W9. design a 3D MOLD, machine it, and cast parts from it

This week we had to design a 3D mold, machine it and cast from it. I decided to use some designs of acoustic panels to use them later for my final project.

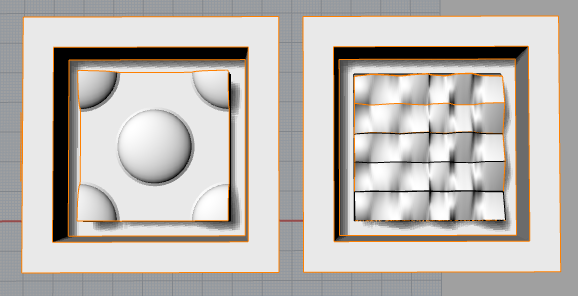

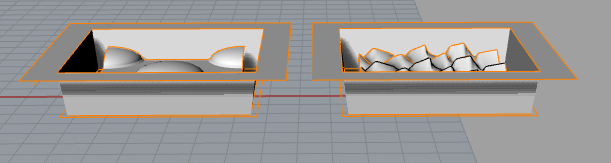

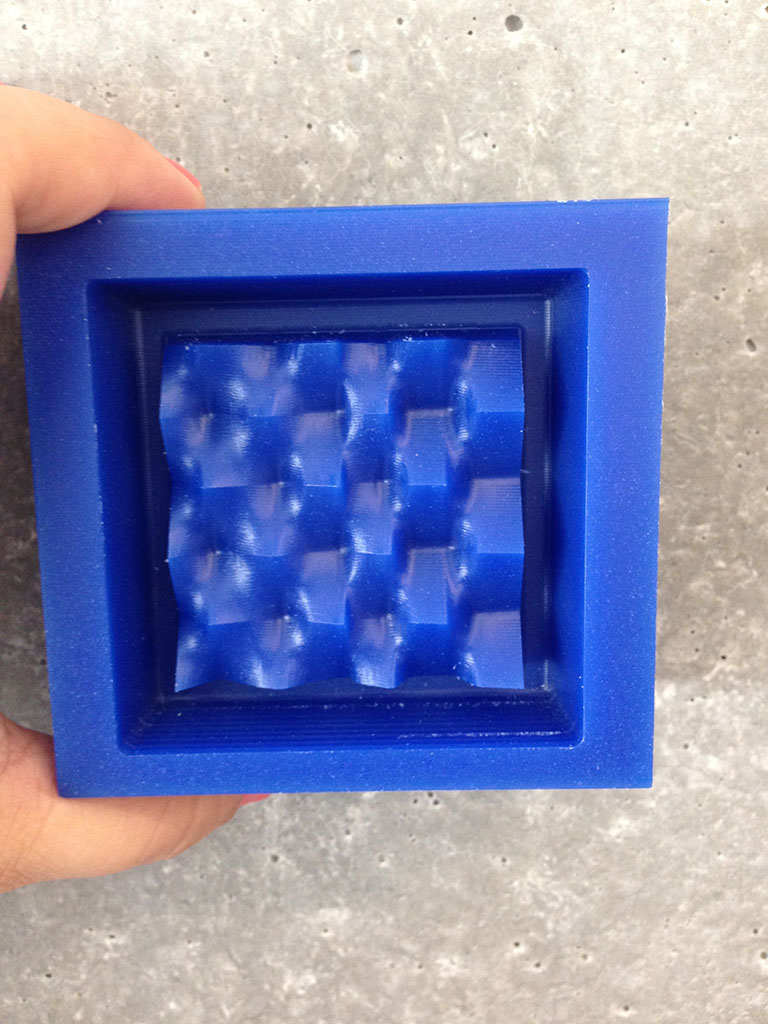

I used Rhinoceros to draw two options for the paneling, one reproducing a design called “swell acoustic panels” from design international and other designed using simple curves with several levels to produce a surface with different angles.

The panel will be of 50x50mms with 100mms from depth and a margen of 2mms of difference from the inner bottom and top so it will be easy to take out the mold. I added a margin of 5mms each side and then a top margin of 50mms.

