HOME

ASSIGMENTS

CONTACT

DOWNLOAD FILES

FINAL

PROJECT

Molding and Casting

For this assignment i used the machining tools of the ROLAND MODELA to shape and obtain the negative volume , copying game RTV silicone and finally the final product used by emptying resin

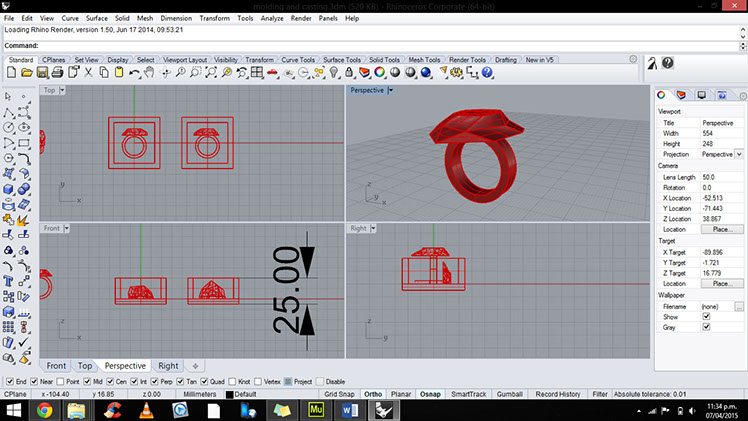

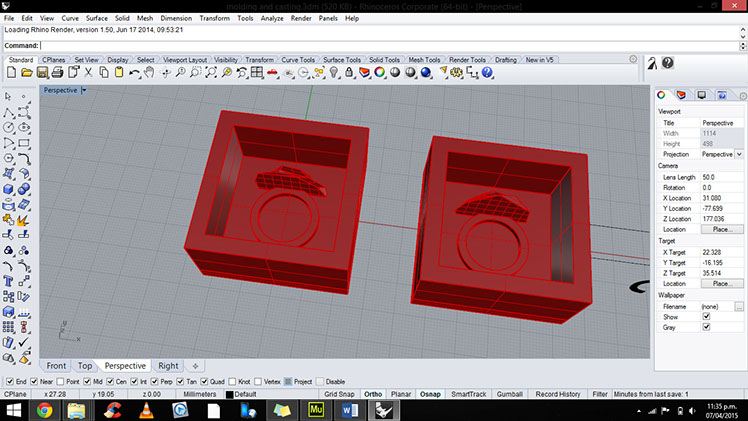

Modeling in Rhino

The first part consists of modeling the ring in 3d , then the molds are generated to be machined

