W.8 Make something

BIG

This week we had to design and fabricate something big. Also, this week our fab lab will the venue for the fab labs reunion of México, so we decided to take this project as a team and have our visitors participate of a workshop to make something big.

The project had to be simple and we needed it to be divided in pieces so everyone of the team could have his own design with the same basis. We decided for a chair in a shape of an hexagon with a diameter of 90 cms, using waffle to build it and an orientation of 45 or 90 degrees.

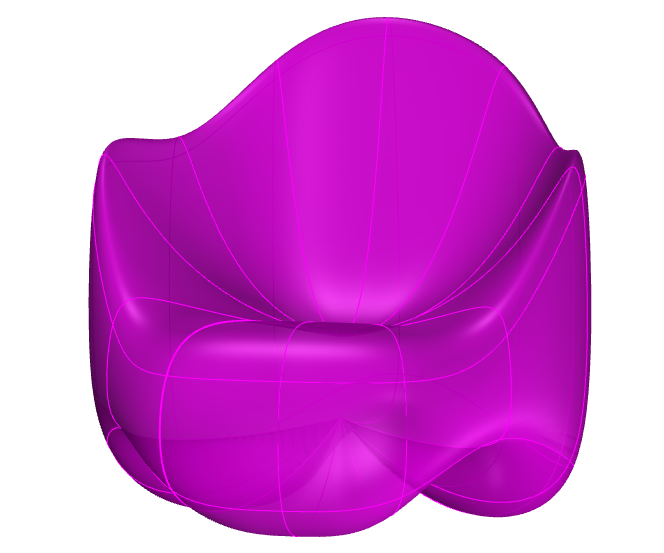

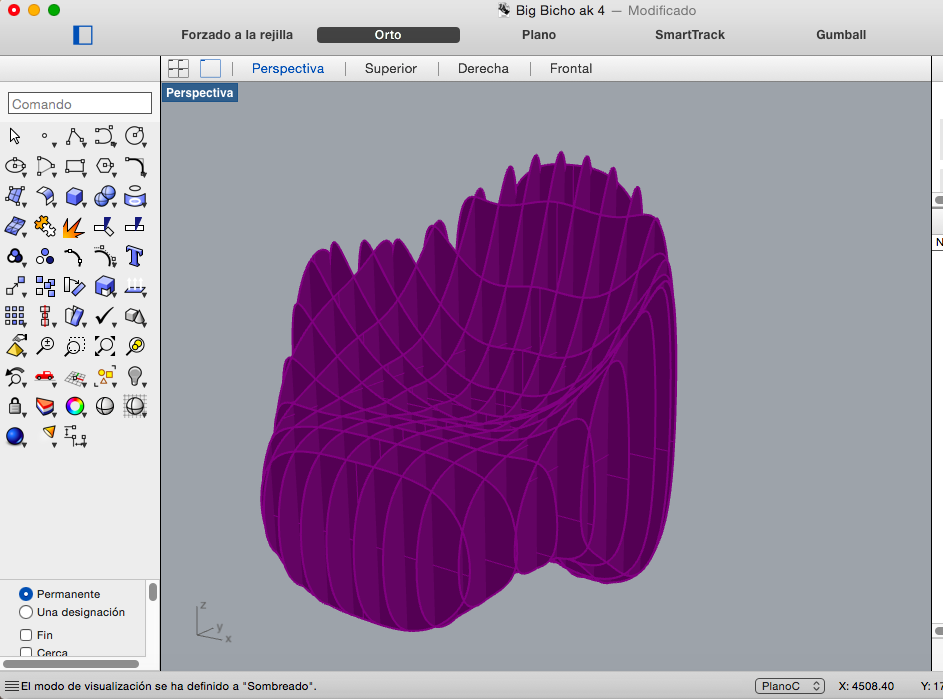

This is my design: (I used rhinoceros)

Waffle of 80 mms separation in x and y axis, and using plywood of 122×2.44 mts x 15mms thickness.

