8week//

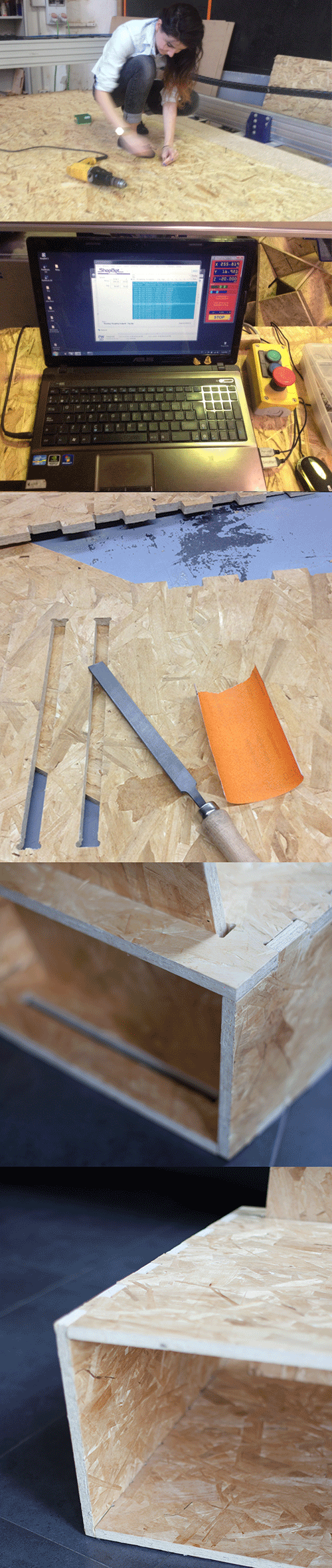

This week I've designed and cutted a lounger shoulder chair with two positions shoulder on OSB material.

I've learned wood tecniches to make something big on the Shopbot CNC router.

This week I've designed and cutted a lounger shoulder chair with two positions shoulder on OSB material.

I've learned wood tecniches to make something big on the Shopbot CNC router.

• I’ve choosen to work with a sheet of OSB 2500x1250x15mm

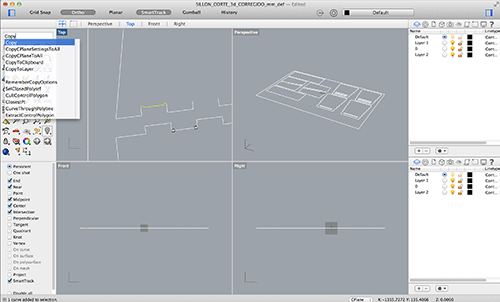

• I've designed my lounger chair with Rhinoceros. I based my design on Gerrit Rietveld "Red and Blue Chair" and I design a chair with a big shoulder with two postions: straight and reclined and with space on the bottom to keep your drink out of the sun ;-) or store your stuff.

• First of all, design a rectangle which size and thikness of the material: 15mm.

• Design the chair was easy for me, so when my first sketch was ready I've studied how joinery works.

I decided leave a void in the center of the joint and concentrates stress on the radiused corners. So a make circle on the corners of my design for the assembled.

• When my chair was ready I exported as .dxf format.

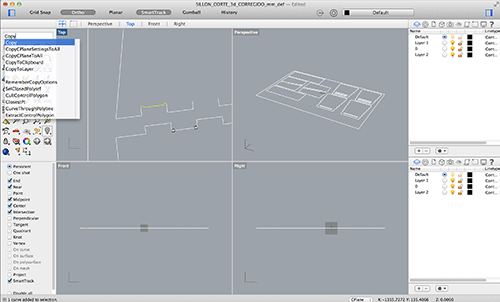

• Computer-controlled machining: setting the files. We used Partworks software and follow this steps to generate the GCodes to cut on the CNC machine:

Partworks (for lines)//

• Import your file • Make 2D file to 3D file • Resize document to the material board size: 2500x12500mm • Set the thinkness of the material: 15mm • Check "use XY origin offset" • Set units to "mm"

Configurations:

- Profile: Allow follow this line "means"

- Cutting Depths: 15.3 mm ( it is 1mm more than material thickness)

- Material Vectors: "on"

- Directions: Climb

- Name: Put a name as you want

- Tool: end mill (6mm)

- Cutting Params: Path Depth - 5 mm (how many material removes)

- Step Over: 8000 - 12000

- Feed Rate: 40 mm

- Plug Rate: 10 mm (z-axis)

- Toolpaths: Toolpaths list

• Select Order: drill, inside, outside

• Select item: (drill) and then save as template

• Select item: (inside) and then save as template

• Select item: (outside) and then save as template

• Save complete projec for possible changes

Partworks 3D (for reliefs)//

• Cuts: C3 Home X: Use sensor machine to find the 0,0 • Load the File: first drill, second interiors and, exteriors • Set spinnable "ON" - green button on the desk control • Press "OK" after set the spinnable "ON"

Files to cut//

drills, inside and outside.

Steps to work on the CNC machine:

• Clean the machine • Fix the material to the base of the CNC using screws aligning the 0,0 point to the top-left corner of the CNC machine • Send the files in this order: drills (and put the screws to fix the material during the cutter), inside and outside.

Don't leave the machine working alone just in case something is wrong!

When pieces was cutted I've used sand paper to make niecer the wood.

• Now: Relaxing Time on my balcony!