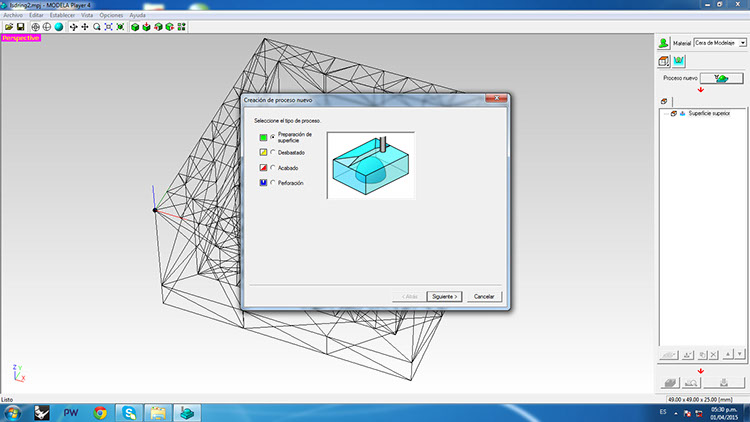

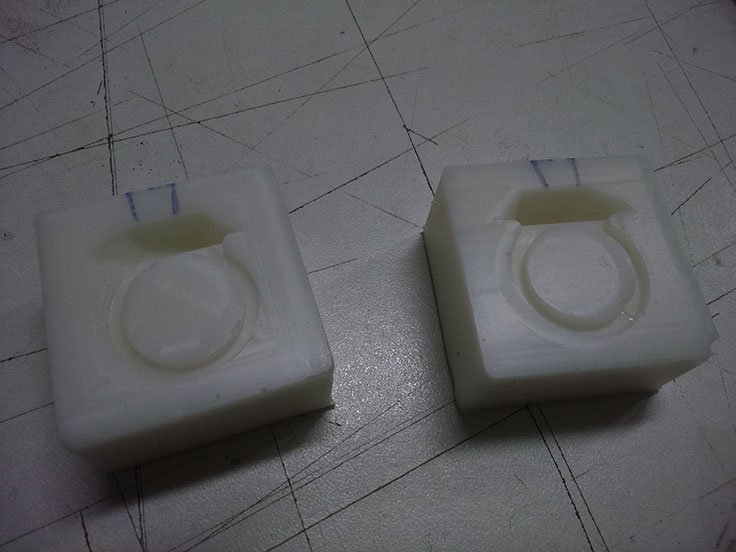

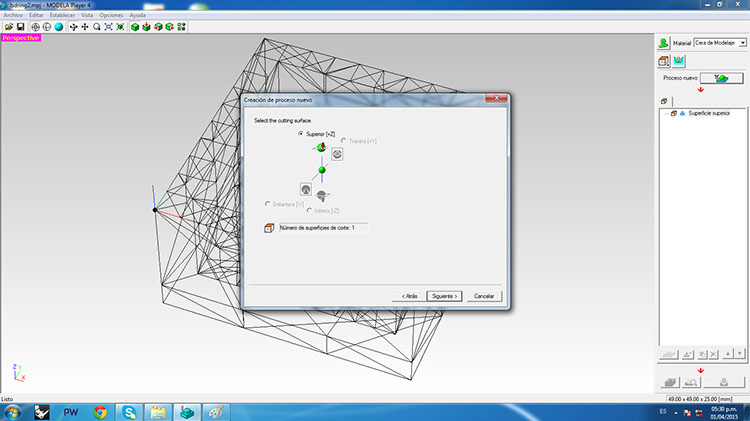

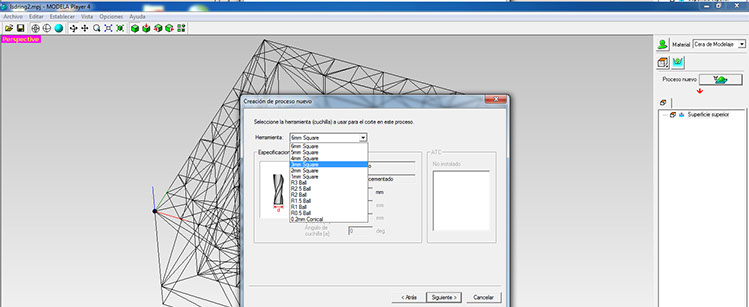

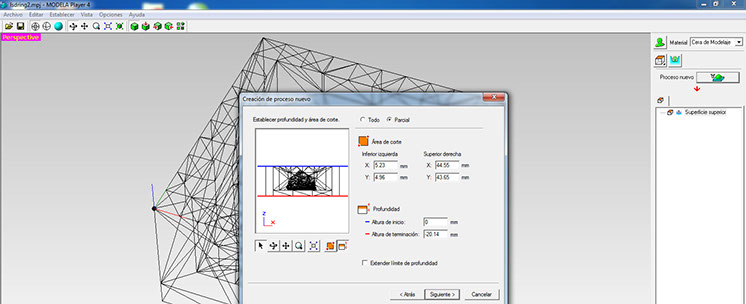

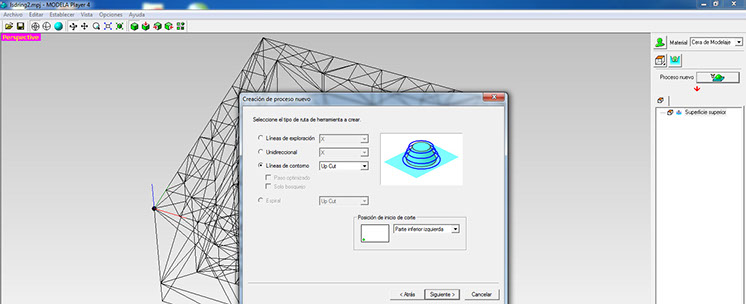

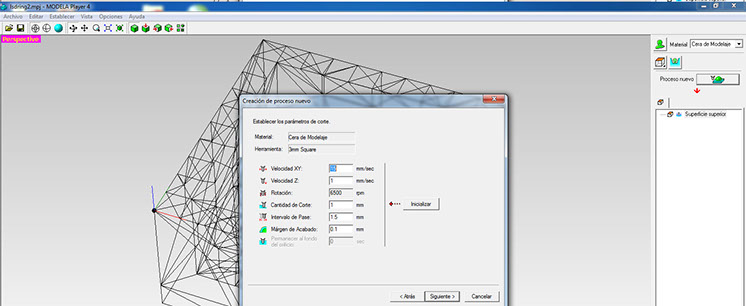

