computer-controlled machining

This week's assignment, was to "make something big" using the CNC Router (ShopBot).

Took me some time to decide what to do, finally I decided to make an insect-robot-alien character with some moving parts, my idea was to install some electronics on it later (inputs and outputs classes) turning it to an interactive object.

I used Autodesk's, Inventor to 3D model the object and later i used rhinoceros to make the cut pattern, i hat to tanke in consideration the diameter of cutting tool in the corners.

Here are some renderings.

Ocho by Wilhelm Schütze on Sketchfab

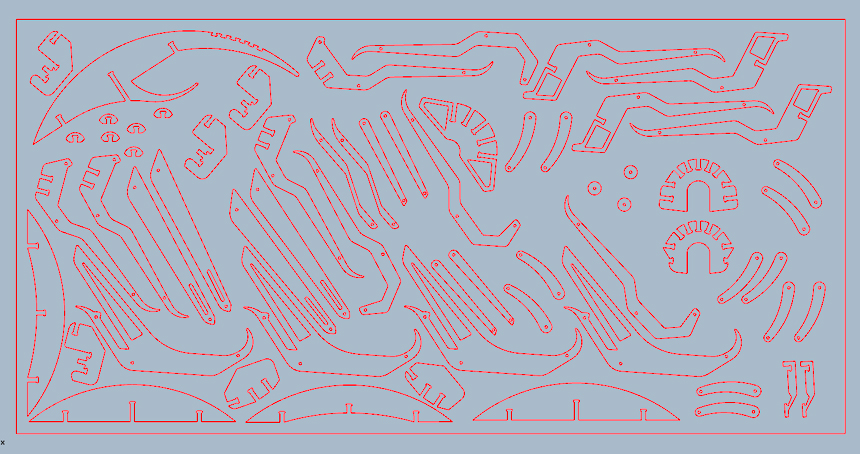

Here is the cutting pattern.

The material I chose was a 2440x1220x12mm plywood board and I used a 6.35mm flat nose mill for cutting the pieces

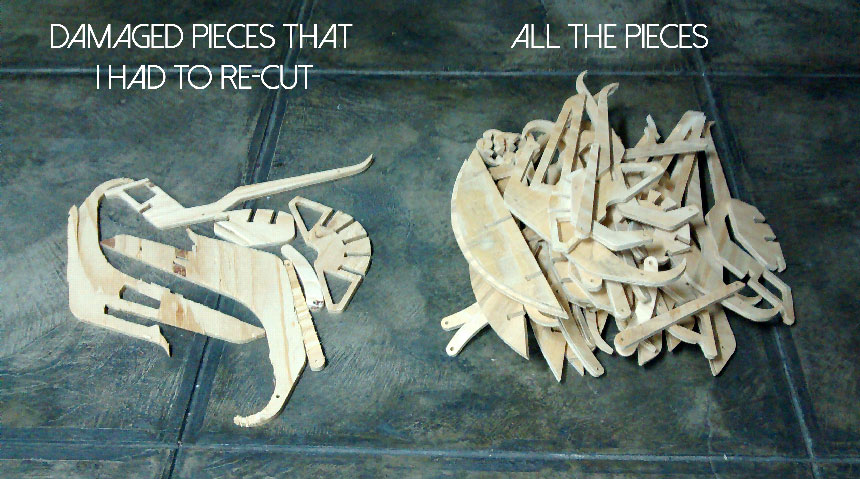

i used shopbot's drilling profile for securing the material to the base and also used taps (2x1.5mm) for keeping the pieces in place.

The material wasn't realy good, it wasen't calibrated and had holes on some parts, so i had to re-cut some pieces

After some hours I assembled al the pieces using press-fit and 5/16" bolts, I used what I had by hand so I have to change the length of some bolts in some parts later.

Here is the final result.

With Bruno : )