W3. design, make and document a press-fit construction kit

design + laser cutting

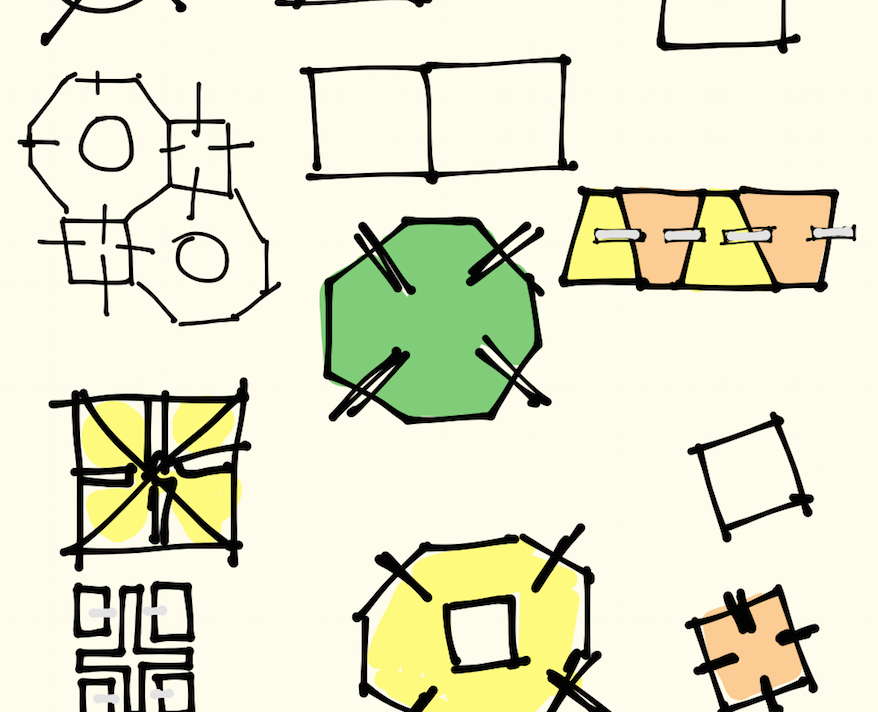

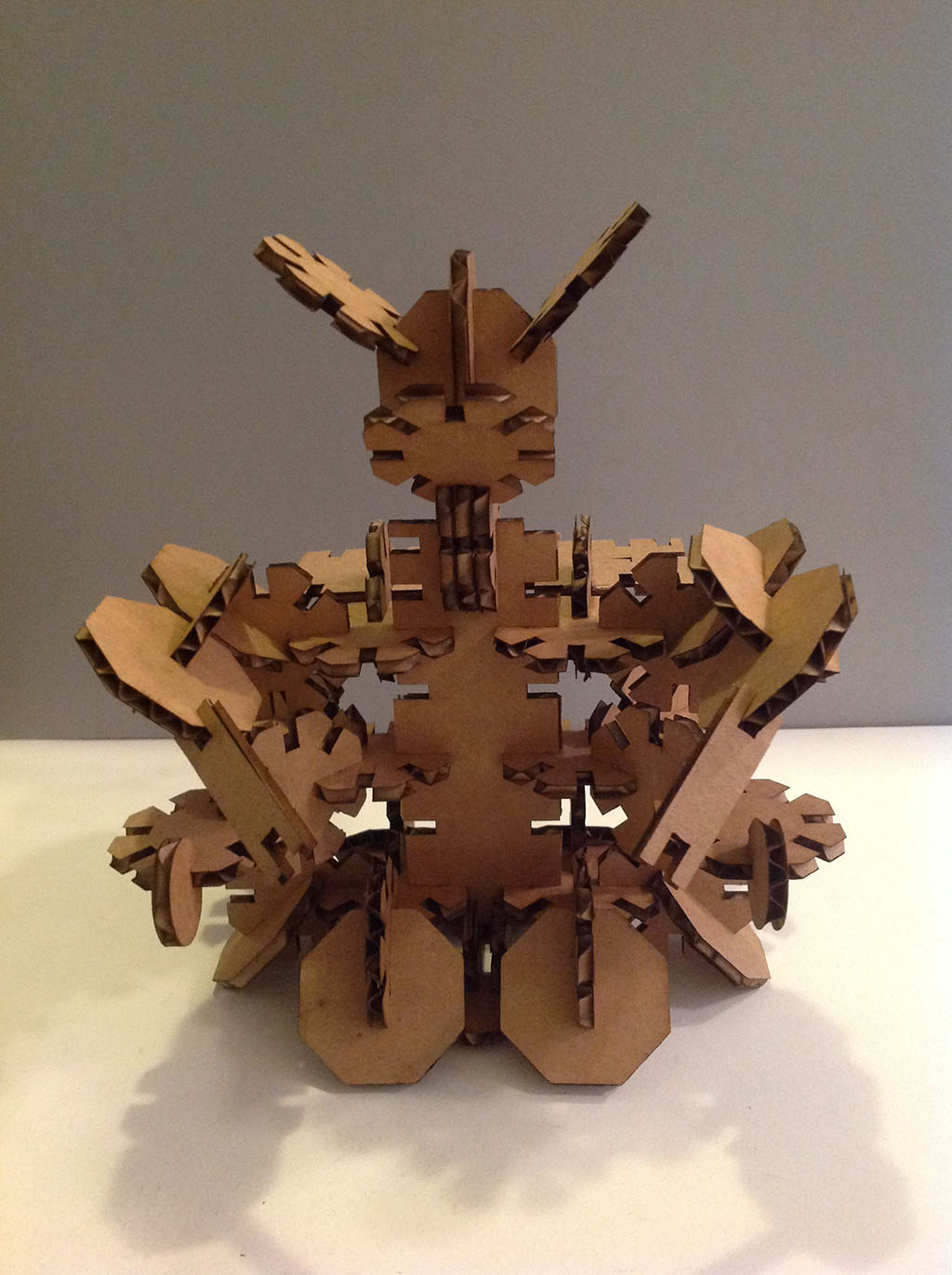

This week we had to design a press fit construction kit to experiment with the assembly of a structure. I used Autocad and Rhino to draw a 2D design of a form that could follow a list of requirements.