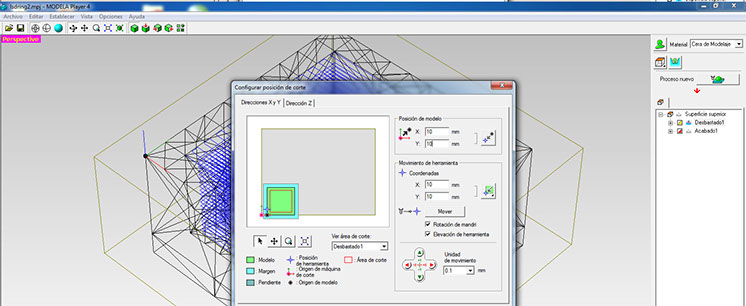

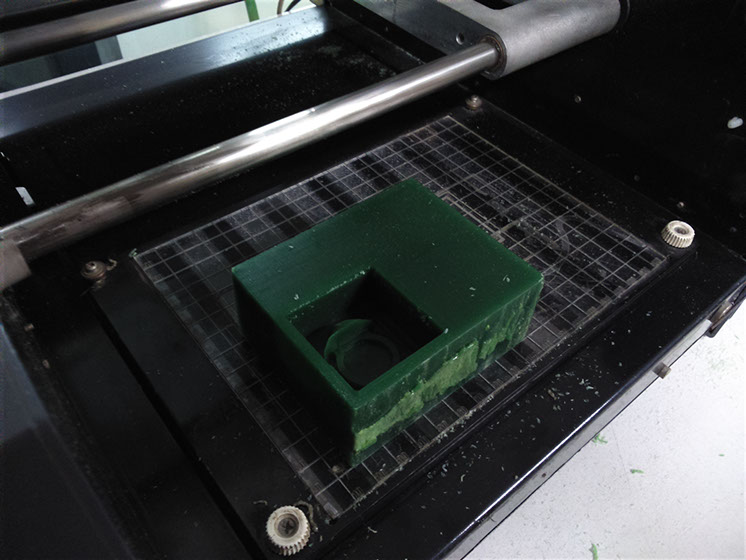

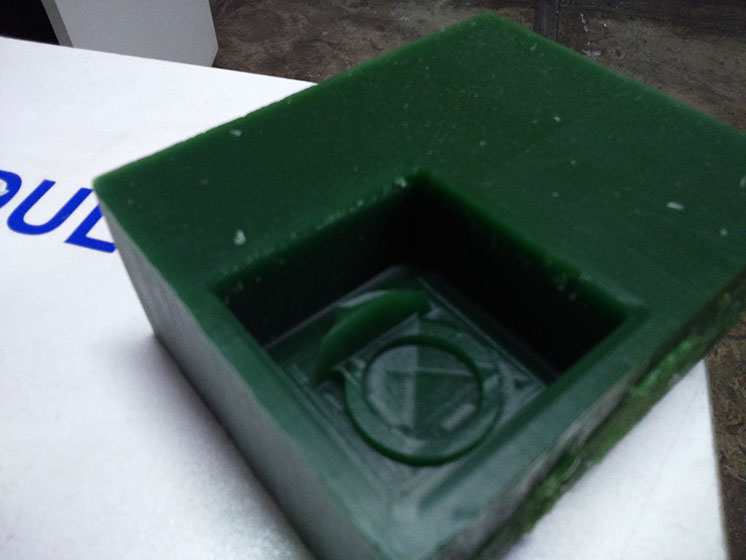

Machining

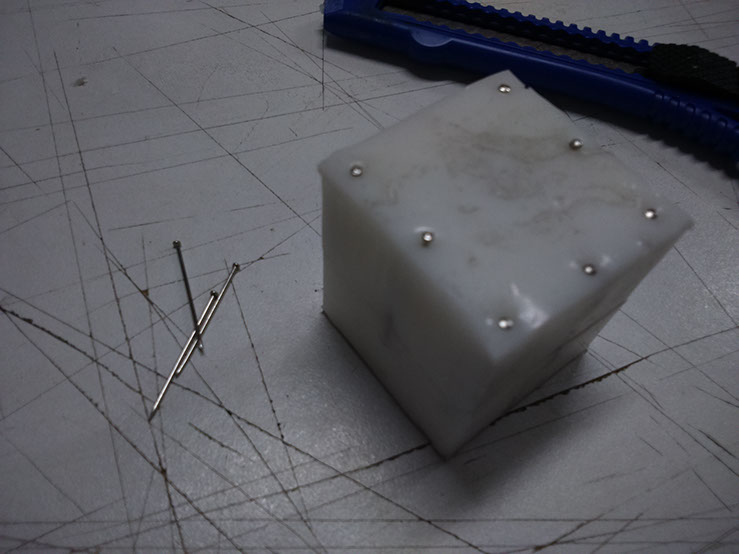

Then the process of roughing and finishing for machinable wax is set, this process took about three hours because the details

