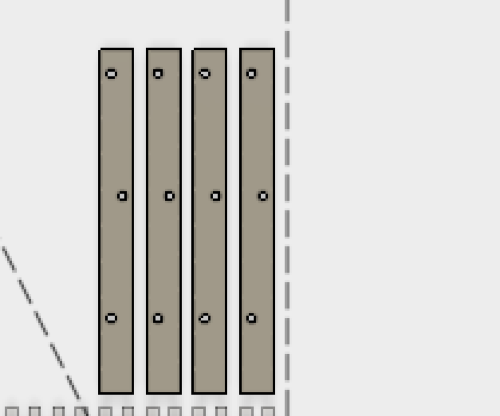

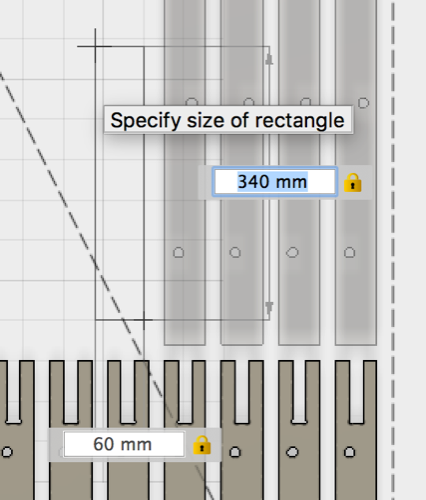

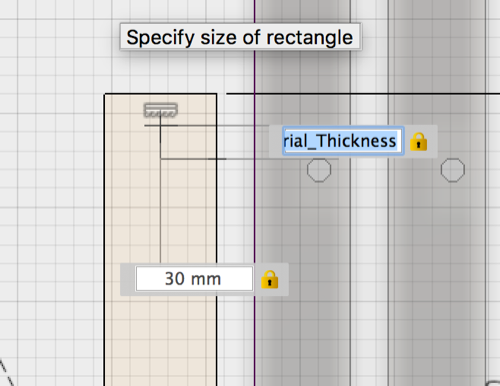

I used Fusion 360 to parametically design the desk, i started with setting up the parameters and then started sketching all the parts while adding dogbone fillets to all the internal edges.

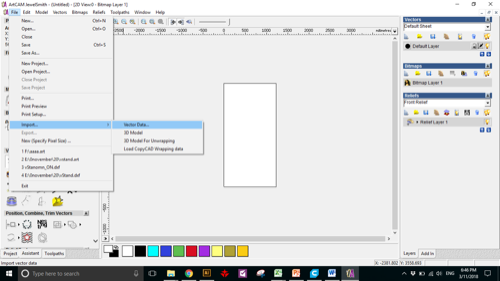

I exported all my parts as DXF by selecting each face, tab new sketch, stop sketch, and then right click the new sketch save as DXF