- simple form or geometry

- allows to have a multiple direction assembly

- minimal waste of material

- it could be one piece with little variations

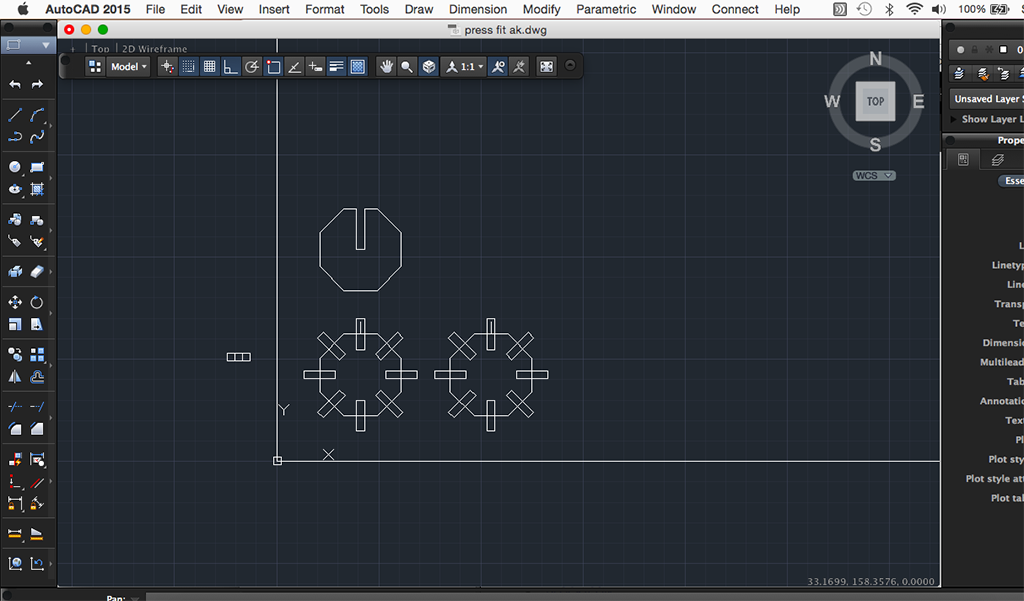

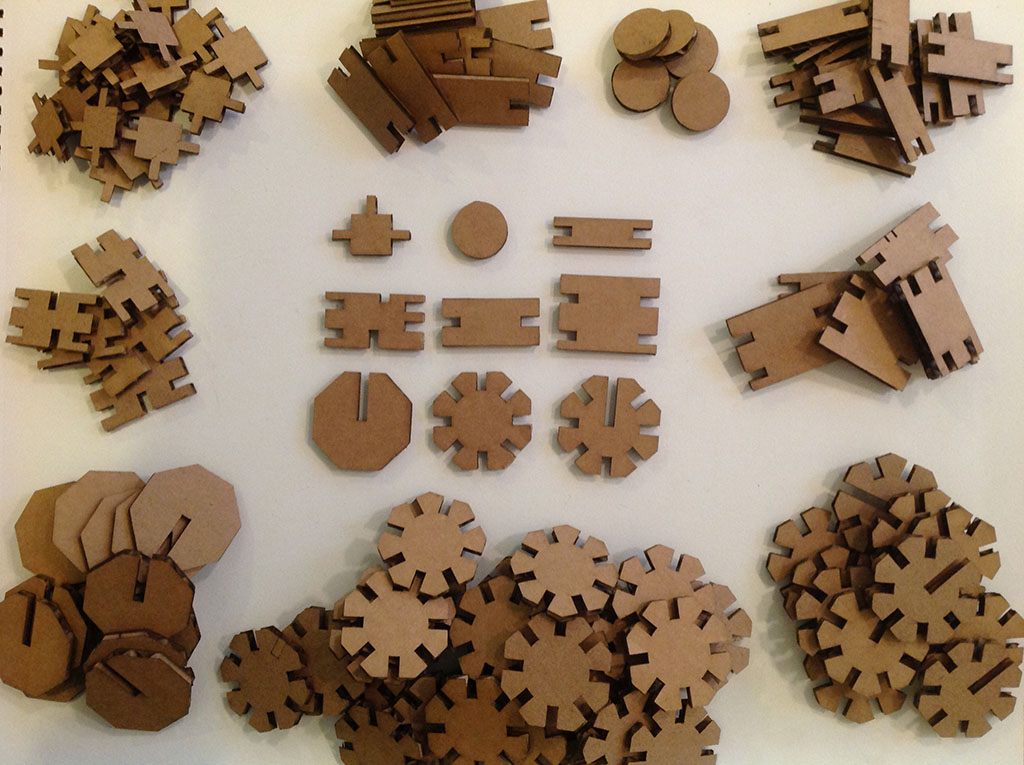

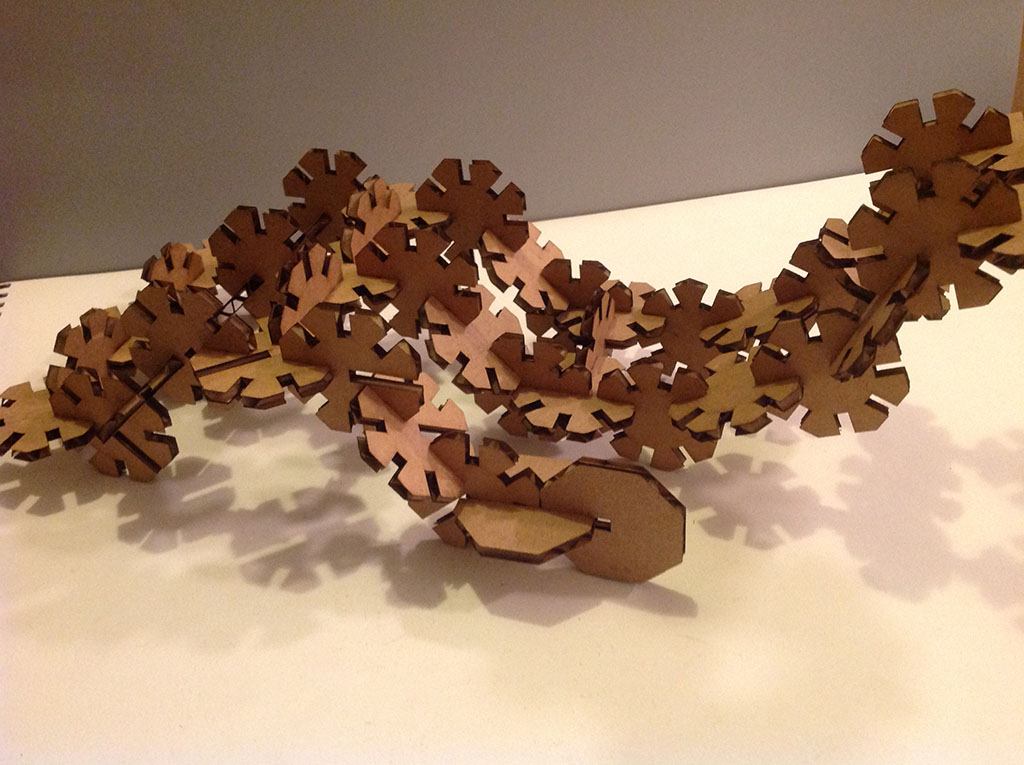

