week06

Electronics design

This week assignment is to redesign the echo hello-world board and add a button and a LED. It was better then I thought it was going to be. The electronics production week was a lot of help in the milling and the soledring part.

Re-draw the echo hello-world board + add button and LED:

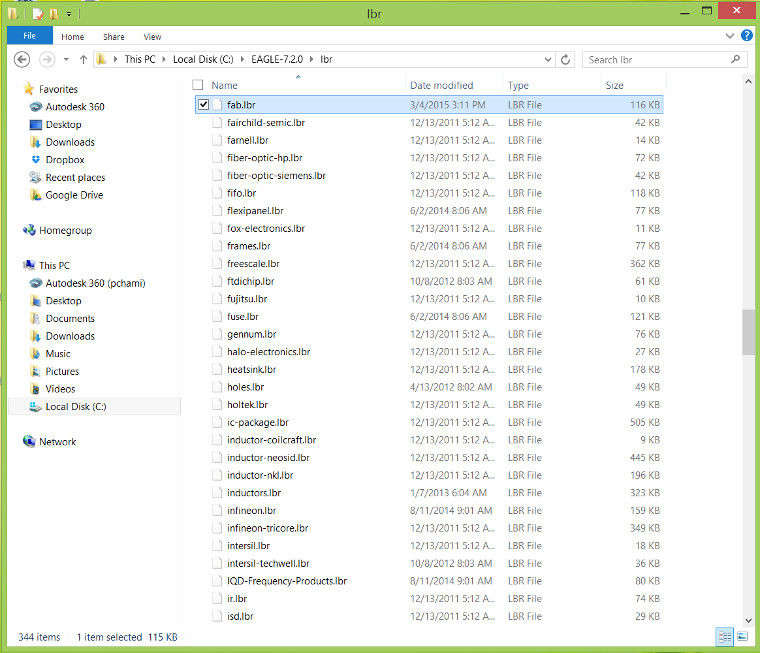

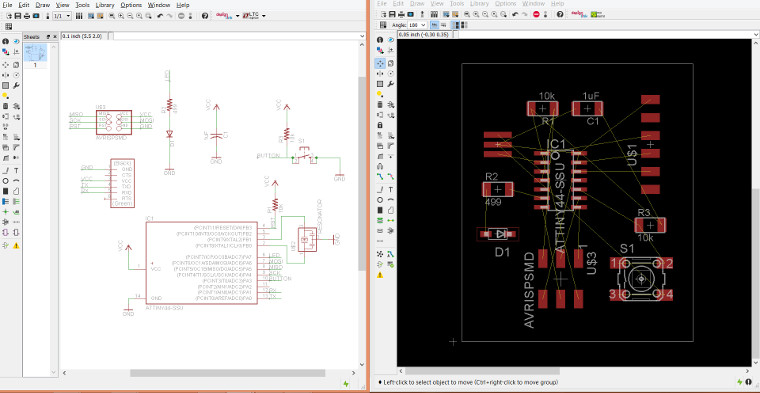

First, I started by downloading Eagle, a PCB design software,and the Fab-libraries, a library of components to use for the hello-world board provided by the academy, to start to re-draw the board. The zip file of the fab libraries should be copied into the local disc on the computer for windows, in my case: Local Disk (C:) - Eagle - lbr.

