This week is all about computer-controlled machining which is something that I always wanted to try again. This time round, I am using Autodesk Inventor to link with Master Cam in order to covert the codes for the 2D router machine to cut out the design I want.

This time round, I will be building a dog house for my dog. I am really excited about it. I am thinking how is it going to look like.

I have to say that I am quite the vintage kind of guy. I am not going to do something fancy but the normal type and nice looking dog house.

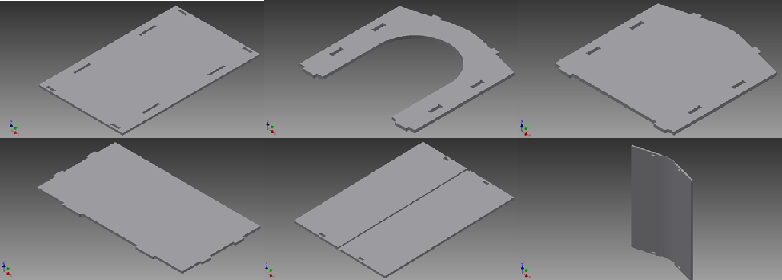

The pictures below are my design for my dog house using Autodesk inventor.

The following picture is a full assembly of my dog house.

After completing the drawings in Autodesk inventor, I will need to convert the files to .stp file format in order for Mastercam to read the files. This is the crucial part of the process because the files from Mastercam will be send to the 2D router for it to cut out the parts of the dog house.

I have problems using mastercam to process the files as I am not used to mastercam. I encounter problems trying to edit the process of cutting the materials. It took me some time before I learn how to use mastercam effectively.

Below are pictures of my dog house using Mastercam to process the cutting outlines of the parts.

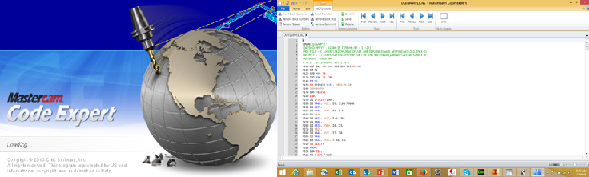

After using mastercam to route the cutting path for the dog house, I used Mastercam Code Expert to convert the files to NC codes. This Code Expert is used to convert into codes readable by the 2D router machine.

Below is a screen shot of the Mastercam Code Expert and the NC codes created by it.

I have already input my files into the console and start cutting on the plywood. I think the cutting was quite cool except for the hot weather. It took me nearly 6 hours to complete cutting my dog house and another 3 hours to file and sand down the rough surfaces.

1) View of the slot cutter cutting the front and back of my dog house

2) Overview of the 2D Router machine that I am using

3) The company that we bought the machine from Signvec

4) Console with my thumb drive - uploading my file to program the machine for cutting

Click on the picture to take at a look of the video (2D router in action)

Finally my dog house is completed, I was really happy while looking at my dog house. Hopefully my dog will love the dog house that I build for him.

Below is a photo taken of my dog house. Pretty Cool...!!! Handsome (My dog's name), you got a new house...!!!