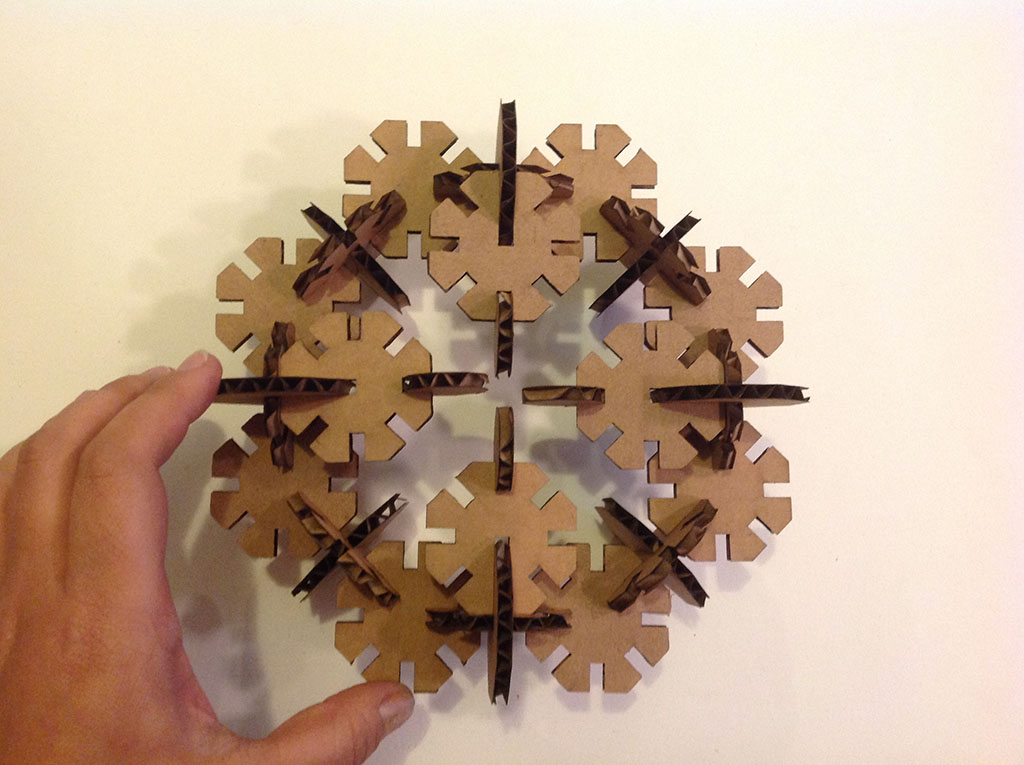

So, what I did was select an octagon and cut pieces in every side, to have 8 different possible directions to connect with other forms. I am using 4mms cardboard so every piece for the subtraction of material has to have 4 mms of width.