Machine Tool Path

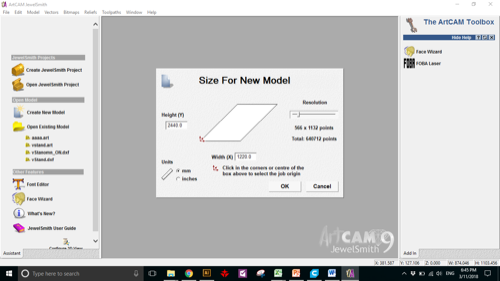

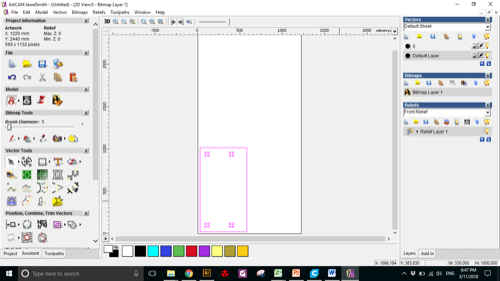

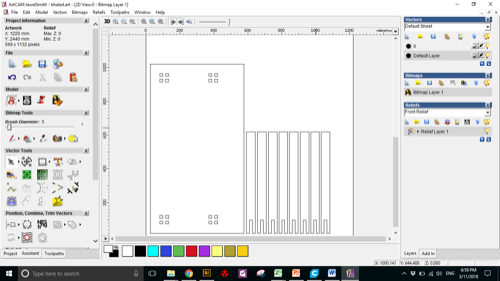

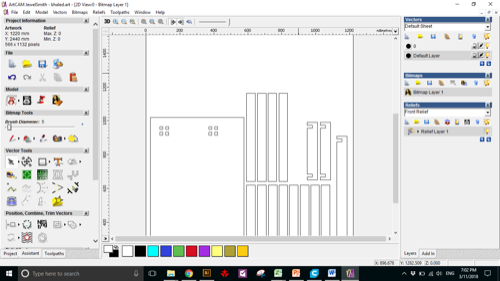

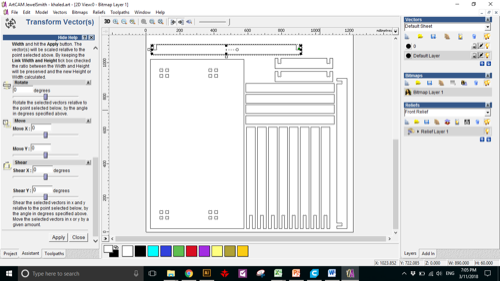

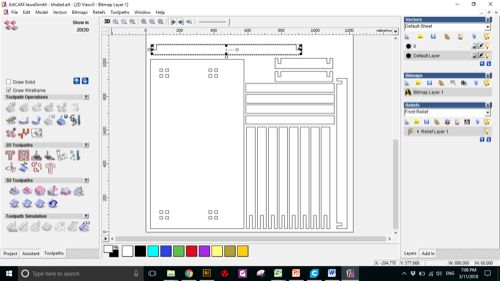

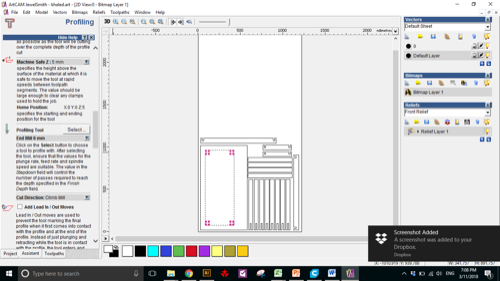

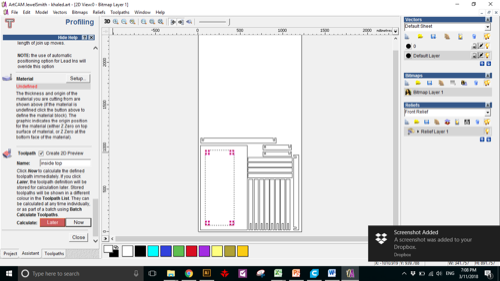

