week15

Applications and Implications

For this week assignment,we had to plan and document a final project that integrates the range of units covered.

what will it do?

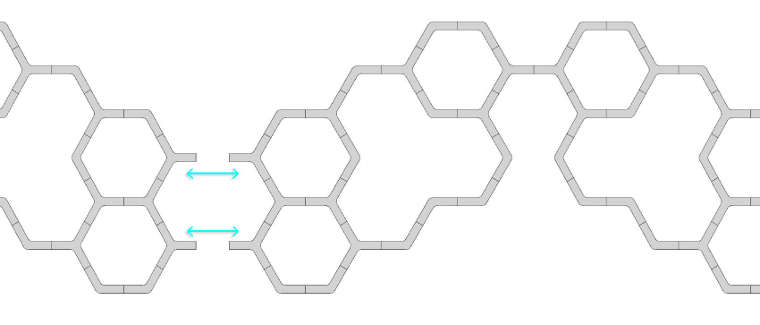

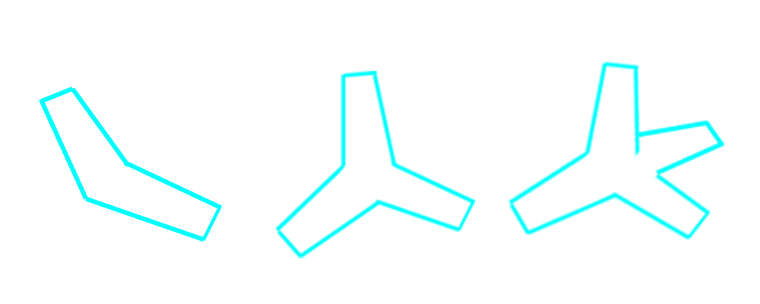

It will be three different modules that can be assembled together to create one customized light fixture and that can interact with its environment.

The user will be able to put together their own light fixture depending on the functionality they desire. It could be installed as wall features or partitions, on columns, set up as a floor lamp; endless use just by assembling the different components together.

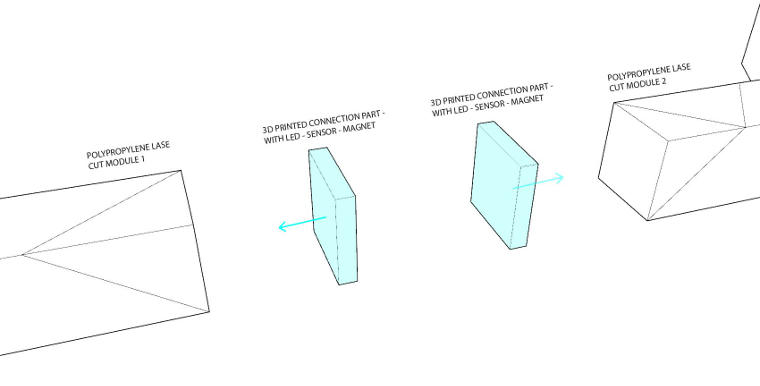

Every module will light up everytime it is connected to another module by the use of magnets. It will also interact with the user through a sensor making them reacts to the movement.

who's done what beforehand?

They are many similar projects that have been done as interactive light installations which I got inspired by and here is a list of nice modular robotic projects:

what materials and components will be required?

As for the components:

where will they come from?

All the materials and components will be provided by the local fab lab.what parts and systems will be made?

what processes will be used?

what tasks need to be completed?

The 3d modeling in rhino is almost completed but I still have to work on all the tasks.what questions need to be answered?

what is the schedule?

There are 3 weeks left before the final presentation, and my goal is to complete tasks by week and start withhow will it be evaluated?

If the lighting connections works between the modules and if they interact with their environement.Fabacademy.org | Copyright © pamelachami | Design by pch