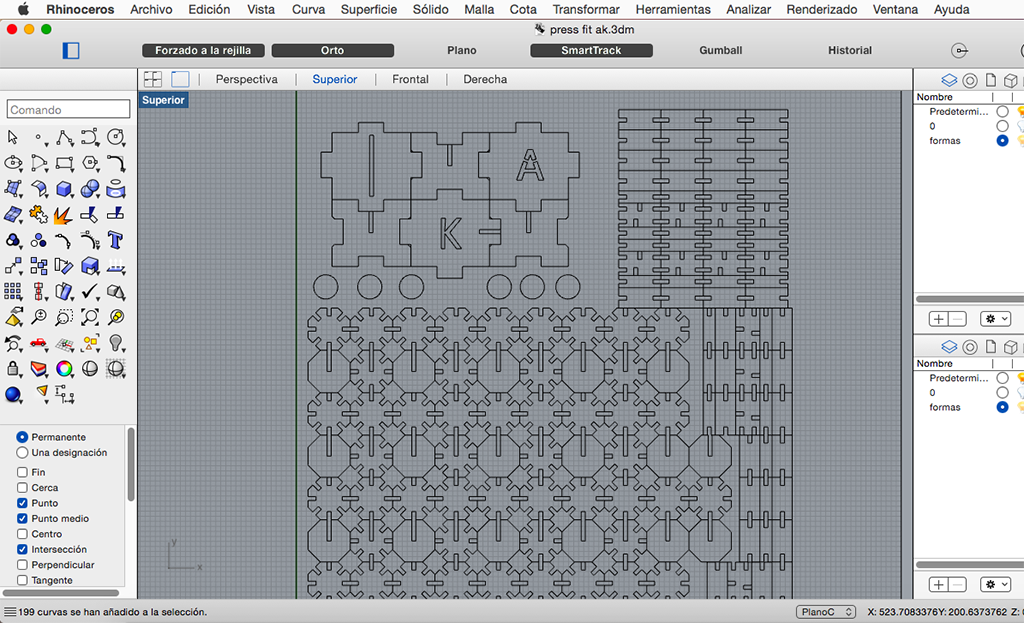

I started drawing in Autocad the octagon and the different subtraction forms, then exported the drawing in to Rhino to use the boolean command to select the final form. After that I duplicated the forms and design an element to connect them.

