Design and produce something with a digital fabrication process not covered in another assignment

For this free of choice week I am going to be experimenting and learning composites. My intention is to test fabrics to achieve the final look I want to the dome in my final project.

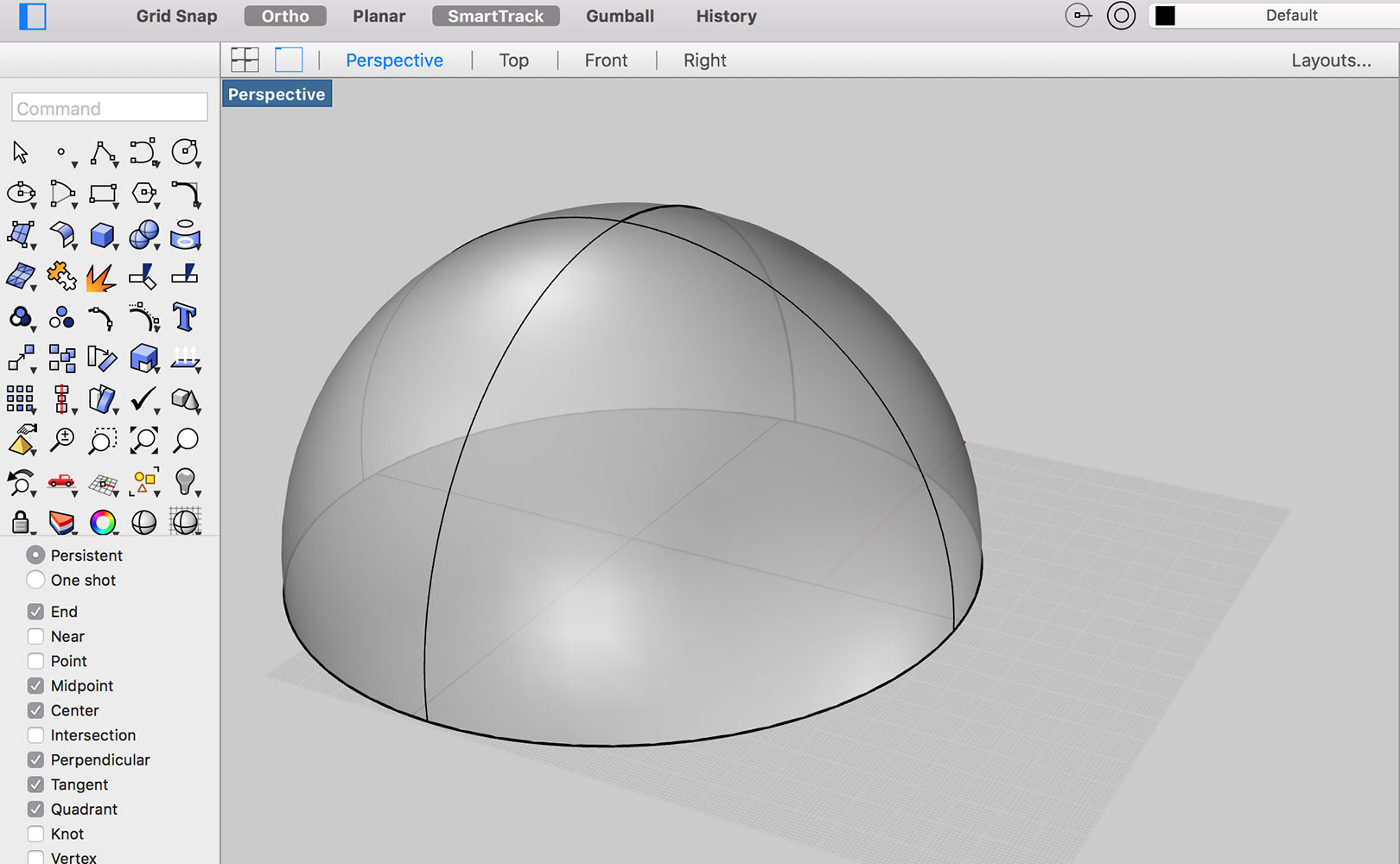

In order to do so I'll design a mini version of the dome and test out how to best achieve the translucid effect I have in my head.

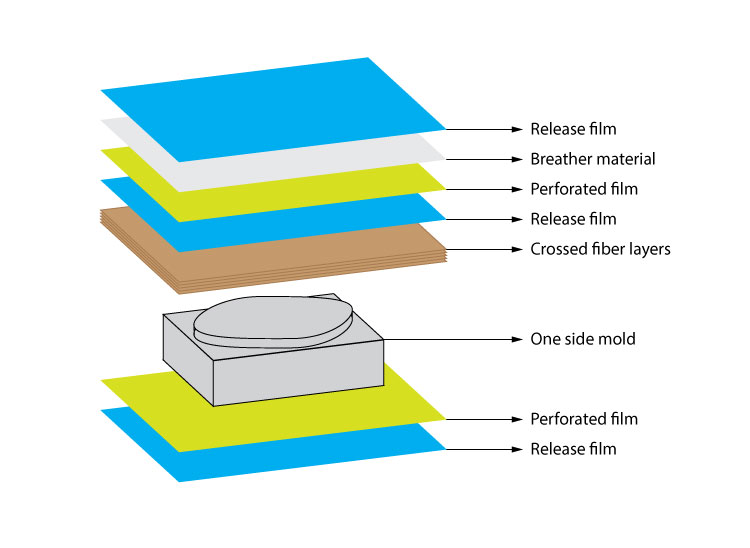

The image above shows how to position the layers of material around the mound in order to create a perfect composite. I started by designing the mini version of my dome in Rhino, my plan is to mill it out from a high-density block of foam we have in the lab. I think that by having a compact structure it should be resistent to the pressure received in the vacumm process.

After creating the strategy in Rhino Cam, I seccured the piece of foam with screws into the bed of wood and proeceed to mill with the CNC. I took a very short time to do as this material is very soft, allowing the machine to go faster. Image below-left a snap of the roughing process and the one on the right CNC doing the finishing process.

I am pleased of my mini dome. The finishing could have been more acurate but I don't mind as this is just a test and I don't think the little lines will be perceeved in the composite.

I am going to use some spare pieces of white thin lycra like cloth I found in the lab. The intetion is for the dome to look like a lamp shade, letting the light go through, so using white thin cloth seemed like a good option. I then covered the foam dome with the corresponding material layers: first the see-through plastic, then my lycra material covered with eopxy, then the release film and the perforated material wiht a final layer of security for protection.

In order to make the composite, I had to wet my lycra material with this a mixture of epoxy and hardener. This is very toxic liquids so it was very important to use gloves and a well ventilated area when working with it. To create the mixture the proportions are 2:1 (2 parts Epoxy to 1 part hardener), after adding this to a glass we quickly mix it and apply it ot the material.

After the everythig is wrapped in a nice pack I carefully placed it in the vacumm machine, set it on and let it dry there overnight.

The next morning, when I uncovered all the layers I found this really hard structure, which was not very pretty, but was certainly hard and translucid.

I even made a test to use it as a lamp, puting some light under it and it worked great. Afterall, I might not use composites for the final project dome, but it was interesting learning the process and the possibilities that composites give us.

Files:

Rhino mini-dome(.3dm)

Mini-dome strategy in RhinoCam(.sbp)