Introduction:In Composite Assignment I made a mold on Shopbot.I made 3D shape of the botton in CATIA. then imported .STL file in PArtwork3D.

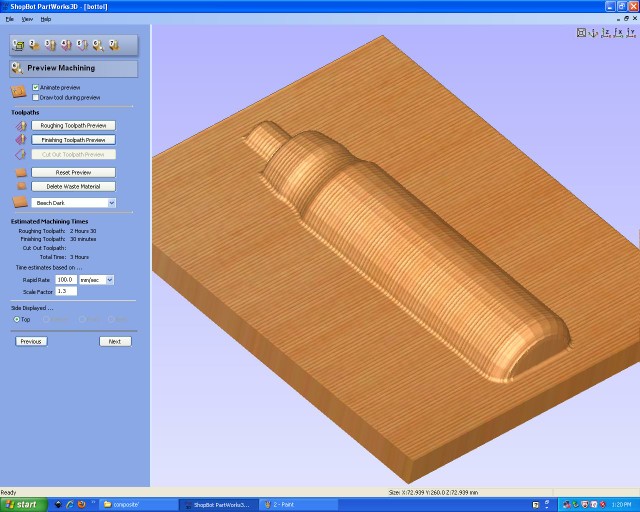

Following bottol shape imported in PARTWORK3D and assigned Roughing and finishing toolpath to make 3D model in wood on shopbot machine

Figure.1

I created roughing toolpath for rough cut It takes 2.30 Hrs to mill rough cut then for finishing it takes 30 minutes.

Figure.2

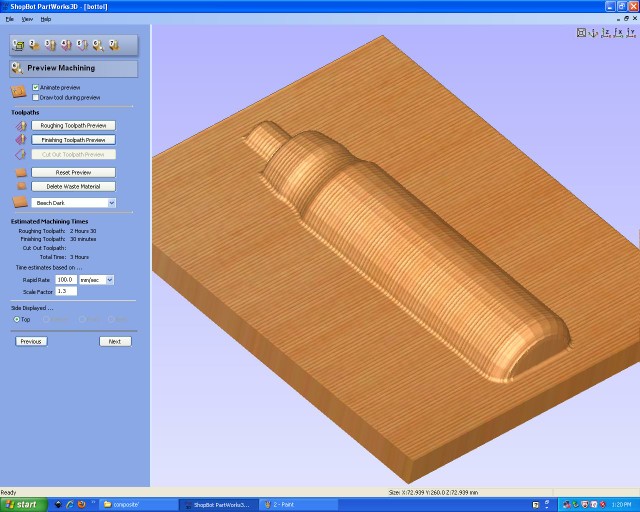

Preview of the milling Shown in following figure.I created half bottol shape in wood block.

Figure.3

Following Figure shows the shopbot consol setting

Figure.4

Figure.4a

Figure.4b

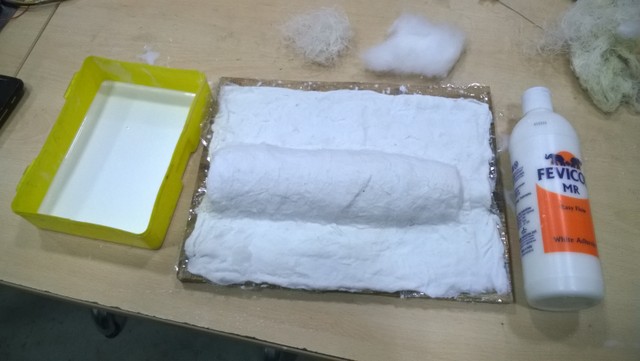

I cut that 3d part from wooden block using Scroll saw and right now dont have vacuume arrangement so i used one sided stick tape to cover my mold so whatever i am going to use to make mold wont stick directly to my wooden mold

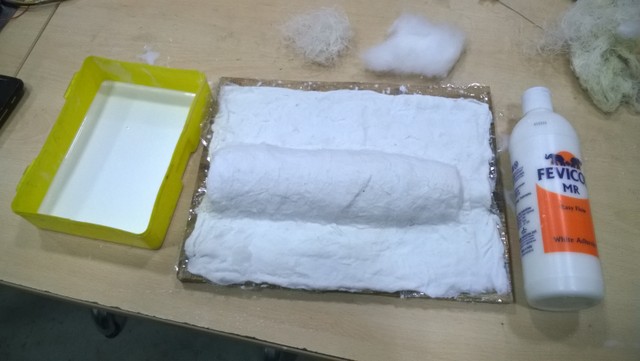

I am using Cotton, String, Fevicol(Adhesive) with water.First i took water and fevicol in 1:1 ratio composition then Kept one layer of medical cotton then other layer of string as a fibers and again another layer of cotton.Then i poured the concentrated fevicol+water on that layer.

Figure.5

It took two days to dry and after two days because i have used plastic one sided stick tape to my mold i could easily release the part from wooden.

Figure.6

Following image shows the another side of composite materials after it gets dry.Strenghth of cotton with the string has improved.

Figure.7