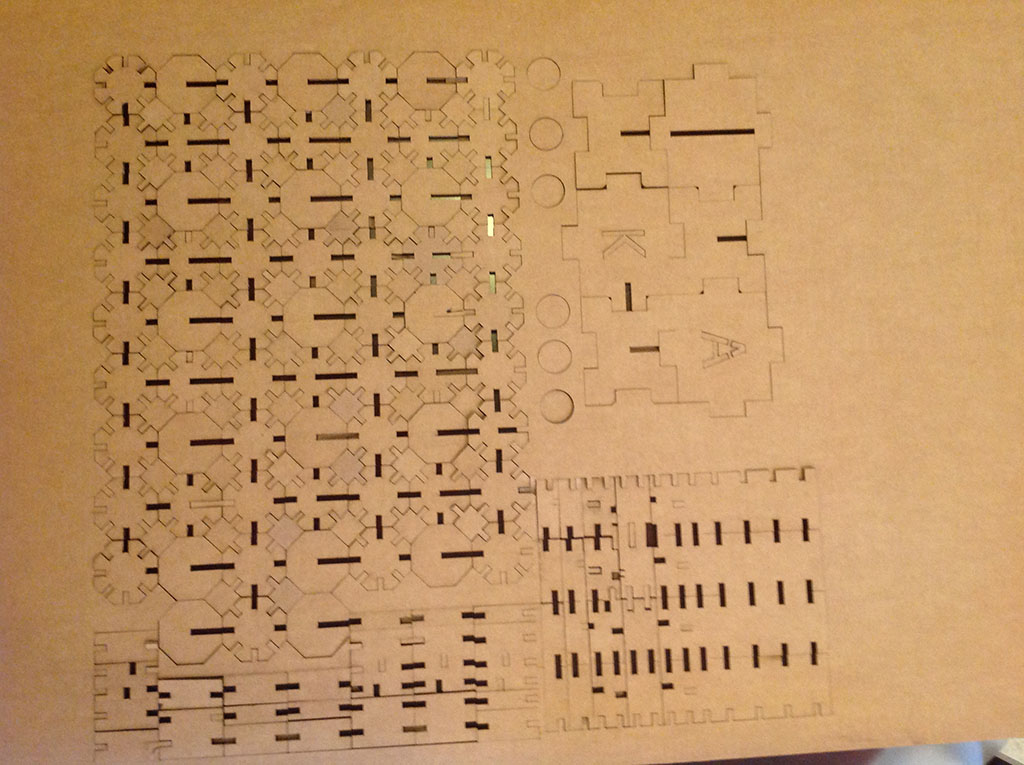

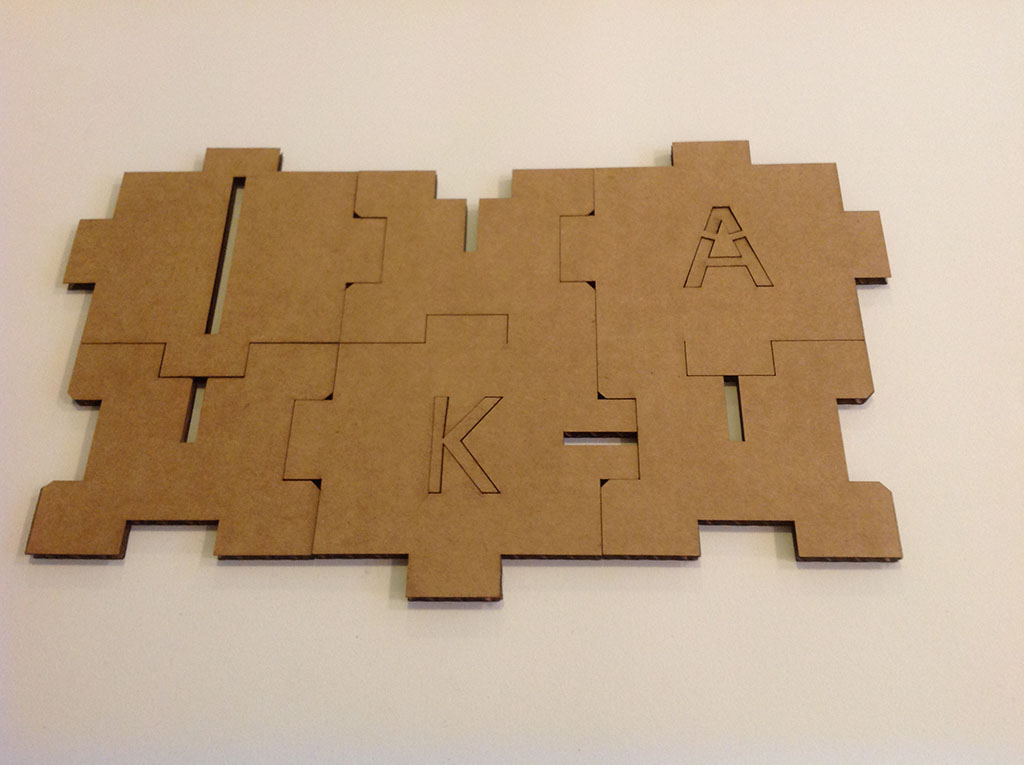

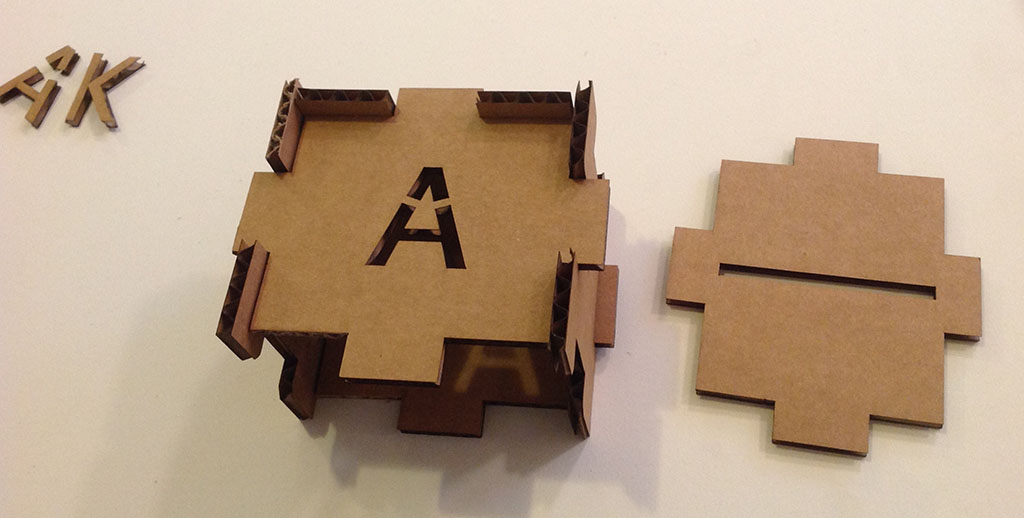

Also I propose a configuration of rectangles with some subtraction of squares to experiment with chamfer edges. This rectangles will be constructing a box with my name initials.

