week04

Electronics Production

This week assignment is about electronics production . We have to make a FabISP in-circuit programmer. There are 3 steps to be accomplished in order to achive it:

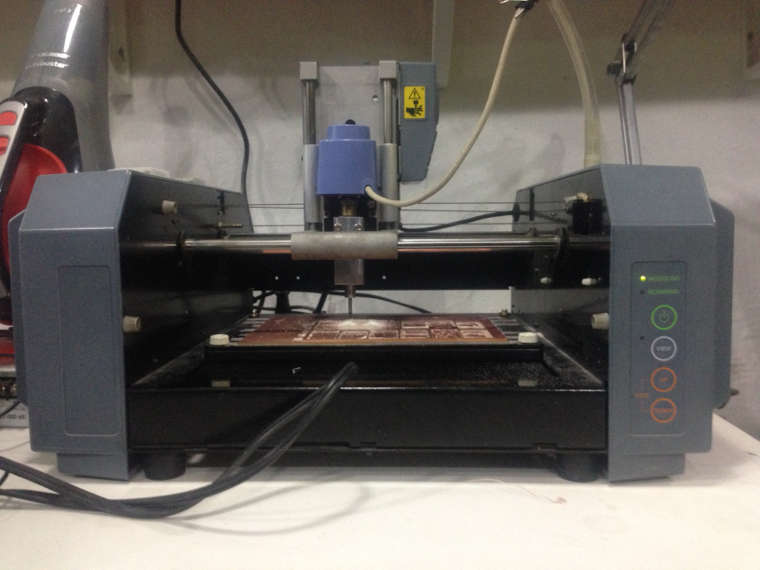

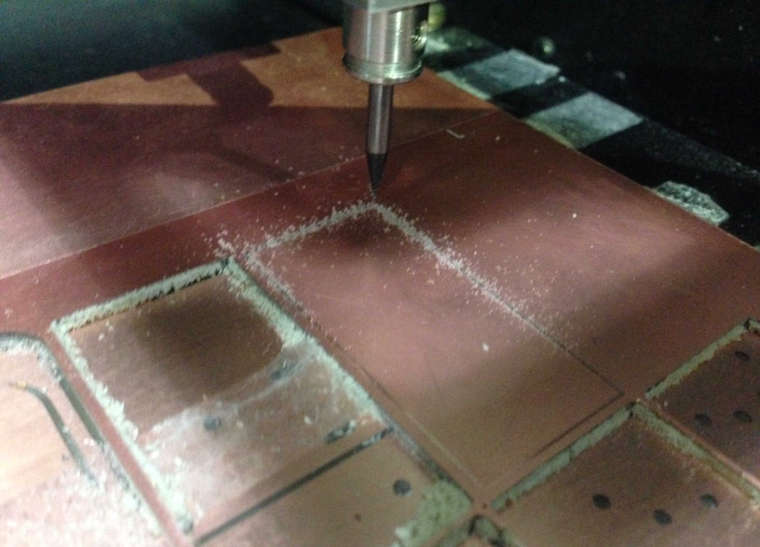

Milling:

