-

See outer in Fab Academy web page:

COMPUTER-CONTROLLED-CUTTING

Get all files: HERE

ASSIGNEMENT # 3

DESIGN, MAKE, AND DOCUMENT A PRESS-FIT CONSTRUCTION KIT

PRESS FIT JOINTS DOCUMENTATION

The first i knew was the new cutting high format machines present in our wood local distributors. at the image the vertical bed cutting pannel machine, security, speed and precision.

On the other hand the preliminary search was referenced the work of Ricardo Torres of Fab Academy 2013. His work it's an excellent referent to get index about different union types that can be used in our excercises on this assignement.

WHAT TO DO

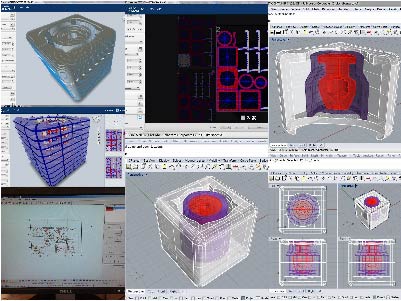

To develop a “cube” that fit between the hands could be the minimum experience possible way “press fit” fabrication technology. Concern from there the query was how to use ahead reduce wasting, by the method of using the maximum material in a bucket developed as like it.

WHAT I LEARNED?

Interested in making with the press fit methode, a little research about it, obtain different exercises made by professionals and too by neophytes. So i got some key learnings:

1- press fit is especially used for developments in various materials laminate wood, cardboard, polycarbonate, polystyrene, and others; but can be used other various materials. Laminate wood are the most favored in our context -colombian- probably because the industrial materials has not so affordable price.

2- flat-rolled plan boards systems determining more “basic” results otherwise that which others that boost from the same material properties (flexibility, resilience, inhercial section ... Others).

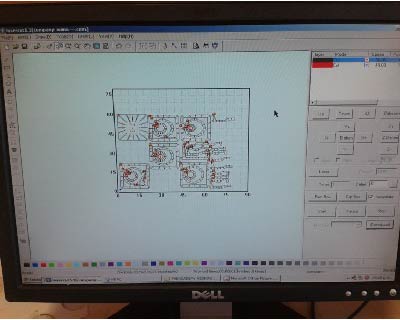

3- The process require a minimum of required skills in hardware and software and some knowledge of vector formats exchange and having discrimination criteria of the three-dimensional drawings readable.

4- If you do not have such programs, the parameter of the multiple steps of sections and joints, even allowed to actually get accurate results. This combine with the advantage of reach a custom piece by piece detail level.

WHAT I TRIED FINALLY?

Attempted goal was a matryoshka collection of sucessively containers type that can have a different shapes and sections of changing. This resulted in a cubic form exercise with a simple face that contain with in two pieces for more.

Finally took a laser cutting with the below specifications