Rhino file press fit ak.3dm

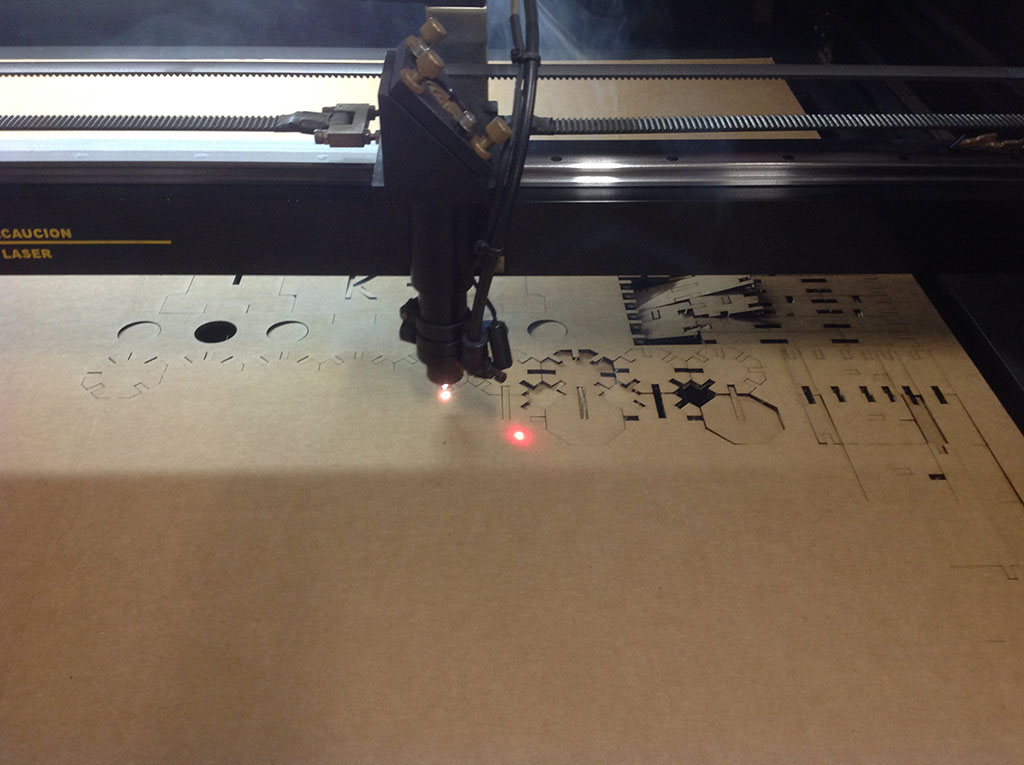

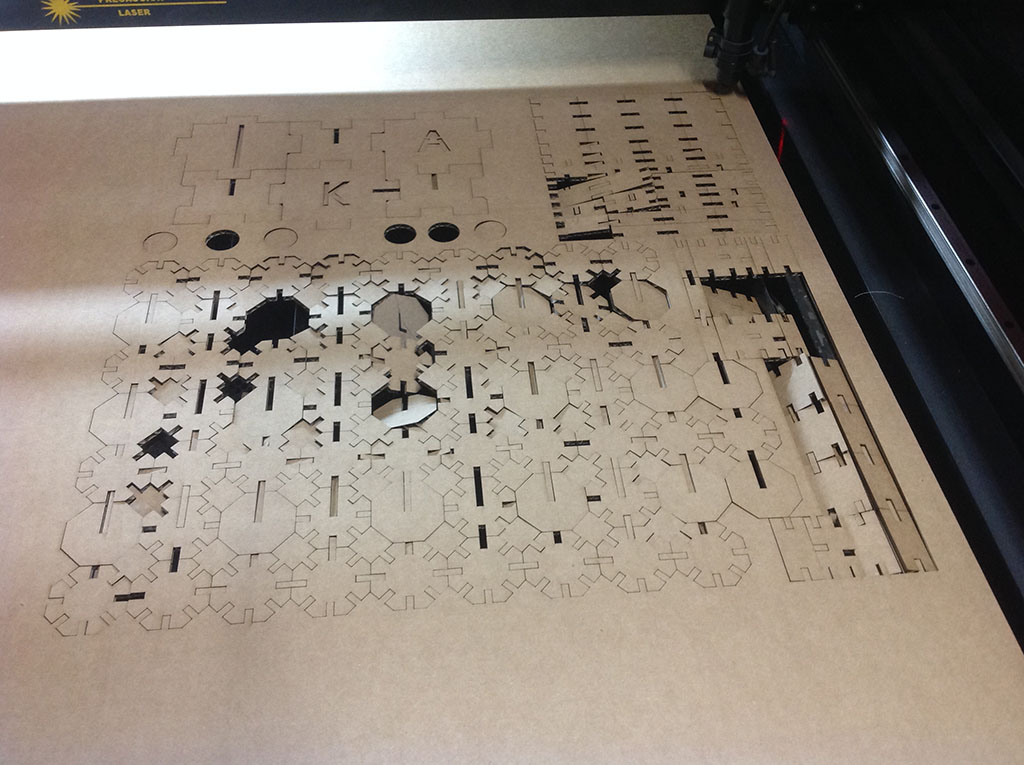

For the laser cutting I export the drawing to a .dxf format and then used the command “overkill” to clean the drawing. Then I search for the cardboard parameters used with the universal laser cutter (40% power, 42mm/s).