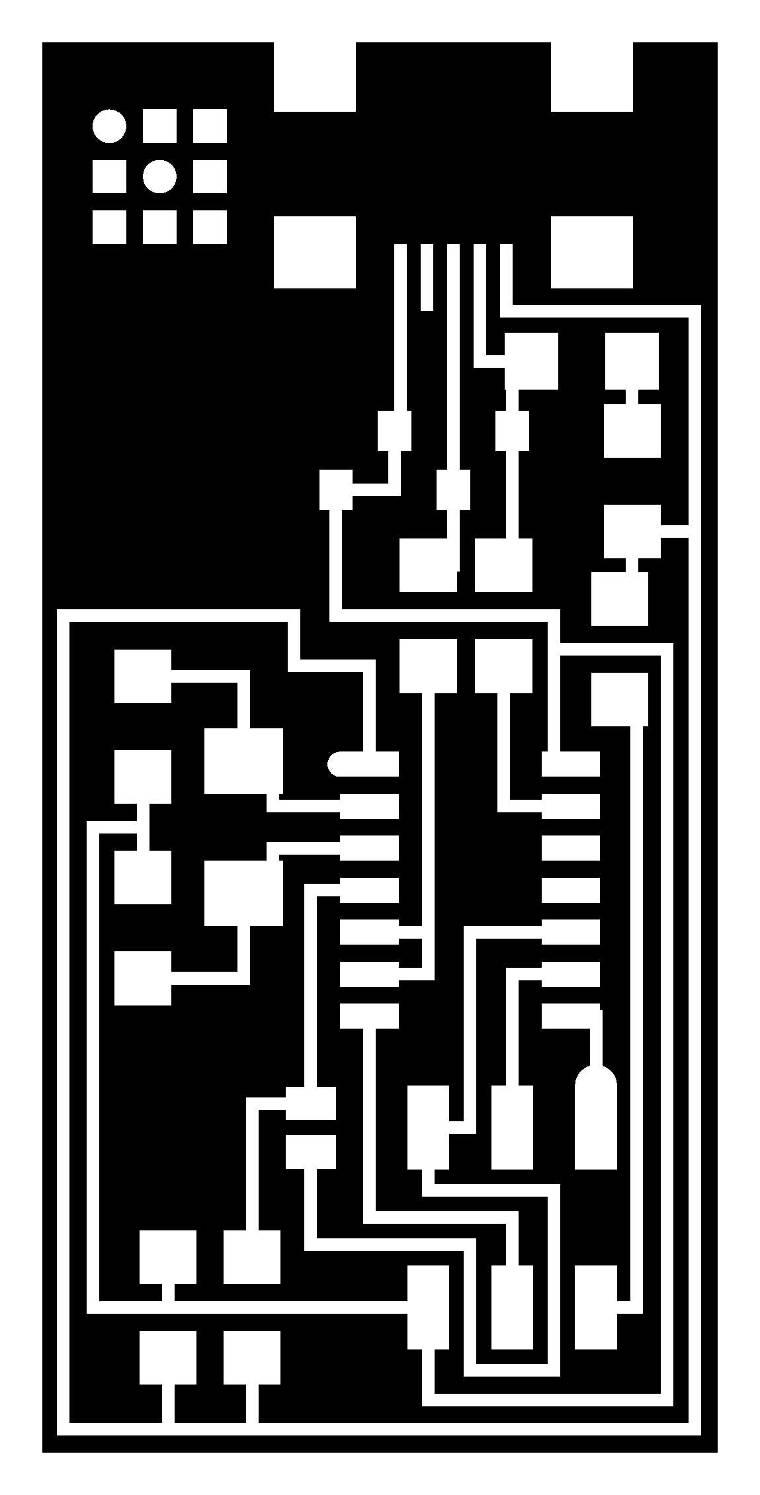

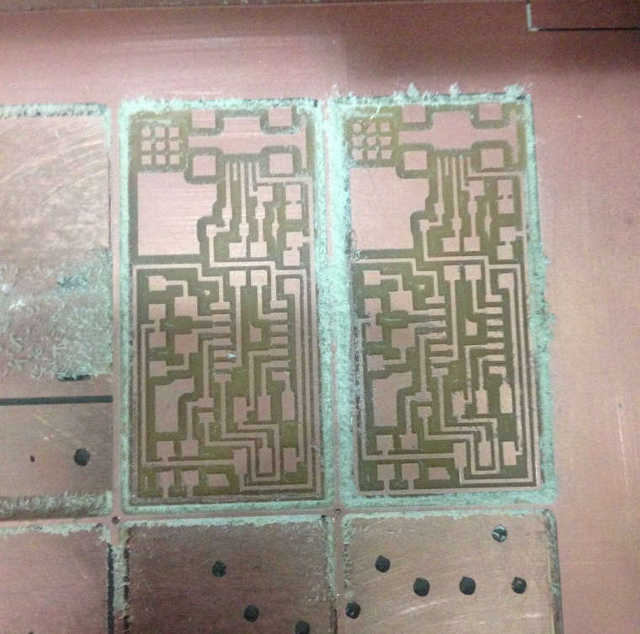

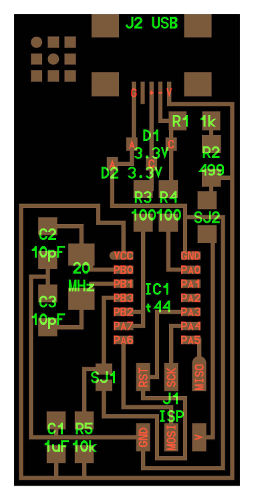

The first step is to mill the PCB board. I have downloaded these two following images of the hello.ISP.44.cad