ASSIGNEMENT 5B

-

See outer in Fab Academy web page:

3D SCAN AN OBJECT (AND OPTIONALLY PRINT IT)

Get all files: HERE

ASSIGNEMENT # 5B

3D SCAN AN OBJECT (AND OPTIONALLY PRINT IT)

3D SCAN AN OBJECT IDEA

The original idea with this assignement was to replicate a little wood sculpture bringed fromo ecuador to my home. i called him: "Jhon". Later i will knowing that scanning has had a little simply rules. This issue could include topics like good lighting exposure; efficient pictures resolution, correct visual registry, and correct reference markings.

RESOURCES

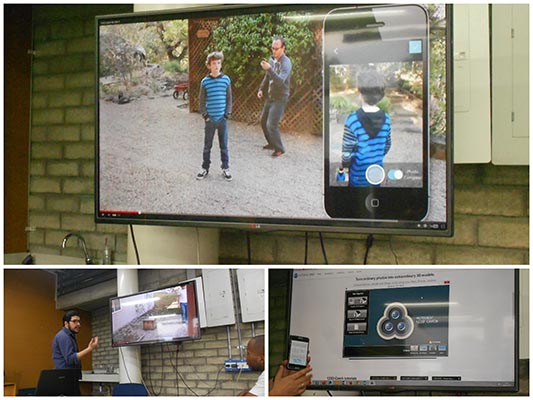

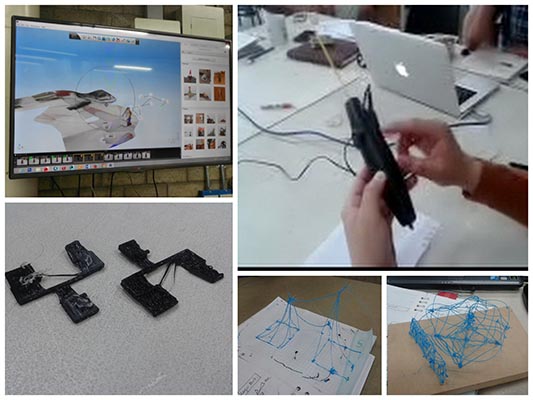

About the resources, specially the expert "know how" was the major input. Between the principal knowledge fonts, were the software "123dcatch" tutorials whiches were easiest and comprehensibles. Second a talk of Andrés Hincapié an enthusiathic maker architect that shared whit us his experience around this theme. In third the 123dcatch and 123dmake apps software that facilitated the process. Finally the important initiative for construct a tangible result.

MATERIALS

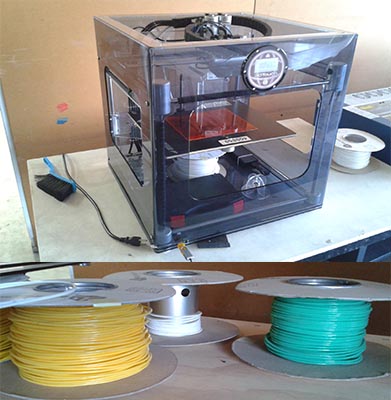

About the materials, the most important after arriving the visual capturing and digitalizing was used the abs ("acrylonitrile-butadiene-styrene" - tough copolymer for moulding fabrication used-) trip; and the injection moulding machine, set wich can achieve trough lay over lay melting of material to construct the desirable model.

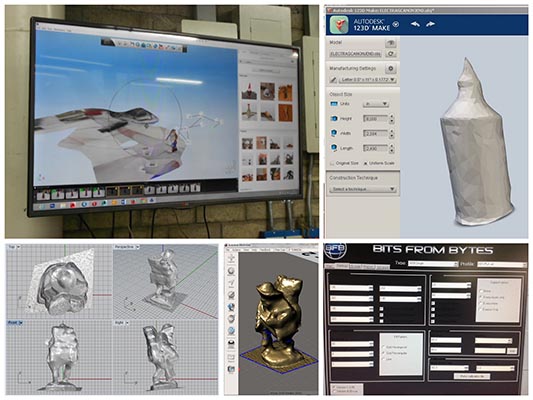

SOFTWARE

The software used -maybe in the fabrication order- was:

MACHINES

Bassically, the relevant machine at this assignement was the molding injection machin. These work Joined uith the last learnings about "scanning and printing" (last assignement of a5a module too in this page)it could be possible to obtain the principal materialization of a little home art piece. The principal aim was to cast in to the machine a formally complicated piece than can to be observed and acquire some learnings.

PROCEDURES

Procedures can divide in to five scopes thereby: One: Catch the figure, where the adequate cam photograph operation allows to ensure the multiple formal point of view which his visual progressive redundancy with try a digital capture. Two: the post processing of the image that can to place the virtual object like a intelligible surface for modeling software; Three: the pass of this virtual mathematic representation to a loadable file in, for example, a 3d-object archive. Three: the convertion of this math image into a injection modeling instructions that can to be more or less adequate for differents material casting angles; and, Fourth: to cast the modeling process with the molding machine to obtain the final result.

PROBLEMS

were founded four problem types: Low accuracy capture; low object deffinition; Inadequate lighting schemes; and: bad data into the machin software.

The low accuracy capture can come from too smooth or too much basic form without determinant formal gestures. The low object deffinition can comoe from the conbination of the first commented whit a badly lighting dispossure tha can to arrive at photographical formal flatten. The inadecuate lighting schemes are the low contrast or excess lignting for the object. Finally, the inadecuate data intro in the machin can create debilitate sections in the growing form, that the same casting procces can colapsse due to accidental nozzles-material forcing.

LEARNINGS

In to the learnings can it learning at least than three issues: The important photogrametric use of the point of view withint a set of sequential images that can be reached from three dimensional reconstructions using software like 123-dcatch. In second one, The important requirement of refer to previous figures plotting stiffer base material allowing adhere to a flat surface Figure thereby preventing collapse in the process due to lack of adherence to the floor. In third point, Could learn and proove from experts hands in the field the existence of another molding injections hardware like the Hand-Molding machine, it allowed develop some excercises in draf mode that are showed in video include.

THE RESULT

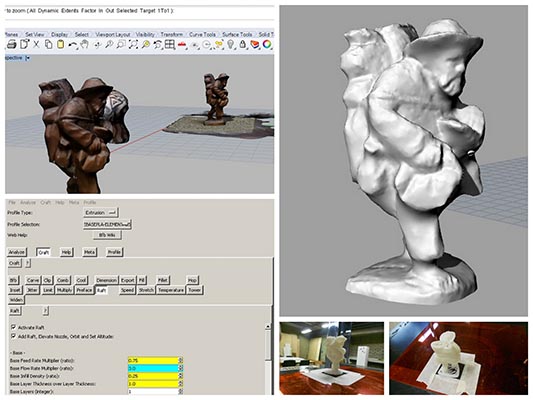

The result at this case was demonstrated from two: virtual image, and, physical model.

JHON3DOBJJ05MR15 by JFTORRESH on Sketchfab

the image projected in to the vrml image (virtual reality modeling language view) of the scanned object "jhon", and the sequence of the original object with his 3d image process about Rhinoceros software.

Finally give place to the small end result, with its original carved wood piece.