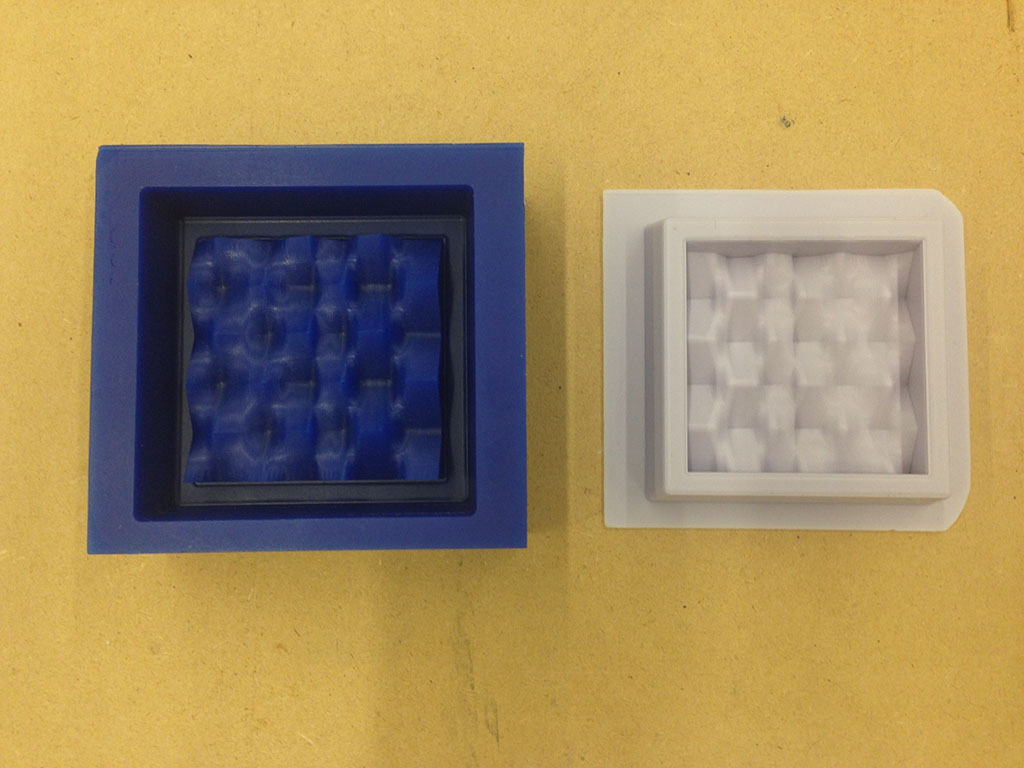

Here are my drawings.stl:

