Persistence and Success

- This assignment was great fun for me. I was able to create my tangrams and bring them back to my classroom. The students really enjoy playing with them.

- This is a new piece of equipment for me. We will have one or two of the Shopbot Buddies in our Fab Lab. I can see so many possibilities in using this machine. I think our teachers and students will love it!

- I really want more time to use this machine. Oh, the things we could make!

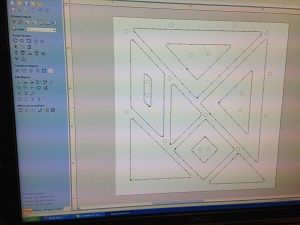

- I started by choosing shapes in Corel Draw to create my tangrams.When I scaled them to the size I wanted, I began to wonder if the smaller students would be able to grab and lift them.

- I chose to create a smaller sized shape within the largest shapes to allow for easier grabbing and lifting.

- I sent the program to the Shopbot. I am in the process of taking a class on pesonal fabrication (also held at Lorain County Community College). In that class we just learned how to use the Shopbot, so I am feeling pretty good about my progress this week. It is important to be aware of all the safety issues when using the Shopbot. I don't want to hurt the machine OR have the machine hurt me!

- After prepping the surface by screwing down my material, I made sure that the bit was in place and that the machine would cut where I wanted. I can't wait to share this with my students. We are currently working on plotting points and point of origin and here is a real-life, practical application! We used a 0.25" flat endmill tool. We set the speed for 12,000 rpm with a feed rate of 2 in/min and a plunge rate of 30.

- As the machine cuts, I stay close near the red button to halt if anything should go wrong.

- The tangrams are cut. Time to unscrew and clean off the machine for the next person. Here is a picture of my tangrams. I can't wait to sand them.

- Next, I used a small router table to soften the edges. I will sand them at my husband's shop before I stain them and use them in the classroom.

- Here is a picture of my tangrams. I shaped them as a dancing woman.

- If you need help visualizing the dancing woman, this picture should help!

Design:

Project Files:

Tangram File Aspire Files

Back to index