to start with: traces and interior.

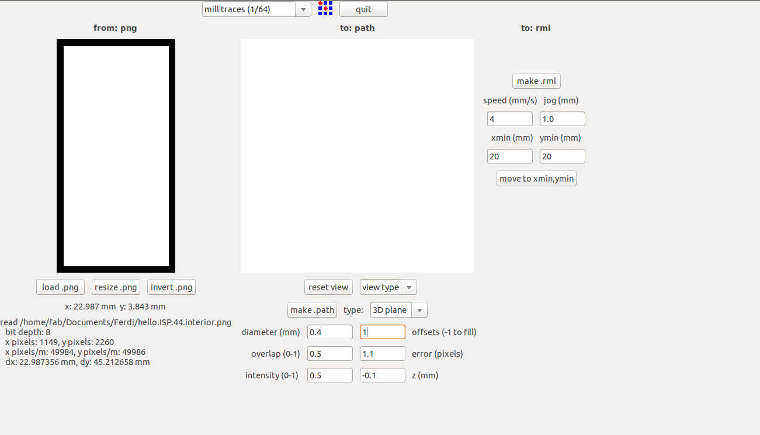

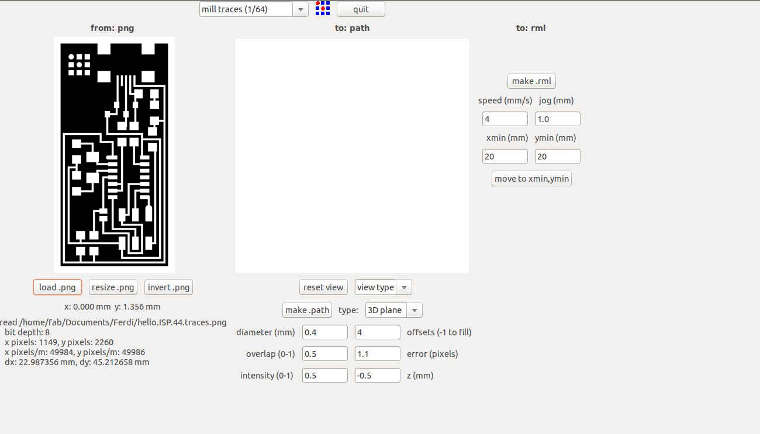

Once the boards are perfectly glue and in place, we need to print the two images downloaded using the FabModules:

