week12

Composites

For this week assignment, we had to design and make a 3D mold, and produce a fiber composite part in it.

Here are the steps that I followed to complete this assignment:

3d Mold

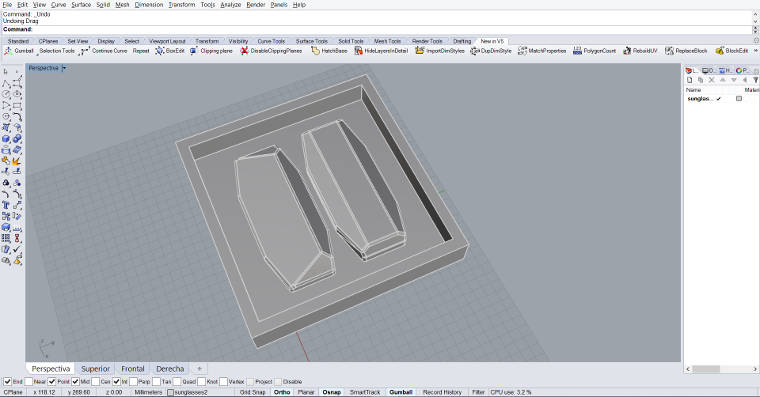

I decided to make a sunglasses case which I designed using the 3d software Rhino.

Milling

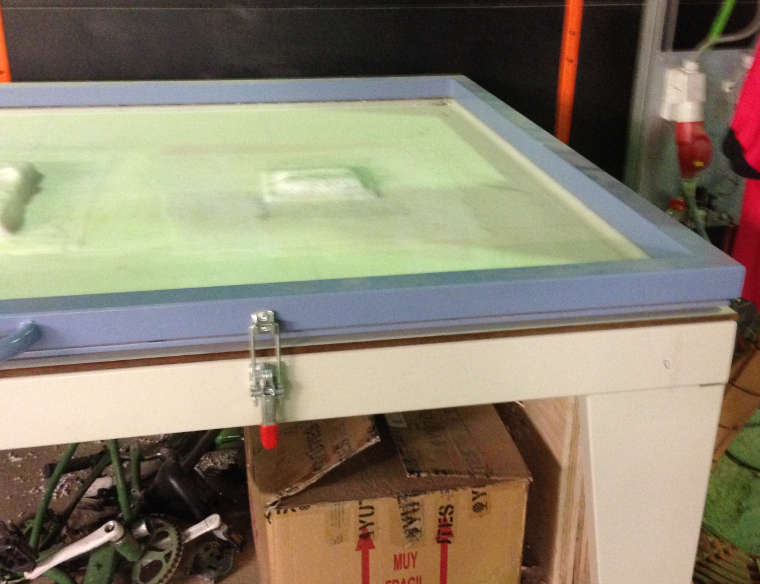

After generating the code using RhinoCAM, I sent it to the Shopbot milling machine to mill the foam.

Two steps to make on RhinoCAM using the machining Operations: Select 3 axis milling operation:

Fiber Composites

Once the foam is milled, it is time to assemble the composite elements on the mold with all protective layers, apply the resin mix and finally vaccum it.

Result

Here is the final result, after vaccuming the mold and the fiber composites layers for 6 hours, I had to clean it and sand it to have the sunglasses case. It didn't turn out to be as I expected it to be but I think the result is okay and the glasses fit perfectly in it.

Fabacademy.org | Copyright © pamelachami | Design by pch