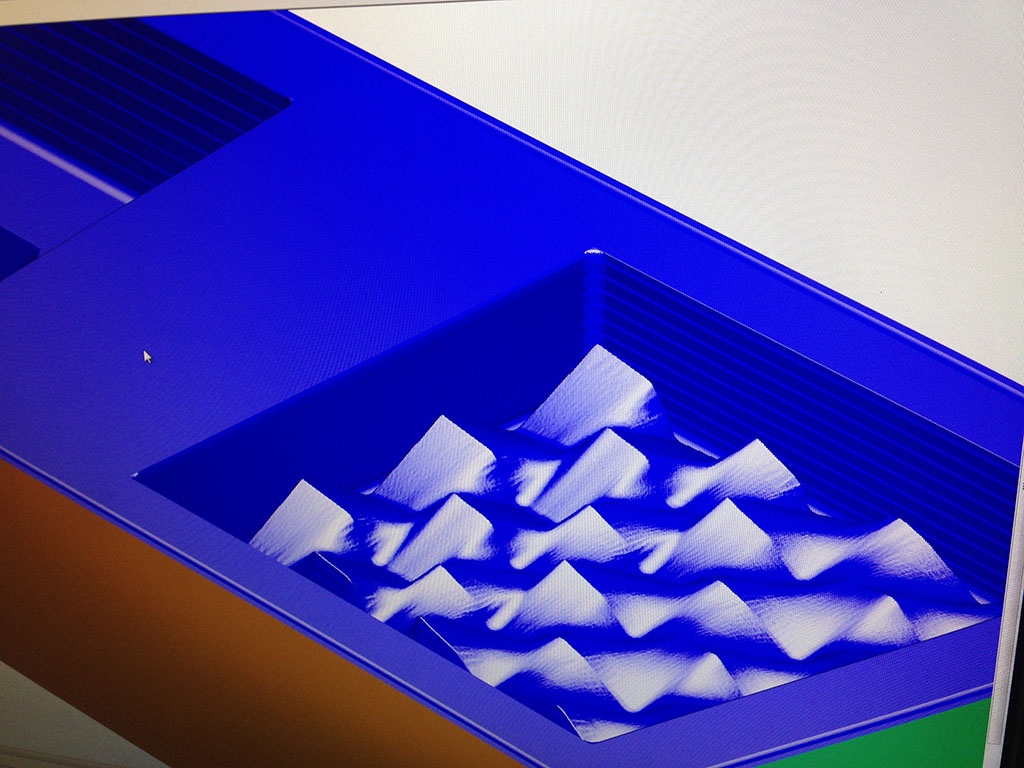

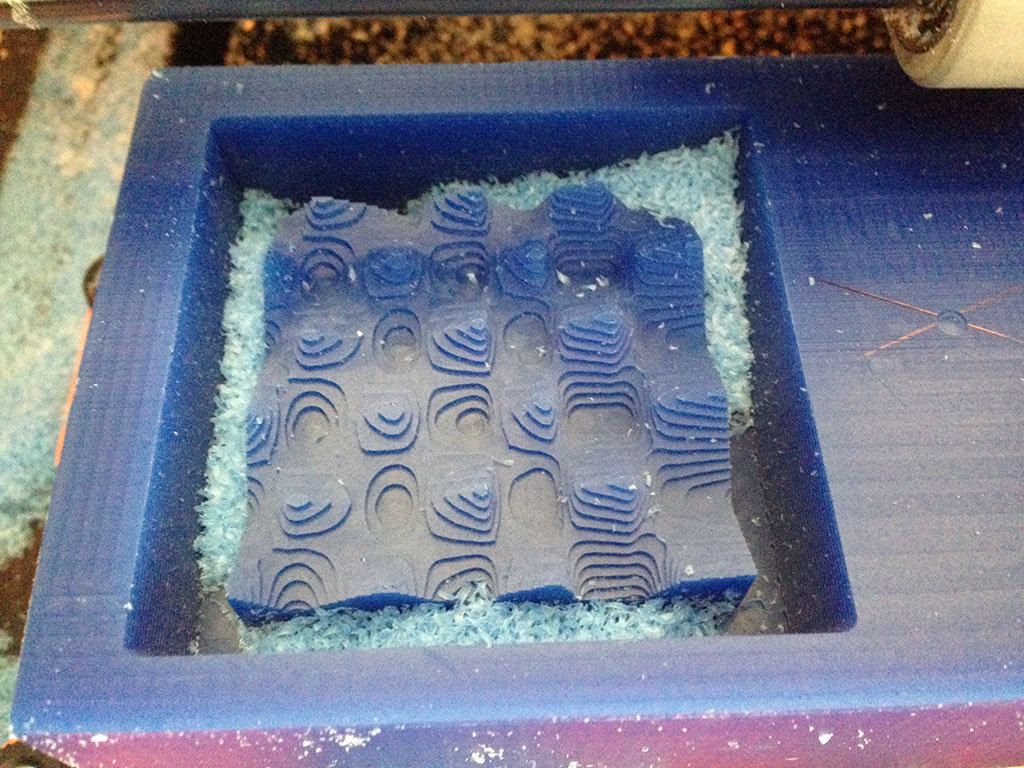

I produce the model in the SRM-20 in blue casting wax as follows. It took almost 2 hours for the firs option.