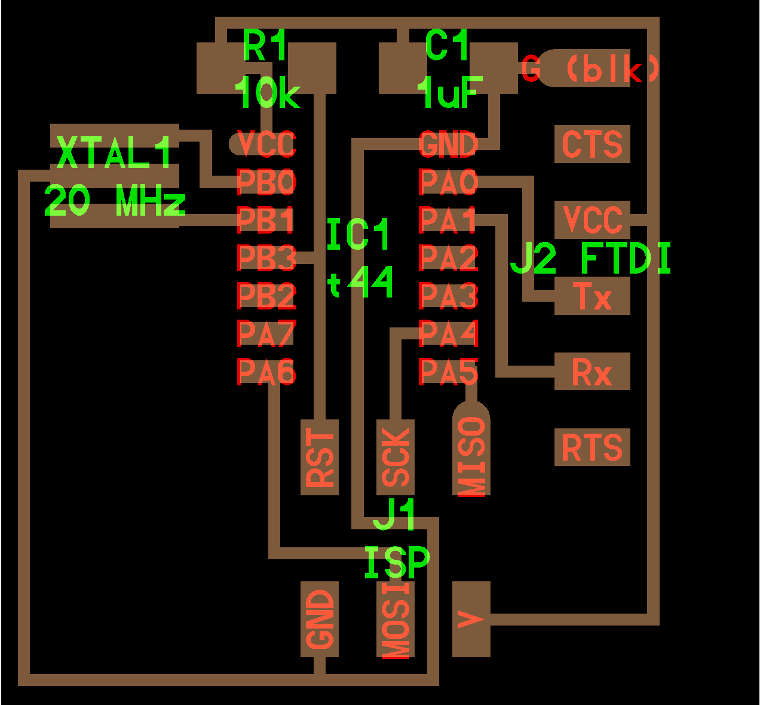

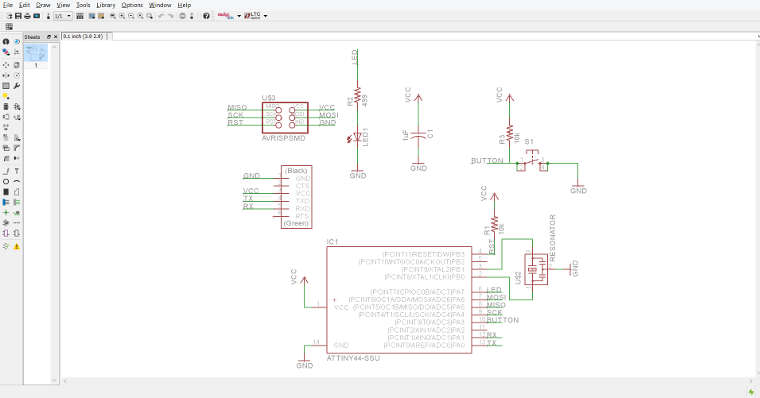

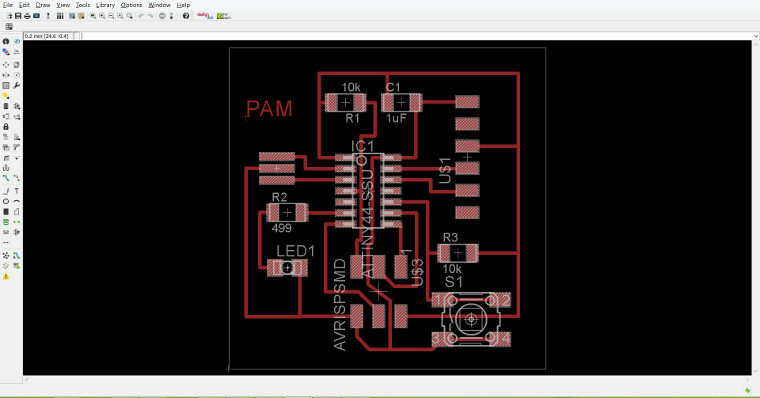

Once Eagle was downloaded and the libraries were set, I have created a new project with the Schematics and the board view which always work both in parralel. Then I have added all the components that I need to use from fab library in the schematic view.

Here is the list of all the components needed for the hello-world board:

