final project -- about me -- weekly assignments -- fab academy

Refining the idea

What it should do

A first version can be quite simple here. It has to move, in a way you can tell it by means of a simple set of joysticks and buttons. No real automation here, just a simple remote manipulator.

To "grab" components vacuum "tweezers" are more or less standard and and I can see no sensible reason for anything else. So, a small vaccum grabber is part of the concept. It has to be able to move vertically, of course.

To actually place components you need a way to see where you're pointing it. You can do that by eye, of course, but that's awkward. So, I want a camera in there, as close as possible to the grabber. The output of that camera can conveniently be displayed on a computer that could, at a later stage, also supply data for automation tasks. And paint a nice set of crosshairs into the image.

To handle circuit boards as well as components, the placer finally needs a way to fix the circuit boards into place, as well as a "loading area" for components. Being able to handle boards that are already populated on the bottom would be cool and shouldn't be too hard. The loading area should be able to handle bulk components as well as (short and long pieces of) tapes.

A lot of stretch goals are possible here, as in later versions I want the placer to work on its own, not only placing components, but also putting solder paste and glue on the boards. Most of those stretch goals are (a lot of) software work, others will require their own hardware (like a solder paste dispenser). I won't do much about most of those now, I just try to keep track so I don't block any later add-ons now. The only stretch goal I do actively keep in mind now is the solder paste dispenser, parts of which might end up as one of the weekly assignments.

What it should look like

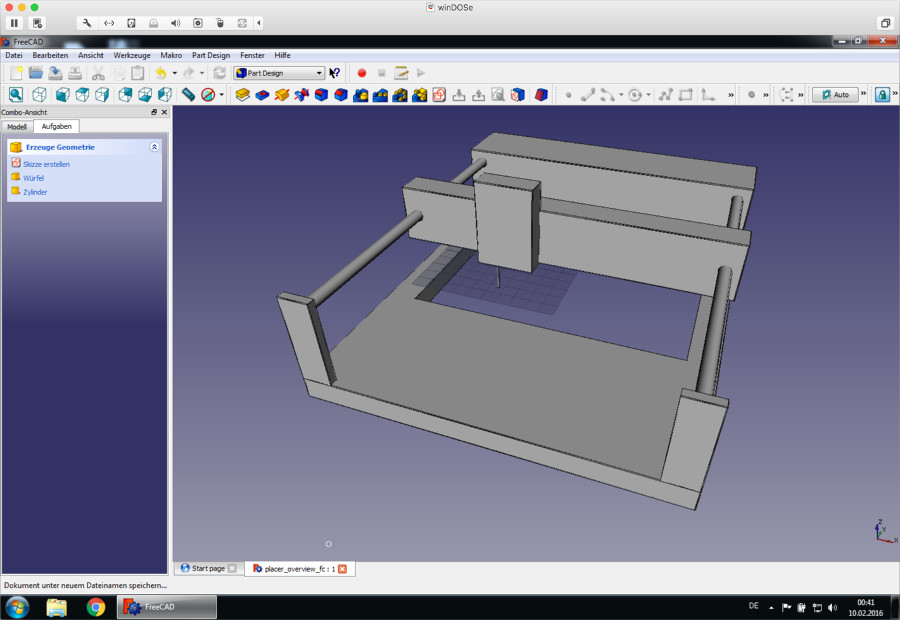

Given that this project is not exactly new, the overall layout has already been through a few radical changes. I still don't know if this one survives the first mock-up, but it's a start:

With the "user side" at the bottom, you face the "loading area" for components, which is intended to have spaces for tapes on both sides. Bulk components can be placed on the surface of this area to be picked up, maybe with some markings for fixed pick up positions.

Behind that is an area for fixing circuit boards. I don't really have a plan yet on how to build it - it is supposed to be an open space, so you can mount board that already have components at the bottom. Maybe I'll build some kind of clamping mechanism for that, I haven't really thought about it yet.

There is some space in the back planned for stuff like the servos for moving and the vacuum pump for the gripper - large stuff that can't fit below the other areas.

I will need some space at the sides of the machine for bearings to move the whole placing mechanism. Those do collide with the idea of tape feeds from the sides, so they'll have to be raised a bit above the rest of the placer:

FreeCAD-model - it's just one part now as it's just an overview. Dimensions won't work out that way, I've omitted a lot of important parts like the belts for moving the placer...

Also, I have not planned to have any user interface on the placer itself. Given the price of good, small joysticks I plan on using an old R/C transmitter, after ripping out the electronics and adding a few buttons, of course. Getting those has been increasingly simple since 2.4GHz systems took over and they cost next to nothing while providing two good joysticks. A screen to show the camera image can be conveniently borrowed from the computer that also provides a placing plan.

final project -- about me -- weekly assignments -- fab academy