As a climber, I have always wanted to know what force is supporting each dam.

Anyone who has practiced climbing for a while, knows that the technique enables complex movements with less force applied. If you could know what force is supporting each dam, on hands and feet that we support, we could correct a poor distribution of the supports.

In many sports it has managed to successfully introduce technology to

improve technique and performance. We can see that there are force platforms

to analyze the tread on athletes, heart rate monitors which are able to

analyze live heart rate, gas analyzers for athlete's physiology, insoles

for athletic shoes, etc.

In the case of climbing, it would be great to have the feedback pressure

patterns and the distribution thereof. This would allow us to understand

what they are doing champions.

Therefore, one of the ideas of Final Project of the Fab Academy is creating

a Climbing Dam which give the feedback of the pressure is receiving.

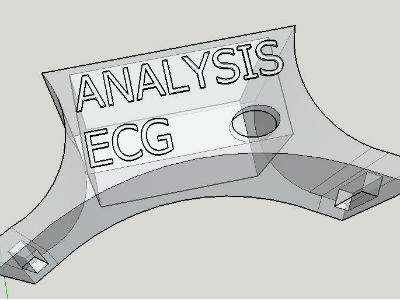

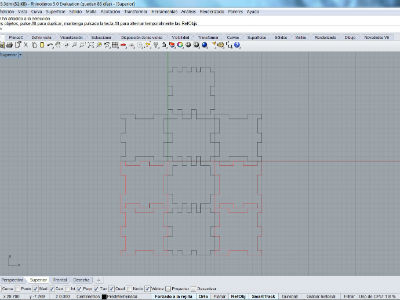

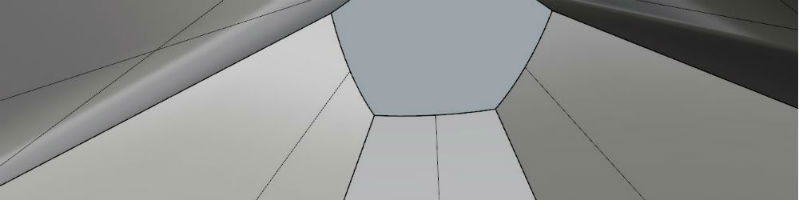

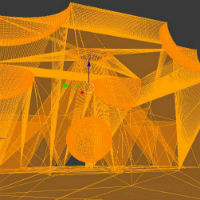

Climbing dam designed with Rhino.

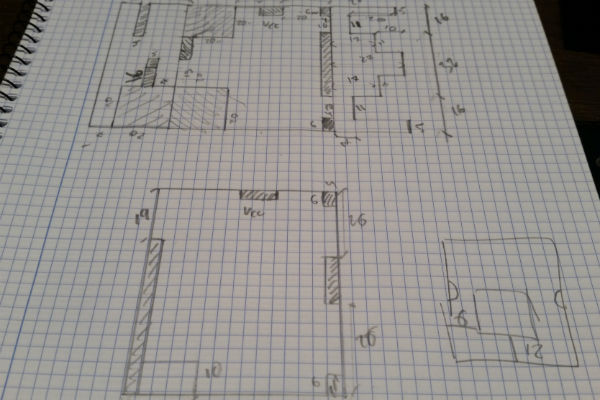

Just for fun, of course. I decided to make all "inside" layers and parts

different. Obviosly, it is not necessary to make all the sizes differents,

and a different assamble joint for every slide, I did it just for fun.

I love puzzles, so these are apportunities for play for a while.

Then, think about how to assamble them (easy way, but just 1 possibility).

Brainstorming...

At Beach Lab (Fab Lab Sitges), there is the Full Spectrum Laser 5th gen.

It need the file in format ".svg", so I've designed all parts with Inkscape

and export them to svg or pdf. For engrave, I have used 100% speed and

40% of power. For cut I have used 20% of speed, 100% power.

After some tries, I realized that as much dark is the color, much heat

gets the acrilic, so less power is needed. In my case I was using black

acrilic.

