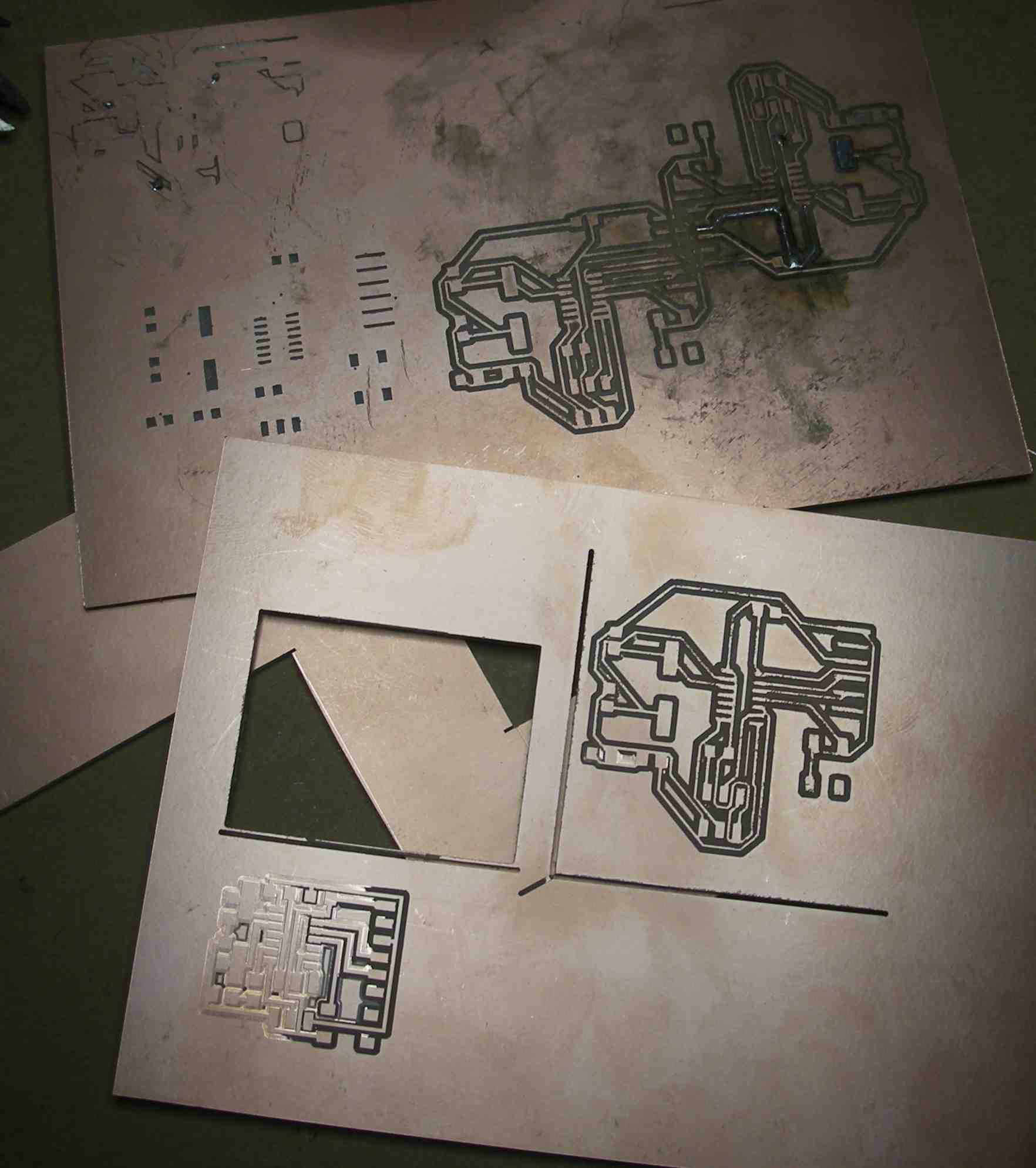

This project started out innocently enough. There was no way to know that before the project was complete many small copper boards would make the ultimate sacrifice.

In the first attempt, Eagle allowed me to design the traces in several places on the board way too close together. Cutting them about with an exacto knife helped only a little so I tried to cut a second board but miscalculated the space left on the larger board. The result was overlapping sets of traces. The third try was better and I almost finished it. We had to create a six pin component by putting loose pins together. To stabilize the pins for soldering we used a six pin plug to hold them. After I soldered all the pins, I tried to remove the plug and all the traces came up with the pin.