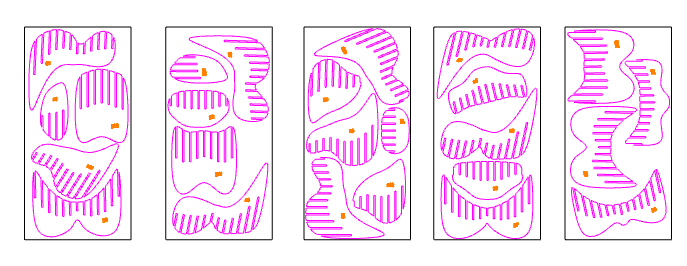

I place the pieces in a line and mark the intersections and make the sections for the assembly, giving a 1.5 mms of margin due to the uneven material (range from 14.9 to 16.5mms). The pieces were placed on five sheets, here is the dxf.

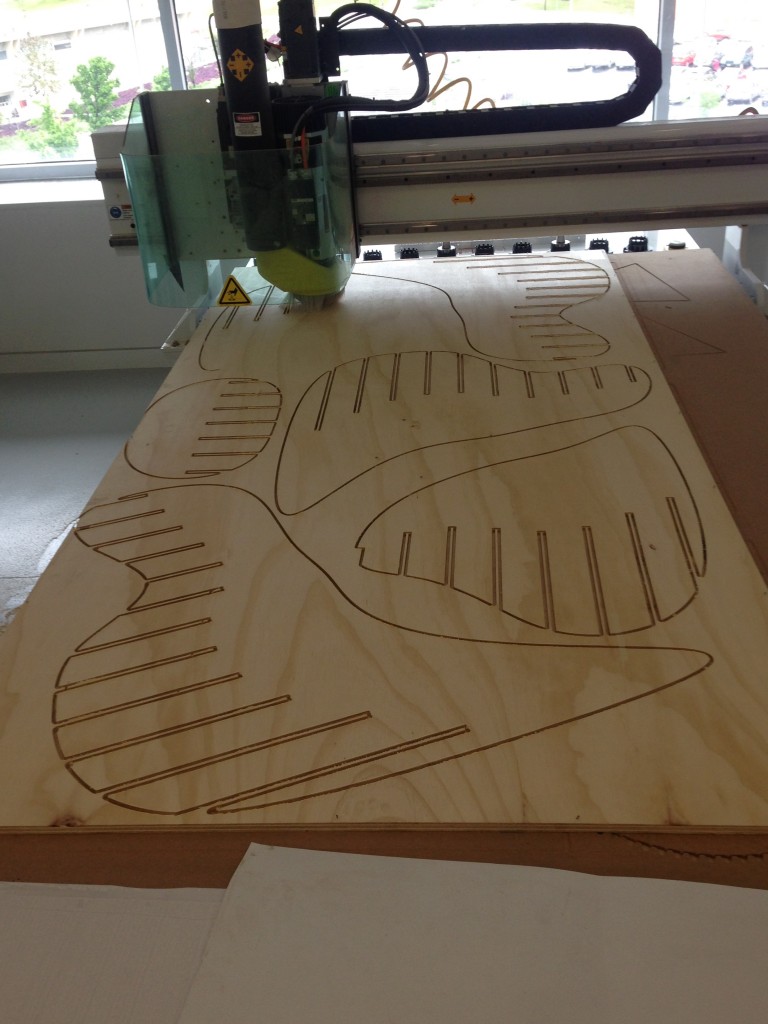

I used our thermwood cnc 3 axis to cut the pieces with a end mill of 1/4″. Each sheet took 30-40 minutes because we had to make a pause and secure the sheets with nails to avoid movement. After cutting I remove the nails, take the pieces off the table and start with the sand process.

I used our thermwood cnc 3 axis to cut the pieces with a end mill of 1/4″. Each sheet took 30-40 minutes because we had to make a pause and secure the sheets with nails to avoid movement. After cutting I remove the nails, take the pieces off the table and start with the sand process.

Here I show the pieces:

For the assembly, I first try to make it by myself using two bottom pieces to hold the top, but it did not work, the pieces were to heave to handle.

So I had an idea, I used two of the pieces as a guide to hold the others. This help me a lot and was really easy to assembly.

Here is my chair… you can see it is really confortable.

And, here you can se the family of chairs of the team, in the center, mine and at the sides Daniela’s and Fernando’s chair.