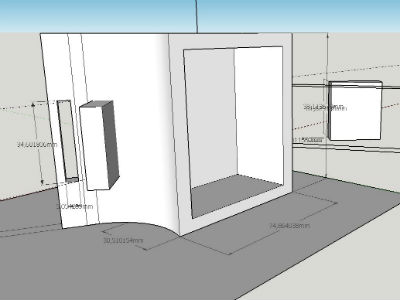

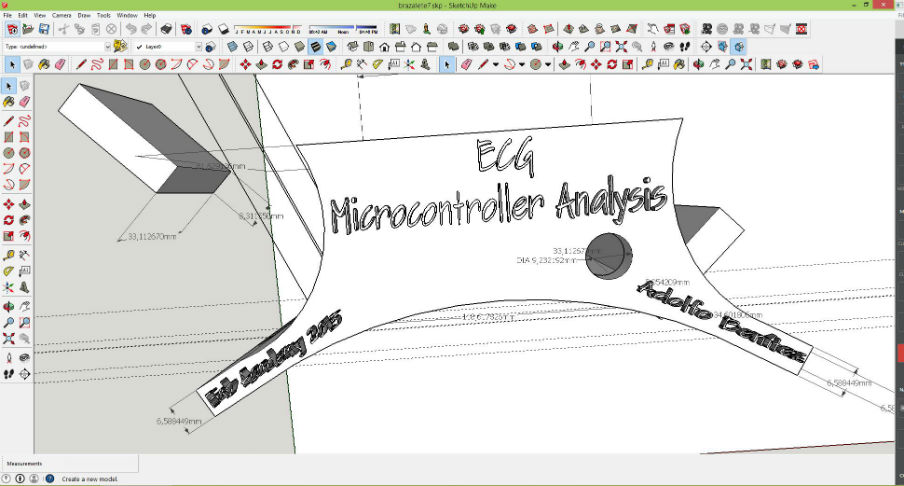

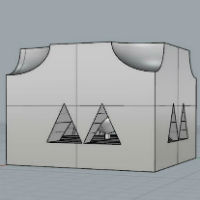

I have used some CAD software this Fab Academy, I would like to try another

one. Sketchup is my option for this design.

Here are all needs listed:

- Room for battery

- Room for 3 PCB

- Open window for ECG cables.

- Window for visual result.

- Have to fit to shoulder.

- Modular

Let's Start to use Sketchup.

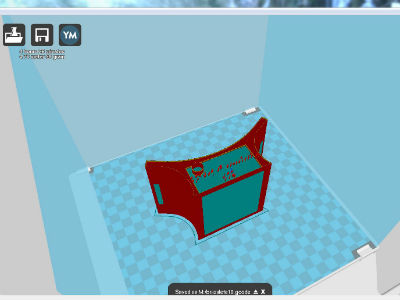

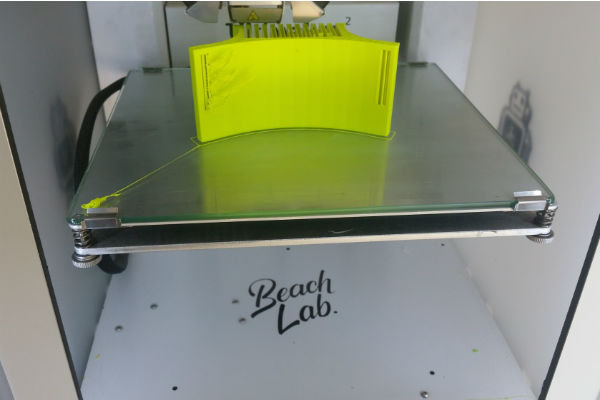

From Sketchup you can export many formats. In this case I have use: ".dae".

Then another open software "Cura" prepare the file for the 3D printer.

You can see the settings for the first iteration:

Nozzle size: 0.4mm

Initial layer thickness: 0.3mm

Initial layer line width: 100%

Cut off object bottom: 0mm

Dual extrusion overlap:0.15mm

Travel speed:80mm/s

Bottom layer speed: 20mm/s

Infill speed: 50mm/s

Top/bottom speed:20mm/s

Outer shell speed: 30mm/s

Inner shell speed: 60mm/s

Minimal layer time: 5sec

Enable cooling fan: yes

Total time according to software: 4h 26min. (Real time: 4h)

Material used: 4.76m, 38gr

Sketchup is very intuitive and easy to use.