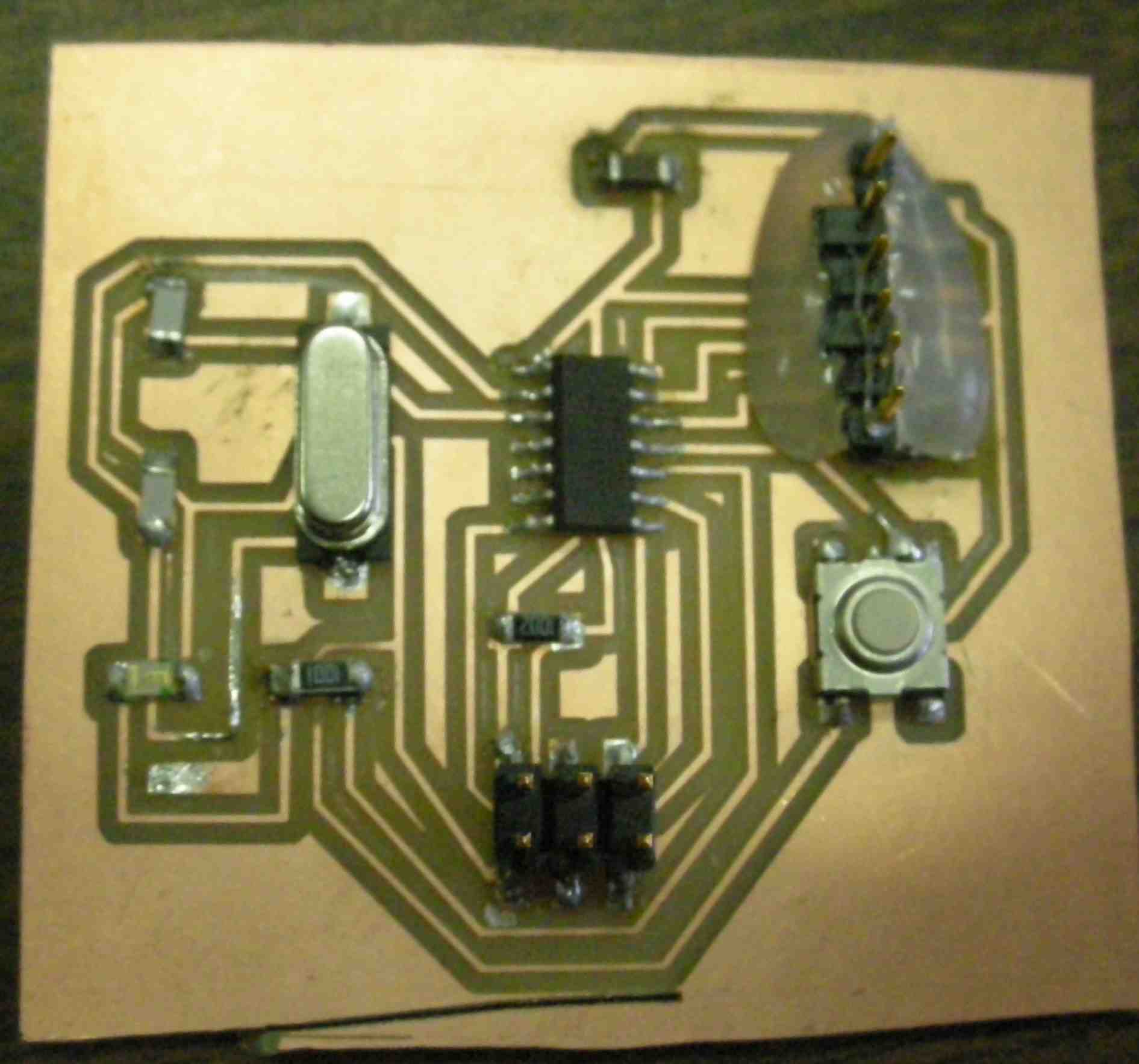

[That lead me to the small saying that became my molding project.] By this time I was becoming much more familiar with the entire process of setting up the modela to make the board. In addition the first board with the narrow traces gave me additional experience using Eagle. I do have the final board complete but we are unable to make the LED light despite lots of checking and reworking??????????? I do think the glue is a nice touch!