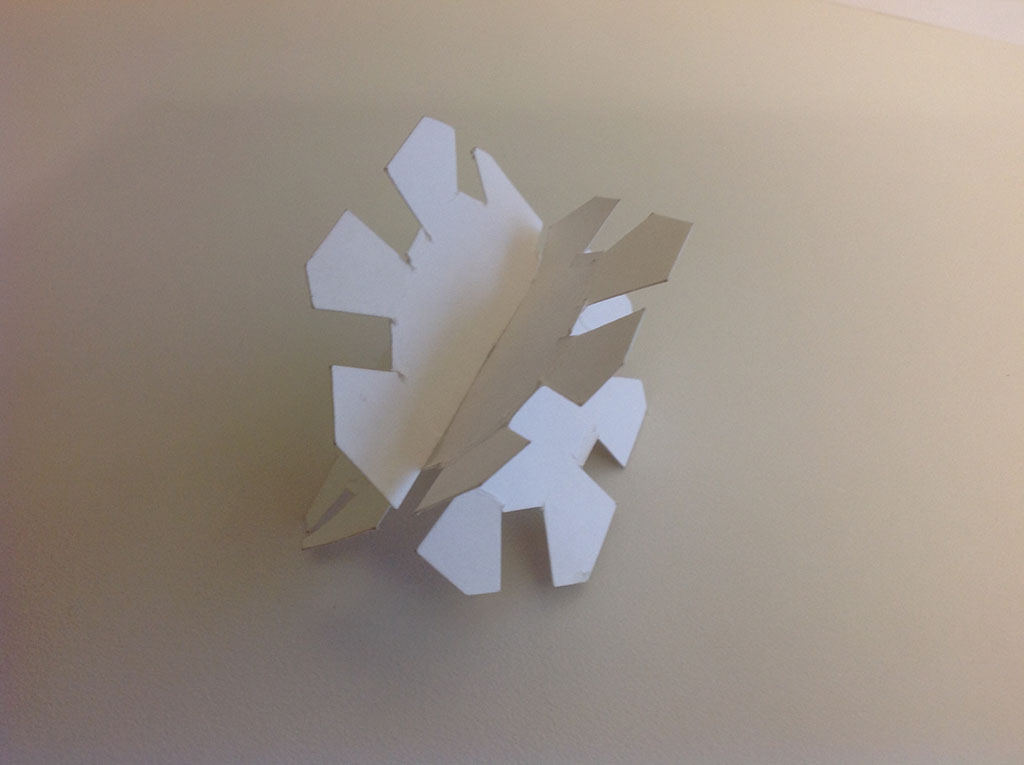

And then the results!

Aspects to consider for the future:

- The cardboard was a little bit uneven because of the weather – check first

- Make a path for the cutting, cutting the big pieces made impossible to cut the little pieces.

- For some pieces like the box, I should make the joints a little bit tighter (+0.01mms)