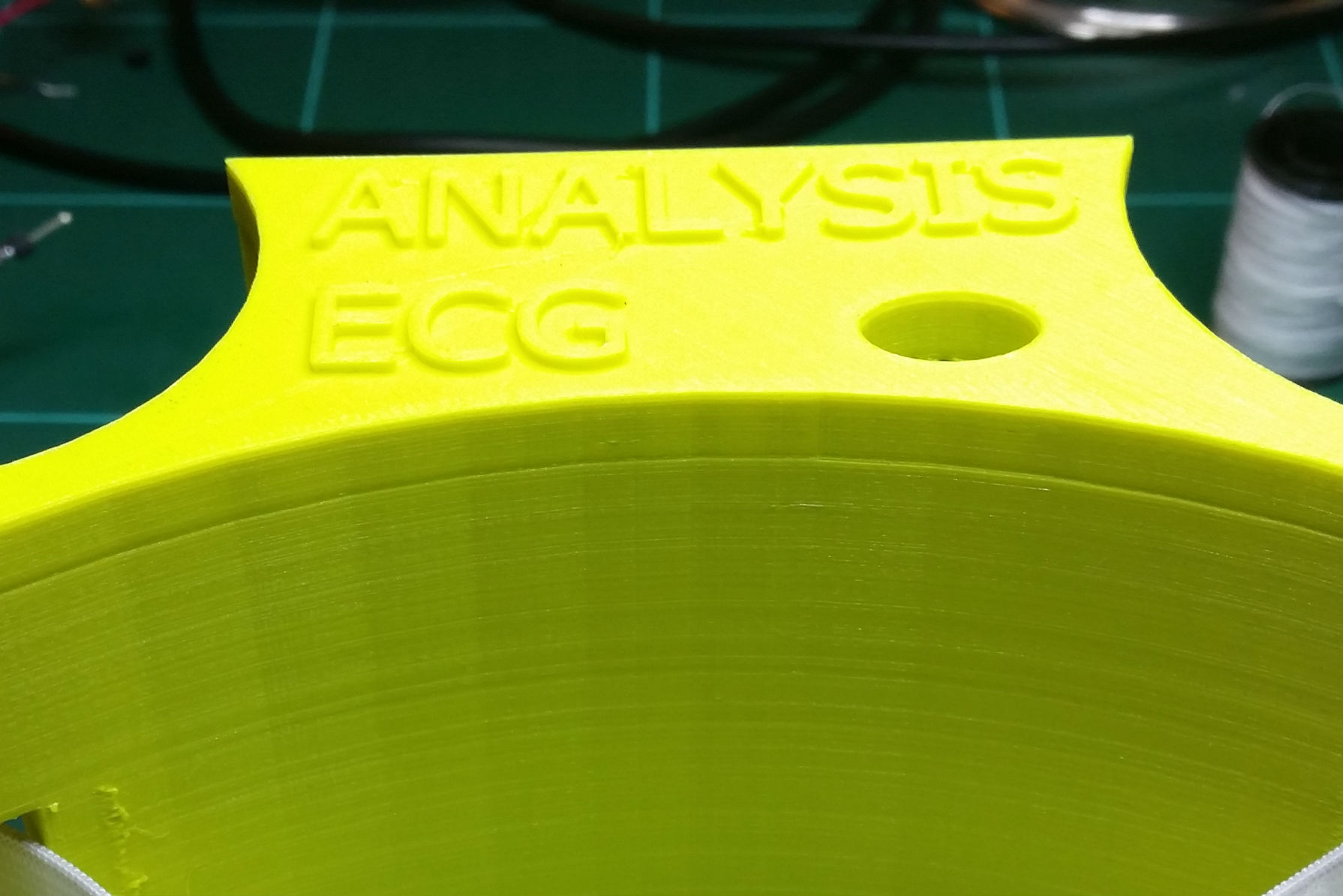

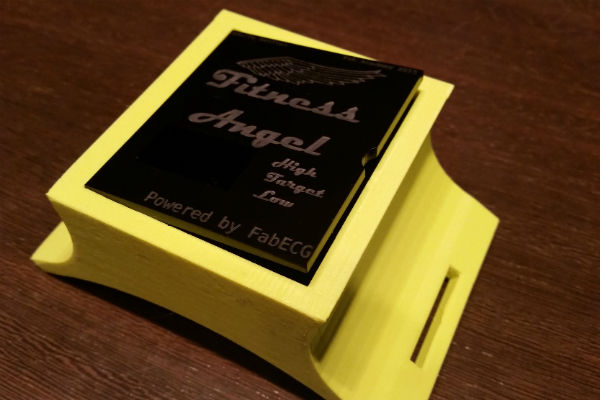

This is my first design. The battery makes me the minimun size. I wish

to write on the top all the minimum information (letters have 0.36mm).