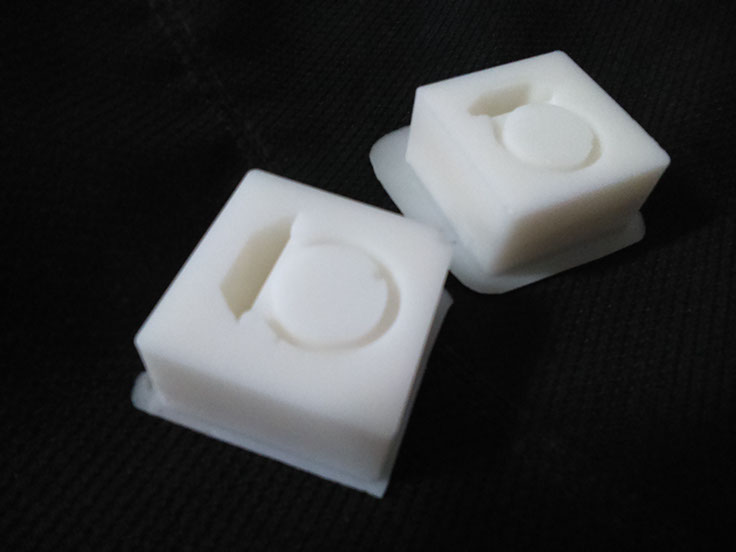

The Silicone

Just could get good results at the third attempt , the first reaction was not homogeneous for not mix well in the second was for the small amount of catalyst, the silicone never completely solidified

Fail #1

Fail #2

Finally

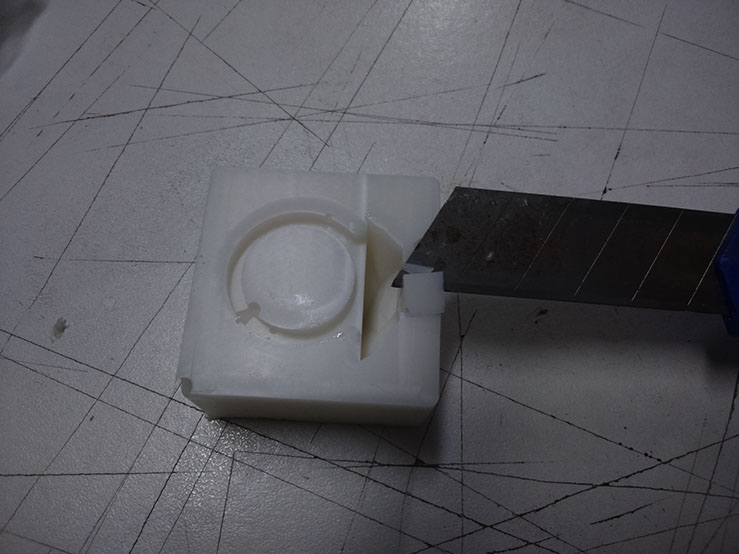

Emptying

For this step i forgot to model the channel to empty , so I had to cut a little the mold with a knife

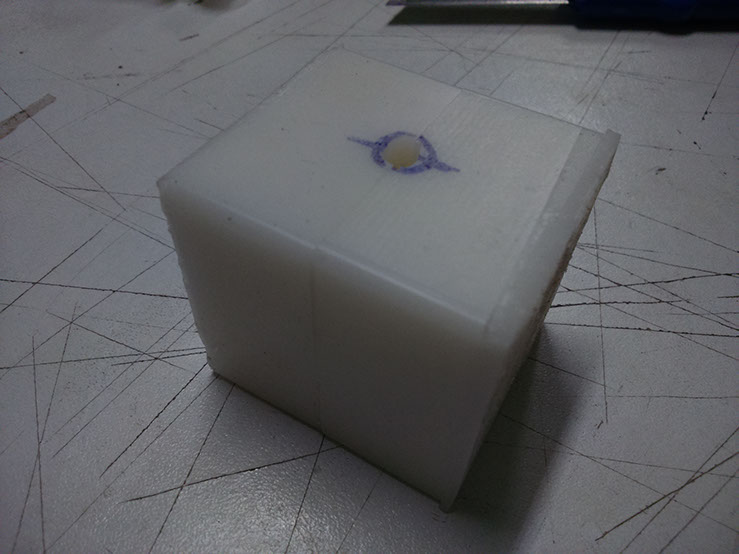

resin

I used epoxy resin components A and B in equal weight but not volume .

The resin hardens yet , I believe that the components were not in the same quantity of volume