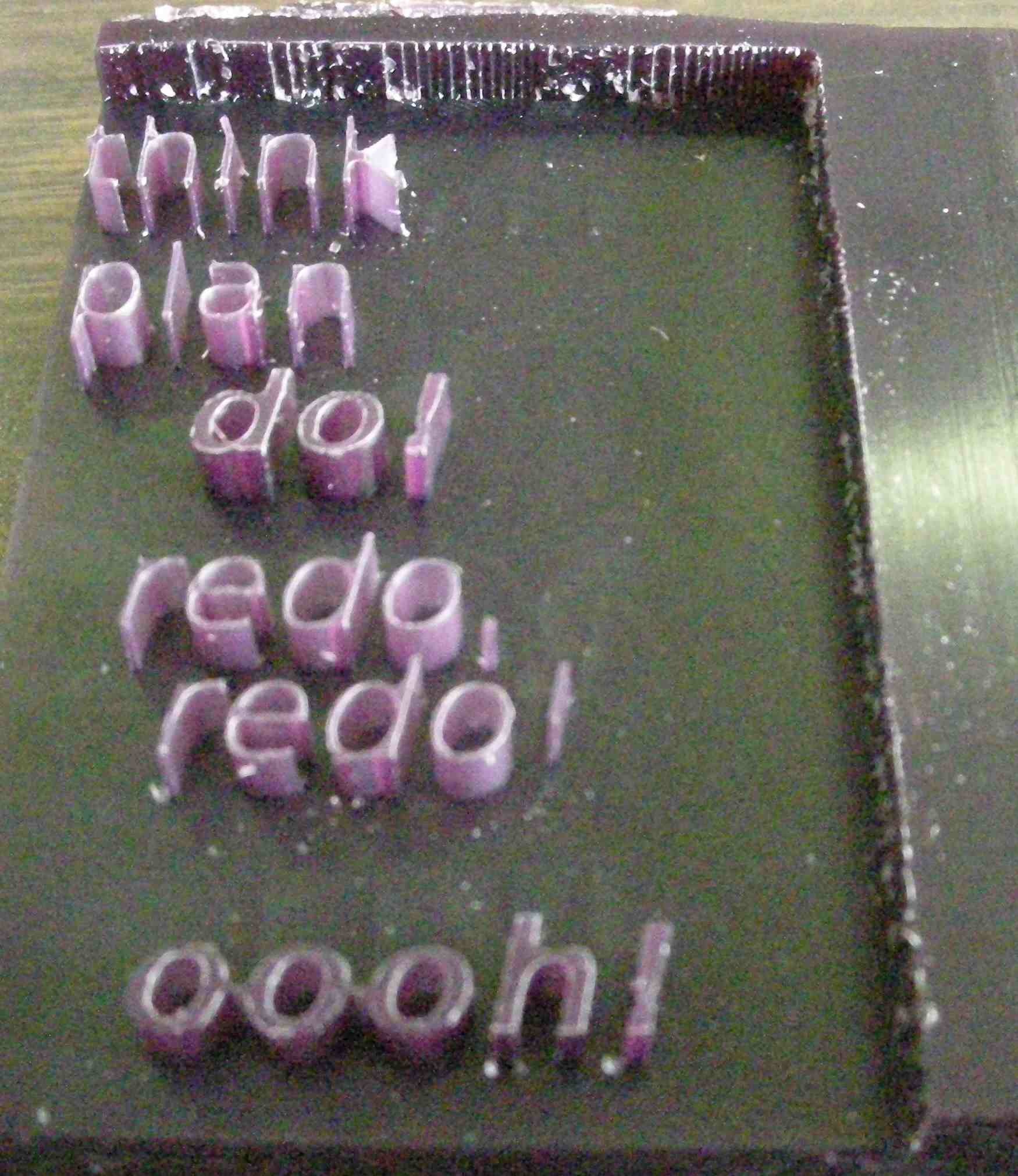

To date this project was the least exciting because I had practically no connection to the process or the lessons to be learned. My experience with the Fab Hello board lead to the small saying that I decided to mold.

Of course that became a self-fulfilling prophecy, as I had to redo do it because the first wax model had letters that were too thin to cast.

So far so good. . . thicker letters and a slow modela.

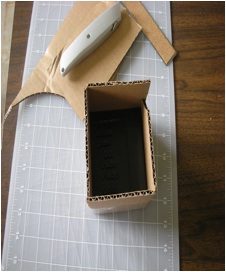

After the wax is cut the block is wrapped in a cardboard collar and prepared to hold the mold making gorp. The rubber molding material take some time to dry but it does finally and then I removed it and mixed the final molding material.The bubbles are clearly visible in the rubber and they also catch in the corners of the letters and then impact the cleanness of the final object.

Once the mold is dry then the casting compound is poured in and it is left to set. After it cures, the rubber mold is removed and the cast obect is removed.

Once the wax is finished cutting, the wax bar is wrapped tightly in a cardboard surround that keeps the rubber mold making material contained. Getting the bubbles out of this mixture is tricky to use a nicer language formulation!