Download the 1st sketchup file

Here it is the first iteration case. As you can see, letters are too thin,

next iteration letters need to be thicker.

Battery fits perfectly, but it's needed more room for cables 9.23mm is not enough. The upper window for cables have to be wider.

New letters thickness : 1.32mm

Window for cables: 13,8mm

Download the final iteration file zip

(sketchup, dae and gcode)

Now, letters and upper window are perfect.

There is just one way to assamble all pieces, that's my puzzle passion!

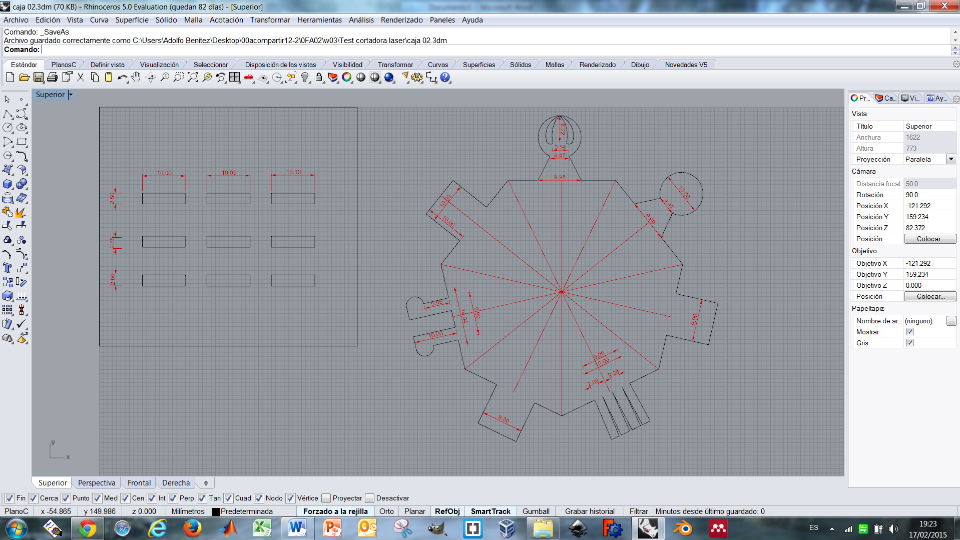

Using Rhino, designing a cube which could be assembled as a puzzle.

One of the most important aspects is the adjustment of the pieces together.

Two layers were done: black layer that will be cut and red layer that

will write without cut. Color red and black will used on laser cutter to

set the tool power.

Download Rhino design with two layers

here.

Now, the assembling time. The first time, it doesn't cut or fit the joints well. It was necessary to do three iterations from step 1, redisigning joints size and changing the laser cutter settings.

After my experience with the cube puzzle, I realise that joints have to fit and be enough strong to make a proper assembly. For that reason I started to design all kind of joints for paperboard. The project is in progress.

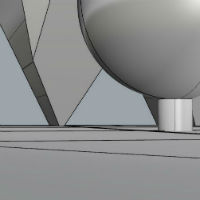

A climbing dam is a hard piece of resin that is used to climb indoor. Usually, a climbing center have a wall full of holes where the dam are screwed.

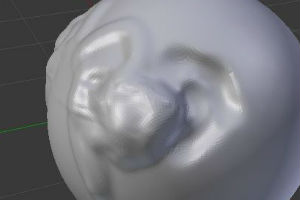

Open Blender and select with rigth button the initial cube, click on "x"

keyboard to erase it.

On menu: add/mesh/ico sphere, create a sphere on the center of the screen.

The have no a good "sphere shape" it looks a poligon yet. To improve that,

go to "add ico sphere" and grow up the value to 3 or 4. I did it to 3.