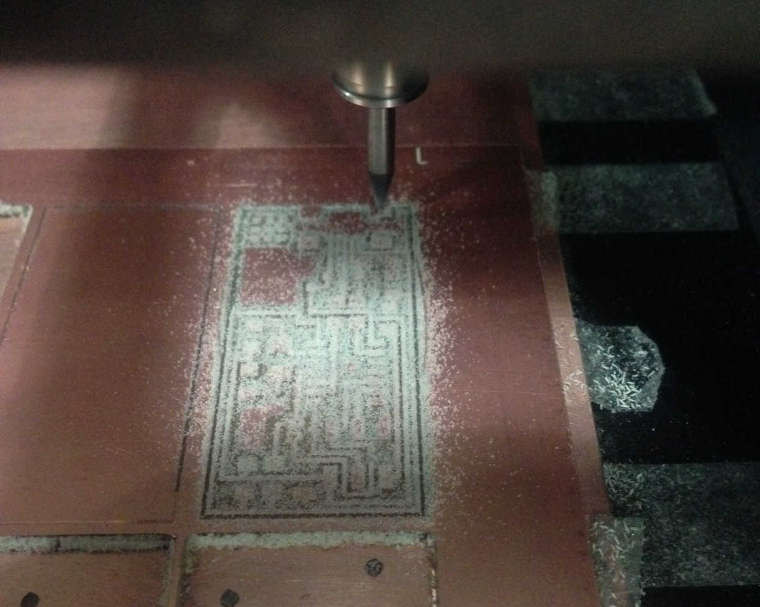

First step, mill the interior.png as a test to verify that the machine is correctly set.

Second step, mill the traces.png with new presets

Once the board is finished, It should be cut out with the following presets:

