W. 12 design and make a 3D mold and produce a fiber composite part in it

MOLD + COMPOSITES

This week I wanted to continue working with the panels that I design for the week 8. I decided to try different materials; first a mold of fomular with a composite of gypsum; and second I want to try fiber glass.

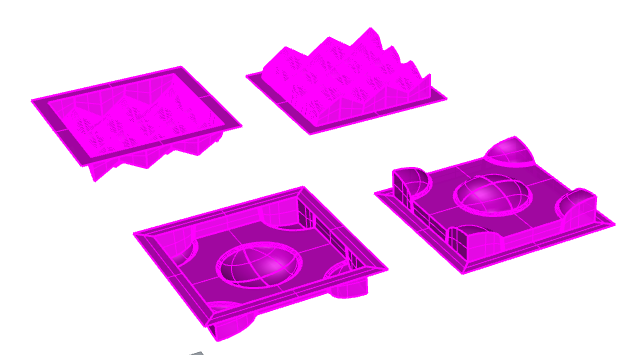

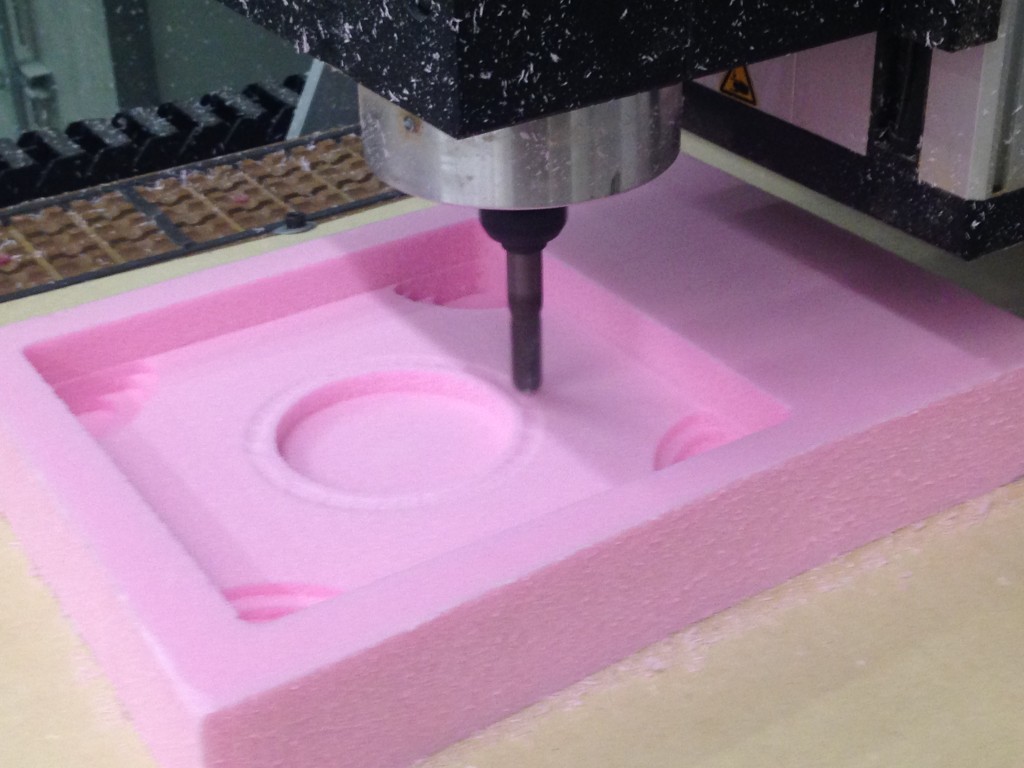

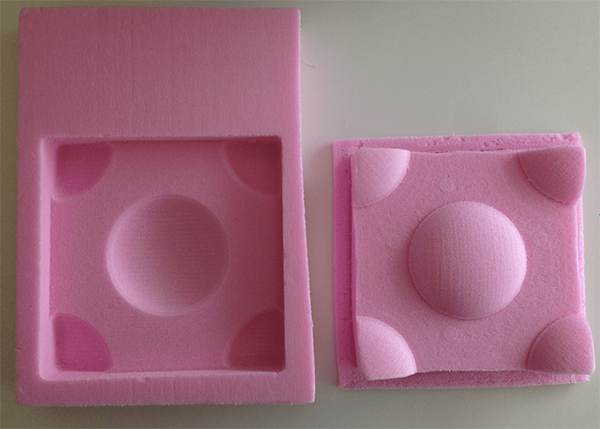

First I used the molds I designed in other assignment as part of a acoustic panel. I used the 3 axis router to manufacture the molds.