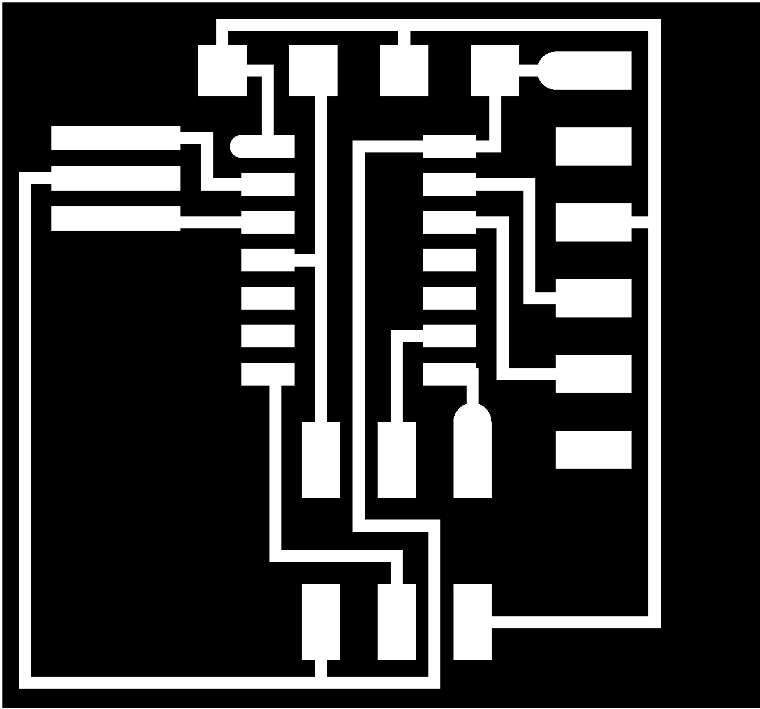

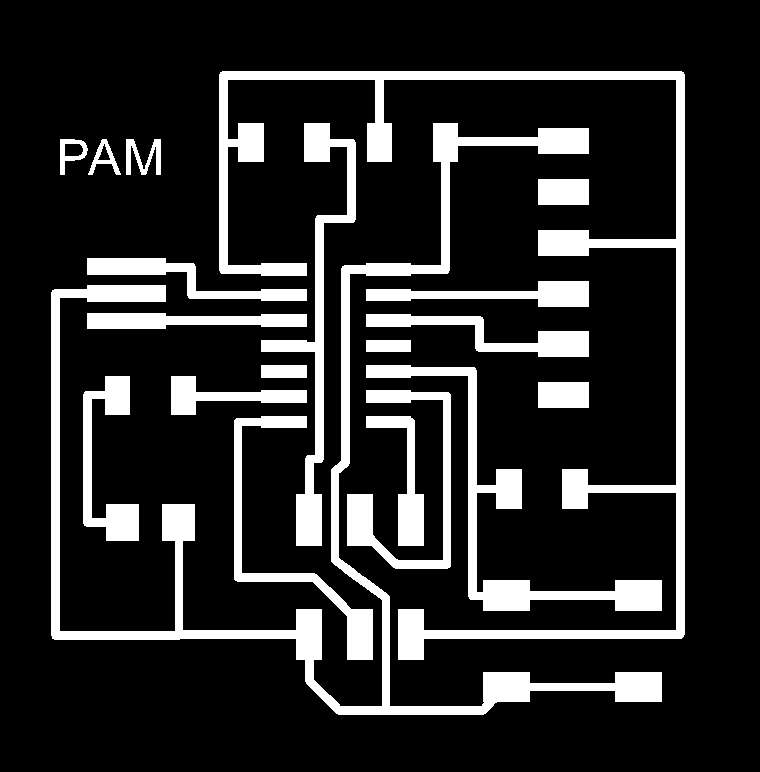

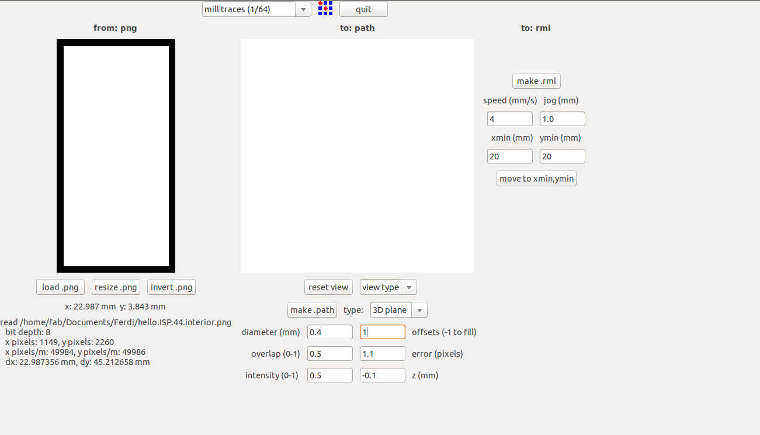

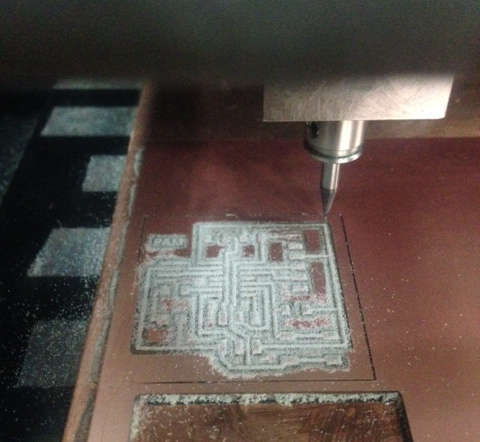

Milling:

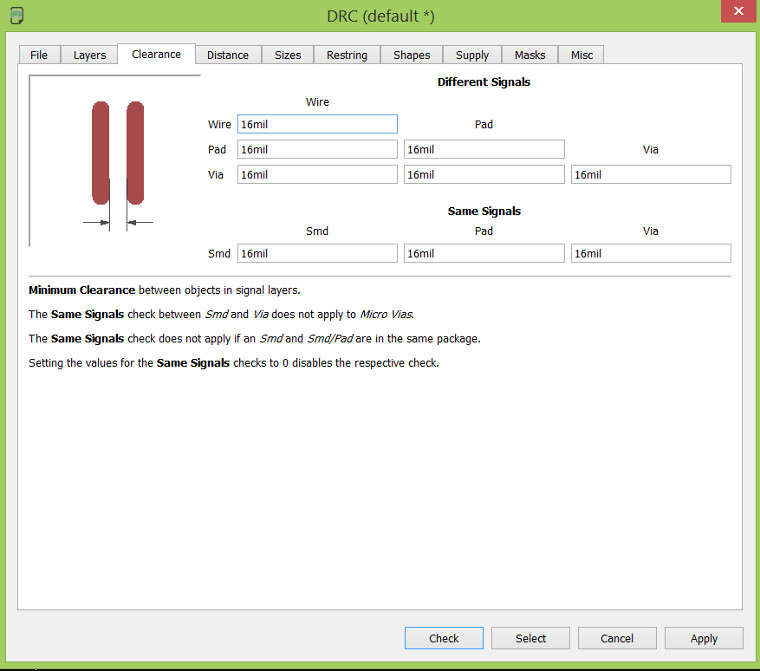

For the milling part using the modela machine, once the images has been exported as .png and the copper boards are perfectly glue and in place, we need to follow the same steps as the previous milling we did couple of weeks ago:

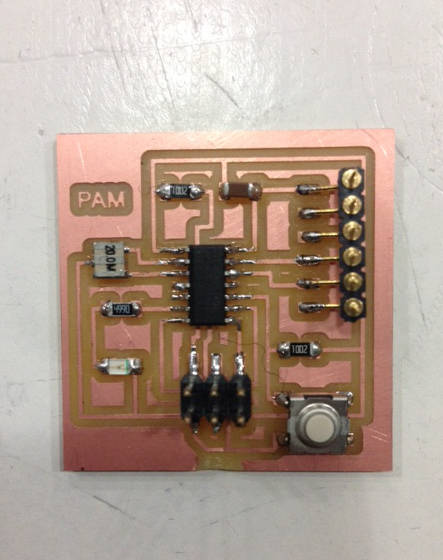

Soldering

The soldering part went good and faster then the first time ! I listed first all my components on a sheet of paper to be sure that I got them all and then started the soldering !!!

Here are some recommended tutorials that hepled me a lot with Eagle:

Download the file here : HelloBoard - eagle file

Fabacademy.org | Copyright © pamelachami | Design by pch