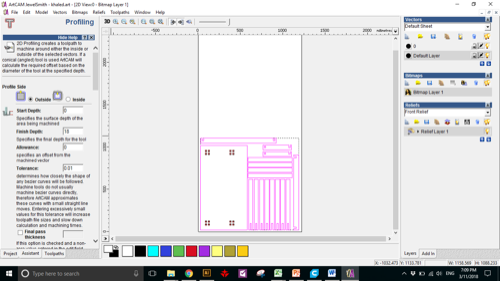

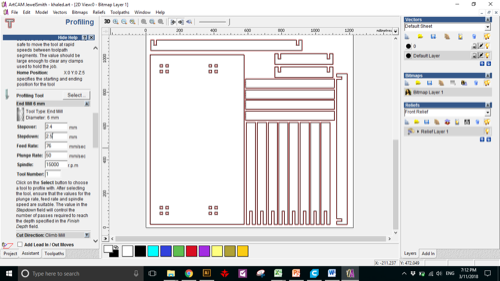

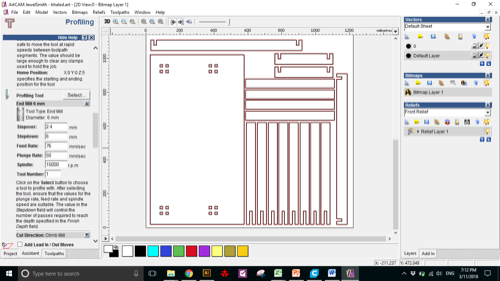

I used Artcam to generate the machine toolpath

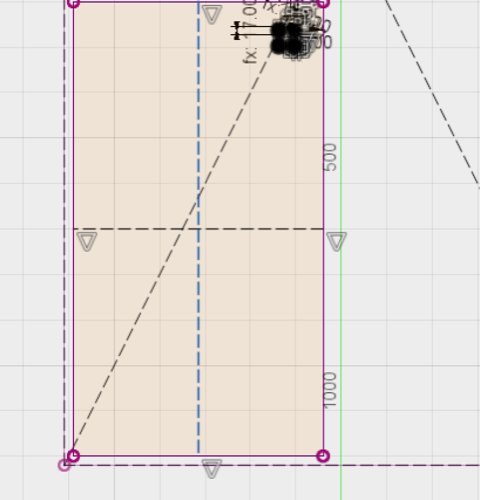

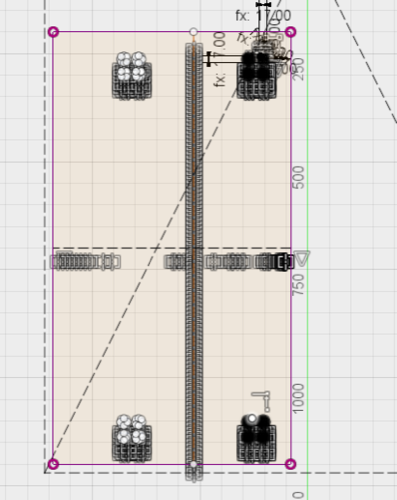

- I made a new file and set the dimensions of my wood sheet to 1220X2440 mm.