On your right side of the screen, click on "object modifiers", add modifier

and look for "multiresolution". Now click on "subdivide" 4 times for get

a rounded shape.

If you look at the top of the screen you will see "61.442 verts"

Now, on the button menu, change "object mode" to "Sculpt mode", you will

do crazy changes on the surface adding material with left mouse button,

and substracting material with ctrl+left mouse button. You can change the

size of those adding, changing the radius on the left menu.

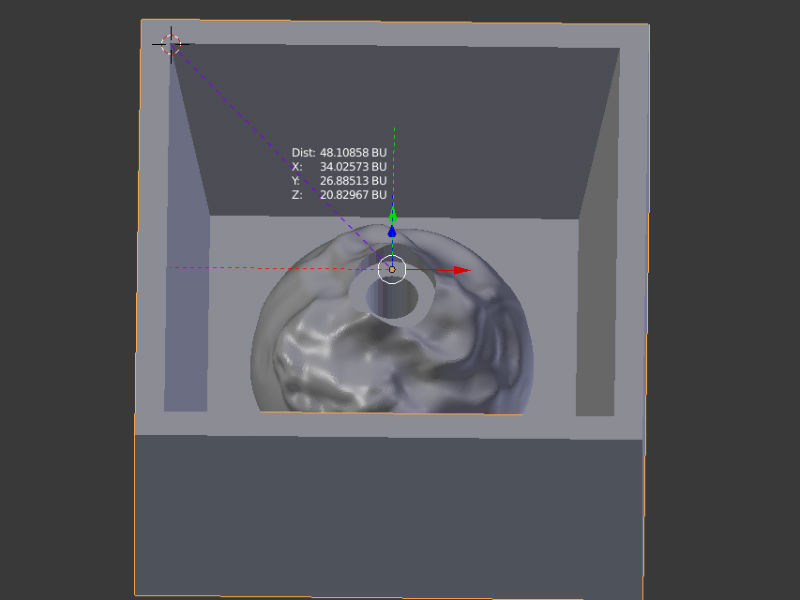

Go to edit mode (button menu). Then view/front in order to place the object

in front view. On the button menu change to wireframe. Click on "A" to

deselect everything. Click B, to create a "box selection" and select the

bottom half sphere and delete it with X.

Now on select, verts of the cutted ring. Alt+F, will fill it. Back to

solid mode to see the changes made.

Now, let's make a hole to be able to screw the dam on a wall. On add/mesh/cylinder

make a cylinder. Now it appears a very big cylinder. Put radius to you

screw. Click on "E" you can scale the selected object in any direction.

The screw head is made with extrude and scale options. With boolean

option to substract one from other.

Add a cube, adjust to the dam. with scale and extrude it's easy to make

the cube border. That's final dam. After finish it, and before mill, it

is necessary to check the object size (it is a 3MB Blender file, so it's

to big to upload to my website).

Download CAD files here (3MB)

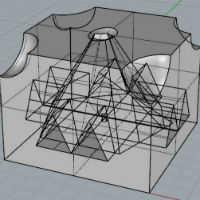

I've started with Rhino, in order to create a simple and easy figure to

practice the 3D design and print.

The first idea was to create a hollow cube and print something inside

of it. I wish to use the MakerBot 3D printer, but it seems that with this

technology make a hollow cube is almost impossible. Top of the cube needs

some supports.

Then I was thinking how to solve it: One possible solution is to

make a lot of supports inside the cube and try to take them off through

the holes of the cube. Another possible solucion is to make an internal

structure that support the top of the cube. That last solution I tried.

The inside structure is a piramid. We could see the view from the bottom

of the inside of the cube at the the picture .

Download CAD files here

Some subtractions to see the interior and structure.

Inside the cube, just in the middle of the piramid's structure, I created a little ball with an easy breakable support.

Finally , I took a few bites of the upper corners of the cube to save some material.

At Blender Software, I make sure that all the normals are well-targeted.

The dam will have two parts: first one comes in contact with climber's

hands and feet. We will call "the dam's body" The second part is the pressure

sensor, could be used a piezoelectric sensor.

I have designed with Rhino, you could have a look of the Rhino files

here.