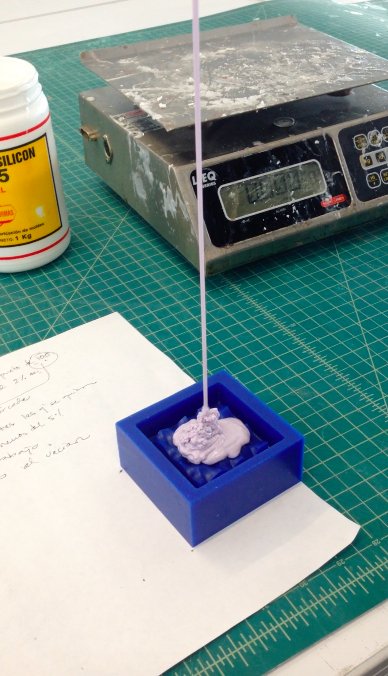

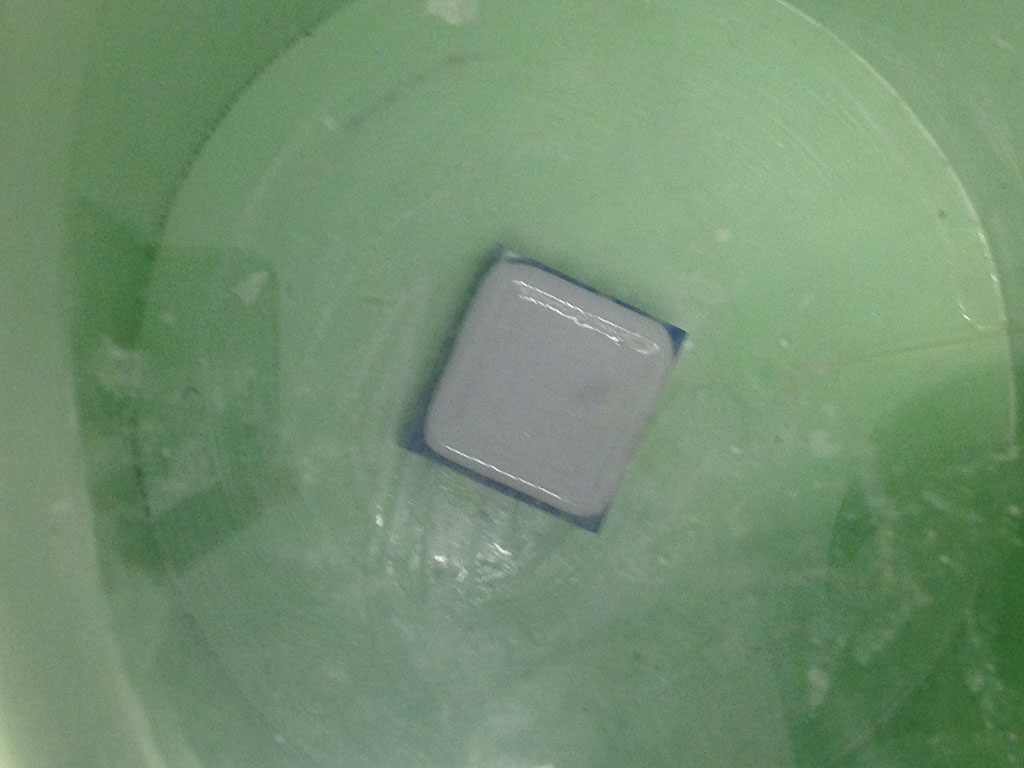

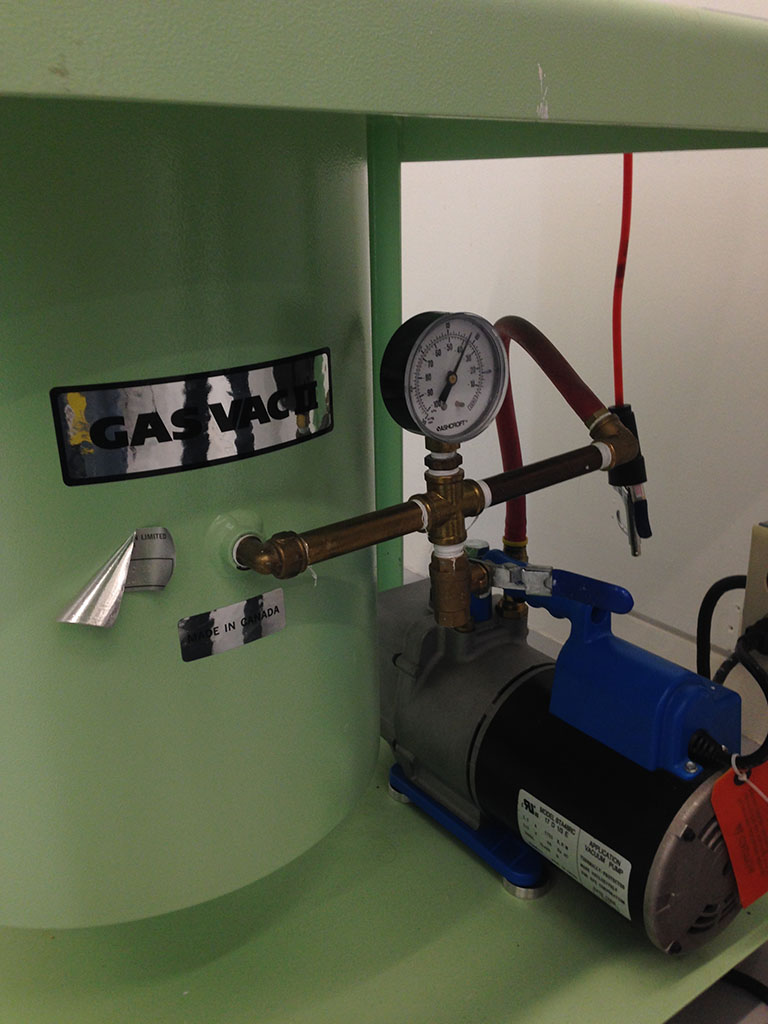

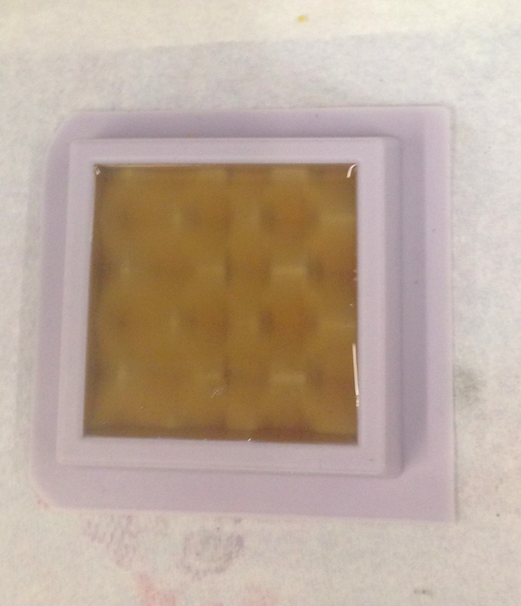

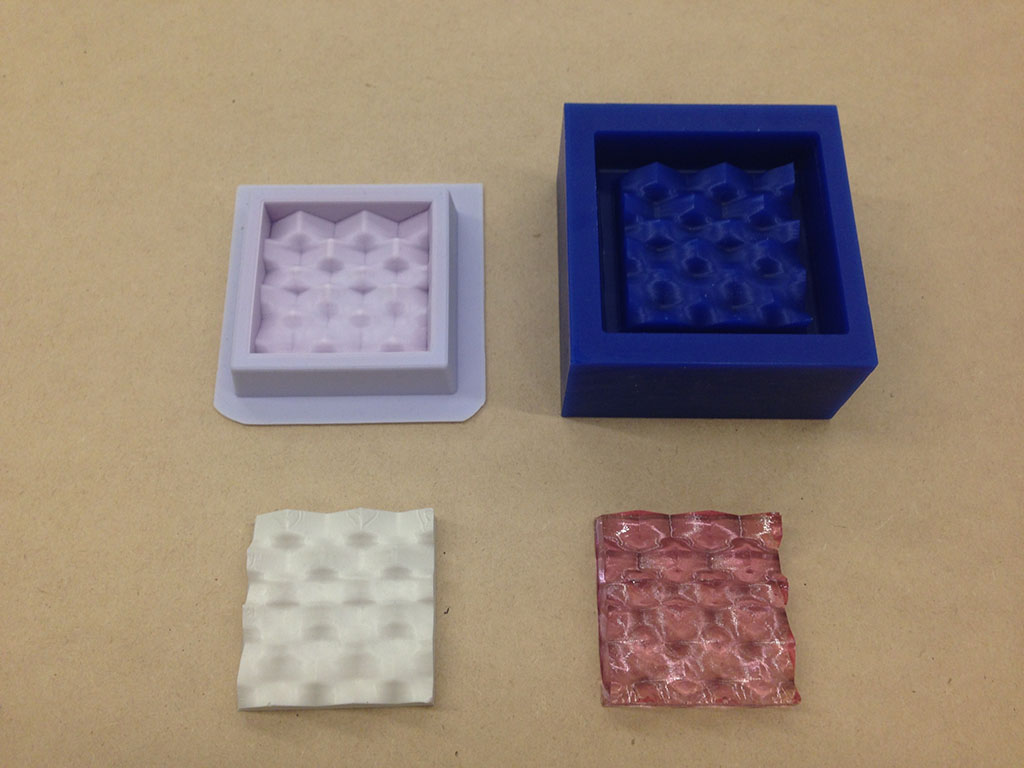

After molding the first step, I prepare the material for making the mold (step 2), using silicon rubber with 2% of catalyst / 100 ml. I need 88grs of silicon rubber, 90 drops of catalyst and added some color red and blue to make sure that the materials were well mixed and also I used for dearing a gas vacII . After It took 4 hours to dry, and this is the result.

