-

See outer in Fab Academy web page:

DESIGN AND 3D PRINT AN OBJECT (SMALL, FEW CM) THAT COULD NOT BE MADE SUBTRACTIVELY

Get all files: HERE

ASSIGNEMENT # 5A

DESIGN AND 3D PRINT AN OBJECT (SMALL, FEW CM) THAT COULD NOT BE MADE SUBTRACTIVELY

DESIGN AND 3D PRINTING IDEA

The idea was based on the three-loops moebieus ring and his capacity to touch at least than three points on floor and the same equal points on apossible over surface. The last end intention was to make a table model drawing this special properties.

(image taked from: http://goo.gl/c2KnTr tuesday, march 03, 2015).

RESOURCES

The Injection Molding Printer; and, The lasser cutter machine. Too was neccesary all the possible 3d design software which gave up the goal to this relativity complex design.

MATERIALS

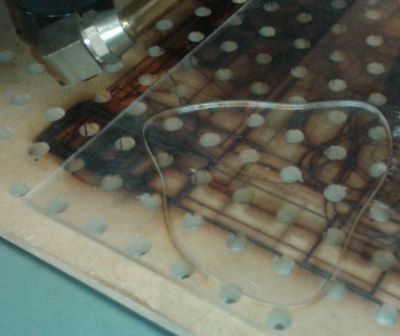

Bassically the available elements was the "PLA" (Poly Lactide Acid) as base material; and, The see-through Polycarbonate surface.

SOFTWARE

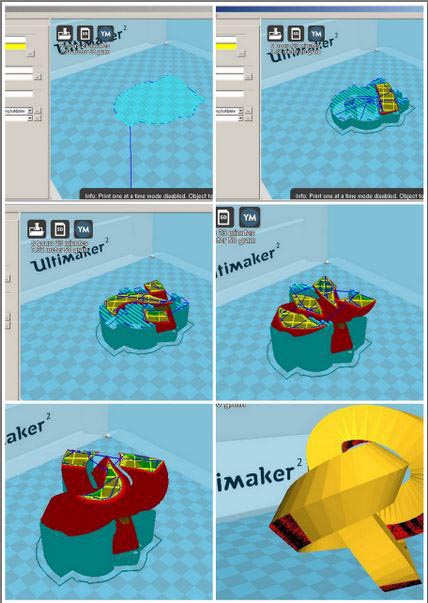

The principal software used to was te 3dStudio Max in teh first nearing about the looked shape. in second time, the Rhinoceros because his intuitive interface and plastic form control. Additionally the machin software in Laser cCutting and the simmilar on the injection molding Machine. Additionally the CURA 15.02.1 software was used for a fabrication proves however this software helps to simmulate the fabrication process about an injection molding method.

MACHINES

As was really sayed the principal machines used for was the injection molding and the Lasser cutting. The first one to follow the assignement in the sens of an aditive fabrication process -that is: not subtractive, and the lasser because the compund pieces of the table: the base (injected) and the surface (cutted) force to do this.

PROCEDURES

The significative procedurs followed included first the design the utility and the design form in 3d; the adecuate cleanning of injection machine nozzles; and the revision of properly temperature and fluid speed. In second time, the mechanical revission about the bed horizontally correct level; the launch of plotting of the first bedding; and the attempts of the model base. At last, the observation of beginning procces and stan up to end.

PROBLEMS

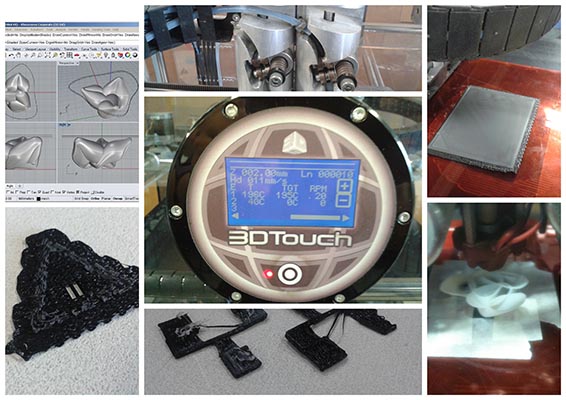

Firt problem was about our group can not to configure the FABMODULES software to plot from it. We have to plot directly from the injection machine. Aditionally, the machin has have a trouble with a the bed level which one that have to be planed carelly and time costly. In the plot process the piece had have the feature that some of your faces (like view show) were too horizontally for the printing resolution. That characteristic happenend in bad surfaced weave but after observation the perception is that this finishing texture could be gratefully if its desired.

LEARNINGS

Three are the principal learnings: The extruder machine have has a carefully graduation of temperature and speed injection that can affect booth formal appeareance and accuracy; the preliminary bed surface and in certain cases the throwaway support are too important to warranty the constructable of the complex pieces, specially those as have pronunncied horizontal projections or unsupported spans; and, that the full horizontal molding have to has enough mass material because of contrary the surface will have bad or less fabricate resolution than expected.

RESULT!

The augmented reality scanning and viewing vía AUGMENTEDEV.COM to show the result on line.

The process in four steps in designing production.

And finally the general view.

Here the Final product: a living room center table for all; there, the table prototype on our hands.