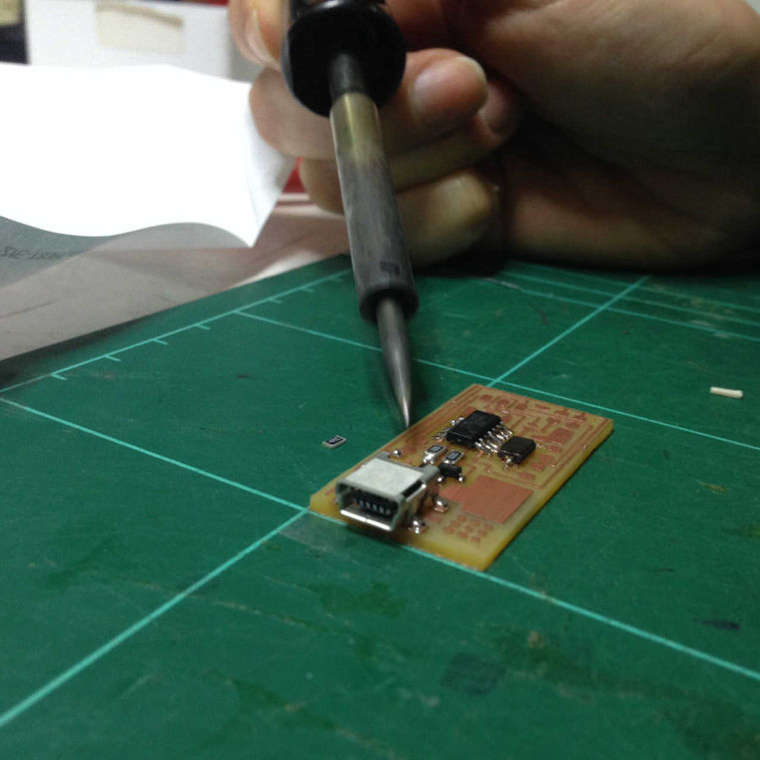

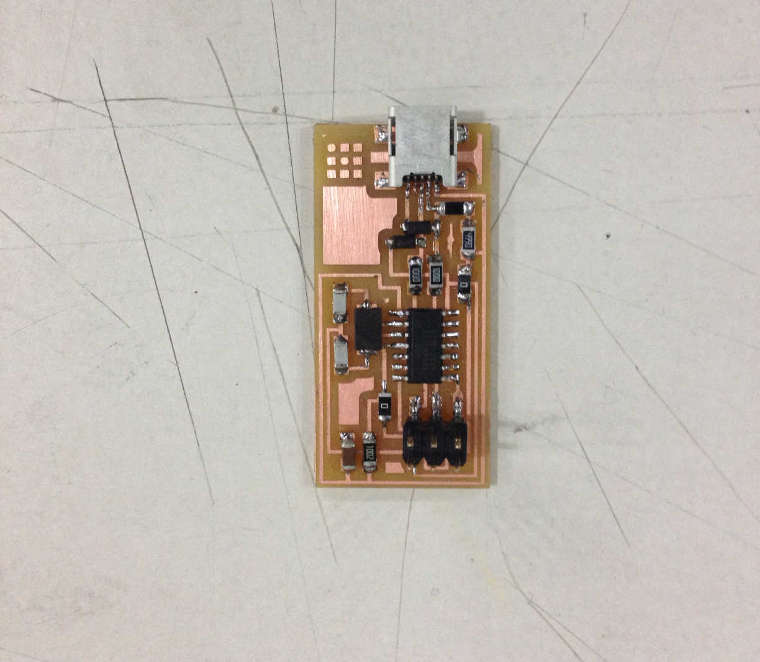

Stuffing:

Before beginning with the stuffing, The PCB board should be cleaned with some alcohol and polished the copper gently with a steel wool.

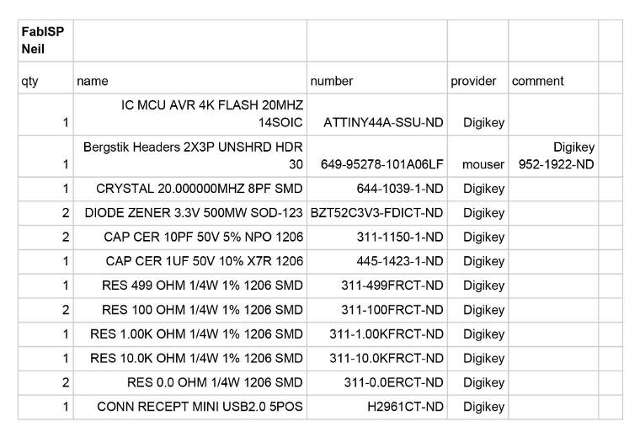

Here is the list of the components that should be soldered to the PCB board that I have selected:

I have followed the steps of the following tutorial Fab Lab Providence which explains clearly how to sloder the component in their right place and direction. Orientation is very important for some components and should be placed in the right way.

It is very important to always:

Programming:

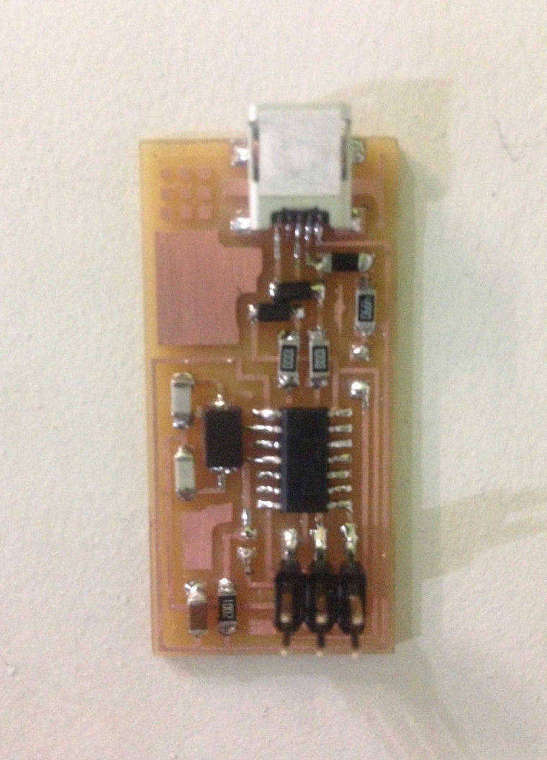

To program the PCB it is necessary to install the AVR program for the operating system and download the FabISP Firmware folder. Then I Plugged the mini USB connector for the FabISP into my computer and separatly plugged the programmer that is connected to the 6-pin programming header to the computer as well.

On the command window :

If the light is green, the FabISP should be programmed and ready to be used.

And finally the last step is to remove the 0 ohm resistor and start progamming other boards !!!

Fabacademy.org | Copyright © pamelachami | Design by pch