I tried to use common resin with fomular but it did not work. While I find the correct one I used other material for the composite assignment.

CAST

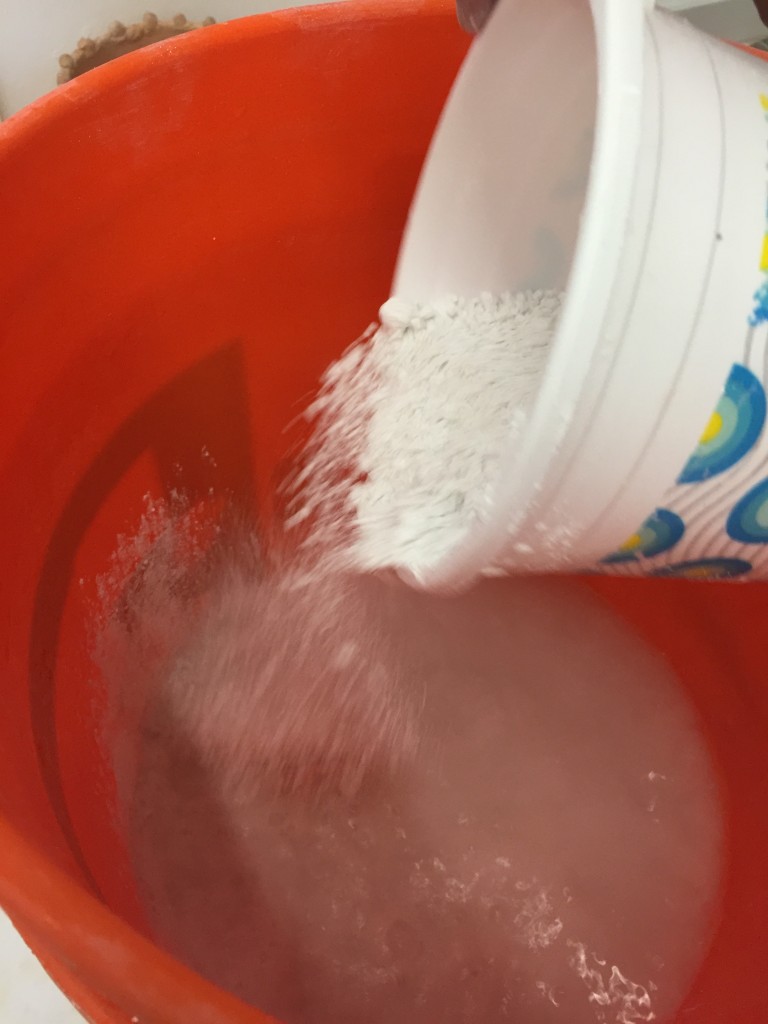

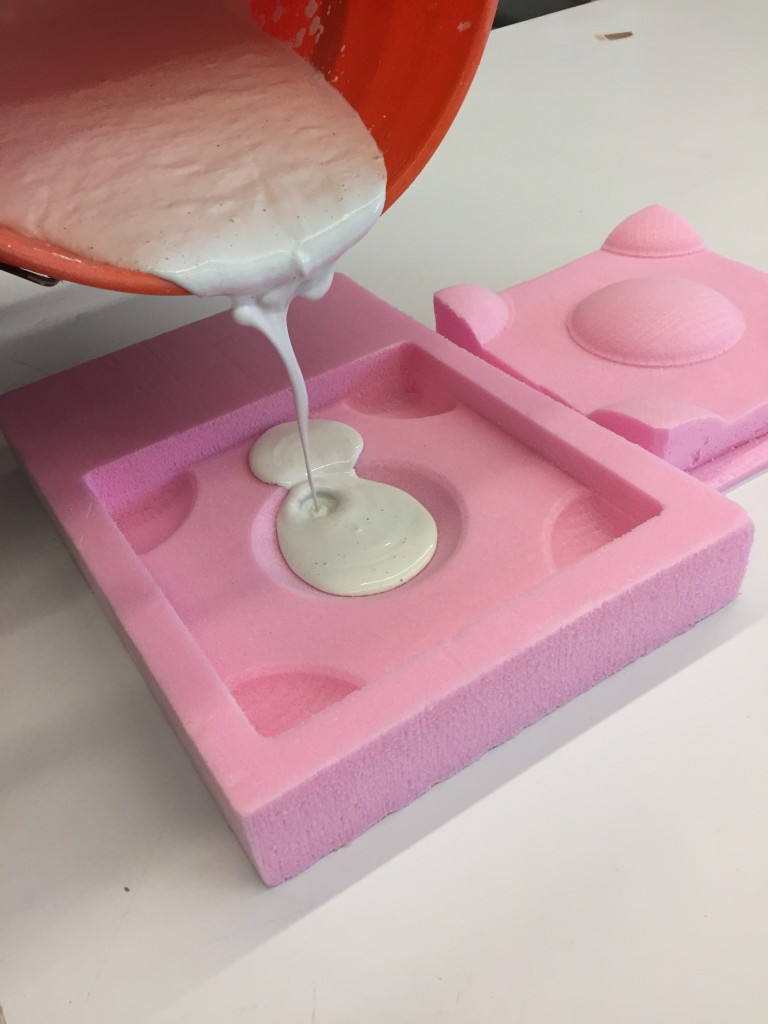

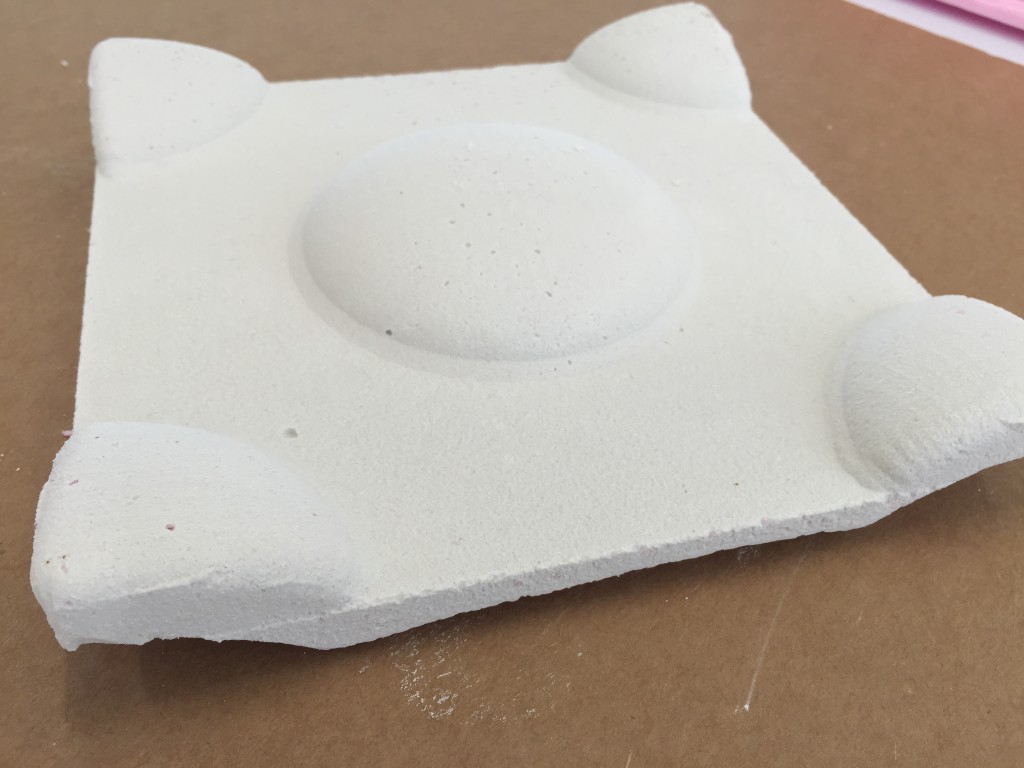

I used gypsum in a proportion of 1 part of gypsum and 1.2 parts of water. I mix the materials and fill the mold with it. After 1 hour the piece was dry but I let it dry overnight before unmolding the piece. I like the result because the fine texture but the piece is very fragile and it is not as easy to unmold as I thought.

FIBER GLASS

Using resin and fiber glass adding one piece at a time I was able to cover the hole on the mold. I wanted to experiment with this forms to have an idea of the resistance of this composite.

Materials:

polyurethane resin 70×60 + catalyst 92ml x 1% + fiber glass

mold release + film

After three layers of fiber glass the result was amazing, the piece was really strong and even doe it was not easy to cover the sides of the mold the piece could be complete covered if I continue with the process.