- I imported the dxf files

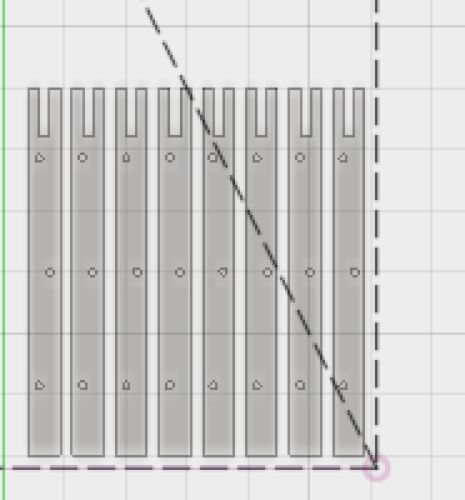

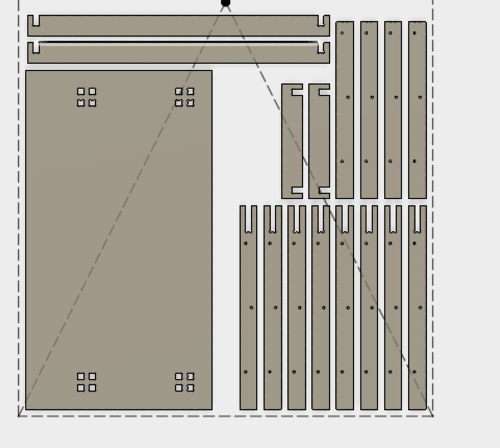

- I arranged the parts to best use the sheet

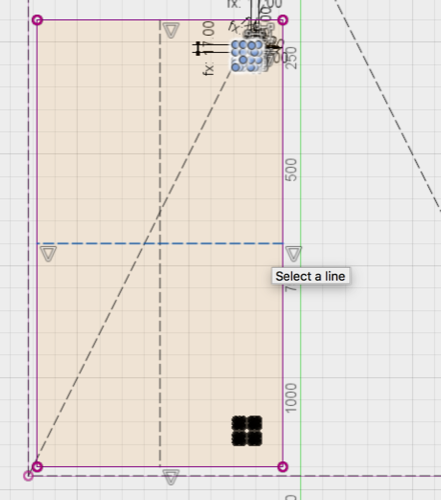

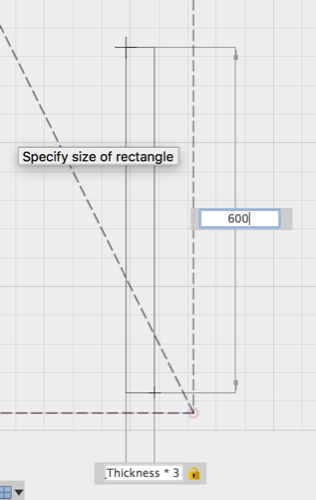

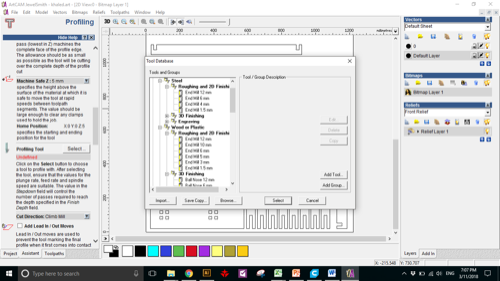

- From the tool path tab, i choosed profiling

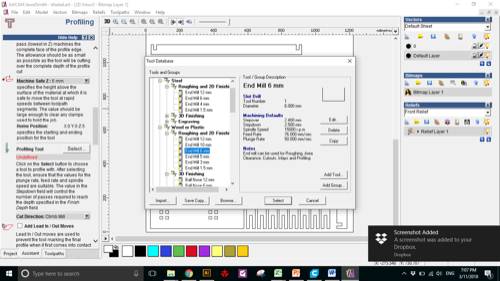

- I choose a 6mm endmill and changed the steps to be 6mm/step instead of 2.5mm/step to increase the speed of cutting

- The wood sheet is 18mm thick so set the cutting depth to 19mm to avoid any buckling or bad uniform of wood

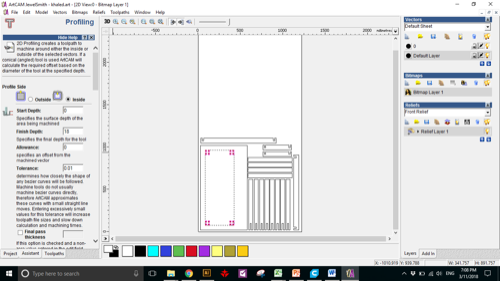

- I made a toolpath for the iside cuts with inside cutting and another toolpath for the circumfrance cutting with outside cut

- Then i save both tool paths in one file with the above order

Machining:

I used the router in the Lab, it's specs can be found in that Link

The Main technical specs are as follow:

- Size = 130 CM x 250 CM

- Spindle Power = 3 / 6 / 7.5 / 9 kw

- Origin = HQD China

- Cooling = air Cooling

- Voltage = 220 - 380 V

I fixed the board on the machine with 6 screws all around, Adjusted the XY zero visually, and adjusted the z axis untill end mill is not turning freely "i.e touching the sheet"

Hit start and enjoy !

Assembley

Failure 1:

I had some un-clean cuts with residues in the bottom of the sheet, i had to clean them with a file and sand paper, i think this problem because of the step setup "6mm" the machine drills 6 mm per step and the material is 18mm and the drill setup is 19mm so the machine makes 4 steps (3*6+1*1) so in the last step some of materials are free and some is just hooked on 1mm thickness which causes the material to break before the endmill cut it.so i suggest using a bigger step to complete the process in just 3 steps.

Starting Assembley

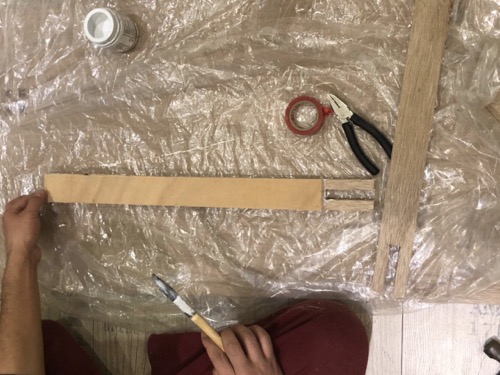

I started with the gluing the 3 legs parts together. and followed with assembling all the parts

Failure 2

The assembled legs didn't fit into the table top, because the leg consists of three parts assembled together so the width of the leg is 3Xmaterial thickness and because the thickness of the material was not uniform the legs didn't fit in the slots and i had to do a lot of sanding to make it fit