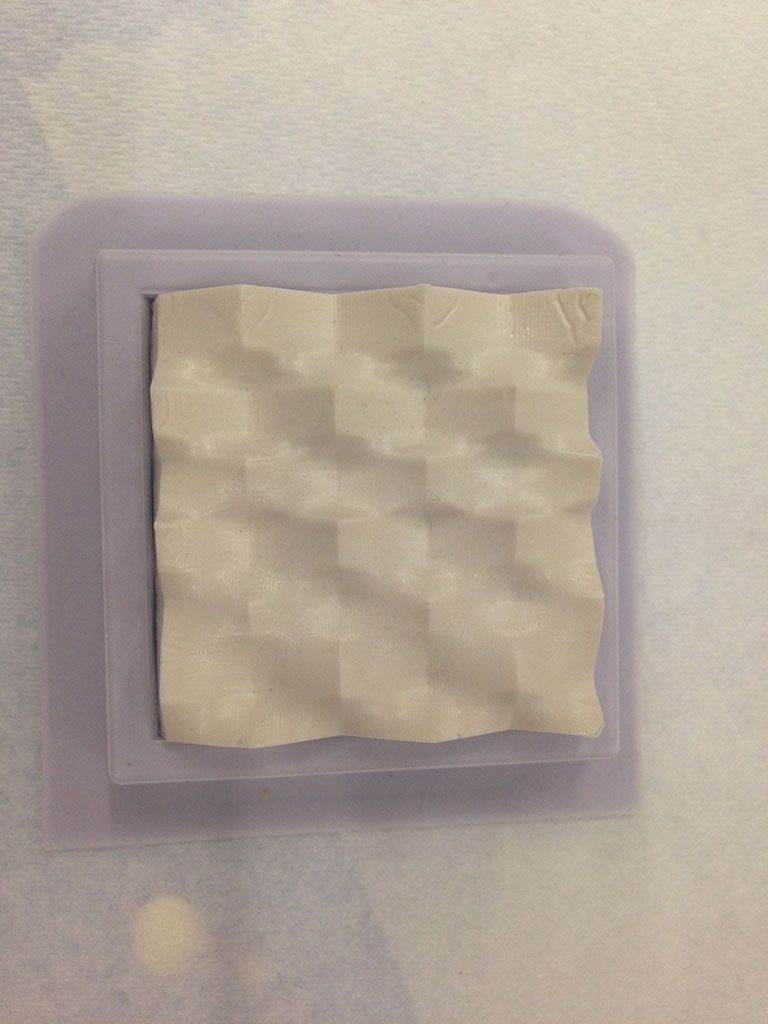

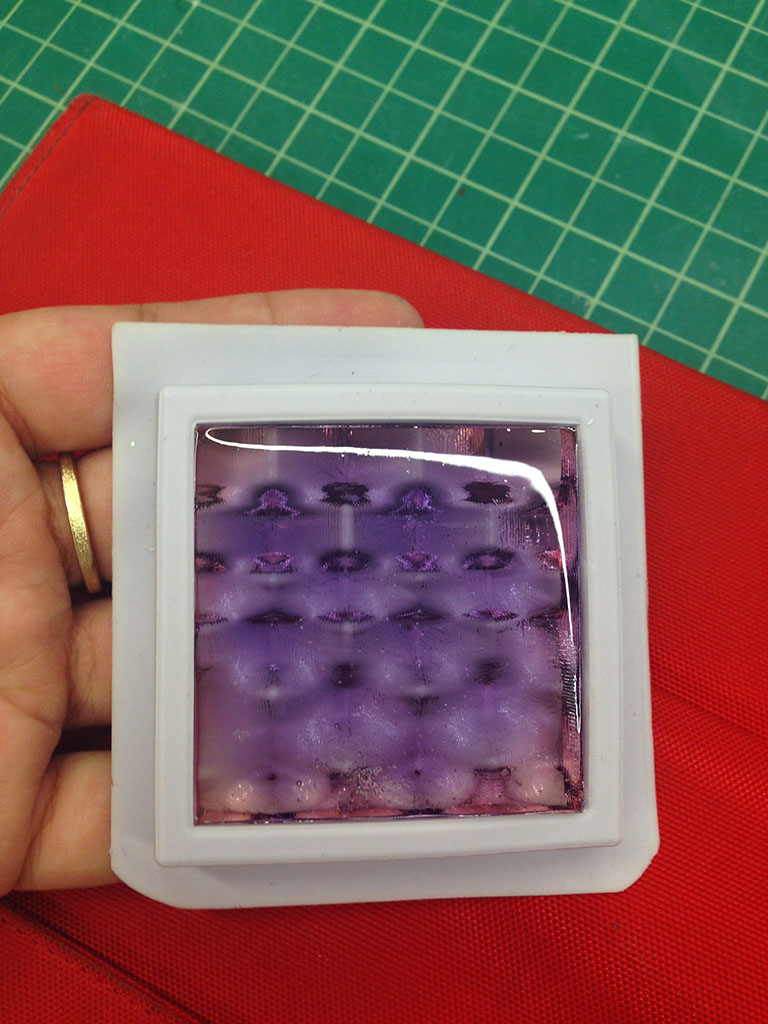

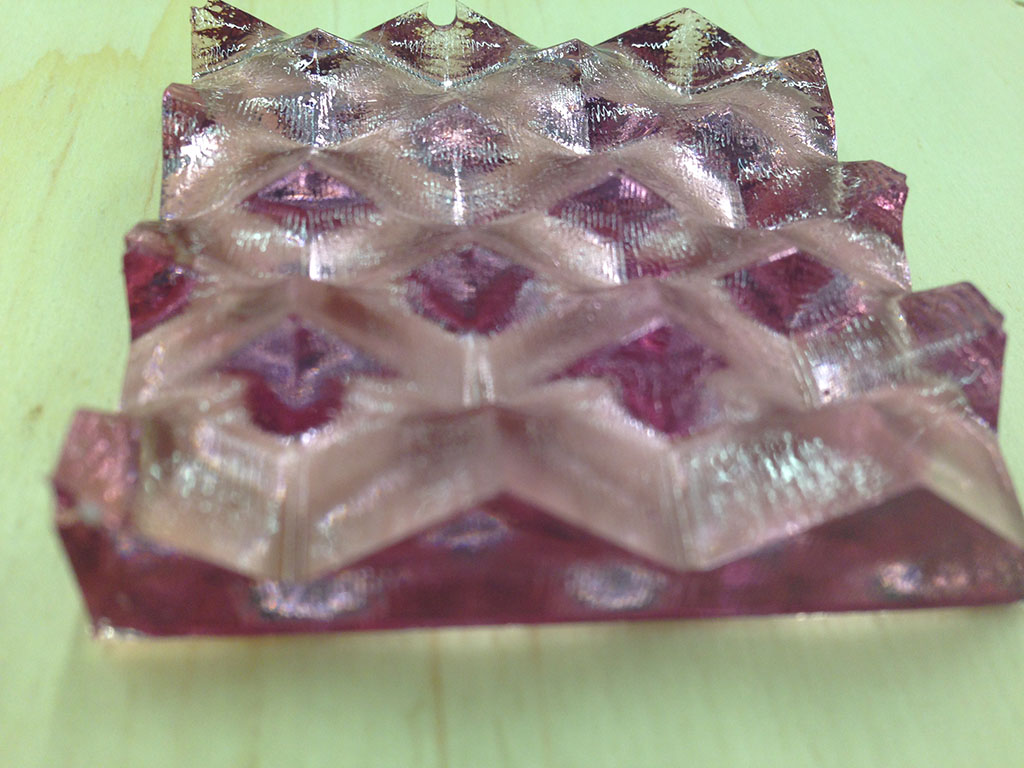

After taking out the mold I prepare the materials for casting the final piece. I had two options, urethane rubber and also a resin of polyester.

Urethane rubber and catalyst (50% each)

Resin of polyester (92ml of resin and 1% catalyst 45 drops or a half of the top of the bottle)

The final result, all steps: